How to Increase Graphene Battery Cycle Life?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries have emerged as a promising technology in the field of energy storage, offering potential advantages over traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its applications across various industries, including energy storage.

The initial development of graphene-based batteries focused on leveraging graphene's exceptional electrical conductivity and high surface area to enhance the performance of existing battery technologies. Early experiments involved incorporating graphene into electrode materials, aiming to improve charge transfer and increase energy density. As research progressed, scientists began exploring the use of graphene as a standalone electrode material, paving the way for more advanced graphene battery designs.

A significant milestone in graphene battery evolution was the development of graphene-based supercapacitors, which demonstrated rapid charging capabilities and high power density. This breakthrough led to increased interest in combining the strengths of graphene supercapacitors with traditional battery chemistries, resulting in hybrid energy storage systems that offered both high energy and power density.

Recent advancements have focused on addressing the challenges associated with graphene battery production, such as scalability and cost-effectiveness. Researchers have made progress in developing more efficient methods for graphene synthesis and integration into battery components, bringing graphene batteries closer to commercial viability.

The primary objective in graphene battery research is to increase cycle life, which is crucial for long-term performance and sustainability. This goal aligns with the broader aim of creating more durable and efficient energy storage solutions. Researchers are exploring various approaches to enhance cycle life, including optimizing electrode structures, developing novel electrolyte formulations, and improving interfacial interactions between graphene and other battery components.

Another key objective is to maximize the energy density of graphene batteries while maintaining their high power capabilities. This involves fine-tuning the graphene structure and composition to achieve an optimal balance between energy storage capacity and charge/discharge rates. Additionally, researchers are working on improving the overall stability and safety of graphene batteries, addressing concerns such as thermal management and potential degradation mechanisms.

As the technology continues to evolve, the ultimate goal is to develop graphene batteries that outperform current lithium-ion batteries in terms of energy density, power output, charging speed, and cycle life. This ambitious objective drives ongoing research into advanced graphene architectures, hybrid materials, and innovative cell designs. The successful realization of these objectives could revolutionize energy storage across various applications, from portable electronics to electric vehicles and grid-scale energy storage systems.

The initial development of graphene-based batteries focused on leveraging graphene's exceptional electrical conductivity and high surface area to enhance the performance of existing battery technologies. Early experiments involved incorporating graphene into electrode materials, aiming to improve charge transfer and increase energy density. As research progressed, scientists began exploring the use of graphene as a standalone electrode material, paving the way for more advanced graphene battery designs.

A significant milestone in graphene battery evolution was the development of graphene-based supercapacitors, which demonstrated rapid charging capabilities and high power density. This breakthrough led to increased interest in combining the strengths of graphene supercapacitors with traditional battery chemistries, resulting in hybrid energy storage systems that offered both high energy and power density.

Recent advancements have focused on addressing the challenges associated with graphene battery production, such as scalability and cost-effectiveness. Researchers have made progress in developing more efficient methods for graphene synthesis and integration into battery components, bringing graphene batteries closer to commercial viability.

The primary objective in graphene battery research is to increase cycle life, which is crucial for long-term performance and sustainability. This goal aligns with the broader aim of creating more durable and efficient energy storage solutions. Researchers are exploring various approaches to enhance cycle life, including optimizing electrode structures, developing novel electrolyte formulations, and improving interfacial interactions between graphene and other battery components.

Another key objective is to maximize the energy density of graphene batteries while maintaining their high power capabilities. This involves fine-tuning the graphene structure and composition to achieve an optimal balance between energy storage capacity and charge/discharge rates. Additionally, researchers are working on improving the overall stability and safety of graphene batteries, addressing concerns such as thermal management and potential degradation mechanisms.

As the technology continues to evolve, the ultimate goal is to develop graphene batteries that outperform current lithium-ion batteries in terms of energy density, power output, charging speed, and cycle life. This ambitious objective drives ongoing research into advanced graphene architectures, hybrid materials, and innovative cell designs. The successful realization of these objectives could revolutionize energy storage across various applications, from portable electronics to electric vehicles and grid-scale energy storage systems.

Market Demand Analysis for Long-Lasting Batteries

The market demand for long-lasting batteries, particularly those incorporating graphene technology, has been steadily increasing across various sectors. This surge is primarily driven by the growing need for high-performance energy storage solutions in consumer electronics, electric vehicles, and renewable energy systems. The global lithium-ion battery market, which includes graphene-enhanced batteries, is projected to reach significant growth in the coming years.

In the consumer electronics sector, smartphone manufacturers are constantly seeking ways to extend battery life while reducing device thickness. Graphene batteries, with their potential for higher energy density and faster charging capabilities, are attracting considerable attention. Wearable technology and portable devices also contribute to this demand, as consumers expect longer operating times between charges.

The electric vehicle (EV) industry is another major driver of demand for advanced battery technologies. As governments worldwide push for reduced carbon emissions, the adoption of EVs is accelerating. This trend creates a substantial market for batteries with improved cycle life, as it directly impacts the longevity and performance of electric vehicles. Graphene-enhanced batteries, with their potential for increased durability and faster charging times, align well with the needs of EV manufacturers and consumers.

Renewable energy storage systems represent another significant market opportunity for long-lasting batteries. As the world transitions towards cleaner energy sources, the need for efficient and durable energy storage solutions becomes crucial. Grid-scale energy storage systems and residential solar installations require batteries that can withstand numerous charge-discharge cycles while maintaining high performance.

The aerospace and defense sectors are also showing increased interest in advanced battery technologies. These industries require high-performance, lightweight energy storage solutions for various applications, including unmanned aerial vehicles (UAVs) and satellite systems. Graphene batteries' potential for improved energy density and cycle life makes them attractive for these demanding applications.

In the industrial sector, there is a growing demand for reliable, long-lasting batteries in applications such as robotics, automated guided vehicles, and backup power systems. The ability of graphene-enhanced batteries to potentially withstand more charge-discharge cycles while maintaining capacity could lead to reduced maintenance costs and improved operational efficiency in these areas.

However, it's important to note that while the potential benefits of graphene batteries are significant, the technology is still in its early stages of commercialization. The market demand is currently driven more by the promise of future performance improvements rather than widely available products. As research progresses and manufacturing processes are refined, the market for graphene-enhanced batteries is expected to expand rapidly, provided they can deliver on their promised benefits of increased cycle life and improved performance.

In the consumer electronics sector, smartphone manufacturers are constantly seeking ways to extend battery life while reducing device thickness. Graphene batteries, with their potential for higher energy density and faster charging capabilities, are attracting considerable attention. Wearable technology and portable devices also contribute to this demand, as consumers expect longer operating times between charges.

The electric vehicle (EV) industry is another major driver of demand for advanced battery technologies. As governments worldwide push for reduced carbon emissions, the adoption of EVs is accelerating. This trend creates a substantial market for batteries with improved cycle life, as it directly impacts the longevity and performance of electric vehicles. Graphene-enhanced batteries, with their potential for increased durability and faster charging times, align well with the needs of EV manufacturers and consumers.

Renewable energy storage systems represent another significant market opportunity for long-lasting batteries. As the world transitions towards cleaner energy sources, the need for efficient and durable energy storage solutions becomes crucial. Grid-scale energy storage systems and residential solar installations require batteries that can withstand numerous charge-discharge cycles while maintaining high performance.

The aerospace and defense sectors are also showing increased interest in advanced battery technologies. These industries require high-performance, lightweight energy storage solutions for various applications, including unmanned aerial vehicles (UAVs) and satellite systems. Graphene batteries' potential for improved energy density and cycle life makes them attractive for these demanding applications.

In the industrial sector, there is a growing demand for reliable, long-lasting batteries in applications such as robotics, automated guided vehicles, and backup power systems. The ability of graphene-enhanced batteries to potentially withstand more charge-discharge cycles while maintaining capacity could lead to reduced maintenance costs and improved operational efficiency in these areas.

However, it's important to note that while the potential benefits of graphene batteries are significant, the technology is still in its early stages of commercialization. The market demand is currently driven more by the promise of future performance improvements rather than widely available products. As research progresses and manufacturing processes are refined, the market for graphene-enhanced batteries is expected to expand rapidly, provided they can deliver on their promised benefits of increased cycle life and improved performance.

Current Challenges in Graphene Battery Longevity

Graphene batteries face several significant challenges that hinder their widespread adoption and commercialization. One of the primary issues is the rapid capacity fading observed during cycling, which severely limits the battery's longevity. This degradation is primarily attributed to the restacking of graphene sheets, leading to a reduction in the active surface area and consequently diminishing the battery's performance over time.

Another critical challenge is the formation of a solid electrolyte interphase (SEI) layer on the graphene electrode surface. While the SEI layer is essential for stabilizing the electrode-electrolyte interface, its uncontrolled growth can lead to increased internal resistance and reduced capacity. Managing the SEI layer formation and stability is crucial for enhancing the cycle life of graphene batteries.

The high surface area of graphene, while beneficial for energy storage, also presents challenges. It can lead to undesirable side reactions with the electrolyte, resulting in electrolyte decomposition and gas evolution. These reactions not only consume the active material but also increase internal pressure within the battery, potentially compromising its safety and long-term stability.

Mechanical stress during cycling is another significant concern. The repeated insertion and extraction of ions cause volume changes in the graphene structure, leading to mechanical degradation and loss of electrical contact between graphene sheets and current collectors. This phenomenon contributes to capacity fade and reduced cycle life.

Furthermore, the synthesis and processing of high-quality graphene materials suitable for battery applications remain challenging. Ensuring consistent quality, purity, and structural integrity of graphene at scale is crucial for achieving reliable and long-lasting battery performance. The presence of defects or impurities in graphene can significantly impact its electrochemical properties and overall battery performance.

Lastly, the integration of graphene into existing battery manufacturing processes poses technical challenges. Developing scalable and cost-effective methods for incorporating graphene into battery electrodes while maintaining its unique properties is essential for commercial viability. Overcoming these manufacturing hurdles is crucial for translating the promising laboratory results of graphene batteries into practical, long-lasting energy storage solutions.

Another critical challenge is the formation of a solid electrolyte interphase (SEI) layer on the graphene electrode surface. While the SEI layer is essential for stabilizing the electrode-electrolyte interface, its uncontrolled growth can lead to increased internal resistance and reduced capacity. Managing the SEI layer formation and stability is crucial for enhancing the cycle life of graphene batteries.

The high surface area of graphene, while beneficial for energy storage, also presents challenges. It can lead to undesirable side reactions with the electrolyte, resulting in electrolyte decomposition and gas evolution. These reactions not only consume the active material but also increase internal pressure within the battery, potentially compromising its safety and long-term stability.

Mechanical stress during cycling is another significant concern. The repeated insertion and extraction of ions cause volume changes in the graphene structure, leading to mechanical degradation and loss of electrical contact between graphene sheets and current collectors. This phenomenon contributes to capacity fade and reduced cycle life.

Furthermore, the synthesis and processing of high-quality graphene materials suitable for battery applications remain challenging. Ensuring consistent quality, purity, and structural integrity of graphene at scale is crucial for achieving reliable and long-lasting battery performance. The presence of defects or impurities in graphene can significantly impact its electrochemical properties and overall battery performance.

Lastly, the integration of graphene into existing battery manufacturing processes poses technical challenges. Developing scalable and cost-effective methods for incorporating graphene into battery electrodes while maintaining its unique properties is essential for commercial viability. Overcoming these manufacturing hurdles is crucial for translating the promising laboratory results of graphene batteries into practical, long-lasting energy storage solutions.

Existing Strategies for Cycle Life Enhancement

01 Graphene-based electrode materials for improved cycle life

Incorporating graphene into battery electrodes can significantly enhance cycle life. Graphene's unique properties, such as high conductivity and large surface area, contribute to improved charge/discharge efficiency and stability. This approach can lead to batteries with longer lifespan and better performance over multiple cycles.- Graphene-based electrode materials: Graphene-based materials are used in battery electrodes to enhance cycle life. These materials, such as graphene oxide or reduced graphene oxide, can improve the stability and conductivity of the electrodes, leading to better overall battery performance and longevity.

- Composite materials with graphene: Composite materials incorporating graphene, such as graphene-metal oxide composites or graphene-polymer composites, are developed to improve battery cycle life. These composites can enhance the mechanical and electrochemical properties of the electrodes, resulting in better cycling stability.

- Electrolyte additives and modifications: Electrolyte additives or modifications, including graphene-based additives, are used to improve the cycle life of batteries. These additives can help form stable solid electrolyte interphase (SEI) layers, reduce side reactions, and enhance the overall electrochemical performance of the battery.

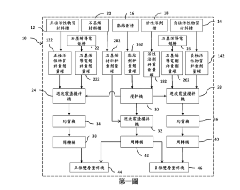

- Battery management systems: Advanced battery management systems are developed to optimize the charging and discharging processes of graphene batteries. These systems can help extend the cycle life by preventing overcharging, over-discharging, and maintaining optimal operating conditions for the battery.

- Nanostructured graphene materials: Nanostructured graphene materials, such as graphene nanosheets, nanotubes, or 3D graphene structures, are engineered to improve battery cycle life. These nanostructures can provide better ion transport, increased surface area, and enhanced mechanical stability, leading to improved cycling performance.

02 Graphene-enhanced electrolyte formulations

Developing electrolyte formulations that include graphene or graphene derivatives can improve battery cycle life. These formulations can help reduce electrolyte decomposition, enhance ion transport, and form more stable solid-electrolyte interphases, all contributing to extended battery lifespan.Expand Specific Solutions03 Graphene-based protective coatings for battery components

Applying graphene-based coatings to battery components, such as electrodes or separators, can protect against degradation and extend cycle life. These coatings can prevent unwanted reactions, reduce material dissolution, and maintain structural integrity over numerous charge-discharge cycles.Expand Specific Solutions04 Hybrid graphene-metal composite electrodes

Developing hybrid electrodes that combine graphene with metals or metal oxides can synergistically improve cycle life. These composites can offer enhanced conductivity, mechanical stability, and electrochemical performance, leading to batteries that maintain capacity over a greater number of cycles.Expand Specific Solutions05 Advanced manufacturing techniques for graphene batteries

Implementing novel manufacturing processes, such as 3D printing or advanced assembly techniques, can optimize the integration of graphene in batteries. These methods can lead to more uniform and controlled structures, resulting in improved cycle life and overall battery performance.Expand Specific Solutions

Key Players in Graphene Battery Development

The graphene battery cycle life improvement landscape is in a dynamic phase, with significant market potential driven by the growing demand for high-performance energy storage solutions. The technology is progressing from early-stage research to commercial applications, though it's not yet fully mature. Key players like Samsung Electronics, TDK Corp, and Contemporary Amperex Technology are investing heavily in R&D, while specialized firms such as Honeycomb Battery Co. and Long Time Technology are focusing on niche innovations. Academic institutions like Northwestern University and the University of Eastern Finland are contributing fundamental research, creating a competitive ecosystem that spans industry and academia.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a graphene-based lithium-ion battery technology that significantly enhances cycle life. Their approach involves incorporating graphene into both the anode and cathode materials. For the anode, they use a graphene-silicon composite that allows for higher capacity and better stability[1]. The cathode utilizes graphene-coated lithium iron phosphate (LFP) particles, which improve conductivity and structural integrity[2]. CATL's proprietary electrolyte formulation includes graphene oxide additives that form a stable solid electrolyte interphase (SEI), reducing unwanted side reactions and enhancing long-term performance[3]. This comprehensive graphene integration strategy has reportedly increased battery cycle life by up to 30% compared to conventional lithium-ion batteries[4].

Strengths: Comprehensive graphene integration in multiple battery components, significant cycle life improvement, and potential for high-volume production. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Samsung Electronics Co., Ltd.

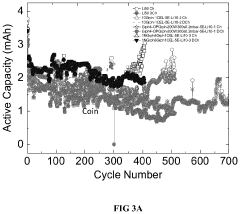

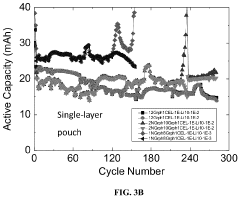

Technical Solution: Samsung has developed a "graphene ball" technology to enhance lithium-ion battery cycle life. This approach involves coating battery electrodes with a graphene-based material that forms a protective layer and facilitates faster charge transfer[1]. The graphene ball coating is applied to both the cathode and anode materials, creating a 3D network that improves structural stability and prevents degradation during cycling[2]. Samsung's research indicates that this technology can increase the battery's capacity retention by up to 78% after 500 cycles, compared to conventional lithium-ion batteries[3]. Additionally, the graphene ball coating enables faster charging rates, potentially reducing charging times by up to 45% without compromising long-term stability[4].

Strengths: Significant improvement in capacity retention, faster charging capabilities, and potential for integration into existing battery manufacturing processes. Weaknesses: Possible challenges in large-scale production of high-quality graphene material and increased production costs.

Innovative Approaches to Graphene Electrode Stability

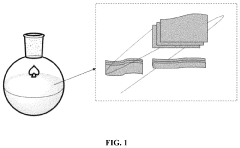

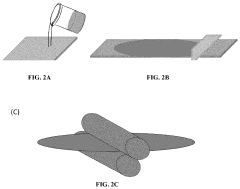

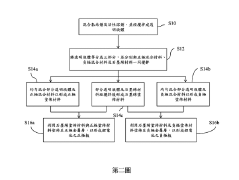

Direct-formation self-assembly graphene from cellulose nanofiber aqueous solution

PatentPendingUS20240088397A1

Innovation

- A self-assembled freestanding graphene membrane or layer is formed using an aqueous dispersion of industrial-grade graphene and cellulose nanofibers with a mass ratio of 12:1 to 20:1, which improves dispersibility and allows for low-temperature direct fabrication, enabling the formation of a stable and conductive graphene scaffold for lithium metal anodes.

Manufacturing method for adding graphene in positive and negative plates of lithium battery capable of extend the cycle life of the finished battery, and increase charge and discharge rate and safety

PatentInactiveTW201840043A

Innovation

- Incorporating graphene into both positive and negative plates of lithium batteries to enhance cycle life, charge/discharge rate, and safety.

- Using a two-step coating process: first applying a graphene coating, then the electrode-specific coating on metal layers.

- Utilizing a common binding agent and active solvent base for both graphene and electrode materials, ensuring compatibility and uniform mixing.

Environmental Impact of Graphene Battery Production

The production of graphene batteries, while promising for their potential to revolutionize energy storage, raises significant environmental concerns that must be carefully considered. The extraction and processing of raw materials for graphene synthesis, particularly graphite, can lead to habitat destruction and water pollution if not properly managed. The chemical processes involved in graphene production often require the use of harsh solvents and energy-intensive methods, contributing to increased carbon emissions and potential chemical waste.

However, advancements in green synthesis techniques are gradually mitigating these impacts. Researchers are developing eco-friendly methods using renewable resources and less toxic chemicals. For instance, the use of plant-based precursors and biodegradable reducing agents in graphene oxide reduction processes shows promise in reducing the environmental footprint of production.

The manufacturing of graphene batteries also presents challenges in terms of energy consumption and resource utilization. The high-precision equipment and controlled environments necessary for graphene production demand substantial energy inputs. Nevertheless, the long-term benefits of graphene batteries, including their extended cycle life and improved energy density, may offset these initial environmental costs by reducing the frequency of battery replacements and improving overall energy efficiency in various applications.

Recycling and end-of-life management of graphene batteries are crucial aspects that require further development. While graphene itself is a highly stable material, the composite nature of battery components complicates recycling processes. Innovative recycling technologies are being explored to recover and reuse graphene and other valuable materials from spent batteries, which could significantly reduce the environmental impact of production by decreasing the demand for virgin materials.

The scalability of graphene battery production also has environmental implications. As production scales up to meet potential market demands, there is a risk of increased environmental pressure. However, economies of scale may also lead to more efficient production processes and resource utilization, potentially reducing the environmental impact per unit produced.

In conclusion, while the environmental impact of graphene battery production presents challenges, ongoing research and technological advancements are paving the way for more sustainable manufacturing processes. The long-term environmental benefits of graphene batteries, coupled with improvements in production methods and recycling technologies, suggest a potentially positive trajectory for their overall environmental impact.

However, advancements in green synthesis techniques are gradually mitigating these impacts. Researchers are developing eco-friendly methods using renewable resources and less toxic chemicals. For instance, the use of plant-based precursors and biodegradable reducing agents in graphene oxide reduction processes shows promise in reducing the environmental footprint of production.

The manufacturing of graphene batteries also presents challenges in terms of energy consumption and resource utilization. The high-precision equipment and controlled environments necessary for graphene production demand substantial energy inputs. Nevertheless, the long-term benefits of graphene batteries, including their extended cycle life and improved energy density, may offset these initial environmental costs by reducing the frequency of battery replacements and improving overall energy efficiency in various applications.

Recycling and end-of-life management of graphene batteries are crucial aspects that require further development. While graphene itself is a highly stable material, the composite nature of battery components complicates recycling processes. Innovative recycling technologies are being explored to recover and reuse graphene and other valuable materials from spent batteries, which could significantly reduce the environmental impact of production by decreasing the demand for virgin materials.

The scalability of graphene battery production also has environmental implications. As production scales up to meet potential market demands, there is a risk of increased environmental pressure. However, economies of scale may also lead to more efficient production processes and resource utilization, potentially reducing the environmental impact per unit produced.

In conclusion, while the environmental impact of graphene battery production presents challenges, ongoing research and technological advancements are paving the way for more sustainable manufacturing processes. The long-term environmental benefits of graphene batteries, coupled with improvements in production methods and recycling technologies, suggest a potentially positive trajectory for their overall environmental impact.

Scalability and Cost Considerations

Scalability and cost considerations are crucial factors in the development and commercialization of graphene batteries with increased cycle life. The ability to produce graphene-based battery components at scale while maintaining cost-effectiveness is essential for widespread adoption in various applications, from consumer electronics to electric vehicles and grid-scale energy storage.

One of the primary challenges in scaling up graphene production for battery applications is the need for consistent quality and uniformity across large batches. Current methods for producing high-quality graphene, such as chemical vapor deposition (CVD), are often limited in their scalability and can be prohibitively expensive for mass production. Research efforts are focused on developing more efficient and cost-effective production techniques, including roll-to-roll manufacturing processes and solution-based methods that can be easily integrated into existing battery production lines.

The cost of raw materials is another significant consideration in graphene battery production. While graphene itself is derived from abundant carbon sources, the processes required to create high-quality graphene sheets or composites can be energy-intensive and require specialized equipment. Efforts to reduce costs are centered on optimizing production processes, exploring alternative precursor materials, and developing more efficient synthesis methods that minimize waste and energy consumption.

Integration of graphene-based components into existing battery manufacturing processes presents both challenges and opportunities. While some modifications to production lines may be necessary, the potential for improved battery performance and longevity could offset initial investment costs. Manufacturers are exploring ways to incorporate graphene additives or coatings into current lithium-ion battery designs as an intermediate step towards fully graphene-based batteries, allowing for a gradual transition that balances performance gains with production scalability.

The environmental impact and sustainability of graphene battery production must also be considered in scaling efforts. Life cycle assessments are being conducted to evaluate the overall environmental footprint of graphene batteries compared to conventional technologies. This includes analyzing the energy requirements for production, the potential for recycling and reusing graphene components, and the long-term environmental benefits of increased battery lifespan and efficiency.

As research progresses and production techniques improve, economies of scale are expected to drive down the costs associated with graphene battery technology. Collaborative efforts between academic institutions, industry partners, and government agencies are accelerating the development of scalable production methods and cost-reduction strategies. These initiatives aim to bridge the gap between laboratory-scale demonstrations and commercial viability, paving the way for widespread adoption of graphene-enhanced batteries with extended cycle life across various sectors of the energy storage market.

One of the primary challenges in scaling up graphene production for battery applications is the need for consistent quality and uniformity across large batches. Current methods for producing high-quality graphene, such as chemical vapor deposition (CVD), are often limited in their scalability and can be prohibitively expensive for mass production. Research efforts are focused on developing more efficient and cost-effective production techniques, including roll-to-roll manufacturing processes and solution-based methods that can be easily integrated into existing battery production lines.

The cost of raw materials is another significant consideration in graphene battery production. While graphene itself is derived from abundant carbon sources, the processes required to create high-quality graphene sheets or composites can be energy-intensive and require specialized equipment. Efforts to reduce costs are centered on optimizing production processes, exploring alternative precursor materials, and developing more efficient synthesis methods that minimize waste and energy consumption.

Integration of graphene-based components into existing battery manufacturing processes presents both challenges and opportunities. While some modifications to production lines may be necessary, the potential for improved battery performance and longevity could offset initial investment costs. Manufacturers are exploring ways to incorporate graphene additives or coatings into current lithium-ion battery designs as an intermediate step towards fully graphene-based batteries, allowing for a gradual transition that balances performance gains with production scalability.

The environmental impact and sustainability of graphene battery production must also be considered in scaling efforts. Life cycle assessments are being conducted to evaluate the overall environmental footprint of graphene batteries compared to conventional technologies. This includes analyzing the energy requirements for production, the potential for recycling and reusing graphene components, and the long-term environmental benefits of increased battery lifespan and efficiency.

As research progresses and production techniques improve, economies of scale are expected to drive down the costs associated with graphene battery technology. Collaborative efforts between academic institutions, industry partners, and government agencies are accelerating the development of scalable production methods and cost-reduction strategies. These initiatives aim to bridge the gap between laboratory-scale demonstrations and commercial viability, paving the way for widespread adoption of graphene-enhanced batteries with extended cycle life across various sectors of the energy storage market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!