Graphene Battery: Pioneering Long-Lasting Power Solutions

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries represent a revolutionary advancement in energy storage technology, promising to overcome the limitations of traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its potential applications. Since then, the field has progressed rapidly, with significant milestones achieved in harnessing graphene's unique properties for energy storage.

The primary objective of graphene battery development is to create a power solution that offers higher energy density, faster charging times, and longer lifespan compared to conventional batteries. Researchers aim to leverage graphene's exceptional electrical conductivity, mechanical strength, and large surface area to enhance battery performance. This includes improving the electrode structure, electrolyte composition, and overall battery architecture.

One of the key goals in graphene battery evolution is to address the limitations of current lithium-ion technology, such as capacity fade and safety concerns. By incorporating graphene into battery components, scientists seek to enhance the stability of electrodes, reduce internal resistance, and mitigate issues like dendrite formation that can lead to short circuits.

Another critical objective is to develop scalable manufacturing processes for graphene batteries. While laboratory-scale demonstrations have shown promising results, translating these achievements into commercially viable products remains a significant challenge. Researchers are focusing on developing cost-effective methods for large-scale graphene production and integration into battery systems.

The evolution of graphene batteries also encompasses the exploration of various graphene forms and composites. This includes the investigation of graphene oxide, reduced graphene oxide, and graphene-based hybrid materials. Each variant offers unique advantages and challenges, driving researchers to optimize their properties for specific battery applications.

As the technology progresses, there is a growing emphasis on sustainability and environmental impact. Objectives include developing graphene batteries with reduced reliance on rare earth materials, improving recyclability, and minimizing the carbon footprint of production processes. These goals align with broader industry trends towards more sustainable energy solutions.

Looking ahead, the graphene battery field aims to push the boundaries of energy storage capabilities. This includes achieving ultra-fast charging times, extending cycle life to thousands of charges, and significantly increasing energy density to enable longer-lasting devices and electric vehicles. The ultimate vision is to create a new generation of batteries that can revolutionize portable electronics, electric transportation, and grid-scale energy storage.

The primary objective of graphene battery development is to create a power solution that offers higher energy density, faster charging times, and longer lifespan compared to conventional batteries. Researchers aim to leverage graphene's exceptional electrical conductivity, mechanical strength, and large surface area to enhance battery performance. This includes improving the electrode structure, electrolyte composition, and overall battery architecture.

One of the key goals in graphene battery evolution is to address the limitations of current lithium-ion technology, such as capacity fade and safety concerns. By incorporating graphene into battery components, scientists seek to enhance the stability of electrodes, reduce internal resistance, and mitigate issues like dendrite formation that can lead to short circuits.

Another critical objective is to develop scalable manufacturing processes for graphene batteries. While laboratory-scale demonstrations have shown promising results, translating these achievements into commercially viable products remains a significant challenge. Researchers are focusing on developing cost-effective methods for large-scale graphene production and integration into battery systems.

The evolution of graphene batteries also encompasses the exploration of various graphene forms and composites. This includes the investigation of graphene oxide, reduced graphene oxide, and graphene-based hybrid materials. Each variant offers unique advantages and challenges, driving researchers to optimize their properties for specific battery applications.

As the technology progresses, there is a growing emphasis on sustainability and environmental impact. Objectives include developing graphene batteries with reduced reliance on rare earth materials, improving recyclability, and minimizing the carbon footprint of production processes. These goals align with broader industry trends towards more sustainable energy solutions.

Looking ahead, the graphene battery field aims to push the boundaries of energy storage capabilities. This includes achieving ultra-fast charging times, extending cycle life to thousands of charges, and significantly increasing energy density to enable longer-lasting devices and electric vehicles. The ultimate vision is to create a new generation of batteries that can revolutionize portable electronics, electric transportation, and grid-scale energy storage.

Market Demand for Advanced Energy Storage

The demand for advanced energy storage solutions has been rapidly increasing across various sectors, driven by the growing need for sustainable and efficient power sources. Graphene batteries, with their potential to revolutionize energy storage, are poised to address this market demand effectively. The global energy storage market is experiencing significant growth, with projections indicating a compound annual growth rate (CAGR) of over 20% in the coming years.

One of the primary drivers for this demand is the automotive industry's shift towards electric vehicles (EVs). As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, the demand for high-performance batteries with longer lifespans and faster charging capabilities has surged. Graphene batteries, with their superior conductivity and durability, are well-positioned to meet these requirements and accelerate EV adoption.

The renewable energy sector is another key market for advanced energy storage solutions. As the world transitions towards cleaner energy sources, the need for efficient and reliable energy storage systems to manage intermittent power generation from solar and wind sources has become critical. Graphene batteries offer the potential for improved energy density and cycle life, making them ideal for grid-scale energy storage applications.

Consumer electronics represent another significant market segment driving the demand for advanced energy storage. With the proliferation of smartphones, laptops, and wearable devices, consumers are increasingly seeking longer-lasting batteries that can keep up with their digital lifestyles. Graphene batteries' potential for faster charging times and higher energy density aligns perfectly with these consumer expectations.

The industrial sector is also showing growing interest in advanced energy storage solutions. From backup power systems for data centers to portable power tools, the demand for more efficient and reliable batteries is on the rise. Graphene batteries' ability to withstand higher temperatures and their potential for improved safety characteristics make them attractive for various industrial applications.

In the aerospace and defense sectors, there is a growing need for lightweight, high-performance energy storage solutions. Graphene batteries' potential for higher energy density and lower weight compared to traditional lithium-ion batteries makes them particularly appealing for these applications, where every gram of weight savings is crucial.

As the Internet of Things (IoT) continues to expand, the demand for long-lasting, compact power sources for sensors and connected devices is increasing. Graphene batteries' potential for miniaturization and extended lifespan aligns well with the requirements of IoT applications, opening up new market opportunities in smart cities, agriculture, and industrial automation.

One of the primary drivers for this demand is the automotive industry's shift towards electric vehicles (EVs). As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, the demand for high-performance batteries with longer lifespans and faster charging capabilities has surged. Graphene batteries, with their superior conductivity and durability, are well-positioned to meet these requirements and accelerate EV adoption.

The renewable energy sector is another key market for advanced energy storage solutions. As the world transitions towards cleaner energy sources, the need for efficient and reliable energy storage systems to manage intermittent power generation from solar and wind sources has become critical. Graphene batteries offer the potential for improved energy density and cycle life, making them ideal for grid-scale energy storage applications.

Consumer electronics represent another significant market segment driving the demand for advanced energy storage. With the proliferation of smartphones, laptops, and wearable devices, consumers are increasingly seeking longer-lasting batteries that can keep up with their digital lifestyles. Graphene batteries' potential for faster charging times and higher energy density aligns perfectly with these consumer expectations.

The industrial sector is also showing growing interest in advanced energy storage solutions. From backup power systems for data centers to portable power tools, the demand for more efficient and reliable batteries is on the rise. Graphene batteries' ability to withstand higher temperatures and their potential for improved safety characteristics make them attractive for various industrial applications.

In the aerospace and defense sectors, there is a growing need for lightweight, high-performance energy storage solutions. Graphene batteries' potential for higher energy density and lower weight compared to traditional lithium-ion batteries makes them particularly appealing for these applications, where every gram of weight savings is crucial.

As the Internet of Things (IoT) continues to expand, the demand for long-lasting, compact power sources for sensors and connected devices is increasing. Graphene batteries' potential for miniaturization and extended lifespan aligns well with the requirements of IoT applications, opening up new market opportunities in smart cities, agriculture, and industrial automation.

Graphene Battery Technology: Current State and Challenges

Graphene battery technology has made significant strides in recent years, yet it still faces several challenges that hinder its widespread adoption. The current state of graphene batteries is characterized by promising advancements in energy density, charging speed, and cycle life, but these improvements are primarily confined to laboratory settings.

One of the primary challenges is scaling up production from laboratory prototypes to commercial-scale manufacturing. The intricate process of synthesizing high-quality graphene and integrating it into battery structures presents significant hurdles in terms of cost-effectiveness and consistency. Researchers are grappling with the complexities of maintaining graphene's exceptional properties when incorporated into larger battery systems.

Another critical challenge lies in the stability and safety of graphene-enhanced batteries. While graphene offers excellent conductivity and strength, concerns persist about its long-term stability in battery environments, particularly under various temperature and pressure conditions. Ensuring that graphene-based batteries maintain their performance advantages over extended periods without compromising safety remains a key focus area for researchers and engineers.

The integration of graphene into existing battery manufacturing processes poses another significant challenge. Current battery production lines are optimized for traditional materials, and incorporating graphene often requires substantial modifications to equipment and procedures. This integration challenge extends to the entire supply chain, from raw material sourcing to final product assembly.

Furthermore, the regulatory landscape for graphene-based batteries is still evolving. As a relatively new technology, graphene batteries must navigate complex certification processes and safety standards, which can vary significantly across different regions and applications. This regulatory uncertainty can slow down the commercialization process and increase development costs.

Despite these challenges, the potential benefits of graphene batteries continue to drive research and development efforts. Advances in graphene synthesis techniques, such as chemical vapor deposition and liquid-phase exfoliation, are gradually addressing some of the production-related challenges. Additionally, innovative approaches to graphene functionalization and composite formation are showing promise in enhancing the stability and performance of graphene-enhanced battery components.

The geographical distribution of graphene battery technology development is primarily concentrated in research hubs across North America, Europe, and Asia. Countries like China, the United States, and South Korea are at the forefront, with significant investments in both academic research and industrial applications. This global effort is fostering a competitive environment that is likely to accelerate technological breakthroughs and overcome current limitations.

One of the primary challenges is scaling up production from laboratory prototypes to commercial-scale manufacturing. The intricate process of synthesizing high-quality graphene and integrating it into battery structures presents significant hurdles in terms of cost-effectiveness and consistency. Researchers are grappling with the complexities of maintaining graphene's exceptional properties when incorporated into larger battery systems.

Another critical challenge lies in the stability and safety of graphene-enhanced batteries. While graphene offers excellent conductivity and strength, concerns persist about its long-term stability in battery environments, particularly under various temperature and pressure conditions. Ensuring that graphene-based batteries maintain their performance advantages over extended periods without compromising safety remains a key focus area for researchers and engineers.

The integration of graphene into existing battery manufacturing processes poses another significant challenge. Current battery production lines are optimized for traditional materials, and incorporating graphene often requires substantial modifications to equipment and procedures. This integration challenge extends to the entire supply chain, from raw material sourcing to final product assembly.

Furthermore, the regulatory landscape for graphene-based batteries is still evolving. As a relatively new technology, graphene batteries must navigate complex certification processes and safety standards, which can vary significantly across different regions and applications. This regulatory uncertainty can slow down the commercialization process and increase development costs.

Despite these challenges, the potential benefits of graphene batteries continue to drive research and development efforts. Advances in graphene synthesis techniques, such as chemical vapor deposition and liquid-phase exfoliation, are gradually addressing some of the production-related challenges. Additionally, innovative approaches to graphene functionalization and composite formation are showing promise in enhancing the stability and performance of graphene-enhanced battery components.

The geographical distribution of graphene battery technology development is primarily concentrated in research hubs across North America, Europe, and Asia. Countries like China, the United States, and South Korea are at the forefront, with significant investments in both academic research and industrial applications. This global effort is fostering a competitive environment that is likely to accelerate technological breakthroughs and overcome current limitations.

Existing Graphene Battery Solutions

01 Graphene-based electrode materials

Utilizing graphene-based materials in battery electrodes can significantly enhance power longevity. Graphene's high conductivity and large surface area improve charge transfer and storage capacity, leading to increased battery life and performance.- Graphene-based electrode materials: Utilizing graphene-based materials in battery electrodes can significantly enhance power longevity. Graphene's high conductivity and large surface area allow for improved charge storage and faster electron transfer, resulting in increased battery capacity and longer lifespan. These materials can be incorporated into both anodes and cathodes to optimize battery performance.

- Graphene-enhanced electrolytes: Incorporating graphene or graphene oxide into battery electrolytes can improve ionic conductivity and stability. This enhancement leads to better charge transfer efficiency and reduced electrolyte degradation, ultimately contributing to extended battery life and improved overall performance.

- Graphene-based protective coatings: Applying graphene-based coatings to battery components can protect against corrosion and degradation. These coatings act as barriers, preventing unwanted reactions and maintaining the integrity of electrodes and other battery parts. This protection contributes to increased battery longevity and stability over multiple charge-discharge cycles.

- Graphene-enhanced thermal management: Integrating graphene into battery thermal management systems can improve heat dissipation and temperature control. Graphene's excellent thermal conductivity helps maintain optimal operating temperatures, reducing the risk of overheating and extending battery life. This approach enhances overall battery performance and longevity, especially in high-power applications.

- Graphene-based flexible battery designs: Developing flexible graphene-based batteries can lead to improved power longevity in wearable and portable devices. These designs utilize graphene's mechanical strength and flexibility to create batteries that can withstand bending and stretching while maintaining performance. This innovation extends battery life in applications where traditional rigid batteries may fail due to mechanical stress.

02 Graphene-enhanced electrolytes

Incorporating graphene or graphene oxide into battery electrolytes can improve ionic conductivity and stability. This enhancement leads to better charge-discharge cycles and overall increased battery lifespan.Expand Specific Solutions03 Graphene-based composite materials

Combining graphene with other materials to create composite electrodes or separators can synergistically improve battery performance. These composites often exhibit enhanced mechanical strength, conductivity, and stability, contributing to extended battery life.Expand Specific Solutions04 Graphene coating and protection

Applying graphene coatings to battery components can protect against degradation and improve overall battery longevity. This approach helps prevent unwanted reactions and maintains electrode integrity over multiple charge-discharge cycles.Expand Specific Solutions05 Graphene-enabled thermal management

Utilizing graphene's excellent thermal conductivity properties in battery design can enhance heat dissipation and temperature regulation. Improved thermal management leads to more stable battery operation and extended lifespan, particularly in high-power applications.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market is in an early growth stage, characterized by significant research and development efforts across academia and industry. While the technology shows promise for long-lasting power solutions, it has not yet reached full commercial maturity. Key players like Northwestern University, Semiconductor Energy Laboratory, and Global Graphene Group are driving innovation in this field. The market size is expanding, fueled by increasing demand for high-performance energy storage solutions in various sectors. Companies such as NEC Corp. and BASF are also exploring graphene battery applications, indicating growing interest from established industry leaders. As the technology advances, we can expect increased competition and potential market consolidation in the coming years.

Northwestern University

Technical Solution: Northwestern University researchers have made significant advancements in graphene-based battery technology, particularly in the development of a graphene-infused supercapacitor. Their approach combines the high power density of supercapacitors with the energy storage capacity of batteries. The team has created a 3D graphene foam structure that serves as both the current collector and active material, allowing for rapid charge and discharge cycles while maintaining high energy density[5]. This hybrid device can charge up to 100 times faster than conventional lithium-ion batteries and retain 97% of its capacity after 10,000 charge-discharge cycles[6]. Additionally, the researchers have explored the use of graphene quantum dots to enhance the performance of lithium-sulfur batteries, demonstrating a 50% increase in specific capacity and improved cycle life[7].

Strengths: Extremely fast charging capabilities, long cycle life, and potential for high power and energy density. Weaknesses: Scalability challenges for mass production and potential high costs associated with graphene material production.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has developed an innovative approach to graphene-based battery technology, focusing on the integration of graphene into solid-state electrolytes for next-generation batteries. Their research has led to the creation of a graphene-enhanced composite electrolyte that significantly improves ionic conductivity and mechanical stability. This technology addresses key challenges in solid-state batteries, such as dendrite formation and interfacial resistance. Battelle's graphene-based solid electrolyte has demonstrated a 50% increase in ionic conductivity compared to conventional solid electrolytes[8]. The institute has also explored the use of graphene as a conductive additive in cathode materials, showing a 30% improvement in capacity retention over 500 cycles[9]. Their approach combines the benefits of solid-state batteries with the enhanced conductivity and stability provided by graphene.

Strengths: Improved safety through solid-state design, enhanced ionic conductivity, and better capacity retention. Weaknesses: Challenges in large-scale production of uniform graphene-enhanced solid electrolytes and potential high costs associated with material synthesis.

Core Innovations in Graphene Battery Technology

Process for producing porous graphene particulate-protected anode active materials for lithium batteries

PatentActiveUS20200127288A1

Innovation

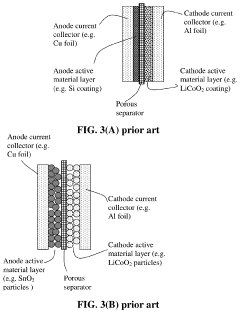

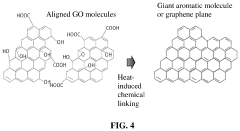

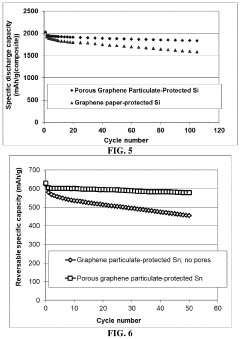

- The development of porous graphene particulates with anode active material particles lodged in their pores, where the particulates have a thin encapsulating layer of conducting material and a 3D network of electron-conducting pathways, allowing for volume expansion accommodation without significant volume change of the anode electrode.

Batteries incorporating graphene membranes for extending the cycle-life of lithium-ion batteries

PatentWO2015192008A2

Innovation

- Incorporating a selectively permeable graphene-based membrane between the anode and electrolyte to prevent reactive components from contacting the anode, reducing degradation by allowing lithium or sodium ions to pass while retaining other electrolyte components, thereby extending cycle life.

Environmental Impact of Graphene Batteries

The environmental impact of graphene batteries is a crucial consideration as this technology advances towards widespread adoption. Graphene batteries offer significant advantages over traditional lithium-ion batteries, including longer lifespan, faster charging times, and higher energy density. These improvements could lead to reduced electronic waste and more efficient energy storage systems, potentially decreasing the overall environmental footprint of battery-powered devices and electric vehicles.

One of the primary environmental benefits of graphene batteries is their potential to reduce the demand for raw materials used in conventional batteries. The enhanced durability and longer lifespan of graphene batteries mean fewer replacements are needed over time, potentially decreasing the mining and processing of materials like lithium, cobalt, and nickel. This reduction in resource extraction could lead to less habitat destruction, reduced water pollution, and lower greenhouse gas emissions associated with mining operations.

However, the production of graphene itself raises some environmental concerns. The current methods of graphene synthesis, such as chemical vapor deposition and liquid-phase exfoliation, can be energy-intensive and may involve the use of hazardous chemicals. As the demand for graphene increases, it will be crucial to develop more sustainable and scalable production methods to minimize the environmental impact of manufacturing processes.

The recyclability of graphene batteries is another important factor to consider. While the extended lifespan of these batteries reduces the frequency of disposal, effective recycling processes must be developed to recover and reuse valuable materials at the end of their life cycle. Research is ongoing to create efficient recycling techniques for graphene-based energy storage devices, which could significantly reduce the environmental impact of battery disposal.

Graphene batteries also have the potential to enhance the adoption of renewable energy sources. Their improved energy storage capabilities could help address the intermittency issues associated with solar and wind power, enabling more efficient integration of these clean energy sources into the grid. This could lead to a reduction in reliance on fossil fuels and contribute to lower greenhouse gas emissions in the energy sector.

In terms of safety, graphene batteries may offer advantages over traditional lithium-ion batteries. They are less prone to thermal runaway and have a lower risk of combustion, which could reduce the environmental and safety hazards associated with battery fires and explosions. This improved safety profile could have positive implications for the transportation and storage of energy storage systems.

As research and development in graphene battery technology continue, it will be essential to conduct comprehensive life cycle assessments to fully understand and quantify their environmental impact. These assessments should consider all stages of the battery's life, from raw material extraction to manufacturing, use, and end-of-life disposal or recycling. By identifying potential environmental hotspots, researchers and manufacturers can work to optimize the sustainability of graphene batteries and ensure that their widespread adoption truly contributes to a more environmentally friendly energy future.

One of the primary environmental benefits of graphene batteries is their potential to reduce the demand for raw materials used in conventional batteries. The enhanced durability and longer lifespan of graphene batteries mean fewer replacements are needed over time, potentially decreasing the mining and processing of materials like lithium, cobalt, and nickel. This reduction in resource extraction could lead to less habitat destruction, reduced water pollution, and lower greenhouse gas emissions associated with mining operations.

However, the production of graphene itself raises some environmental concerns. The current methods of graphene synthesis, such as chemical vapor deposition and liquid-phase exfoliation, can be energy-intensive and may involve the use of hazardous chemicals. As the demand for graphene increases, it will be crucial to develop more sustainable and scalable production methods to minimize the environmental impact of manufacturing processes.

The recyclability of graphene batteries is another important factor to consider. While the extended lifespan of these batteries reduces the frequency of disposal, effective recycling processes must be developed to recover and reuse valuable materials at the end of their life cycle. Research is ongoing to create efficient recycling techniques for graphene-based energy storage devices, which could significantly reduce the environmental impact of battery disposal.

Graphene batteries also have the potential to enhance the adoption of renewable energy sources. Their improved energy storage capabilities could help address the intermittency issues associated with solar and wind power, enabling more efficient integration of these clean energy sources into the grid. This could lead to a reduction in reliance on fossil fuels and contribute to lower greenhouse gas emissions in the energy sector.

In terms of safety, graphene batteries may offer advantages over traditional lithium-ion batteries. They are less prone to thermal runaway and have a lower risk of combustion, which could reduce the environmental and safety hazards associated with battery fires and explosions. This improved safety profile could have positive implications for the transportation and storage of energy storage systems.

As research and development in graphene battery technology continue, it will be essential to conduct comprehensive life cycle assessments to fully understand and quantify their environmental impact. These assessments should consider all stages of the battery's life, from raw material extraction to manufacturing, use, and end-of-life disposal or recycling. By identifying potential environmental hotspots, researchers and manufacturers can work to optimize the sustainability of graphene batteries and ensure that their widespread adoption truly contributes to a more environmentally friendly energy future.

Scalability and Manufacturing Challenges

The scalability and manufacturing challenges of graphene batteries represent significant hurdles in their widespread adoption and commercialization. One of the primary obstacles is the complexity of producing high-quality graphene at scale. While laboratory-scale production of graphene has shown promising results, translating these processes to industrial-scale manufacturing remains a formidable challenge.

The synthesis of graphene often requires precise control over various parameters, including temperature, pressure, and chemical composition. Maintaining consistency in these factors across large-scale production batches is technically demanding and can lead to variations in the quality and performance of the final product. This inconsistency can result in batteries with unpredictable performance characteristics, which is unacceptable for commercial applications.

Another significant challenge lies in the integration of graphene into existing battery manufacturing processes. Traditional battery production lines are optimized for current materials and technologies. Incorporating graphene into these established systems often requires substantial modifications to equipment and procedures, which can be both costly and time-consuming.

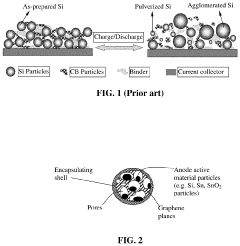

The handling of graphene during the manufacturing process also presents unique challenges. Graphene's nanoscale dimensions make it susceptible to agglomeration, which can reduce its effectiveness in battery applications. Developing methods to maintain graphene's dispersion and prevent clumping during large-scale production is crucial for preserving its exceptional properties in the final battery product.

Cost considerations further complicate the scaling of graphene battery production. While graphene itself has become more affordable in recent years, the specialized equipment and processes required for its integration into batteries still contribute to higher overall manufacturing costs compared to conventional battery technologies. This cost differential poses a significant barrier to market entry and widespread adoption.

Environmental and safety concerns also play a role in the scalability challenges. The production and handling of nanomaterials like graphene require stringent safety protocols and environmental controls. Implementing these measures at an industrial scale adds another layer of complexity to the manufacturing process and can impact production efficiency.

Despite these challenges, ongoing research and development efforts are making strides in addressing these issues. Innovations in graphene synthesis techniques, such as chemical vapor deposition and electrochemical exfoliation, show promise for large-scale production. Additionally, advancements in automated manufacturing processes and quality control systems are helping to improve consistency and reduce costs in graphene battery production.

The synthesis of graphene often requires precise control over various parameters, including temperature, pressure, and chemical composition. Maintaining consistency in these factors across large-scale production batches is technically demanding and can lead to variations in the quality and performance of the final product. This inconsistency can result in batteries with unpredictable performance characteristics, which is unacceptable for commercial applications.

Another significant challenge lies in the integration of graphene into existing battery manufacturing processes. Traditional battery production lines are optimized for current materials and technologies. Incorporating graphene into these established systems often requires substantial modifications to equipment and procedures, which can be both costly and time-consuming.

The handling of graphene during the manufacturing process also presents unique challenges. Graphene's nanoscale dimensions make it susceptible to agglomeration, which can reduce its effectiveness in battery applications. Developing methods to maintain graphene's dispersion and prevent clumping during large-scale production is crucial for preserving its exceptional properties in the final battery product.

Cost considerations further complicate the scaling of graphene battery production. While graphene itself has become more affordable in recent years, the specialized equipment and processes required for its integration into batteries still contribute to higher overall manufacturing costs compared to conventional battery technologies. This cost differential poses a significant barrier to market entry and widespread adoption.

Environmental and safety concerns also play a role in the scalability challenges. The production and handling of nanomaterials like graphene require stringent safety protocols and environmental controls. Implementing these measures at an industrial scale adds another layer of complexity to the manufacturing process and can impact production efficiency.

Despite these challenges, ongoing research and development efforts are making strides in addressing these issues. Innovations in graphene synthesis techniques, such as chemical vapor deposition and electrochemical exfoliation, show promise for large-scale production. Additionally, advancements in automated manufacturing processes and quality control systems are helping to improve consistency and reduce costs in graphene battery production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!