How to Innovate Graphene Battery Cooling Techniques?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Cooling: Background and Objectives

Graphene, a two-dimensional carbon allotrope, has emerged as a revolutionary material in various technological applications, including battery cooling. The development of graphene-based cooling techniques for batteries represents a significant advancement in energy storage technology, addressing critical challenges in thermal management and performance optimization.

The evolution of battery technology has been marked by continuous efforts to enhance energy density, power output, and operational safety. As batteries have become more powerful and compact, the issue of heat generation and dissipation has grown increasingly prominent. Traditional cooling methods have often fallen short in managing the thermal challenges posed by high-performance batteries, particularly in demanding applications such as electric vehicles and portable electronics.

Graphene's exceptional thermal conductivity, which surpasses that of copper and other conventional materials, has positioned it as a promising candidate for innovative cooling solutions. The material's ability to efficiently conduct heat, coupled with its lightweight nature and mechanical strength, offers a unique combination of properties that can potentially revolutionize battery thermal management systems.

The primary objective of graphene battery cooling techniques is to effectively dissipate heat generated during charge and discharge cycles, thereby maintaining optimal operating temperatures and extending battery life. By leveraging graphene's superior thermal properties, researchers and engineers aim to develop cooling systems that are more efficient, compact, and adaptable than existing solutions.

Another key goal is to enhance the overall performance and safety of battery systems. Effective thermal management can prevent thermal runaway, a dangerous condition that can lead to battery failure or even fires. By implementing graphene-based cooling techniques, it becomes possible to push the boundaries of battery performance while maintaining stringent safety standards.

Furthermore, the development of graphene battery cooling techniques aligns with broader trends in sustainable technology and energy efficiency. As the world transitions towards cleaner energy sources and electrification of transportation, the demand for high-performance, thermally efficient batteries continues to grow. Graphene-based solutions have the potential to play a crucial role in this transition, enabling the creation of more energy-dense and reliable battery systems.

The pursuit of innovative graphene battery cooling techniques also intersects with advancements in materials science and nanotechnology. Researchers are exploring various forms of graphene, including graphene foams, composites, and hybrid structures, to optimize thermal management capabilities. This interdisciplinary approach opens up new avenues for technological breakthroughs and cross-sector applications.

The evolution of battery technology has been marked by continuous efforts to enhance energy density, power output, and operational safety. As batteries have become more powerful and compact, the issue of heat generation and dissipation has grown increasingly prominent. Traditional cooling methods have often fallen short in managing the thermal challenges posed by high-performance batteries, particularly in demanding applications such as electric vehicles and portable electronics.

Graphene's exceptional thermal conductivity, which surpasses that of copper and other conventional materials, has positioned it as a promising candidate for innovative cooling solutions. The material's ability to efficiently conduct heat, coupled with its lightweight nature and mechanical strength, offers a unique combination of properties that can potentially revolutionize battery thermal management systems.

The primary objective of graphene battery cooling techniques is to effectively dissipate heat generated during charge and discharge cycles, thereby maintaining optimal operating temperatures and extending battery life. By leveraging graphene's superior thermal properties, researchers and engineers aim to develop cooling systems that are more efficient, compact, and adaptable than existing solutions.

Another key goal is to enhance the overall performance and safety of battery systems. Effective thermal management can prevent thermal runaway, a dangerous condition that can lead to battery failure or even fires. By implementing graphene-based cooling techniques, it becomes possible to push the boundaries of battery performance while maintaining stringent safety standards.

Furthermore, the development of graphene battery cooling techniques aligns with broader trends in sustainable technology and energy efficiency. As the world transitions towards cleaner energy sources and electrification of transportation, the demand for high-performance, thermally efficient batteries continues to grow. Graphene-based solutions have the potential to play a crucial role in this transition, enabling the creation of more energy-dense and reliable battery systems.

The pursuit of innovative graphene battery cooling techniques also intersects with advancements in materials science and nanotechnology. Researchers are exploring various forms of graphene, including graphene foams, composites, and hybrid structures, to optimize thermal management capabilities. This interdisciplinary approach opens up new avenues for technological breakthroughs and cross-sector applications.

Market Demand Analysis for Advanced Battery Cooling

The market demand for advanced battery cooling technologies, particularly those utilizing graphene, has been experiencing significant growth in recent years. This surge is primarily driven by the rapid expansion of the electric vehicle (EV) market and the increasing adoption of high-performance batteries in various industries. As battery technologies continue to evolve, the need for more efficient and effective cooling solutions becomes paramount to ensure optimal performance, longevity, and safety of battery systems.

In the automotive sector, the global EV market has been expanding at an unprecedented rate, with major manufacturers investing heavily in electric and hybrid vehicle production. This growth has created a substantial demand for advanced battery cooling systems that can manage the heat generated during charging and discharging cycles effectively. Graphene-based cooling techniques have emerged as a promising solution due to their superior thermal conductivity and lightweight properties.

Beyond the automotive industry, the demand for advanced battery cooling extends to consumer electronics, renewable energy storage systems, and aerospace applications. As devices become more powerful and energy-dense, the need for efficient heat dissipation becomes critical. Graphene-enhanced cooling solutions offer the potential to address these challenges across various sectors, driving market growth and innovation.

The energy storage market, particularly for grid-scale applications, is another significant driver for advanced battery cooling technologies. As renewable energy sources become more prevalent, the demand for large-scale battery storage systems increases. These systems require sophisticated cooling solutions to maintain optimal operating temperatures and extend battery life, creating opportunities for graphene-based cooling techniques.

Market analysts project that the global battery thermal management system market will continue to grow substantially in the coming years. This growth is attributed to the increasing demand for EVs, the push for longer-range electric vehicles, and the need for faster charging capabilities. Graphene-based cooling technologies are positioned to capture a significant portion of this market due to their superior performance characteristics.

The industrial sector also presents a growing market for advanced battery cooling solutions. As industries increasingly adopt automation and electrification, the demand for high-performance batteries with efficient cooling systems rises. Graphene-based cooling techniques offer the potential to improve the reliability and efficiency of industrial battery systems, driving adoption across manufacturing, logistics, and other industrial applications.

In conclusion, the market demand for advanced battery cooling technologies, particularly those leveraging graphene, is robust and diverse. The convergence of automotive electrification, renewable energy adoption, and industrial automation is creating a fertile ground for innovation in battery cooling techniques. As the technology matures and demonstrates its effectiveness, we can expect to see increased adoption across various sectors, further driving market growth and technological advancement in the field of graphene-based battery cooling solutions.

In the automotive sector, the global EV market has been expanding at an unprecedented rate, with major manufacturers investing heavily in electric and hybrid vehicle production. This growth has created a substantial demand for advanced battery cooling systems that can manage the heat generated during charging and discharging cycles effectively. Graphene-based cooling techniques have emerged as a promising solution due to their superior thermal conductivity and lightweight properties.

Beyond the automotive industry, the demand for advanced battery cooling extends to consumer electronics, renewable energy storage systems, and aerospace applications. As devices become more powerful and energy-dense, the need for efficient heat dissipation becomes critical. Graphene-enhanced cooling solutions offer the potential to address these challenges across various sectors, driving market growth and innovation.

The energy storage market, particularly for grid-scale applications, is another significant driver for advanced battery cooling technologies. As renewable energy sources become more prevalent, the demand for large-scale battery storage systems increases. These systems require sophisticated cooling solutions to maintain optimal operating temperatures and extend battery life, creating opportunities for graphene-based cooling techniques.

Market analysts project that the global battery thermal management system market will continue to grow substantially in the coming years. This growth is attributed to the increasing demand for EVs, the push for longer-range electric vehicles, and the need for faster charging capabilities. Graphene-based cooling technologies are positioned to capture a significant portion of this market due to their superior performance characteristics.

The industrial sector also presents a growing market for advanced battery cooling solutions. As industries increasingly adopt automation and electrification, the demand for high-performance batteries with efficient cooling systems rises. Graphene-based cooling techniques offer the potential to improve the reliability and efficiency of industrial battery systems, driving adoption across manufacturing, logistics, and other industrial applications.

In conclusion, the market demand for advanced battery cooling technologies, particularly those leveraging graphene, is robust and diverse. The convergence of automotive electrification, renewable energy adoption, and industrial automation is creating a fertile ground for innovation in battery cooling techniques. As the technology matures and demonstrates its effectiveness, we can expect to see increased adoption across various sectors, further driving market growth and technological advancement in the field of graphene-based battery cooling solutions.

Current Challenges in Graphene-Based Battery Cooling

Graphene-based battery cooling technologies have shown immense potential in addressing thermal management challenges in high-performance batteries. However, several significant obstacles hinder their widespread adoption and optimal performance. One of the primary challenges is the scalability of graphene production for large-scale battery applications. While laboratory-scale synthesis of high-quality graphene is well-established, translating this to industrial-scale production while maintaining consistent quality and properties remains a formidable task.

Another critical challenge lies in the integration of graphene into existing battery cooling systems. The unique two-dimensional structure of graphene, while beneficial for thermal conductivity, poses difficulties in creating uniform and stable dispersions within cooling fluids or polymer matrices. This integration challenge often results in suboptimal thermal performance and reduced long-term stability of the cooling system.

The thermal interface resistance between graphene and other materials in the battery system presents another significant hurdle. Despite graphene's excellent intrinsic thermal conductivity, the efficiency of heat transfer can be severely limited by poor thermal coupling at material interfaces. Overcoming this interface resistance is crucial for maximizing the cooling efficiency of graphene-based systems.

Durability and long-term performance stability of graphene-enhanced cooling solutions in harsh battery environments are also areas of concern. The high temperatures, chemical reactions, and mechanical stresses present in battery systems can potentially degrade graphene's structure and properties over time, affecting the cooling performance and overall battery lifespan.

Cost considerations pose a substantial challenge to the widespread adoption of graphene-based cooling technologies. The current production costs of high-quality graphene remain relatively high, making it economically challenging to implement in mass-market battery applications. Balancing the enhanced performance with cost-effectiveness is crucial for commercial viability.

Environmental and safety concerns associated with graphene production and disposal also need to be addressed. As the use of graphene in battery cooling systems increases, developing environmentally friendly production methods and establishing proper recycling and disposal protocols become increasingly important.

Lastly, the lack of standardization in graphene quality and characterization methods complicates the development and comparison of different graphene-based cooling solutions. Establishing industry-wide standards for graphene materials used in battery cooling applications is essential for consistent performance evaluation and quality control.

Another critical challenge lies in the integration of graphene into existing battery cooling systems. The unique two-dimensional structure of graphene, while beneficial for thermal conductivity, poses difficulties in creating uniform and stable dispersions within cooling fluids or polymer matrices. This integration challenge often results in suboptimal thermal performance and reduced long-term stability of the cooling system.

The thermal interface resistance between graphene and other materials in the battery system presents another significant hurdle. Despite graphene's excellent intrinsic thermal conductivity, the efficiency of heat transfer can be severely limited by poor thermal coupling at material interfaces. Overcoming this interface resistance is crucial for maximizing the cooling efficiency of graphene-based systems.

Durability and long-term performance stability of graphene-enhanced cooling solutions in harsh battery environments are also areas of concern. The high temperatures, chemical reactions, and mechanical stresses present in battery systems can potentially degrade graphene's structure and properties over time, affecting the cooling performance and overall battery lifespan.

Cost considerations pose a substantial challenge to the widespread adoption of graphene-based cooling technologies. The current production costs of high-quality graphene remain relatively high, making it economically challenging to implement in mass-market battery applications. Balancing the enhanced performance with cost-effectiveness is crucial for commercial viability.

Environmental and safety concerns associated with graphene production and disposal also need to be addressed. As the use of graphene in battery cooling systems increases, developing environmentally friendly production methods and establishing proper recycling and disposal protocols become increasingly important.

Lastly, the lack of standardization in graphene quality and characterization methods complicates the development and comparison of different graphene-based cooling solutions. Establishing industry-wide standards for graphene materials used in battery cooling applications is essential for consistent performance evaluation and quality control.

Existing Graphene Battery Cooling Solutions

01 Graphene-based heat dissipation structures

Utilizing graphene's excellent thermal conductivity properties to create efficient heat dissipation structures for battery cooling. These structures can include graphene films, coatings, or composite materials integrated into battery components to enhance heat transfer and maintain optimal operating temperatures.- Graphene-based heat dissipation structures: Utilizing graphene's excellent thermal conductivity properties to create heat dissipation structures in batteries. These structures can include graphene sheets, films, or composites integrated into battery components to efficiently transfer heat away from critical areas, improving overall cooling performance and battery life.

- Liquid cooling systems with graphene additives: Incorporating graphene or graphene oxide into liquid cooling systems for batteries. The addition of graphene-based materials to cooling fluids enhances their thermal conductivity and heat transfer capabilities, resulting in more effective temperature management within the battery pack.

- Graphene-enhanced thermal interface materials: Developing thermal interface materials (TIMs) infused with graphene to improve heat transfer between battery cells and cooling systems. These graphene-enhanced TIMs provide better thermal conductivity and reduce thermal resistance at contact points, enhancing overall cooling efficiency.

- Graphene-based phase change materials for battery cooling: Integrating graphene into phase change materials (PCMs) used for battery thermal management. The high thermal conductivity of graphene improves the heat absorption and distribution capabilities of PCMs, allowing for more effective temperature regulation during battery charge and discharge cycles.

- Graphene-coated battery components for enhanced cooling: Applying graphene coatings to various battery components, such as electrodes, current collectors, or separators, to improve heat dissipation. These coatings leverage graphene's high thermal conductivity to facilitate faster and more uniform heat transfer throughout the battery structure.

02 Phase change materials with graphene

Incorporating phase change materials (PCMs) enhanced with graphene into battery cooling systems. The graphene-PCM composites can absorb and store excess heat during battery operation, and release it when the temperature drops, providing effective thermal management and temperature stabilization.Expand Specific Solutions03 Graphene-based cooling fluids and heat transfer media

Developing cooling fluids or heat transfer media containing graphene nanoparticles or graphene oxide. These fluids can be circulated through battery cooling systems to improve heat dissipation efficiency and overall thermal management performance.Expand Specific Solutions04 Graphene-enhanced battery electrode designs

Designing battery electrodes with graphene-based materials to improve thermal conductivity and heat dissipation within the battery structure. This approach can help distribute heat more evenly and reduce hotspots, enhancing overall cooling efficiency.Expand Specific Solutions05 Graphene-based thermal interface materials

Developing and applying graphene-based thermal interface materials between battery components and cooling systems. These materials can significantly improve thermal contact and heat transfer efficiency, enhancing the overall cooling performance of the battery system.Expand Specific Solutions

Key Players in Graphene and Battery Cooling Industry

The graphene battery cooling technology market is in its early growth stage, characterized by rapid innovation and increasing competition. The market size is expanding as demand for high-performance batteries in electric vehicles and electronics grows. While the technology is still evolving, several key players are making significant strides. Companies like Applied Materials, LG Energy Solution, and IBM are leveraging their expertise in materials science and battery technology to develop advanced cooling solutions. Universities such as Jilin University and King Abdullah University of Science & Technology are contributing through fundamental research. Startups like BGT Materials and Honeycomb Battery Co. are also emerging as innovative forces in this space, focusing on specialized graphene applications for battery cooling.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed an innovative graphene-based cooling solution for batteries. Their approach involves creating a highly conductive graphene coating that is applied directly to battery cells. This coating acts as a thermal management layer, efficiently dissipating heat generated during charging and discharging cycles. The company has reported that their graphene coating can reduce battery temperature by up to 20°C compared to conventional cooling methods[1]. Additionally, they have integrated graphene heat spreaders into their battery pack designs, which work in conjunction with the coating to further enhance heat dissipation[3].

Strengths: Significantly improved thermal management, potential for increased battery lifespan and performance. Weaknesses: Potential high cost of graphene materials, complexity in large-scale manufacturing processes.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a graphene-enhanced battery cooling system that utilizes a graphene-infused coolant. This innovative approach involves dispersing graphene nanoparticles in a specialized coolant fluid, which is then circulated through channels integrated into the battery pack. The graphene nanoparticles significantly enhance the thermal conductivity of the coolant, allowing for more efficient heat transfer from the battery cells to the cooling system. LG Energy Solution reports that this technology can improve cooling efficiency by up to 40% compared to traditional liquid cooling systems[2]. Furthermore, they have developed a graphene-based thermal interface material that reduces thermal resistance between battery cells and cooling plates[4].

Strengths: Highly efficient cooling, compatibility with existing liquid cooling infrastructures. Weaknesses: Potential for graphene particle agglomeration over time, need for specialized coolant maintenance.

Core Innovations in Graphene Cooling Technologies

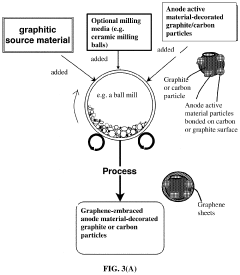

Method of producing graphene-encapsulated graphite-supported anode active material for lithium-ion batteries

PatentInactiveUS20200313162A1

Innovation

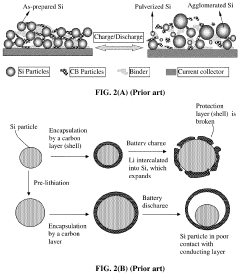

- The development of graphene-embraced anode particulates, where a thin encapsulating layer of graphene sheets is applied to graphite or carbon particles decorated with anode active materials, providing mechanical protection and maintaining lithium ion conductivity, thereby reducing volume expansion and internal stress during lithium insertion and extraction.

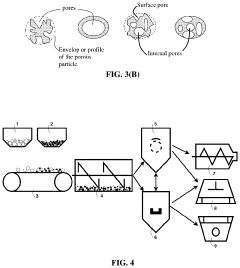

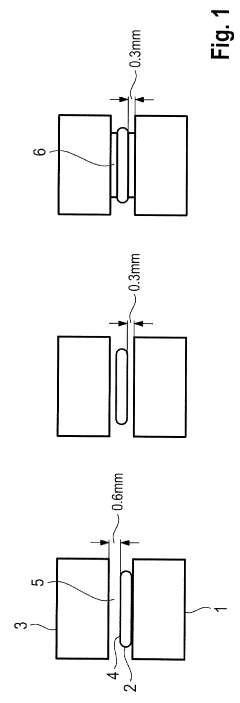

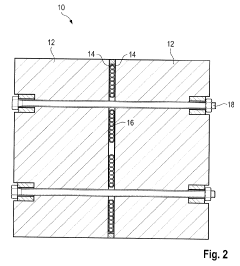

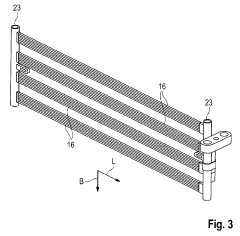

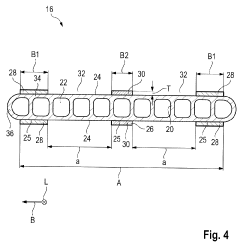

Cooling module for a battery, battery for a vehicle and method for producing a cooling module

PatentInactiveUS20190214690A1

Innovation

- A cooling module design featuring a profile element with partially covered side surfaces by filling material, allowing for reduced compression forces and improved heat transfer, using a combination of extrusion profiles and strategically arranged filling material strips to compensate for tolerances and distribute forces effectively.

Environmental Impact of Graphene Cooling Techniques

The environmental impact of graphene cooling techniques in battery systems is a crucial consideration as this technology advances. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers exceptional thermal conductivity properties that can significantly enhance battery cooling efficiency. However, its production and application in cooling systems may have both positive and negative environmental implications.

One of the primary environmental benefits of graphene cooling techniques is the potential for improved energy efficiency in battery systems. By effectively dissipating heat, graphene-based cooling solutions can extend battery life, reduce energy waste, and potentially decrease the overall carbon footprint associated with battery production and replacement. This improved efficiency could lead to a reduction in raw material extraction and processing, which are often energy-intensive and environmentally detrimental activities.

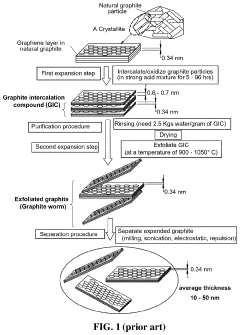

However, the production of graphene itself raises environmental concerns. Current manufacturing processes for high-quality graphene can be energy-intensive and may involve the use of hazardous chemicals. The environmental impact of graphene production varies depending on the specific method used, such as chemical vapor deposition (CVD) or exfoliation of graphite. Efforts are ongoing to develop more sustainable and scalable production methods, but the current processes may contribute to increased carbon emissions and chemical waste.

The use of graphene in battery cooling systems also introduces questions about end-of-life management and recyclability. While graphene itself is a form of carbon and theoretically recyclable, the integration of graphene into complex cooling systems may complicate the recycling process. This could potentially lead to increased electronic waste if not properly addressed through innovative recycling technologies and circular economy approaches.

On the other hand, the durability and efficiency of graphene-enhanced cooling systems could reduce the frequency of battery replacements, potentially offsetting some of the environmental costs associated with production. Additionally, the improved thermal management could lead to safer battery operations, reducing the risk of thermal runaway and associated environmental hazards.

The environmental impact of graphene cooling techniques extends beyond the immediate battery system. By enabling more efficient and compact battery designs, this technology could facilitate the broader adoption of electric vehicles and renewable energy storage solutions. This shift towards electrification and clean energy has the potential to significantly reduce greenhouse gas emissions and dependence on fossil fuels, contributing to global efforts to combat climate change.

In conclusion, while graphene cooling techniques offer promising environmental benefits through improved battery efficiency and performance, careful consideration must be given to the entire lifecycle of these systems. Continued research and development are necessary to optimize production processes, enhance recyclability, and maximize the positive environmental impact of this innovative technology.

One of the primary environmental benefits of graphene cooling techniques is the potential for improved energy efficiency in battery systems. By effectively dissipating heat, graphene-based cooling solutions can extend battery life, reduce energy waste, and potentially decrease the overall carbon footprint associated with battery production and replacement. This improved efficiency could lead to a reduction in raw material extraction and processing, which are often energy-intensive and environmentally detrimental activities.

However, the production of graphene itself raises environmental concerns. Current manufacturing processes for high-quality graphene can be energy-intensive and may involve the use of hazardous chemicals. The environmental impact of graphene production varies depending on the specific method used, such as chemical vapor deposition (CVD) or exfoliation of graphite. Efforts are ongoing to develop more sustainable and scalable production methods, but the current processes may contribute to increased carbon emissions and chemical waste.

The use of graphene in battery cooling systems also introduces questions about end-of-life management and recyclability. While graphene itself is a form of carbon and theoretically recyclable, the integration of graphene into complex cooling systems may complicate the recycling process. This could potentially lead to increased electronic waste if not properly addressed through innovative recycling technologies and circular economy approaches.

On the other hand, the durability and efficiency of graphene-enhanced cooling systems could reduce the frequency of battery replacements, potentially offsetting some of the environmental costs associated with production. Additionally, the improved thermal management could lead to safer battery operations, reducing the risk of thermal runaway and associated environmental hazards.

The environmental impact of graphene cooling techniques extends beyond the immediate battery system. By enabling more efficient and compact battery designs, this technology could facilitate the broader adoption of electric vehicles and renewable energy storage solutions. This shift towards electrification and clean energy has the potential to significantly reduce greenhouse gas emissions and dependence on fossil fuels, contributing to global efforts to combat climate change.

In conclusion, while graphene cooling techniques offer promising environmental benefits through improved battery efficiency and performance, careful consideration must be given to the entire lifecycle of these systems. Continued research and development are necessary to optimize production processes, enhance recyclability, and maximize the positive environmental impact of this innovative technology.

Safety Considerations in Graphene-Enhanced Battery Systems

The integration of graphene into battery systems brings significant advancements in performance and efficiency. However, it also introduces new safety considerations that must be carefully addressed. One primary concern is the potential for graphene particles to cause short circuits within the battery. Due to graphene's high electrical conductivity, any loose particles could create unintended pathways for current flow, leading to internal shorts and potentially hazardous thermal events.

Another safety aspect to consider is the chemical stability of graphene in the battery environment. While graphene is generally inert, its large surface area can potentially catalyze unwanted side reactions, especially in the presence of electrolytes. This could lead to accelerated degradation of battery components or the formation of volatile compounds, compromising both performance and safety.

The mechanical properties of graphene also present unique challenges. Its exceptional strength and flexibility could affect the structural integrity of battery components over time, potentially leading to internal deformation or stress on other materials. This may result in premature wear or failure of critical battery elements.

Heat management is a crucial safety factor in graphene-enhanced batteries. While graphene's thermal conductivity can improve overall heat dissipation, localized heat buildup at graphene interfaces must be carefully monitored and controlled to prevent thermal runaway scenarios.

Environmental and health considerations are also paramount. The production and disposal of graphene-containing batteries must be evaluated for potential environmental impacts and human exposure risks. Proper handling protocols and recycling procedures need to be established to mitigate any long-term safety concerns.

Regulatory compliance is another critical aspect of safety in graphene-enhanced battery systems. As a relatively new material in battery applications, graphene may require specific safety certifications and standards. Manufacturers must work closely with regulatory bodies to ensure that all safety requirements are met and that proper testing protocols are in place.

Lastly, the long-term stability and aging characteristics of graphene in battery systems must be thoroughly investigated. Understanding how graphene interacts with other battery components over extended periods and multiple charge-discharge cycles is crucial for predicting and preventing potential safety issues that may arise during the battery's lifetime.

Another safety aspect to consider is the chemical stability of graphene in the battery environment. While graphene is generally inert, its large surface area can potentially catalyze unwanted side reactions, especially in the presence of electrolytes. This could lead to accelerated degradation of battery components or the formation of volatile compounds, compromising both performance and safety.

The mechanical properties of graphene also present unique challenges. Its exceptional strength and flexibility could affect the structural integrity of battery components over time, potentially leading to internal deformation or stress on other materials. This may result in premature wear or failure of critical battery elements.

Heat management is a crucial safety factor in graphene-enhanced batteries. While graphene's thermal conductivity can improve overall heat dissipation, localized heat buildup at graphene interfaces must be carefully monitored and controlled to prevent thermal runaway scenarios.

Environmental and health considerations are also paramount. The production and disposal of graphene-containing batteries must be evaluated for potential environmental impacts and human exposure risks. Proper handling protocols and recycling procedures need to be established to mitigate any long-term safety concerns.

Regulatory compliance is another critical aspect of safety in graphene-enhanced battery systems. As a relatively new material in battery applications, graphene may require specific safety certifications and standards. Manufacturers must work closely with regulatory bodies to ensure that all safety requirements are met and that proper testing protocols are in place.

Lastly, the long-term stability and aging characteristics of graphene in battery systems must be thoroughly investigated. Understanding how graphene interacts with other battery components over extended periods and multiple charge-discharge cycles is crucial for predicting and preventing potential safety issues that may arise during the battery's lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!