Exploring New Horizons with Graphene Battery Storage

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution

Graphene battery technology has undergone a remarkable evolution since its inception, marking significant milestones in the quest for more efficient and powerful energy storage solutions. The journey began with the discovery of graphene's exceptional properties in 2004, which sparked intense research into its potential applications in various fields, including energy storage.

In the early stages of development, researchers focused on understanding graphene's unique characteristics, such as its high electrical conductivity, mechanical strength, and large surface area. These properties made graphene an ideal candidate for enhancing battery performance. The initial experiments involved incorporating graphene into existing battery technologies, primarily lithium-ion batteries, to improve their capacity and charging speeds.

By 2010, scientists had made significant progress in developing graphene-enhanced electrodes for batteries. These early prototypes demonstrated improved energy density and faster charging capabilities compared to conventional lithium-ion batteries. However, challenges remained in terms of scalability and manufacturing processes.

The period between 2010 and 2015 saw a surge in research activities aimed at overcoming these challenges. Scientists explored various methods of graphene synthesis and integration into battery components. This phase also witnessed the emergence of graphene-based supercapacitors, which promised ultra-fast charging and discharging capabilities.

From 2015 onwards, the focus shifted towards commercialization efforts. Several startups and established companies began investing heavily in graphene battery technology. This period saw the development of more advanced graphene-based materials, such as graphene oxide and reduced graphene oxide, which offered improved performance and easier integration into existing manufacturing processes.

A significant breakthrough came in 2017 with the announcement of the first commercially viable graphene battery. This development marked a turning point in the technology's evolution, demonstrating its potential for real-world applications. Since then, researchers have continued to refine the technology, exploring new graphene composites and hybrid materials to further enhance battery performance.

Recent years have seen an increased focus on sustainability and environmental considerations in graphene battery development. Efforts are being made to develop eco-friendly production methods and to improve the recyclability of graphene-based batteries. Additionally, researchers are exploring the potential of graphene in next-generation battery technologies, such as solid-state batteries and metal-air batteries.

As we look to the future, the evolution of graphene battery technology continues to accelerate. With ongoing advancements in materials science and manufacturing techniques, graphene batteries are poised to play a crucial role in addressing the growing energy storage needs of various sectors, from consumer electronics to electric vehicles and renewable energy systems.

In the early stages of development, researchers focused on understanding graphene's unique characteristics, such as its high electrical conductivity, mechanical strength, and large surface area. These properties made graphene an ideal candidate for enhancing battery performance. The initial experiments involved incorporating graphene into existing battery technologies, primarily lithium-ion batteries, to improve their capacity and charging speeds.

By 2010, scientists had made significant progress in developing graphene-enhanced electrodes for batteries. These early prototypes demonstrated improved energy density and faster charging capabilities compared to conventional lithium-ion batteries. However, challenges remained in terms of scalability and manufacturing processes.

The period between 2010 and 2015 saw a surge in research activities aimed at overcoming these challenges. Scientists explored various methods of graphene synthesis and integration into battery components. This phase also witnessed the emergence of graphene-based supercapacitors, which promised ultra-fast charging and discharging capabilities.

From 2015 onwards, the focus shifted towards commercialization efforts. Several startups and established companies began investing heavily in graphene battery technology. This period saw the development of more advanced graphene-based materials, such as graphene oxide and reduced graphene oxide, which offered improved performance and easier integration into existing manufacturing processes.

A significant breakthrough came in 2017 with the announcement of the first commercially viable graphene battery. This development marked a turning point in the technology's evolution, demonstrating its potential for real-world applications. Since then, researchers have continued to refine the technology, exploring new graphene composites and hybrid materials to further enhance battery performance.

Recent years have seen an increased focus on sustainability and environmental considerations in graphene battery development. Efforts are being made to develop eco-friendly production methods and to improve the recyclability of graphene-based batteries. Additionally, researchers are exploring the potential of graphene in next-generation battery technologies, such as solid-state batteries and metal-air batteries.

As we look to the future, the evolution of graphene battery technology continues to accelerate. With ongoing advancements in materials science and manufacturing techniques, graphene batteries are poised to play a crucial role in addressing the growing energy storage needs of various sectors, from consumer electronics to electric vehicles and renewable energy systems.

Market Demand Analysis

The market demand for graphene battery storage technology has been steadily growing, driven by the increasing need for high-performance energy storage solutions across various industries. The automotive sector, in particular, has shown significant interest in graphene-based batteries due to their potential to revolutionize electric vehicle (EV) performance. With major automakers investing heavily in EV development, the demand for batteries with higher energy density, faster charging capabilities, and longer lifespans has surged.

Consumer electronics represent another key market for graphene battery technology. Smartphone manufacturers are constantly seeking ways to improve battery life and reduce charging times, making graphene-enhanced batteries an attractive option. The wearable technology sector, including smartwatches and fitness trackers, also stands to benefit from the compact yet powerful nature of graphene-based energy storage solutions.

In the renewable energy sector, the intermittent nature of solar and wind power generation has created a pressing need for efficient energy storage systems. Graphene batteries, with their potential for high capacity and rapid charge/discharge cycles, could play a crucial role in grid stabilization and energy management. This application has garnered attention from utility companies and renewable energy providers worldwide.

The aerospace industry has also expressed interest in graphene battery technology. The lightweight properties of graphene, combined with its superior energy storage capabilities, make it an ideal candidate for use in satellites, drones, and even electric aircraft. This sector's demand is expected to grow as the push for more sustainable aviation solutions intensifies.

Industrial applications, including power tools and backup power systems, represent another significant market for graphene battery technology. The ability of graphene-enhanced batteries to withstand high-stress environments and deliver consistent power output aligns well with the demands of these sectors.

Market analysts project substantial growth in the graphene battery market over the coming years. The increasing focus on sustainability and the transition towards clean energy sources are expected to further boost demand. Additionally, government initiatives and regulations promoting the adoption of electric vehicles and renewable energy storage solutions are likely to create a favorable market environment for graphene battery technology.

However, it's important to note that the market demand is contingent upon overcoming current technological and production challenges. The ability to scale up graphene production and integrate it effectively into battery manufacturing processes will be crucial in meeting the growing market expectations. As research and development efforts continue to advance, the potential for graphene batteries to disrupt and reshape the energy storage landscape remains significant.

Consumer electronics represent another key market for graphene battery technology. Smartphone manufacturers are constantly seeking ways to improve battery life and reduce charging times, making graphene-enhanced batteries an attractive option. The wearable technology sector, including smartwatches and fitness trackers, also stands to benefit from the compact yet powerful nature of graphene-based energy storage solutions.

In the renewable energy sector, the intermittent nature of solar and wind power generation has created a pressing need for efficient energy storage systems. Graphene batteries, with their potential for high capacity and rapid charge/discharge cycles, could play a crucial role in grid stabilization and energy management. This application has garnered attention from utility companies and renewable energy providers worldwide.

The aerospace industry has also expressed interest in graphene battery technology. The lightweight properties of graphene, combined with its superior energy storage capabilities, make it an ideal candidate for use in satellites, drones, and even electric aircraft. This sector's demand is expected to grow as the push for more sustainable aviation solutions intensifies.

Industrial applications, including power tools and backup power systems, represent another significant market for graphene battery technology. The ability of graphene-enhanced batteries to withstand high-stress environments and deliver consistent power output aligns well with the demands of these sectors.

Market analysts project substantial growth in the graphene battery market over the coming years. The increasing focus on sustainability and the transition towards clean energy sources are expected to further boost demand. Additionally, government initiatives and regulations promoting the adoption of electric vehicles and renewable energy storage solutions are likely to create a favorable market environment for graphene battery technology.

However, it's important to note that the market demand is contingent upon overcoming current technological and production challenges. The ability to scale up graphene production and integrate it effectively into battery manufacturing processes will be crucial in meeting the growing market expectations. As research and development efforts continue to advance, the potential for graphene batteries to disrupt and reshape the energy storage landscape remains significant.

Technical Challenges

Graphene battery storage technology, while promising, faces several significant technical challenges that need to be addressed before widespread commercial adoption can be realized. One of the primary obstacles is the scalability of graphene production. Current methods for producing high-quality graphene in large quantities are limited and costly, hindering the mass production of graphene-based batteries.

Another major challenge lies in the integration of graphene into existing battery architectures. While graphene exhibits exceptional electrical and thermal conductivity, incorporating it into battery electrodes without compromising structural integrity or performance remains a complex task. Researchers are grappling with issues such as graphene agglomeration and non-uniform distribution within the electrode matrix, which can lead to reduced efficiency and capacity.

The stability of graphene-based electrodes in battery environments is also a concern. Long-term cycling stability and capacity retention are critical factors for battery performance, and graphene electrodes have shown susceptibility to degradation over extended charge-discharge cycles. This degradation can be attributed to factors such as electrolyte decomposition and the formation of solid-electrolyte interphase (SEI) layers, which can impede ion transport and reduce overall battery efficiency.

Furthermore, the development of suitable electrolytes compatible with graphene-based electrodes presents another technical hurdle. Traditional liquid electrolytes may not be optimal for graphene batteries, as they can lead to unwanted side reactions and accelerated degradation. Research into solid-state or gel electrolytes that can effectively work with graphene electrodes is ongoing but still faces challenges in terms of ionic conductivity and interfacial stability.

Safety concerns also pose significant technical challenges for graphene battery storage. The high electrical conductivity of graphene, while beneficial for performance, can potentially increase the risk of short circuits if not properly managed. Developing robust safety mechanisms and protective layers to prevent thermal runaway and ensure safe operation under various conditions is crucial for the widespread adoption of graphene batteries.

Lastly, the environmental impact and recyclability of graphene batteries need to be carefully considered. While graphene itself is a carbon-based material, the production processes and additional components used in battery manufacturing may have environmental implications. Developing eco-friendly production methods and establishing efficient recycling processes for graphene batteries are essential challenges that need to be addressed to ensure the long-term sustainability of this technology.

Another major challenge lies in the integration of graphene into existing battery architectures. While graphene exhibits exceptional electrical and thermal conductivity, incorporating it into battery electrodes without compromising structural integrity or performance remains a complex task. Researchers are grappling with issues such as graphene agglomeration and non-uniform distribution within the electrode matrix, which can lead to reduced efficiency and capacity.

The stability of graphene-based electrodes in battery environments is also a concern. Long-term cycling stability and capacity retention are critical factors for battery performance, and graphene electrodes have shown susceptibility to degradation over extended charge-discharge cycles. This degradation can be attributed to factors such as electrolyte decomposition and the formation of solid-electrolyte interphase (SEI) layers, which can impede ion transport and reduce overall battery efficiency.

Furthermore, the development of suitable electrolytes compatible with graphene-based electrodes presents another technical hurdle. Traditional liquid electrolytes may not be optimal for graphene batteries, as they can lead to unwanted side reactions and accelerated degradation. Research into solid-state or gel electrolytes that can effectively work with graphene electrodes is ongoing but still faces challenges in terms of ionic conductivity and interfacial stability.

Safety concerns also pose significant technical challenges for graphene battery storage. The high electrical conductivity of graphene, while beneficial for performance, can potentially increase the risk of short circuits if not properly managed. Developing robust safety mechanisms and protective layers to prevent thermal runaway and ensure safe operation under various conditions is crucial for the widespread adoption of graphene batteries.

Lastly, the environmental impact and recyclability of graphene batteries need to be carefully considered. While graphene itself is a carbon-based material, the production processes and additional components used in battery manufacturing may have environmental implications. Developing eco-friendly production methods and establishing efficient recycling processes for graphene batteries are essential challenges that need to be addressed to ensure the long-term sustainability of this technology.

Current Graphene Solutions

01 Graphene-based electrode materials

Graphene-based materials are used as electrode components in batteries to enhance storage capacity. The high surface area and excellent conductivity of graphene allow for improved charge storage and faster electron transfer, leading to increased energy density and power output in battery systems.- Graphene-based electrode materials: Graphene-based materials are used as electrode components in batteries to enhance storage capacity. The high surface area and excellent conductivity of graphene allow for improved charge storage and faster electron transfer, leading to increased energy density and power output in batteries.

- Composite materials with graphene: Composite materials incorporating graphene are developed to improve battery storage capacity. These composites combine graphene with other materials such as metal oxides or polymers to create synergistic effects, enhancing the overall performance and capacity of the battery.

- Graphene-enhanced electrolytes: Graphene is utilized in electrolyte formulations to improve ionic conductivity and stability. This enhancement leads to better charge transfer and increased storage capacity in batteries, while also potentially improving the overall lifespan of the battery.

- Graphene-based supercapacitors: Graphene is employed in the development of supercapacitors with high energy storage capacity. The unique properties of graphene allow for the creation of devices that combine the high power density of traditional capacitors with the high energy density of batteries, resulting in improved energy storage solutions.

- Graphene functionalization for capacity enhancement: Various methods of functionalizing graphene are explored to further increase its storage capacity in batteries. These modifications can include doping, surface treatments, or the creation of graphene-based hybrid structures, all aimed at optimizing the material's performance in energy storage applications.

02 Composite materials with graphene

Composite materials incorporating graphene are developed to improve battery storage capacity. These composites often combine graphene with other materials such as metal oxides or polymers to create synergistic effects, enhancing the overall performance and capacity of the battery.Expand Specific Solutions03 Graphene-enhanced electrolytes

Graphene is utilized to enhance electrolyte performance in batteries. By incorporating graphene or graphene derivatives into the electrolyte, ionic conductivity can be improved, leading to better charge transfer and increased storage capacity of the battery system.Expand Specific Solutions04 Nanostructured graphene for energy storage

Nanostructured graphene materials are engineered to maximize surface area and optimize charge storage capabilities. These nanostructures can include graphene nanosheets, 3D graphene networks, or graphene quantum dots, which offer enhanced storage capacity due to their unique physical and chemical properties.Expand Specific Solutions05 Graphene-based supercapacitors

Graphene is employed in the development of high-performance supercapacitors. The material's properties allow for the creation of devices with high power density and improved energy storage capacity, bridging the gap between conventional capacitors and batteries.Expand Specific Solutions

Key Industry Players

The graphene battery storage market is in its early growth stage, characterized by rapid technological advancements and increasing investments. The global market size is projected to expand significantly in the coming years, driven by the growing demand for high-performance energy storage solutions. While the technology is still evolving, several key players are making substantial progress. Companies like Semiconductor Energy Laboratory, Global Graphene Group, and Vorbeck Materials are at the forefront of graphene battery research and development. Academic institutions such as Northwestern University and The University of Manchester are also contributing significantly to the field. The technology's maturity is advancing, with some companies already commercializing graphene-enhanced batteries, though widespread adoption is still in progress.

Global Graphene Group, Inc.

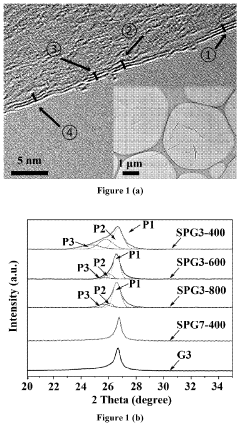

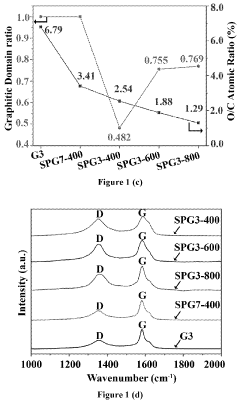

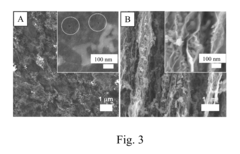

Technical Solution: Global Graphene Group (G3) has developed a proprietary graphene-enhanced silicon anode technology for lithium-ion batteries. Their Si-G composite anode material combines silicon nanoparticles with graphene, addressing the volume expansion issues of silicon during charging cycles. This technology enables higher energy density, faster charging rates, and improved cycle life compared to traditional graphite anodes[1][3]. G3's approach involves encapsulating silicon nanoparticles within a graphene matrix, which provides structural stability and enhances conductivity. The company claims their Si-G anodes can achieve specific capacities of over 1000 mAh/g, significantly higher than conventional graphite anodes (372 mAh/g)[2].

Strengths: Higher energy density, faster charging, improved cycle life. Weaknesses: Potential higher production costs, scalability challenges for mass production.

Vorbeck Materials Corp.

Technical Solution: Vorbeck Materials has developed a proprietary graphene material called Vor-x®, which they apply to various energy storage solutions. For battery applications, Vorbeck has created graphene-enhanced electrodes that significantly improve the performance of lead-acid batteries. Their technology involves coating traditional lead-acid battery plates with a thin layer of graphene, resulting in faster charging times, increased cycle life, and improved power density[7]. Vorbeck claims their graphene-enhanced lead-acid batteries can achieve up to 4x faster recharge rates and 2x longer cycle life compared to conventional lead-acid batteries[8]. The company has also explored graphene applications in lithium-ion batteries, focusing on silicon-graphene composite anodes for higher energy density.

Strengths: Improved performance in established lead-acid battery technology, potential for easy integration into existing manufacturing processes. Weaknesses: Limited focus on newer battery chemistries, potential cost increase for traditional lead-acid batteries.

Breakthrough Technologies

Graphene processing technique

PatentPendingUS20240021820A1

Innovation

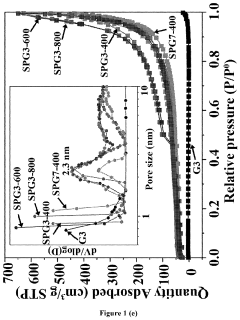

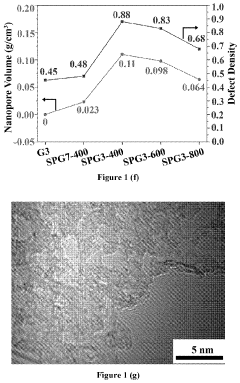

- A surfactant-assisted thermal reductive perforation process using poly(alkylene oxide) to generate surface-perforated graphene with in-plane mesopores, expanded interlayer lattice, and low oxygen content, facilitating AlCl4− ion storage by weakening interlayer interactions and creating accessible sites.

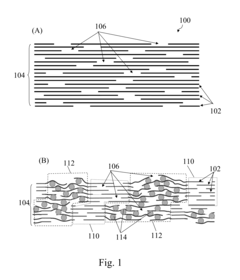

Graphene Materials Having Randomly Distributed Two-Dimensional Structural Defects

PatentActiveUS20140015160A1

Innovation

- Graphene-based materials with randomly distributed defect pores formed by in-plane carbon vacancies are used, creating a vertical stack with a continuous network of graphitic regions integrated with disordered portions and electrochemically active materials like silicon nanoparticles, enhancing Li ion diffusion and mechanical integrity.

Environmental Impact

Graphene battery storage technology presents a promising avenue for advancing energy storage capabilities while potentially reducing environmental impact compared to traditional battery technologies. The production of graphene-based batteries involves fewer toxic materials and heavy metals, which can significantly decrease the environmental footprint associated with battery manufacturing. Moreover, the enhanced durability and longer lifespan of graphene batteries may lead to reduced waste generation over time, as fewer replacements would be needed.

The improved energy density and faster charging capabilities of graphene batteries could contribute to the wider adoption of electric vehicles and renewable energy systems. This shift would help reduce greenhouse gas emissions and dependence on fossil fuels, thereby mitigating climate change impacts. Additionally, the lightweight nature of graphene batteries could lead to more energy-efficient transportation and portable devices, further reducing overall energy consumption.

However, it is crucial to consider the potential environmental challenges associated with large-scale graphene production. The extraction and processing of graphite, the primary raw material for graphene, may have localized environmental impacts, including land disturbance and water usage. Efforts to develop sustainable graphene production methods, such as using renewable energy sources and implementing closed-loop manufacturing processes, are essential to minimize these impacts.

The end-of-life management of graphene batteries also requires careful consideration. While graphene itself is non-toxic and potentially recyclable, the development of efficient recycling processes for graphene-based batteries is still in its early stages. Establishing robust recycling infrastructure and protocols will be crucial to ensure the responsible disposal and recovery of valuable materials from spent graphene batteries.

Furthermore, the potential for graphene to enhance the efficiency of various environmental technologies should not be overlooked. Graphene-based materials show promise in water purification, air filtration, and even carbon capture applications. Integrating graphene battery storage with these environmental technologies could create synergistic solutions that address multiple sustainability challenges simultaneously.

As research and development in graphene battery storage progresses, it is imperative to conduct comprehensive life cycle assessments to fully understand and quantify the environmental impacts and benefits of this technology. This holistic approach will help guide the sustainable development and implementation of graphene battery storage solutions, ensuring that their potential environmental advantages are maximized while minimizing any negative impacts.

The improved energy density and faster charging capabilities of graphene batteries could contribute to the wider adoption of electric vehicles and renewable energy systems. This shift would help reduce greenhouse gas emissions and dependence on fossil fuels, thereby mitigating climate change impacts. Additionally, the lightweight nature of graphene batteries could lead to more energy-efficient transportation and portable devices, further reducing overall energy consumption.

However, it is crucial to consider the potential environmental challenges associated with large-scale graphene production. The extraction and processing of graphite, the primary raw material for graphene, may have localized environmental impacts, including land disturbance and water usage. Efforts to develop sustainable graphene production methods, such as using renewable energy sources and implementing closed-loop manufacturing processes, are essential to minimize these impacts.

The end-of-life management of graphene batteries also requires careful consideration. While graphene itself is non-toxic and potentially recyclable, the development of efficient recycling processes for graphene-based batteries is still in its early stages. Establishing robust recycling infrastructure and protocols will be crucial to ensure the responsible disposal and recovery of valuable materials from spent graphene batteries.

Furthermore, the potential for graphene to enhance the efficiency of various environmental technologies should not be overlooked. Graphene-based materials show promise in water purification, air filtration, and even carbon capture applications. Integrating graphene battery storage with these environmental technologies could create synergistic solutions that address multiple sustainability challenges simultaneously.

As research and development in graphene battery storage progresses, it is imperative to conduct comprehensive life cycle assessments to fully understand and quantify the environmental impacts and benefits of this technology. This holistic approach will help guide the sustainable development and implementation of graphene battery storage solutions, ensuring that their potential environmental advantages are maximized while minimizing any negative impacts.

Scalability and Production

The scalability and production of graphene-based battery storage systems present both significant challenges and opportunities for the industry. As the demand for high-performance energy storage solutions continues to grow, the ability to manufacture graphene batteries at scale becomes crucial for their widespread adoption.

Currently, the production of graphene for battery applications faces several hurdles. The primary challenge lies in developing cost-effective methods for large-scale graphene synthesis while maintaining consistent quality and purity. Traditional methods like mechanical exfoliation are not suitable for industrial-scale production, leading researchers to focus on chemical vapor deposition (CVD) and liquid-phase exfoliation techniques.

CVD has shown promise for producing high-quality graphene sheets, but scaling up this process for battery production remains complex. Liquid-phase exfoliation, on the other hand, offers better scalability but often results in lower-quality graphene with more defects. Striking a balance between quality and quantity is essential for the successful commercialization of graphene batteries.

Another critical aspect of scalability is the integration of graphene into existing battery manufacturing processes. This requires the development of new production techniques and equipment capable of handling graphene's unique properties. Researchers are exploring methods such as roll-to-roll processing and 3D printing to facilitate large-scale production of graphene-enhanced battery components.

The supply chain for graphene production also plays a crucial role in scalability. Ensuring a stable and cost-effective supply of high-quality graphene is vital for sustained production. This has led to increased efforts in developing standardized graphene products and establishing reliable supplier networks.

As production scales up, addressing environmental concerns becomes increasingly important. Developing eco-friendly synthesis methods and implementing efficient recycling processes for graphene batteries will be crucial for long-term sustainability.

Despite these challenges, recent advancements in graphene production technologies are promising. Innovations in plasma-enhanced CVD and electrochemical exfoliation are showing potential for large-scale, high-quality graphene synthesis. Additionally, the emergence of graphene-based composite materials is opening new avenues for easier integration into existing battery manufacturing processes.

To achieve commercial viability, continued investment in research and development is essential. Collaboration between academic institutions, industry leaders, and government bodies will be crucial in overcoming the remaining obstacles to large-scale production of graphene batteries. As these challenges are addressed, the potential for graphene to revolutionize energy storage becomes increasingly tangible, promising a future of more efficient, powerful, and sustainable battery technologies.

Currently, the production of graphene for battery applications faces several hurdles. The primary challenge lies in developing cost-effective methods for large-scale graphene synthesis while maintaining consistent quality and purity. Traditional methods like mechanical exfoliation are not suitable for industrial-scale production, leading researchers to focus on chemical vapor deposition (CVD) and liquid-phase exfoliation techniques.

CVD has shown promise for producing high-quality graphene sheets, but scaling up this process for battery production remains complex. Liquid-phase exfoliation, on the other hand, offers better scalability but often results in lower-quality graphene with more defects. Striking a balance between quality and quantity is essential for the successful commercialization of graphene batteries.

Another critical aspect of scalability is the integration of graphene into existing battery manufacturing processes. This requires the development of new production techniques and equipment capable of handling graphene's unique properties. Researchers are exploring methods such as roll-to-roll processing and 3D printing to facilitate large-scale production of graphene-enhanced battery components.

The supply chain for graphene production also plays a crucial role in scalability. Ensuring a stable and cost-effective supply of high-quality graphene is vital for sustained production. This has led to increased efforts in developing standardized graphene products and establishing reliable supplier networks.

As production scales up, addressing environmental concerns becomes increasingly important. Developing eco-friendly synthesis methods and implementing efficient recycling processes for graphene batteries will be crucial for long-term sustainability.

Despite these challenges, recent advancements in graphene production technologies are promising. Innovations in plasma-enhanced CVD and electrochemical exfoliation are showing potential for large-scale, high-quality graphene synthesis. Additionally, the emergence of graphene-based composite materials is opening new avenues for easier integration into existing battery manufacturing processes.

To achieve commercial viability, continued investment in research and development is essential. Collaboration between academic institutions, industry leaders, and government bodies will be crucial in overcoming the remaining obstacles to large-scale production of graphene batteries. As these challenges are addressed, the potential for graphene to revolutionize energy storage becomes increasingly tangible, promising a future of more efficient, powerful, and sustainable battery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!