Graphene Battery for Compact High-Energy Applications

AUG 6, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries have emerged as a promising technology in the field of energy storage, offering potential solutions for compact high-energy applications. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its unique properties and potential applications. Since then, significant progress has been made in harnessing graphene's exceptional electrical conductivity, mechanical strength, and high surface area for battery development.

The initial stages of graphene battery research focused on incorporating graphene into existing lithium-ion battery architectures. Scientists explored the use of graphene as an additive to enhance the performance of traditional electrode materials. This approach led to improvements in battery capacity, charging speed, and cycle life. However, the full potential of graphene in battery technology remained largely untapped.

As research progressed, the focus shifted towards developing graphene-based electrodes and electrolytes. Scientists began experimenting with graphene foams, graphene oxide, and reduced graphene oxide to create more efficient and durable battery components. These efforts resulted in the development of prototype graphene batteries with significantly higher energy densities and faster charging capabilities compared to conventional lithium-ion batteries.

The current state of graphene battery technology represents a convergence of various research streams, including materials science, nanotechnology, and electrochemistry. Recent breakthroughs have demonstrated the feasibility of creating all-graphene batteries, where both electrodes and the electrolyte are graphene-based. These advancements have opened up new possibilities for compact high-energy applications, particularly in sectors such as portable electronics, electric vehicles, and aerospace.

Looking ahead, the objectives for graphene battery research are multifaceted. One primary goal is to further increase energy density, aiming to surpass the theoretical limits of lithium-ion batteries. This involves optimizing the structure and composition of graphene-based electrodes to maximize their charge storage capacity. Another crucial objective is to enhance the power density of graphene batteries, enabling ultra-fast charging and high-current discharge capabilities.

Improving the long-term stability and cycle life of graphene batteries is also a key focus area. Researchers are working on mitigating issues such as electrode degradation and electrolyte decomposition to ensure that graphene batteries can withstand thousands of charge-discharge cycles without significant performance loss. Additionally, there is a strong emphasis on developing scalable and cost-effective manufacturing processes to facilitate the commercialization of graphene battery technology.

Environmental sustainability is another important consideration in graphene battery development. Objectives in this area include reducing the environmental impact of battery production, improving recyclability, and exploring the use of eco-friendly materials in conjunction with graphene. These efforts align with the broader goal of creating more sustainable energy storage solutions for a wide range of applications.

The initial stages of graphene battery research focused on incorporating graphene into existing lithium-ion battery architectures. Scientists explored the use of graphene as an additive to enhance the performance of traditional electrode materials. This approach led to improvements in battery capacity, charging speed, and cycle life. However, the full potential of graphene in battery technology remained largely untapped.

As research progressed, the focus shifted towards developing graphene-based electrodes and electrolytes. Scientists began experimenting with graphene foams, graphene oxide, and reduced graphene oxide to create more efficient and durable battery components. These efforts resulted in the development of prototype graphene batteries with significantly higher energy densities and faster charging capabilities compared to conventional lithium-ion batteries.

The current state of graphene battery technology represents a convergence of various research streams, including materials science, nanotechnology, and electrochemistry. Recent breakthroughs have demonstrated the feasibility of creating all-graphene batteries, where both electrodes and the electrolyte are graphene-based. These advancements have opened up new possibilities for compact high-energy applications, particularly in sectors such as portable electronics, electric vehicles, and aerospace.

Looking ahead, the objectives for graphene battery research are multifaceted. One primary goal is to further increase energy density, aiming to surpass the theoretical limits of lithium-ion batteries. This involves optimizing the structure and composition of graphene-based electrodes to maximize their charge storage capacity. Another crucial objective is to enhance the power density of graphene batteries, enabling ultra-fast charging and high-current discharge capabilities.

Improving the long-term stability and cycle life of graphene batteries is also a key focus area. Researchers are working on mitigating issues such as electrode degradation and electrolyte decomposition to ensure that graphene batteries can withstand thousands of charge-discharge cycles without significant performance loss. Additionally, there is a strong emphasis on developing scalable and cost-effective manufacturing processes to facilitate the commercialization of graphene battery technology.

Environmental sustainability is another important consideration in graphene battery development. Objectives in this area include reducing the environmental impact of battery production, improving recyclability, and exploring the use of eco-friendly materials in conjunction with graphene. These efforts align with the broader goal of creating more sustainable energy storage solutions for a wide range of applications.

Market Analysis for Compact High-Energy Storage

The market for compact high-energy storage solutions is experiencing rapid growth, driven by the increasing demand for portable electronic devices, electric vehicles, and renewable energy systems. Graphene batteries, with their potential for high energy density and fast charging capabilities, are poised to play a significant role in this expanding market.

The global energy storage market is projected to reach substantial growth in the coming years, with a particular focus on compact and high-performance solutions. This growth is fueled by several factors, including the proliferation of smartphones, tablets, and wearable devices, which require longer battery life in smaller form factors. Additionally, the automotive industry's shift towards electric vehicles is creating a massive demand for advanced battery technologies that can provide extended range and faster charging times.

In the consumer electronics sector, graphene batteries could revolutionize portable device performance. Manufacturers are constantly seeking ways to increase battery life while reducing device thickness and weight. Graphene's excellent conductivity and mechanical properties make it an attractive option for next-generation batteries in smartphones, laptops, and other personal electronics.

The electric vehicle market presents another significant opportunity for graphene battery technology. As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, the demand for electric vehicles is surging. Graphene batteries could potentially address key challenges in this sector, such as range anxiety and charging time, by offering higher energy density and faster charging capabilities compared to traditional lithium-ion batteries.

Renewable energy storage is another area where graphene batteries could make a substantial impact. As the world transitions towards cleaner energy sources, the need for efficient and compact energy storage solutions becomes crucial. Graphene batteries could provide the necessary performance improvements to make grid-scale energy storage more viable, supporting the integration of intermittent renewable energy sources like solar and wind power.

The aerospace and defense industries are also showing interest in compact high-energy storage solutions. Graphene batteries could potentially enhance the performance of unmanned aerial vehicles (UAVs), satellites, and other aerospace applications where weight and energy density are critical factors.

However, it's important to note that the market for graphene batteries is still in its early stages. While the potential benefits are significant, challenges such as scalability, cost, and integration with existing manufacturing processes need to be addressed before widespread adoption can occur. As research and development efforts continue, the market for graphene-based compact high-energy storage solutions is expected to evolve rapidly, potentially disrupting traditional battery technologies and opening up new applications across various industries.

The global energy storage market is projected to reach substantial growth in the coming years, with a particular focus on compact and high-performance solutions. This growth is fueled by several factors, including the proliferation of smartphones, tablets, and wearable devices, which require longer battery life in smaller form factors. Additionally, the automotive industry's shift towards electric vehicles is creating a massive demand for advanced battery technologies that can provide extended range and faster charging times.

In the consumer electronics sector, graphene batteries could revolutionize portable device performance. Manufacturers are constantly seeking ways to increase battery life while reducing device thickness and weight. Graphene's excellent conductivity and mechanical properties make it an attractive option for next-generation batteries in smartphones, laptops, and other personal electronics.

The electric vehicle market presents another significant opportunity for graphene battery technology. As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, the demand for electric vehicles is surging. Graphene batteries could potentially address key challenges in this sector, such as range anxiety and charging time, by offering higher energy density and faster charging capabilities compared to traditional lithium-ion batteries.

Renewable energy storage is another area where graphene batteries could make a substantial impact. As the world transitions towards cleaner energy sources, the need for efficient and compact energy storage solutions becomes crucial. Graphene batteries could provide the necessary performance improvements to make grid-scale energy storage more viable, supporting the integration of intermittent renewable energy sources like solar and wind power.

The aerospace and defense industries are also showing interest in compact high-energy storage solutions. Graphene batteries could potentially enhance the performance of unmanned aerial vehicles (UAVs), satellites, and other aerospace applications where weight and energy density are critical factors.

However, it's important to note that the market for graphene batteries is still in its early stages. While the potential benefits are significant, challenges such as scalability, cost, and integration with existing manufacturing processes need to be addressed before widespread adoption can occur. As research and development efforts continue, the market for graphene-based compact high-energy storage solutions is expected to evolve rapidly, potentially disrupting traditional battery technologies and opening up new applications across various industries.

Graphene Battery Technology: Current Status and Challenges

Graphene battery technology has emerged as a promising solution for compact high-energy applications, offering potential advantages over traditional lithium-ion batteries. However, the current status of graphene battery development is characterized by both significant progress and persistent challenges.

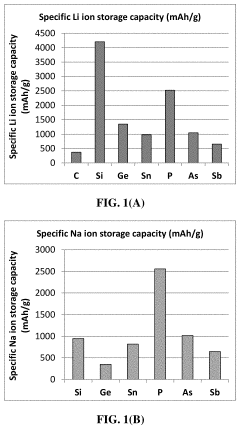

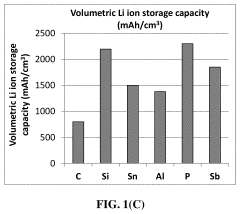

One of the primary advancements in graphene battery technology is the improvement in energy density. Researchers have demonstrated that graphene-based electrodes can potentially store up to 10 times more energy than conventional lithium-ion batteries. This increased capacity is attributed to graphene's unique properties, including its high surface area and excellent electrical conductivity. Additionally, graphene batteries have shown faster charging capabilities, with some prototypes achieving full charge in a matter of minutes rather than hours.

Despite these promising developments, several technical hurdles remain. The production of high-quality, large-scale graphene sheets suitable for battery applications is still a significant challenge. Current manufacturing processes often result in defects or impurities that can negatively impact battery performance. Moreover, the long-term stability of graphene electrodes in battery environments is a concern, as repeated charge-discharge cycles can lead to structural degradation.

Another critical challenge is the integration of graphene into existing battery architectures. While graphene shows excellent potential as an electrode material, optimizing its interaction with electrolytes and other battery components is crucial for achieving practical, high-performance devices. Researchers are exploring various approaches, including graphene composites and hybrid materials, to address these integration issues.

The scalability of graphene battery production also presents a significant hurdle. Current laboratory-scale successes need to be translated into commercially viable manufacturing processes. This transition requires overcoming issues related to cost-effectiveness, reproducibility, and quality control in large-scale production.

Safety concerns, particularly regarding the potential for thermal runaway and short circuits, are also being actively addressed. While graphene's high thermal conductivity may offer advantages in heat dissipation, ensuring the overall safety and reliability of graphene batteries under various operating conditions remains a priority for researchers and manufacturers.

In conclusion, while graphene battery technology shows immense promise for compact high-energy applications, it currently exists in a state of dynamic development. The field is characterized by exciting breakthroughs in energy density and charging speed, balanced against persistent challenges in production, integration, scalability, and safety. Ongoing research and development efforts are focused on addressing these challenges to realize the full potential of graphene batteries in practical applications.

One of the primary advancements in graphene battery technology is the improvement in energy density. Researchers have demonstrated that graphene-based electrodes can potentially store up to 10 times more energy than conventional lithium-ion batteries. This increased capacity is attributed to graphene's unique properties, including its high surface area and excellent electrical conductivity. Additionally, graphene batteries have shown faster charging capabilities, with some prototypes achieving full charge in a matter of minutes rather than hours.

Despite these promising developments, several technical hurdles remain. The production of high-quality, large-scale graphene sheets suitable for battery applications is still a significant challenge. Current manufacturing processes often result in defects or impurities that can negatively impact battery performance. Moreover, the long-term stability of graphene electrodes in battery environments is a concern, as repeated charge-discharge cycles can lead to structural degradation.

Another critical challenge is the integration of graphene into existing battery architectures. While graphene shows excellent potential as an electrode material, optimizing its interaction with electrolytes and other battery components is crucial for achieving practical, high-performance devices. Researchers are exploring various approaches, including graphene composites and hybrid materials, to address these integration issues.

The scalability of graphene battery production also presents a significant hurdle. Current laboratory-scale successes need to be translated into commercially viable manufacturing processes. This transition requires overcoming issues related to cost-effectiveness, reproducibility, and quality control in large-scale production.

Safety concerns, particularly regarding the potential for thermal runaway and short circuits, are also being actively addressed. While graphene's high thermal conductivity may offer advantages in heat dissipation, ensuring the overall safety and reliability of graphene batteries under various operating conditions remains a priority for researchers and manufacturers.

In conclusion, while graphene battery technology shows immense promise for compact high-energy applications, it currently exists in a state of dynamic development. The field is characterized by exciting breakthroughs in energy density and charging speed, balanced against persistent challenges in production, integration, scalability, and safety. Ongoing research and development efforts are focused on addressing these challenges to realize the full potential of graphene batteries in practical applications.

Existing Graphene Battery Solutions

01 Graphene-based electrode materials

Graphene-based materials are used as electrode components in batteries to enhance energy density. These materials offer high surface area, excellent conductivity, and improved charge storage capacity, leading to batteries with higher energy density compared to traditional electrode materials.- Graphene-based electrode materials: Graphene-based materials are used as electrode components in batteries to enhance energy density. These materials offer high surface area, excellent conductivity, and improved charge storage capacity, leading to batteries with higher energy density compared to traditional electrode materials.

- Graphene-enhanced electrolytes: Incorporating graphene or graphene oxide into battery electrolytes can improve ionic conductivity and stability. This enhancement leads to better overall battery performance, including increased energy density and longer cycle life.

- Graphene-based composite materials: Combining graphene with other materials such as metal oxides or polymers creates composite electrode materials. These composites can synergistically improve energy storage capacity, conductivity, and structural stability, resulting in batteries with higher energy density.

- Graphene-enabled 3D electrode structures: Three-dimensional electrode structures incorporating graphene can significantly increase the effective surface area for charge storage. This approach allows for higher energy density while maintaining good power density and mechanical stability.

- Graphene as a conductive additive: Using graphene as a conductive additive in battery electrodes can enhance electron transport and reduce internal resistance. This improvement leads to better overall battery performance, including increased energy density and improved rate capability.

02 Graphene-enhanced electrolytes

Incorporating graphene or graphene oxide into battery electrolytes can improve ionic conductivity and enhance overall battery performance. This approach can lead to increased energy density by facilitating more efficient charge transfer and reducing internal resistance.Expand Specific Solutions03 Graphene-based composite materials

Combining graphene with other materials such as metal oxides or polymers creates composite electrode materials with synergistic properties. These composites can offer improved energy storage capacity, cycling stability, and overall energy density compared to individual components.Expand Specific Solutions04 Graphene-enhanced current collectors

Using graphene-coated or graphene-integrated current collectors can improve the overall conductivity and reduce the internal resistance of batteries. This enhancement leads to more efficient charge collection and distribution, contributing to increased energy density.Expand Specific Solutions05 Graphene-based solid-state batteries

Incorporating graphene into solid-state battery designs can address challenges related to interfacial resistance and ion transport. This approach can lead to the development of high-energy-density solid-state batteries with improved safety and performance characteristics.Expand Specific Solutions

Key Players in Graphene Battery Industry

The research on graphene batteries for compact high-energy applications is in an early development stage, with significant potential for growth. The market size is expanding rapidly, driven by increasing demand for high-performance energy storage solutions in various sectors. Technologically, graphene batteries are still evolving, with companies like Nanotek Instruments, Honeycomb Battery Co., and Resonac Corp. leading the way in innovation. Academic institutions such as Northwestern University and Zhejiang University are contributing to fundamental research, while national laboratories like Lawrence Livermore National Security LLC are exploring advanced applications. The competitive landscape is diverse, with both established corporations and startups vying for breakthroughs in this promising field.

Northwestern University

Technical Solution: Northwestern University has developed a novel graphene-based battery technology that significantly enhances energy density and charging speed. Their approach involves creating a three-dimensional graphene foam structure as an electrode material, which provides a large surface area for energy storage and facilitates rapid ion transport. This 3D graphene foam is produced through a chemical vapor deposition process, resulting in a highly conductive and mechanically robust structure[1]. The university's research team has also incorporated silicon nanoparticles into the graphene foam to further increase the battery's capacity. This hybrid graphene-silicon anode has demonstrated a capacity of over 1,000 mAh/g, which is nearly three times higher than conventional graphite anodes[2]. Additionally, the team has developed a unique electrolyte formulation that enhances the stability of the graphene-based electrodes, leading to improved cycle life and safety performance[3].

Strengths: High energy density, fast charging capabilities, and improved cycle life. The 3D graphene foam structure provides excellent conductivity and mechanical stability. Weaknesses: Potential high production costs and scalability challenges for mass production.

Nanotek Instruments, Inc.

Technical Solution: Nanotek Instruments has developed a proprietary graphene-based battery technology focusing on high-energy density and rapid charging for compact applications. Their approach utilizes a unique graphene synthesis method that produces high-quality, defect-free graphene sheets with controlled thickness and lateral size[4]. These graphene sheets are then functionalized with specific chemical groups to enhance their electrochemical properties. The company has also developed a novel electrode fabrication process that ensures uniform distribution of graphene in the electrode matrix, resulting in improved conductivity and charge storage capacity. Nanotek's graphene-based anodes have demonstrated a specific capacity of up to 1,500 mAh/g, significantly higher than conventional graphite anodes[5]. Furthermore, their batteries exhibit excellent rate capability, allowing for fast charging without compromising cycle life or safety.

Strengths: High energy density, fast charging capabilities, and scalable production process. Weaknesses: Potential high material costs and need for specialized manufacturing equipment.

Breakthrough Graphene Battery Technologies

Conducting polymer network-protected phosphorus anode active material for lithium-ion or sodium-ion batteries

PatentActiveUS20210351409A1

Innovation

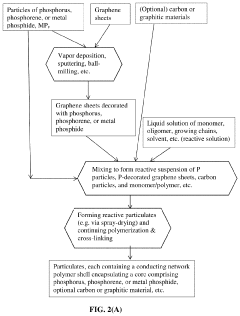

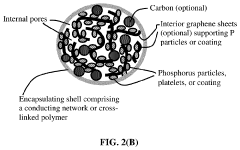

- A conducting polymer network-encapsulated phosphorus-based anode particulate is developed, where a core of phosphorus material is encapsulated within a cross-linked polymer shell, enhancing electronic and ion conductivity, and accommodating volume expansion, thereby reducing direct contact with the electrolyte and minimizing SEI destruction.

Environmental Impact of Graphene Batteries

The environmental impact of graphene batteries is a crucial consideration as this technology advances towards widespread adoption. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers promising characteristics for energy storage applications. However, its production and use in batteries raise important environmental concerns that must be addressed.

The manufacturing process of graphene can be energy-intensive, potentially contributing to increased carbon emissions if not managed sustainably. Traditional methods of graphene production, such as chemical vapor deposition, often require high temperatures and harsh chemicals. These processes can lead to the release of greenhouse gases and toxic byproducts, necessitating careful waste management and emission control strategies.

Water usage is another significant environmental factor in graphene production. Some manufacturing techniques require substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Additionally, the potential release of graphene nanoparticles into water systems during production or disposal poses risks to aquatic ecosystems, as the long-term effects of these materials on marine life are not yet fully understood.

On the positive side, graphene batteries have the potential to significantly reduce the environmental footprint of energy storage systems. Their higher energy density and longer lifespan compared to traditional lithium-ion batteries mean fewer batteries are needed over time, potentially reducing overall resource consumption and waste generation. The improved efficiency of graphene batteries could also lead to reduced energy losses during charging and discharging, contributing to overall energy conservation.

The recyclability of graphene batteries is an area of ongoing research and development. While graphene itself is theoretically recyclable, the complex composition of battery systems presents challenges. Developing efficient recycling processes for graphene batteries is crucial to minimize waste and recover valuable materials, thereby reducing the need for new raw material extraction.

As graphene battery technology matures, life cycle assessments will be essential to fully understand and quantify their environmental impact. These assessments should consider the entire lifecycle of the batteries, from raw material extraction to manufacturing, use, and end-of-life disposal or recycling. Such comprehensive analyses will help identify areas for improvement and guide the development of more sustainable production methods and recycling technologies.

In conclusion, while graphene batteries offer promising environmental benefits in terms of energy efficiency and potential longevity, their production and end-of-life management present significant environmental challenges. Addressing these challenges through sustainable manufacturing practices, efficient recycling methods, and comprehensive lifecycle management will be crucial for realizing the full potential of graphene batteries as an environmentally friendly energy storage solution.

The manufacturing process of graphene can be energy-intensive, potentially contributing to increased carbon emissions if not managed sustainably. Traditional methods of graphene production, such as chemical vapor deposition, often require high temperatures and harsh chemicals. These processes can lead to the release of greenhouse gases and toxic byproducts, necessitating careful waste management and emission control strategies.

Water usage is another significant environmental factor in graphene production. Some manufacturing techniques require substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Additionally, the potential release of graphene nanoparticles into water systems during production or disposal poses risks to aquatic ecosystems, as the long-term effects of these materials on marine life are not yet fully understood.

On the positive side, graphene batteries have the potential to significantly reduce the environmental footprint of energy storage systems. Their higher energy density and longer lifespan compared to traditional lithium-ion batteries mean fewer batteries are needed over time, potentially reducing overall resource consumption and waste generation. The improved efficiency of graphene batteries could also lead to reduced energy losses during charging and discharging, contributing to overall energy conservation.

The recyclability of graphene batteries is an area of ongoing research and development. While graphene itself is theoretically recyclable, the complex composition of battery systems presents challenges. Developing efficient recycling processes for graphene batteries is crucial to minimize waste and recover valuable materials, thereby reducing the need for new raw material extraction.

As graphene battery technology matures, life cycle assessments will be essential to fully understand and quantify their environmental impact. These assessments should consider the entire lifecycle of the batteries, from raw material extraction to manufacturing, use, and end-of-life disposal or recycling. Such comprehensive analyses will help identify areas for improvement and guide the development of more sustainable production methods and recycling technologies.

In conclusion, while graphene batteries offer promising environmental benefits in terms of energy efficiency and potential longevity, their production and end-of-life management present significant environmental challenges. Addressing these challenges through sustainable manufacturing practices, efficient recycling methods, and comprehensive lifecycle management will be crucial for realizing the full potential of graphene batteries as an environmentally friendly energy storage solution.

Graphene Battery Manufacturing Processes

The manufacturing processes for graphene batteries involve several key steps, each crucial for achieving high-performance and compact energy storage solutions. The process typically begins with the production of high-quality graphene, which can be accomplished through various methods such as chemical vapor deposition (CVD), liquid-phase exfoliation, or electrochemical exfoliation. The choice of method depends on the desired properties and scale of production.

Once the graphene is produced, it undergoes functionalization to enhance its electrochemical properties. This may involve chemical treatments to introduce specific functional groups or doping with other elements to improve conductivity and energy storage capacity. The functionalized graphene is then incorporated into the battery structure, often as a component of the anode or cathode.

The next stage involves the assembly of the battery components. This includes the preparation of electrodes, where graphene-based materials are combined with other active materials and binders to form a composite. The electrodes are then coated onto current collectors, typically made of copper or aluminum foils. The cathode and anode are separated by a porous membrane soaked in electrolyte, which facilitates ion movement during charge and discharge cycles.

Advanced manufacturing techniques are employed to ensure precise control over the battery's internal structure. These may include roll-to-roll processing for continuous production, laser patterning for creating intricate electrode designs, or 3D printing for customized battery geometries. Such techniques allow for the optimization of the battery's internal architecture, maximizing energy density and power output.

Quality control is a critical aspect of the manufacturing process. This involves rigorous testing of individual components and assembled batteries to ensure consistency, safety, and performance. Advanced characterization techniques such as scanning electron microscopy (SEM) and X-ray diffraction (XRD) are used to analyze the graphene-based materials and battery structures at the nanoscale.

The final stages of production include packaging and sealing of the battery cells. For compact high-energy applications, special attention is given to minimizing the overall size and weight of the battery while maintaining structural integrity and safety features. This may involve the use of advanced packaging materials and designs that can withstand high energy densities and potential thermal management challenges.

Throughout the manufacturing process, strict environmental controls are maintained to prevent contamination and ensure the purity of materials. Many steps are conducted in cleanroom environments to minimize the introduction of impurities that could degrade battery performance. Additionally, sustainable manufacturing practices are increasingly being adopted, focusing on reducing waste, recycling materials, and minimizing the environmental impact of production.

Once the graphene is produced, it undergoes functionalization to enhance its electrochemical properties. This may involve chemical treatments to introduce specific functional groups or doping with other elements to improve conductivity and energy storage capacity. The functionalized graphene is then incorporated into the battery structure, often as a component of the anode or cathode.

The next stage involves the assembly of the battery components. This includes the preparation of electrodes, where graphene-based materials are combined with other active materials and binders to form a composite. The electrodes are then coated onto current collectors, typically made of copper or aluminum foils. The cathode and anode are separated by a porous membrane soaked in electrolyte, which facilitates ion movement during charge and discharge cycles.

Advanced manufacturing techniques are employed to ensure precise control over the battery's internal structure. These may include roll-to-roll processing for continuous production, laser patterning for creating intricate electrode designs, or 3D printing for customized battery geometries. Such techniques allow for the optimization of the battery's internal architecture, maximizing energy density and power output.

Quality control is a critical aspect of the manufacturing process. This involves rigorous testing of individual components and assembled batteries to ensure consistency, safety, and performance. Advanced characterization techniques such as scanning electron microscopy (SEM) and X-ray diffraction (XRD) are used to analyze the graphene-based materials and battery structures at the nanoscale.

The final stages of production include packaging and sealing of the battery cells. For compact high-energy applications, special attention is given to minimizing the overall size and weight of the battery while maintaining structural integrity and safety features. This may involve the use of advanced packaging materials and designs that can withstand high energy densities and potential thermal management challenges.

Throughout the manufacturing process, strict environmental controls are maintained to prevent contamination and ensure the purity of materials. Many steps are conducted in cleanroom environments to minimize the introduction of impurities that could degrade battery performance. Additionally, sustainable manufacturing practices are increasingly being adopted, focusing on reducing waste, recycling materials, and minimizing the environmental impact of production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!