Graphene Battery for High-Performance Consumer Electronics

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries represent a significant leap forward in energy storage technology, particularly for high-performance consumer electronics. The evolution of this technology can be traced back to the discovery of graphene in 2004, which sparked intense research into its potential applications. Initially, the focus was on understanding the unique properties of graphene, such as its exceptional electrical conductivity, mechanical strength, and high surface area.

As research progressed, scientists began exploring graphene's potential in battery technology. The primary objective was to overcome the limitations of traditional lithium-ion batteries, including slow charging times, limited energy density, and degradation over time. Graphene's ability to enhance electron mobility and facilitate faster ion transport made it an ideal candidate for improving battery performance.

The development of graphene batteries has been marked by several key milestones. Early experiments focused on incorporating graphene into existing battery components, such as electrodes and electrolytes. This approach led to incremental improvements in battery performance, but the full potential of graphene remained untapped.

A significant breakthrough came with the development of graphene-based composite materials, which allowed for more efficient energy storage and faster charge/discharge cycles. These composites combined graphene with other materials to create synergistic effects, enhancing overall battery performance.

The current objectives in graphene battery research for consumer electronics are multifaceted. Firstly, there is a push to increase energy density, allowing devices to store more power in a smaller form factor. This is crucial for the development of thinner, lighter, and more powerful electronic devices.

Secondly, researchers are focusing on improving charging speeds. The goal is to develop batteries that can be fully charged in minutes rather than hours, addressing one of the most significant pain points for consumers. This rapid charging capability could revolutionize the way we use and interact with our electronic devices.

Another key objective is to enhance the longevity and stability of graphene batteries. By improving the cycle life and reducing capacity fade, researchers aim to create batteries that maintain their performance over thousands of charge cycles, significantly extending the lifespan of consumer electronics.

Additionally, there is a growing emphasis on developing environmentally friendly and sustainable battery technologies. Graphene batteries have the potential to reduce the environmental impact of battery production and disposal, aligning with global efforts to create more sustainable technologies.

As research continues, the ultimate goal is to create a new generation of batteries that not only outperform current lithium-ion technology but also enable new functionalities in consumer electronics. This includes the possibility of flexible and wearable devices, as well as integration with emerging technologies such as augmented reality and artificial intelligence.

As research progressed, scientists began exploring graphene's potential in battery technology. The primary objective was to overcome the limitations of traditional lithium-ion batteries, including slow charging times, limited energy density, and degradation over time. Graphene's ability to enhance electron mobility and facilitate faster ion transport made it an ideal candidate for improving battery performance.

The development of graphene batteries has been marked by several key milestones. Early experiments focused on incorporating graphene into existing battery components, such as electrodes and electrolytes. This approach led to incremental improvements in battery performance, but the full potential of graphene remained untapped.

A significant breakthrough came with the development of graphene-based composite materials, which allowed for more efficient energy storage and faster charge/discharge cycles. These composites combined graphene with other materials to create synergistic effects, enhancing overall battery performance.

The current objectives in graphene battery research for consumer electronics are multifaceted. Firstly, there is a push to increase energy density, allowing devices to store more power in a smaller form factor. This is crucial for the development of thinner, lighter, and more powerful electronic devices.

Secondly, researchers are focusing on improving charging speeds. The goal is to develop batteries that can be fully charged in minutes rather than hours, addressing one of the most significant pain points for consumers. This rapid charging capability could revolutionize the way we use and interact with our electronic devices.

Another key objective is to enhance the longevity and stability of graphene batteries. By improving the cycle life and reducing capacity fade, researchers aim to create batteries that maintain their performance over thousands of charge cycles, significantly extending the lifespan of consumer electronics.

Additionally, there is a growing emphasis on developing environmentally friendly and sustainable battery technologies. Graphene batteries have the potential to reduce the environmental impact of battery production and disposal, aligning with global efforts to create more sustainable technologies.

As research continues, the ultimate goal is to create a new generation of batteries that not only outperform current lithium-ion technology but also enable new functionalities in consumer electronics. This includes the possibility of flexible and wearable devices, as well as integration with emerging technologies such as augmented reality and artificial intelligence.

Consumer Electronics Market Demand Analysis

The consumer electronics market has witnessed a significant surge in demand for high-performance devices, particularly those powered by advanced battery technologies. This trend is driven by the increasing reliance on portable devices and the growing expectations for longer battery life, faster charging times, and improved overall performance. Graphene batteries have emerged as a promising solution to meet these evolving consumer needs.

In the smartphone segment, which represents a substantial portion of the consumer electronics market, users are seeking devices that can last throughout the day without requiring frequent recharging. This demand has led manufacturers to explore innovative battery technologies, with graphene-based solutions gaining traction due to their potential for higher energy density and faster charging capabilities.

The wearable technology sector, including smartwatches and fitness trackers, has also experienced rapid growth. These devices require compact yet powerful batteries that can support a wide range of features while maintaining a slim profile. Graphene batteries offer the potential to address these requirements, potentially revolutionizing the wearables market.

In the laptop and tablet market, consumers are increasingly demanding devices that offer extended battery life without compromising on performance or portability. The lightweight and high-capacity characteristics of graphene batteries align well with these consumer expectations, potentially enabling the development of thinner, lighter, and more powerful portable computing devices.

The electric vehicle (EV) market, while not traditionally considered part of consumer electronics, is closely related and has a significant influence on battery technology development. The demand for longer-range EVs and faster charging times has spurred research into advanced battery technologies, including graphene-based solutions. Advancements in this sector often trickle down to smaller consumer electronics, driving innovation across the industry.

Market research indicates that consumers are willing to pay a premium for devices with superior battery performance. This willingness to invest in advanced technology creates a favorable environment for the development and commercialization of graphene batteries in consumer electronics.

However, it is important to note that the adoption of graphene batteries in consumer electronics faces challenges. These include the need for scalable and cost-effective production methods, as well as concerns about long-term reliability and safety. Overcoming these hurdles will be crucial for widespread market acceptance and integration of graphene battery technology in consumer electronic devices.

In the smartphone segment, which represents a substantial portion of the consumer electronics market, users are seeking devices that can last throughout the day without requiring frequent recharging. This demand has led manufacturers to explore innovative battery technologies, with graphene-based solutions gaining traction due to their potential for higher energy density and faster charging capabilities.

The wearable technology sector, including smartwatches and fitness trackers, has also experienced rapid growth. These devices require compact yet powerful batteries that can support a wide range of features while maintaining a slim profile. Graphene batteries offer the potential to address these requirements, potentially revolutionizing the wearables market.

In the laptop and tablet market, consumers are increasingly demanding devices that offer extended battery life without compromising on performance or portability. The lightweight and high-capacity characteristics of graphene batteries align well with these consumer expectations, potentially enabling the development of thinner, lighter, and more powerful portable computing devices.

The electric vehicle (EV) market, while not traditionally considered part of consumer electronics, is closely related and has a significant influence on battery technology development. The demand for longer-range EVs and faster charging times has spurred research into advanced battery technologies, including graphene-based solutions. Advancements in this sector often trickle down to smaller consumer electronics, driving innovation across the industry.

Market research indicates that consumers are willing to pay a premium for devices with superior battery performance. This willingness to invest in advanced technology creates a favorable environment for the development and commercialization of graphene batteries in consumer electronics.

However, it is important to note that the adoption of graphene batteries in consumer electronics faces challenges. These include the need for scalable and cost-effective production methods, as well as concerns about long-term reliability and safety. Overcoming these hurdles will be crucial for widespread market acceptance and integration of graphene battery technology in consumer electronic devices.

Graphene Battery Technology Status and Challenges

Graphene battery technology has made significant strides in recent years, positioning itself as a promising solution for high-performance consumer electronics. However, despite its potential, several challenges remain in its widespread adoption and commercialization.

The current status of graphene battery technology is characterized by impressive theoretical capabilities and ongoing research efforts. Graphene's unique properties, including high electrical conductivity, mechanical strength, and large surface area, make it an ideal candidate for enhancing battery performance. Researchers have demonstrated that graphene-based electrodes can significantly improve energy density, charge/discharge rates, and cycle life compared to traditional lithium-ion batteries.

One of the primary challenges facing graphene battery technology is scalability. While laboratory-scale prototypes have shown promising results, translating these achievements into large-scale manufacturing processes remains difficult. The production of high-quality graphene in sufficient quantities for mass production is still a bottleneck, limiting the technology's commercial viability.

Another significant challenge is the integration of graphene into existing battery architectures. While graphene can enhance various battery components, such as electrodes and electrolytes, optimizing its incorporation without compromising other aspects of battery performance requires careful engineering and extensive testing.

Cost remains a major hurdle in the widespread adoption of graphene batteries. The production of high-quality graphene is currently expensive, making graphene-enhanced batteries significantly costlier than conventional alternatives. This price differential poses a significant barrier to market entry, particularly in price-sensitive consumer electronics segments.

Safety concerns also present challenges for graphene battery technology. While graphene has the potential to improve battery safety by enhancing thermal management and reducing the risk of short circuits, long-term stability and safety under various operating conditions need to be thoroughly evaluated and validated.

The environmental impact of graphene production and disposal is another area of concern. Sustainable manufacturing processes and recycling methods for graphene batteries need to be developed to ensure the technology aligns with growing environmental consciousness and regulations.

Standardization and quality control pose additional challenges. As the field rapidly evolves, establishing industry-wide standards for graphene quality, battery performance metrics, and safety protocols is crucial for fostering trust and facilitating widespread adoption.

Despite these challenges, ongoing research and development efforts are making steady progress. Collaborations between academic institutions, research laboratories, and industry partners are driving innovations in graphene synthesis, battery design, and manufacturing processes. These efforts are gradually addressing the technical and economic barriers, bringing graphene battery technology closer to commercial reality for high-performance consumer electronics.

The current status of graphene battery technology is characterized by impressive theoretical capabilities and ongoing research efforts. Graphene's unique properties, including high electrical conductivity, mechanical strength, and large surface area, make it an ideal candidate for enhancing battery performance. Researchers have demonstrated that graphene-based electrodes can significantly improve energy density, charge/discharge rates, and cycle life compared to traditional lithium-ion batteries.

One of the primary challenges facing graphene battery technology is scalability. While laboratory-scale prototypes have shown promising results, translating these achievements into large-scale manufacturing processes remains difficult. The production of high-quality graphene in sufficient quantities for mass production is still a bottleneck, limiting the technology's commercial viability.

Another significant challenge is the integration of graphene into existing battery architectures. While graphene can enhance various battery components, such as electrodes and electrolytes, optimizing its incorporation without compromising other aspects of battery performance requires careful engineering and extensive testing.

Cost remains a major hurdle in the widespread adoption of graphene batteries. The production of high-quality graphene is currently expensive, making graphene-enhanced batteries significantly costlier than conventional alternatives. This price differential poses a significant barrier to market entry, particularly in price-sensitive consumer electronics segments.

Safety concerns also present challenges for graphene battery technology. While graphene has the potential to improve battery safety by enhancing thermal management and reducing the risk of short circuits, long-term stability and safety under various operating conditions need to be thoroughly evaluated and validated.

The environmental impact of graphene production and disposal is another area of concern. Sustainable manufacturing processes and recycling methods for graphene batteries need to be developed to ensure the technology aligns with growing environmental consciousness and regulations.

Standardization and quality control pose additional challenges. As the field rapidly evolves, establishing industry-wide standards for graphene quality, battery performance metrics, and safety protocols is crucial for fostering trust and facilitating widespread adoption.

Despite these challenges, ongoing research and development efforts are making steady progress. Collaborations between academic institutions, research laboratories, and industry partners are driving innovations in graphene synthesis, battery design, and manufacturing processes. These efforts are gradually addressing the technical and economic barriers, bringing graphene battery technology closer to commercial reality for high-performance consumer electronics.

Current Graphene Battery Solutions

01 Graphene-based electrode materials

Graphene is used as an electrode material in batteries to enhance performance. Its high surface area and excellent electrical conductivity contribute to improved energy density and faster charge/discharge rates. Graphene can be incorporated into both anode and cathode materials, often in combination with other materials to create composite electrodes.- Graphene-based electrode materials: Graphene is used as an electrode material in batteries to enhance performance. Its high surface area and excellent electrical conductivity contribute to improved energy density and faster charge/discharge rates. Graphene can be incorporated into both anode and cathode materials, often in combination with other materials to create composite electrodes.

- Graphene-enhanced electrolytes: Graphene is utilized to improve electrolyte performance in batteries. It can be added to liquid electrolytes or used in solid-state electrolytes to enhance ionic conductivity and stability. This leads to better overall battery performance, including improved cycle life and safety characteristics.

- Graphene-based current collectors: Graphene is employed as a material for current collectors in batteries. Its high conductivity and lightweight nature make it an excellent alternative to traditional metal current collectors. This can lead to reduced battery weight and improved energy density, as well as better overall performance and durability.

- Graphene-enhanced thermal management: Graphene is used to improve thermal management in batteries. Its excellent thermal conductivity helps dissipate heat more efficiently, leading to better temperature control during charging and discharging. This can result in improved battery safety, longer lifespan, and more consistent performance under various operating conditions.

- Graphene-based flexible and wearable batteries: Graphene is utilized in the development of flexible and wearable battery technologies. Its mechanical properties, such as flexibility and strength, make it ideal for creating bendable and stretchable battery components. This enables the design of batteries that can be integrated into wearable devices or flexible electronics while maintaining high performance.

02 Graphene-enhanced electrolytes

Graphene is utilized to improve battery electrolytes. By incorporating graphene or graphene oxide into the electrolyte, ionic conductivity can be increased, leading to better overall battery performance. This modification can also enhance the stability of the electrolyte and improve the battery's cycle life.Expand Specific Solutions03 Graphene-based current collectors

Graphene is employed as a material for current collectors in batteries. Its high conductivity and lightweight nature make it an excellent alternative to traditional metal current collectors. This can lead to reduced battery weight and improved energy density, while maintaining good electrical performance.Expand Specific Solutions04 Graphene-enhanced separators

Graphene is used to improve battery separators. By incorporating graphene or graphene oxide into separator materials, thermal stability and mechanical strength can be enhanced. This modification can also help prevent dendrite formation and improve overall battery safety and performance.Expand Specific Solutions05 Graphene-based thermal management

Graphene is utilized for thermal management in batteries. Its excellent thermal conductivity allows for more efficient heat dissipation, which can prevent overheating and improve overall battery performance and safety. This can be achieved through the incorporation of graphene into various battery components or as a coating on the battery exterior.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market for high-performance consumer electronics is in an early growth stage, with significant potential for expansion. The global market size is projected to increase substantially in the coming years, driven by the growing demand for longer-lasting, faster-charging batteries in smartphones, laptops, and wearables. While the technology is still evolving, several key players are making strides in research and development. Companies like Samsung Electronics, Apple, and Vorbeck Materials are investing heavily in graphene battery technology, while academic institutions such as Northwestern University and Zhejiang University are contributing to fundamental research. The involvement of both established tech giants and specialized startups indicates a competitive landscape with diverse approaches to commercialization, suggesting that graphene batteries are progressing towards market readiness.

Northwestern University

Technical Solution: Northwestern University has made significant advancements in graphene battery technology for high-performance consumer electronics. Their research team has developed a graphene-based electrode material that enables lithium-ion batteries to hold a charge up to 10 times greater than conventional graphite anodes[17]. This breakthrough involves using a unique chemical oxidation process to create holey graphene frameworks (HGF) that allow for more efficient lithium storage[18]. The university's approach also addresses the issue of volume expansion in high-capacity battery materials by creating a flexible, porous structure that can accommodate the stress of charging cycles[19]. Additionally, Northwestern researchers have explored the use of graphene quantum dots to enhance the performance of lithium-sulfur batteries, potentially offering even higher energy densities for future consumer electronics[20].

Strengths: Significantly increased energy storage capacity, innovative material design, and potential for application in next-generation battery technologies. Weaknesses: Early-stage research that may require further development for commercial applications.

Honeycomb Battery Co.

Technical Solution: Honeycomb Battery Co. has developed a unique approach to graphene battery technology for high-performance consumer electronics. Their patented "honeycomb" structure utilizes graphene-coated nickel foam as a three-dimensional current collector, which significantly increases the surface area for energy storage[9]. This design allows for faster electron transfer and improved ion diffusion, resulting in higher power density and faster charging capabilities[10]. The company claims their batteries can achieve up to 80% charge in just 5 minutes while maintaining a longer cycle life compared to traditional lithium-ion batteries[11]. Honeycomb Battery Co. is also exploring the integration of their technology with silicon anodes to further enhance energy density and overall performance[12].

Strengths: Innovative 3D structure for improved performance, fast charging capabilities, and potential for high energy density. Weaknesses: Relatively new technology with limited real-world testing and potential scaling challenges.

Core Graphene Battery Innovations

Graphene processing technique

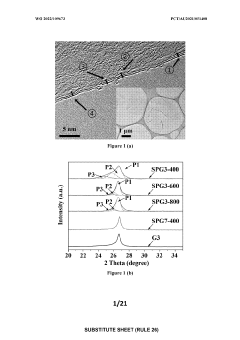

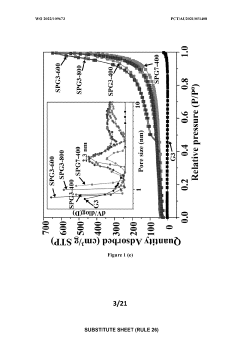

PatentWO2022109673A1

Innovation

- A surfactant-assisted thermal reductive perforation (TRP) process using poly(alkylene oxide) to create surface-perforated graphene (SPG) with in-plane mesopores and low oxygen content, expanding interlayer spacing and enhancing ion diffusion.

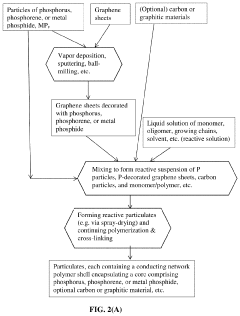

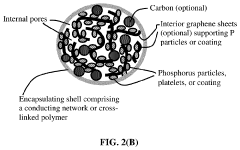

Conducting polymer network-protected phosphorus anode active material for lithium-ion or sodium-ion batteries

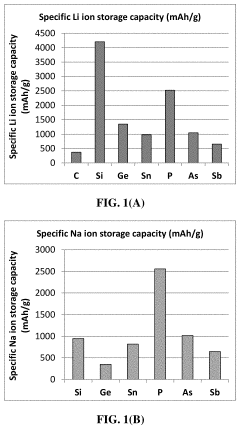

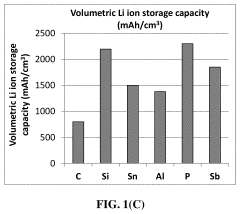

PatentActiveUS20210351409A1

Innovation

- A conducting polymer network-encapsulated phosphorus-based anode particulate is developed, where a core of phosphorus material is encapsulated within a cross-linked polymer shell, enhancing electronic and ion conductivity, and accommodating volume expansion, thereby reducing direct contact with the electrolyte and minimizing SEI destruction.

Environmental Impact of Graphene Batteries

The environmental impact of graphene batteries is a crucial consideration in their development and adoption for high-performance consumer electronics. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers significant advantages over traditional battery materials in terms of energy density, charging speed, and longevity. However, its production and use also raise important environmental concerns that must be addressed.

One of the primary environmental benefits of graphene batteries is their potential to reduce electronic waste. Due to their superior durability and longer lifespan compared to conventional lithium-ion batteries, graphene batteries could significantly decrease the frequency of battery replacements in consumer electronics. This reduction in waste generation aligns with global efforts to minimize the environmental footprint of electronic devices.

The production of graphene, however, presents some environmental challenges. Current manufacturing processes often involve energy-intensive methods or the use of potentially harmful chemicals. As research progresses, more environmentally friendly production techniques are being developed, such as the use of renewable precursors and green synthesis methods. These advancements aim to reduce the carbon footprint and overall environmental impact of graphene production.

Graphene batteries also offer the potential for improved energy efficiency in consumer electronics. Their higher energy density means that devices can operate longer on a single charge, potentially reducing overall energy consumption. Additionally, the faster charging capabilities of graphene batteries could lead to more efficient use of charging infrastructure, potentially reducing peak load demands on power grids.

The end-of-life management of graphene batteries is another important environmental consideration. While graphene itself is a form of carbon and theoretically recyclable, the complex composition of battery systems presents recycling challenges. Research is ongoing to develop effective recycling processes for graphene-based batteries, which could significantly reduce the environmental impact of their disposal.

In terms of raw material sourcing, graphene batteries may offer advantages over traditional lithium-ion batteries. Graphene can be produced from various carbon sources, potentially reducing reliance on geographically concentrated and environmentally problematic mining operations associated with some battery materials like cobalt.

As graphene battery technology advances, it is crucial to conduct comprehensive life cycle assessments to fully understand and mitigate their environmental impacts. This includes evaluating the entire production chain, from raw material extraction to manufacturing, use, and disposal. Such assessments will be vital in ensuring that the environmental benefits of graphene batteries are maximized while potential negative impacts are minimized.

One of the primary environmental benefits of graphene batteries is their potential to reduce electronic waste. Due to their superior durability and longer lifespan compared to conventional lithium-ion batteries, graphene batteries could significantly decrease the frequency of battery replacements in consumer electronics. This reduction in waste generation aligns with global efforts to minimize the environmental footprint of electronic devices.

The production of graphene, however, presents some environmental challenges. Current manufacturing processes often involve energy-intensive methods or the use of potentially harmful chemicals. As research progresses, more environmentally friendly production techniques are being developed, such as the use of renewable precursors and green synthesis methods. These advancements aim to reduce the carbon footprint and overall environmental impact of graphene production.

Graphene batteries also offer the potential for improved energy efficiency in consumer electronics. Their higher energy density means that devices can operate longer on a single charge, potentially reducing overall energy consumption. Additionally, the faster charging capabilities of graphene batteries could lead to more efficient use of charging infrastructure, potentially reducing peak load demands on power grids.

The end-of-life management of graphene batteries is another important environmental consideration. While graphene itself is a form of carbon and theoretically recyclable, the complex composition of battery systems presents recycling challenges. Research is ongoing to develop effective recycling processes for graphene-based batteries, which could significantly reduce the environmental impact of their disposal.

In terms of raw material sourcing, graphene batteries may offer advantages over traditional lithium-ion batteries. Graphene can be produced from various carbon sources, potentially reducing reliance on geographically concentrated and environmentally problematic mining operations associated with some battery materials like cobalt.

As graphene battery technology advances, it is crucial to conduct comprehensive life cycle assessments to fully understand and mitigate their environmental impacts. This includes evaluating the entire production chain, from raw material extraction to manufacturing, use, and disposal. Such assessments will be vital in ensuring that the environmental benefits of graphene batteries are maximized while potential negative impacts are minimized.

Graphene Battery Manufacturing Processes

The manufacturing processes for graphene batteries involve several key steps, each crucial for achieving high performance in consumer electronics applications. The first stage typically begins with the production of graphene itself, which can be accomplished through various methods such as chemical vapor deposition (CVD), exfoliation of graphite, or reduction of graphene oxide. Each method has its own advantages and challenges in terms of scalability, cost-effectiveness, and quality of the resulting graphene.

Once high-quality graphene is obtained, it is incorporated into the battery structure. This often involves creating a composite material by combining graphene with traditional battery materials like lithium or silicon. The integration process is critical, as it directly affects the battery's capacity, charging speed, and overall performance. Advanced techniques such as spray coating, roll-to-roll processing, or 3D printing are employed to ensure uniform distribution and optimal bonding of graphene within the battery components.

The next phase focuses on the assembly of battery cells. This includes the precise layering of anodes, cathodes, and separators, with graphene-enhanced materials strategically incorporated. The manufacturing process must maintain strict control over environmental conditions such as temperature and humidity to prevent contamination and ensure consistent quality. Advanced automation and robotics are often employed to achieve the necessary precision and repeatability in this stage.

Post-assembly, the batteries undergo rigorous testing and quality control procedures. This includes charge-discharge cycling, capacity testing, and safety evaluations to ensure that the graphene-enhanced batteries meet or exceed the performance standards of conventional batteries. The testing phase is particularly critical for consumer electronics applications, where reliability and safety are paramount.

Finally, the manufacturing process concludes with packaging and integration steps. This involves encasing the battery cells in protective materials and incorporating necessary safety features and control electronics. For consumer electronics, the packaging must be compact and lightweight while still providing adequate protection and thermal management. The integration process may also include customization steps to fit specific device requirements, ensuring seamless compatibility with various consumer electronic products.

Throughout these manufacturing stages, continuous research and development efforts are directed towards optimizing each step, with a focus on increasing production efficiency, reducing costs, and enhancing the overall performance of graphene batteries. As the technology matures, innovations in manufacturing processes are expected to play a crucial role in bringing high-performance graphene batteries to the mass consumer electronics market.

Once high-quality graphene is obtained, it is incorporated into the battery structure. This often involves creating a composite material by combining graphene with traditional battery materials like lithium or silicon. The integration process is critical, as it directly affects the battery's capacity, charging speed, and overall performance. Advanced techniques such as spray coating, roll-to-roll processing, or 3D printing are employed to ensure uniform distribution and optimal bonding of graphene within the battery components.

The next phase focuses on the assembly of battery cells. This includes the precise layering of anodes, cathodes, and separators, with graphene-enhanced materials strategically incorporated. The manufacturing process must maintain strict control over environmental conditions such as temperature and humidity to prevent contamination and ensure consistent quality. Advanced automation and robotics are often employed to achieve the necessary precision and repeatability in this stage.

Post-assembly, the batteries undergo rigorous testing and quality control procedures. This includes charge-discharge cycling, capacity testing, and safety evaluations to ensure that the graphene-enhanced batteries meet or exceed the performance standards of conventional batteries. The testing phase is particularly critical for consumer electronics applications, where reliability and safety are paramount.

Finally, the manufacturing process concludes with packaging and integration steps. This involves encasing the battery cells in protective materials and incorporating necessary safety features and control electronics. For consumer electronics, the packaging must be compact and lightweight while still providing adequate protection and thermal management. The integration process may also include customization steps to fit specific device requirements, ensuring seamless compatibility with various consumer electronic products.

Throughout these manufacturing stages, continuous research and development efforts are directed towards optimizing each step, with a focus on increasing production efficiency, reducing costs, and enhancing the overall performance of graphene batteries. As the technology matures, innovations in manufacturing processes are expected to play a crucial role in bringing high-performance graphene batteries to the mass consumer electronics market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!