How to Design High-Capacity Graphene Battery Systems?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene, a two-dimensional carbon allotrope, has emerged as a revolutionary material in the field of energy storage since its discovery in 2004. The evolution of graphene-based battery systems has been marked by significant advancements in both theoretical understanding and practical applications. Initially, researchers focused on exploring the fundamental properties of graphene, such as its exceptional electrical conductivity, high surface area, and mechanical strength.

As the potential of graphene in energy storage became apparent, scientists began to investigate its integration into battery systems. The early stages of development centered on using graphene as an additive to enhance the performance of traditional lithium-ion batteries. Researchers discovered that incorporating graphene into electrode materials could improve conductivity, stability, and overall battery capacity.

The next phase of evolution saw the development of graphene-based composite materials specifically designed for battery applications. These composites combined graphene with other active materials to create hybrid structures that leveraged the unique properties of each component. This approach led to significant improvements in energy density, charge-discharge rates, and cycle life of battery systems.

Recent years have witnessed a shift towards the creation of all-graphene battery architectures. These designs aim to fully exploit graphene's potential by utilizing it as both the anode and cathode material. The objective is to achieve unprecedented energy storage capabilities while maintaining the lightweight and flexible nature of graphene-based systems.

The current frontier in graphene battery evolution focuses on addressing key challenges such as scalable production, long-term stability, and integration with existing manufacturing processes. Researchers are exploring novel synthesis methods, surface modifications, and structural engineering techniques to optimize graphene's performance in battery applications.

The overarching objective in designing high-capacity graphene battery systems is to develop energy storage solutions that significantly outperform current technologies. This includes achieving higher energy densities, faster charging rates, longer cycle life, and improved safety profiles. Additionally, there is a strong emphasis on creating environmentally friendly and sustainable battery systems that align with global efforts to reduce carbon emissions and promote clean energy technologies.

As the field progresses, researchers are also exploring the potential of graphene in next-generation battery technologies beyond lithium-ion, such as lithium-sulfur and lithium-air batteries. The ultimate goal is to revolutionize energy storage across various sectors, including electric vehicles, portable electronics, and grid-scale energy storage, by harnessing the full potential of graphene-based battery systems.

As the potential of graphene in energy storage became apparent, scientists began to investigate its integration into battery systems. The early stages of development centered on using graphene as an additive to enhance the performance of traditional lithium-ion batteries. Researchers discovered that incorporating graphene into electrode materials could improve conductivity, stability, and overall battery capacity.

The next phase of evolution saw the development of graphene-based composite materials specifically designed for battery applications. These composites combined graphene with other active materials to create hybrid structures that leveraged the unique properties of each component. This approach led to significant improvements in energy density, charge-discharge rates, and cycle life of battery systems.

Recent years have witnessed a shift towards the creation of all-graphene battery architectures. These designs aim to fully exploit graphene's potential by utilizing it as both the anode and cathode material. The objective is to achieve unprecedented energy storage capabilities while maintaining the lightweight and flexible nature of graphene-based systems.

The current frontier in graphene battery evolution focuses on addressing key challenges such as scalable production, long-term stability, and integration with existing manufacturing processes. Researchers are exploring novel synthesis methods, surface modifications, and structural engineering techniques to optimize graphene's performance in battery applications.

The overarching objective in designing high-capacity graphene battery systems is to develop energy storage solutions that significantly outperform current technologies. This includes achieving higher energy densities, faster charging rates, longer cycle life, and improved safety profiles. Additionally, there is a strong emphasis on creating environmentally friendly and sustainable battery systems that align with global efforts to reduce carbon emissions and promote clean energy technologies.

As the field progresses, researchers are also exploring the potential of graphene in next-generation battery technologies beyond lithium-ion, such as lithium-sulfur and lithium-air batteries. The ultimate goal is to revolutionize energy storage across various sectors, including electric vehicles, portable electronics, and grid-scale energy storage, by harnessing the full potential of graphene-based battery systems.

Market Demand Analysis for High-Capacity Energy Storage

The market demand for high-capacity energy storage systems has been experiencing significant growth in recent years, driven by the increasing adoption of renewable energy sources and the need for more efficient power management solutions. The global energy storage market is projected to reach substantial value by 2030, with a compound annual growth rate exceeding 20% over the next decade.

Graphene-based battery systems have emerged as a promising technology to meet this growing demand. These advanced energy storage solutions offer several advantages over traditional lithium-ion batteries, including higher energy density, faster charging capabilities, and improved cycle life. The automotive industry, in particular, has shown keen interest in graphene battery technology, as it could potentially revolutionize electric vehicle performance and range.

The renewable energy sector is another key driver for high-capacity energy storage demand. As solar and wind power generation continues to expand, the need for efficient and large-scale energy storage solutions becomes critical to address intermittency issues and ensure grid stability. Graphene batteries could play a crucial role in this context, offering the potential for longer-duration storage and more rapid response times to fluctuations in energy supply and demand.

In the consumer electronics market, there is a growing appetite for devices with longer battery life and faster charging times. Graphene-based batteries could meet these requirements, potentially leading to a new generation of smartphones, laptops, and wearable devices with significantly improved power performance.

The industrial and commercial sectors are also showing increased interest in high-capacity energy storage solutions. Large-scale graphene battery systems could provide more efficient and cost-effective backup power for data centers, manufacturing facilities, and other critical infrastructure. Additionally, the ability to store and manage energy more effectively could lead to substantial cost savings and improved operational efficiency for businesses.

However, the market adoption of graphene battery technology faces several challenges. The high production costs associated with graphene materials and the need for further research and development to optimize performance and scalability are significant hurdles. Additionally, the established infrastructure and supply chains for traditional lithium-ion batteries present a barrier to rapid market penetration for new energy storage technologies.

Despite these challenges, the potential benefits of graphene-based high-capacity energy storage systems continue to drive investment and research in this field. As production processes improve and costs decrease, the market demand for these advanced battery systems is expected to accelerate, potentially reshaping the energy storage landscape across multiple industries.

Graphene-based battery systems have emerged as a promising technology to meet this growing demand. These advanced energy storage solutions offer several advantages over traditional lithium-ion batteries, including higher energy density, faster charging capabilities, and improved cycle life. The automotive industry, in particular, has shown keen interest in graphene battery technology, as it could potentially revolutionize electric vehicle performance and range.

The renewable energy sector is another key driver for high-capacity energy storage demand. As solar and wind power generation continues to expand, the need for efficient and large-scale energy storage solutions becomes critical to address intermittency issues and ensure grid stability. Graphene batteries could play a crucial role in this context, offering the potential for longer-duration storage and more rapid response times to fluctuations in energy supply and demand.

In the consumer electronics market, there is a growing appetite for devices with longer battery life and faster charging times. Graphene-based batteries could meet these requirements, potentially leading to a new generation of smartphones, laptops, and wearable devices with significantly improved power performance.

The industrial and commercial sectors are also showing increased interest in high-capacity energy storage solutions. Large-scale graphene battery systems could provide more efficient and cost-effective backup power for data centers, manufacturing facilities, and other critical infrastructure. Additionally, the ability to store and manage energy more effectively could lead to substantial cost savings and improved operational efficiency for businesses.

However, the market adoption of graphene battery technology faces several challenges. The high production costs associated with graphene materials and the need for further research and development to optimize performance and scalability are significant hurdles. Additionally, the established infrastructure and supply chains for traditional lithium-ion batteries present a barrier to rapid market penetration for new energy storage technologies.

Despite these challenges, the potential benefits of graphene-based high-capacity energy storage systems continue to drive investment and research in this field. As production processes improve and costs decrease, the market demand for these advanced battery systems is expected to accelerate, potentially reshaping the energy storage landscape across multiple industries.

Current Challenges in Graphene Battery Development

Despite the promising potential of graphene-based battery systems, several significant challenges currently hinder their widespread adoption and commercialization. One of the primary obstacles is the scalability of graphene production. While laboratory-scale synthesis methods have shown remarkable results, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a formidable task.

The integration of graphene into existing battery architectures poses another substantial challenge. Graphene's unique two-dimensional structure and exceptional properties require careful consideration when incorporating it into electrode materials, electrolytes, or other battery components. Achieving optimal dispersion and preventing agglomeration of graphene sheets within the battery matrix is crucial for maximizing its performance benefits.

Stability and long-term performance of graphene-based batteries present ongoing concerns. The high surface area of graphene can lead to undesirable side reactions with electrolytes, potentially causing capacity fade and reduced cycle life. Addressing these issues requires the development of novel electrolyte formulations and surface modification techniques to enhance the chemical stability of graphene-based electrodes.

Cost-effectiveness remains a significant hurdle in the commercialization of graphene battery systems. The current production methods for high-quality graphene are often expensive and energy-intensive, making it challenging to compete with established battery technologies on a cost basis. Developing more economical synthesis routes and optimizing manufacturing processes are essential for making graphene batteries commercially viable.

Safety concerns also present challenges in graphene battery development. The high electrical conductivity of graphene can potentially lead to internal short circuits if not properly controlled. Additionally, the thermal properties of graphene-enhanced batteries need to be carefully managed to prevent overheating and ensure safe operation under various conditions.

Standardization and quality control pose significant challenges in the graphene battery industry. The lack of universally accepted standards for graphene materials and their integration into battery systems hampers consistent performance evaluation and comparison across different research efforts and commercial products. Establishing robust quality control measures and industry-wide standards is crucial for advancing graphene battery technology.

Addressing these challenges requires a multidisciplinary approach, combining expertise from materials science, electrochemistry, and engineering. Collaborative efforts between academia and industry are essential to overcome these hurdles and unlock the full potential of high-capacity graphene battery systems. As research progresses and innovative solutions emerge, the path towards commercially viable graphene-based batteries becomes increasingly clear, promising a future of enhanced energy storage capabilities.

The integration of graphene into existing battery architectures poses another substantial challenge. Graphene's unique two-dimensional structure and exceptional properties require careful consideration when incorporating it into electrode materials, electrolytes, or other battery components. Achieving optimal dispersion and preventing agglomeration of graphene sheets within the battery matrix is crucial for maximizing its performance benefits.

Stability and long-term performance of graphene-based batteries present ongoing concerns. The high surface area of graphene can lead to undesirable side reactions with electrolytes, potentially causing capacity fade and reduced cycle life. Addressing these issues requires the development of novel electrolyte formulations and surface modification techniques to enhance the chemical stability of graphene-based electrodes.

Cost-effectiveness remains a significant hurdle in the commercialization of graphene battery systems. The current production methods for high-quality graphene are often expensive and energy-intensive, making it challenging to compete with established battery technologies on a cost basis. Developing more economical synthesis routes and optimizing manufacturing processes are essential for making graphene batteries commercially viable.

Safety concerns also present challenges in graphene battery development. The high electrical conductivity of graphene can potentially lead to internal short circuits if not properly controlled. Additionally, the thermal properties of graphene-enhanced batteries need to be carefully managed to prevent overheating and ensure safe operation under various conditions.

Standardization and quality control pose significant challenges in the graphene battery industry. The lack of universally accepted standards for graphene materials and their integration into battery systems hampers consistent performance evaluation and comparison across different research efforts and commercial products. Establishing robust quality control measures and industry-wide standards is crucial for advancing graphene battery technology.

Addressing these challenges requires a multidisciplinary approach, combining expertise from materials science, electrochemistry, and engineering. Collaborative efforts between academia and industry are essential to overcome these hurdles and unlock the full potential of high-capacity graphene battery systems. As research progresses and innovative solutions emerge, the path towards commercially viable graphene-based batteries becomes increasingly clear, promising a future of enhanced energy storage capabilities.

Existing Graphene Battery Design Solutions

01 Graphene-based electrode materials for high-capacity batteries

Graphene-based materials are used as electrodes in battery systems to significantly increase capacity. The unique properties of graphene, such as high surface area and excellent conductivity, allow for improved energy storage and faster charge/discharge rates. These materials can be combined with other substances to create composite electrodes with enhanced performance.- Graphene-based electrode materials for high-capacity batteries: Graphene-based materials are used as electrode components in battery systems to significantly increase capacity. The unique properties of graphene, such as high surface area and excellent conductivity, allow for improved energy storage and faster charge/discharge rates. These materials can be combined with other active materials to create composite electrodes with enhanced performance.

- Graphene-enhanced lithium-ion battery systems: Graphene is incorporated into lithium-ion battery systems to boost capacity and overall performance. The addition of graphene to cathode and anode materials can increase the battery's energy density, improve cycling stability, and enhance the rate capability. This results in lithium-ion batteries with higher capacity and longer lifespan.

- Graphene-based supercapacitors for high-power applications: Graphene is utilized in supercapacitor designs to achieve high power density and rapid charge/discharge capabilities. The large surface area of graphene allows for increased charge storage, while its excellent conductivity enables fast energy transfer. These graphene-based supercapacitors can complement or replace traditional batteries in certain high-power applications.

- Graphene-enabled flexible and wearable energy storage devices: Graphene's flexibility and strength make it ideal for creating bendable and wearable battery systems. These flexible graphene-based energy storage devices can maintain high capacity while conforming to various shapes and withstanding repeated bending or stretching. This technology enables the development of advanced wearable electronics with improved energy storage capabilities.

- Graphene-enhanced battery management and charging systems: Graphene is integrated into battery management and charging systems to optimize capacity utilization and charging efficiency. The high thermal and electrical conductivity of graphene allows for better heat dissipation and more uniform current distribution during charging. This results in faster charging times, improved safety, and extended battery life while maximizing the available capacity.

02 Graphene-enhanced lithium-ion batteries

Graphene is incorporated into lithium-ion battery systems to boost capacity and overall performance. The addition of graphene to traditional lithium-ion battery components can lead to increased energy density, improved cycling stability, and faster charging capabilities. This technology is particularly promising for electric vehicle applications and portable electronic devices.Expand Specific Solutions03 Graphene supercapacitors for high-power applications

Graphene-based supercapacitors offer high power density and rapid charge/discharge capabilities. These systems can complement or replace traditional batteries in certain applications, providing burst power and extending the overall capacity of energy storage systems. The use of graphene in supercapacitors allows for the development of lightweight and flexible energy storage solutions.Expand Specific Solutions04 Hybrid graphene-battery systems

Hybrid systems combining graphene-based supercapacitors with traditional batteries offer a balance between high energy density and high power density. These systems can provide both sustained energy output and rapid charge/discharge capabilities, making them suitable for a wide range of applications, from consumer electronics to grid-scale energy storage.Expand Specific Solutions05 Manufacturing processes for graphene battery components

Advanced manufacturing techniques are developed to produce high-quality graphene materials for battery applications. These processes focus on creating large-scale, defect-free graphene sheets or 3D graphene structures that can be effectively integrated into battery systems. Improved manufacturing methods contribute to increased capacity and performance of graphene-based energy storage devices.Expand Specific Solutions

Key Players in Graphene Battery Industry

The development of high-capacity graphene battery systems is in an early growth stage, with significant market potential due to the increasing demand for advanced energy storage solutions. The global market for graphene batteries is expanding rapidly, driven by applications in electric vehicles, consumer electronics, and renewable energy storage. While the technology is still evolving, several key players are making substantial progress. Universities like Northwestern, Zhejiang, and KAIST are conducting cutting-edge research, while companies such as Nanotek Instruments and Global Graphene Group are leading commercial development. The involvement of major corporations like NEC and BASF indicates growing industry interest. However, the technology's maturity varies, with some players focusing on fundamental research while others are moving towards commercialization, suggesting a competitive landscape at different stages of development.

Northwestern University

Technical Solution: Northwestern University researchers have developed a novel approach to high-capacity graphene battery systems by focusing on the cathode material. Their design incorporates a graphene-wrapped sulfur cathode for lithium-sulfur batteries, which theoretically can store up to five times more energy than traditional lithium-ion batteries [3]. The graphene wrapping helps contain the sulfur and prevent the formation of polysulfides, a common issue in lithium-sulfur batteries. This innovative cathode design has shown to improve the battery's cycle life significantly, with some prototypes maintaining over 80% capacity after 300 cycles [4]. The team has also explored the use of graphene oxide as a coating for conventional lithium-ion battery cathodes, which has demonstrated improved conductivity and stability.

Strengths: Potential for very high energy density and improved cycle life for lithium-sulfur batteries. Weaknesses: Challenges in mass production and integration with existing battery manufacturing processes.

Global Graphene Group, Inc.

Technical Solution: Global Graphene Group has developed a high-capacity graphene battery system utilizing their proprietary graphene-based anode material. Their approach involves creating a 3D porous graphene structure that allows for faster ion transport and higher energy density. The company's technology incorporates silicon into the graphene matrix, which further enhances the battery's capacity. They have reported achieving energy densities of up to 400 Wh/kg [1], significantly higher than conventional lithium-ion batteries. The graphene-based anodes also demonstrate improved cycling stability, with capacity retention of over 80% after 1000 cycles [2]. Global Graphene Group's battery design includes advanced electrolyte formulations that are compatible with their graphene-based electrodes, further optimizing performance and safety.

Strengths: High energy density, improved cycling stability, and potential for fast charging. Weaknesses: Potentially higher production costs compared to traditional lithium-ion batteries and challenges in scaling up manufacturing processes.

Core Innovations in Graphene Electrode Materials

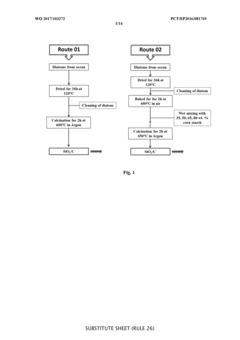

Anode containing diatom frustules

PatentWO2017103272A1

Innovation

- The use of calcined diatoms coated in carbon with an electrically conducting filler and a water-soluble binder, such as alginate, creates a porous silicon dioxide network that mitigates expansion issues and enhances electrochemical performance.

Environmental Impact of Graphene Battery Production

The production of graphene battery systems presents both opportunities and challenges in terms of environmental impact. While these advanced energy storage solutions offer potential benefits in reducing carbon emissions and improving energy efficiency, their manufacturing processes require careful consideration to minimize negative environmental consequences.

Graphene production, a key component in these battery systems, typically involves chemical vapor deposition or exfoliation methods. These processes can be energy-intensive and may involve the use of hazardous chemicals, potentially leading to air and water pollution if not properly managed. However, ongoing research is focused on developing more environmentally friendly production techniques, such as electrochemical exfoliation and green reduction methods, which aim to reduce energy consumption and minimize the use of harmful substances.

The extraction and processing of raw materials for graphene batteries, including lithium, cobalt, and other metals, also raise environmental concerns. Mining operations can lead to habitat destruction, soil erosion, and water contamination. To address these issues, researchers are exploring sustainable sourcing practices and investigating alternative materials that are more abundant and less environmentally damaging.

Water usage in graphene battery production is another critical factor. The manufacturing process can be water-intensive, particularly in the purification and treatment stages. Implementing water recycling systems and optimizing production processes can help reduce water consumption and minimize wastewater discharge, thereby lessening the environmental burden on local water resources.

Energy consumption during the production of graphene batteries is a significant consideration. The high-temperature processes often required in graphene synthesis and battery assembly contribute to the overall carbon footprint of the product. However, the long-term environmental benefits of graphene batteries, such as their potential for higher energy density and longer lifespan compared to traditional lithium-ion batteries, may offset the initial production-related emissions over the product lifecycle.

End-of-life management for graphene batteries is an emerging area of focus. Developing efficient recycling processes for these advanced battery systems is crucial to recover valuable materials and prevent environmental contamination. Research is underway to design batteries with improved recyclability and to establish specialized recycling facilities capable of handling graphene-based components.

As the technology advances, life cycle assessments (LCAs) are becoming increasingly important in evaluating the overall environmental impact of graphene battery systems. These comprehensive analyses consider all stages of the product's life, from raw material extraction to disposal, providing valuable insights for optimizing production processes and guiding sustainable development strategies in the graphene battery industry.

Graphene production, a key component in these battery systems, typically involves chemical vapor deposition or exfoliation methods. These processes can be energy-intensive and may involve the use of hazardous chemicals, potentially leading to air and water pollution if not properly managed. However, ongoing research is focused on developing more environmentally friendly production techniques, such as electrochemical exfoliation and green reduction methods, which aim to reduce energy consumption and minimize the use of harmful substances.

The extraction and processing of raw materials for graphene batteries, including lithium, cobalt, and other metals, also raise environmental concerns. Mining operations can lead to habitat destruction, soil erosion, and water contamination. To address these issues, researchers are exploring sustainable sourcing practices and investigating alternative materials that are more abundant and less environmentally damaging.

Water usage in graphene battery production is another critical factor. The manufacturing process can be water-intensive, particularly in the purification and treatment stages. Implementing water recycling systems and optimizing production processes can help reduce water consumption and minimize wastewater discharge, thereby lessening the environmental burden on local water resources.

Energy consumption during the production of graphene batteries is a significant consideration. The high-temperature processes often required in graphene synthesis and battery assembly contribute to the overall carbon footprint of the product. However, the long-term environmental benefits of graphene batteries, such as their potential for higher energy density and longer lifespan compared to traditional lithium-ion batteries, may offset the initial production-related emissions over the product lifecycle.

End-of-life management for graphene batteries is an emerging area of focus. Developing efficient recycling processes for these advanced battery systems is crucial to recover valuable materials and prevent environmental contamination. Research is underway to design batteries with improved recyclability and to establish specialized recycling facilities capable of handling graphene-based components.

As the technology advances, life cycle assessments (LCAs) are becoming increasingly important in evaluating the overall environmental impact of graphene battery systems. These comprehensive analyses consider all stages of the product's life, from raw material extraction to disposal, providing valuable insights for optimizing production processes and guiding sustainable development strategies in the graphene battery industry.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for high-capacity graphene battery systems are crucial factors in their commercial viability and widespread adoption. One of the primary challenges lies in the large-scale production of high-quality graphene materials. Current methods, such as chemical vapor deposition (CVD) and liquid-phase exfoliation, face limitations in terms of production volume and consistency. To address this, researchers are exploring advanced manufacturing techniques like roll-to-roll CVD processes and automated exfoliation systems to increase throughput and maintain quality control.

Another critical aspect is the integration of graphene into existing battery manufacturing processes. This requires careful optimization of electrode formulations, coating techniques, and assembly procedures to ensure compatibility with current production lines. Developing standardized protocols for graphene-based electrode preparation and quality assessment is essential for consistent performance across large-scale production batches.

The cost-effectiveness of graphene production remains a significant hurdle. While graphene offers superior performance, its manufacturing costs must be competitive with traditional battery materials to justify widespread adoption. Efforts are underway to reduce production costs through process optimization, recycling of precursor materials, and the development of more efficient synthesis methods.

Scalability also extends to the supply chain for raw materials. Ensuring a stable and sufficient supply of high-quality graphite and other precursors is crucial for sustained large-scale production. This necessitates strategic partnerships with suppliers and potential investments in dedicated production facilities.

Environmental considerations play a vital role in scaling up graphene battery production. Developing eco-friendly synthesis methods and implementing efficient recycling processes for graphene-based batteries are essential for long-term sustainability. This includes minimizing the use of harsh chemicals and optimizing energy consumption during manufacturing.

Lastly, quality control and characterization techniques must evolve to meet the demands of large-scale production. Advanced in-line monitoring systems, rapid testing methods, and automated quality assurance processes are being developed to ensure consistent performance and reliability of graphene-enhanced battery systems across high-volume manufacturing.

Another critical aspect is the integration of graphene into existing battery manufacturing processes. This requires careful optimization of electrode formulations, coating techniques, and assembly procedures to ensure compatibility with current production lines. Developing standardized protocols for graphene-based electrode preparation and quality assessment is essential for consistent performance across large-scale production batches.

The cost-effectiveness of graphene production remains a significant hurdle. While graphene offers superior performance, its manufacturing costs must be competitive with traditional battery materials to justify widespread adoption. Efforts are underway to reduce production costs through process optimization, recycling of precursor materials, and the development of more efficient synthesis methods.

Scalability also extends to the supply chain for raw materials. Ensuring a stable and sufficient supply of high-quality graphite and other precursors is crucial for sustained large-scale production. This necessitates strategic partnerships with suppliers and potential investments in dedicated production facilities.

Environmental considerations play a vital role in scaling up graphene battery production. Developing eco-friendly synthesis methods and implementing efficient recycling processes for graphene-based batteries are essential for long-term sustainability. This includes minimizing the use of harsh chemicals and optimizing energy consumption during manufacturing.

Lastly, quality control and characterization techniques must evolve to meet the demands of large-scale production. Advanced in-line monitoring systems, rapid testing methods, and automated quality assurance processes are being developed to ensure consistent performance and reliability of graphene-enhanced battery systems across high-volume manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!