How to Maximize Efficiency in Graphene Battery Production?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries have emerged as a promising technology in the energy storage landscape, offering potential advantages over traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its applications across various fields, including energy storage.

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into battery electrodes could improve conductivity, increase surface area, and enhance overall battery performance. This marked the first phase of graphene battery development, focusing on incremental improvements to existing battery designs.

As research progressed, scientists began exploring the potential of graphene as a primary component in battery construction. This led to the development of graphene-based anodes and cathodes, which promised higher energy density, faster charging rates, and improved cycle life compared to conventional battery materials. The transition from graphene as an additive to a core component represents a significant milestone in the evolution of graphene battery technology.

Recent years have seen a shift towards more advanced graphene battery architectures. Researchers are now investigating three-dimensional graphene structures, graphene-metal composites, and hybrid graphene-silicon materials to further enhance battery performance. These innovations aim to address key challenges in energy storage, such as increasing energy density, improving charge/discharge rates, and extending battery lifespan.

The primary objectives in graphene battery development are multifaceted. First and foremost is the goal of maximizing energy density, enabling batteries to store more energy in a smaller volume. This is crucial for applications ranging from portable electronics to electric vehicles, where space and weight are at a premium. Another key objective is to improve charging speeds, potentially allowing for ultra-fast charging capabilities that could revolutionize the adoption of electric vehicles and portable devices.

Enhancing cycle life and stability is another critical objective in graphene battery research. By developing more durable battery materials and structures, researchers aim to create batteries that can withstand thousands of charge-discharge cycles without significant degradation. This would not only improve the longevity of devices but also reduce electronic waste and the environmental impact of battery production.

Safety is an equally important objective in graphene battery development. Researchers are exploring how graphene's unique properties can be leveraged to create batteries that are less prone to overheating, short-circuiting, or other safety issues that have plagued some lithium-ion battery designs. The goal is to develop batteries that are not only more efficient but also inherently safer for consumer use.

As the technology continues to evolve, the ultimate objective is to create commercially viable graphene batteries that can outperform existing energy storage solutions across all key metrics. This includes not only performance characteristics but also scalability and cost-effectiveness in production. Achieving these objectives could lead to a paradigm shift in energy storage, enabling new applications and accelerating the transition to renewable energy sources.

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into battery electrodes could improve conductivity, increase surface area, and enhance overall battery performance. This marked the first phase of graphene battery development, focusing on incremental improvements to existing battery designs.

As research progressed, scientists began exploring the potential of graphene as a primary component in battery construction. This led to the development of graphene-based anodes and cathodes, which promised higher energy density, faster charging rates, and improved cycle life compared to conventional battery materials. The transition from graphene as an additive to a core component represents a significant milestone in the evolution of graphene battery technology.

Recent years have seen a shift towards more advanced graphene battery architectures. Researchers are now investigating three-dimensional graphene structures, graphene-metal composites, and hybrid graphene-silicon materials to further enhance battery performance. These innovations aim to address key challenges in energy storage, such as increasing energy density, improving charge/discharge rates, and extending battery lifespan.

The primary objectives in graphene battery development are multifaceted. First and foremost is the goal of maximizing energy density, enabling batteries to store more energy in a smaller volume. This is crucial for applications ranging from portable electronics to electric vehicles, where space and weight are at a premium. Another key objective is to improve charging speeds, potentially allowing for ultra-fast charging capabilities that could revolutionize the adoption of electric vehicles and portable devices.

Enhancing cycle life and stability is another critical objective in graphene battery research. By developing more durable battery materials and structures, researchers aim to create batteries that can withstand thousands of charge-discharge cycles without significant degradation. This would not only improve the longevity of devices but also reduce electronic waste and the environmental impact of battery production.

Safety is an equally important objective in graphene battery development. Researchers are exploring how graphene's unique properties can be leveraged to create batteries that are less prone to overheating, short-circuiting, or other safety issues that have plagued some lithium-ion battery designs. The goal is to develop batteries that are not only more efficient but also inherently safer for consumer use.

As the technology continues to evolve, the ultimate objective is to create commercially viable graphene batteries that can outperform existing energy storage solutions across all key metrics. This includes not only performance characteristics but also scalability and cost-effectiveness in production. Achieving these objectives could lead to a paradigm shift in energy storage, enabling new applications and accelerating the transition to renewable energy sources.

Market Demand Analysis for Graphene Batteries

The market demand for graphene batteries has been experiencing significant growth in recent years, driven by the increasing need for high-performance energy storage solutions across various industries. The automotive sector, in particular, has shown a strong interest in graphene batteries due to their potential to revolutionize electric vehicle (EV) technology. With major automakers investing heavily in EV development, the demand for more efficient and longer-lasting batteries has surged.

Consumer electronics represent another key market for graphene batteries. As smartphones, laptops, and wearable devices continue to evolve, manufacturers are seeking power sources that can deliver higher energy density and faster charging capabilities. Graphene batteries, with their superior conductivity and thermal management properties, are well-positioned to meet these requirements.

The renewable energy sector is also contributing to the growing demand for graphene batteries. As the world shifts towards cleaner energy sources, the need for efficient energy storage systems to manage intermittent power generation from solar and wind has become crucial. Graphene batteries offer promising solutions for grid-scale energy storage, potentially enhancing the stability and reliability of renewable energy systems.

In the aerospace and defense industries, there is a rising interest in lightweight, high-performance batteries. Graphene batteries' potential to offer significant weight reduction while maintaining or improving power output makes them attractive for applications in aircraft, satellites, and military equipment.

Market analysts project substantial growth in the graphene battery market over the coming years. The global market size is expected to expand at a compound annual growth rate (CAGR) of over 20% from 2021 to 2026. This growth is attributed to the increasing adoption of electric vehicles, the proliferation of portable electronic devices, and the growing emphasis on renewable energy integration.

However, the market demand is not without challenges. The high production costs associated with graphene batteries currently limit their widespread adoption. As manufacturing processes improve and economies of scale are achieved, it is anticipated that the cost barrier will gradually decrease, further stimulating market demand.

Geographically, Asia-Pacific is expected to dominate the graphene battery market, with China and South Korea leading in research and development efforts. North America and Europe are also significant markets, driven by strong investments in clean energy technologies and electric vehicle infrastructure.

Consumer electronics represent another key market for graphene batteries. As smartphones, laptops, and wearable devices continue to evolve, manufacturers are seeking power sources that can deliver higher energy density and faster charging capabilities. Graphene batteries, with their superior conductivity and thermal management properties, are well-positioned to meet these requirements.

The renewable energy sector is also contributing to the growing demand for graphene batteries. As the world shifts towards cleaner energy sources, the need for efficient energy storage systems to manage intermittent power generation from solar and wind has become crucial. Graphene batteries offer promising solutions for grid-scale energy storage, potentially enhancing the stability and reliability of renewable energy systems.

In the aerospace and defense industries, there is a rising interest in lightweight, high-performance batteries. Graphene batteries' potential to offer significant weight reduction while maintaining or improving power output makes them attractive for applications in aircraft, satellites, and military equipment.

Market analysts project substantial growth in the graphene battery market over the coming years. The global market size is expected to expand at a compound annual growth rate (CAGR) of over 20% from 2021 to 2026. This growth is attributed to the increasing adoption of electric vehicles, the proliferation of portable electronic devices, and the growing emphasis on renewable energy integration.

However, the market demand is not without challenges. The high production costs associated with graphene batteries currently limit their widespread adoption. As manufacturing processes improve and economies of scale are achieved, it is anticipated that the cost barrier will gradually decrease, further stimulating market demand.

Geographically, Asia-Pacific is expected to dominate the graphene battery market, with China and South Korea leading in research and development efforts. North America and Europe are also significant markets, driven by strong investments in clean energy technologies and electric vehicle infrastructure.

Graphene Battery Production Challenges

Graphene battery production faces several significant challenges that hinder its widespread adoption and efficiency maximization. One of the primary obstacles is the high cost of graphene production, which directly impacts the overall expense of manufacturing graphene-based batteries. The current methods for synthesizing high-quality graphene, such as chemical vapor deposition (CVD) and epitaxial growth, are complex and energy-intensive processes that require specialized equipment and controlled environments.

Another major challenge lies in scaling up graphene production to meet industrial demands. While laboratory-scale production has shown promising results, translating these processes to large-scale manufacturing without compromising quality remains a significant hurdle. The uniformity and consistency of graphene sheets produced at industrial scales are critical factors that directly affect battery performance and reliability.

The integration of graphene into existing battery manufacturing processes presents additional complications. Conventional battery production lines are not optimized for handling graphene materials, necessitating substantial modifications to equipment and procedures. This adaptation process can be time-consuming and costly, potentially offsetting the benefits gained from graphene's superior properties.

Quality control and characterization of graphene materials pose another set of challenges. The properties of graphene can vary significantly based on the number of layers, defects, and impurities present. Developing rapid and reliable methods for assessing graphene quality in real-time during production is crucial for maintaining consistent battery performance but remains a technical challenge.

Environmental concerns and safety considerations also play a role in graphene battery production. The potential health impacts of graphene nanoparticles are not yet fully understood, necessitating stringent safety protocols and containment measures in production facilities. Additionally, ensuring the environmental sustainability of graphene production processes is essential for long-term viability and regulatory compliance.

Lastly, the lack of standardization in graphene production and characterization methods complicates the comparison and validation of different manufacturing approaches. This absence of industry-wide standards makes it difficult for manufacturers to benchmark their processes and products, potentially slowing down innovation and efficiency improvements in graphene battery production.

Another major challenge lies in scaling up graphene production to meet industrial demands. While laboratory-scale production has shown promising results, translating these processes to large-scale manufacturing without compromising quality remains a significant hurdle. The uniformity and consistency of graphene sheets produced at industrial scales are critical factors that directly affect battery performance and reliability.

The integration of graphene into existing battery manufacturing processes presents additional complications. Conventional battery production lines are not optimized for handling graphene materials, necessitating substantial modifications to equipment and procedures. This adaptation process can be time-consuming and costly, potentially offsetting the benefits gained from graphene's superior properties.

Quality control and characterization of graphene materials pose another set of challenges. The properties of graphene can vary significantly based on the number of layers, defects, and impurities present. Developing rapid and reliable methods for assessing graphene quality in real-time during production is crucial for maintaining consistent battery performance but remains a technical challenge.

Environmental concerns and safety considerations also play a role in graphene battery production. The potential health impacts of graphene nanoparticles are not yet fully understood, necessitating stringent safety protocols and containment measures in production facilities. Additionally, ensuring the environmental sustainability of graphene production processes is essential for long-term viability and regulatory compliance.

Lastly, the lack of standardization in graphene production and characterization methods complicates the comparison and validation of different manufacturing approaches. This absence of industry-wide standards makes it difficult for manufacturers to benchmark their processes and products, potentially slowing down innovation and efficiency improvements in graphene battery production.

Current Graphene Battery Production Methods

01 Graphene-based electrode materials

Graphene-based materials are used to enhance electrode performance in batteries. These materials can improve energy density, charge/discharge rates, and overall efficiency due to their high conductivity and large surface area. Graphene can be incorporated into both anode and cathode materials to boost battery performance.- Graphene-based electrode materials: Graphene-based materials are used to enhance electrode performance in batteries. These materials can improve energy density, charge/discharge rates, and overall efficiency due to their high surface area and excellent electrical conductivity. Graphene can be incorporated into both anode and cathode materials to boost battery performance.

- Graphene-enhanced electrolytes: Graphene can be used to improve electrolyte performance in batteries. By incorporating graphene or graphene oxide into the electrolyte, ionic conductivity can be increased, leading to better overall battery efficiency. This approach can also help in reducing dendrite formation and improving the stability of the electrolyte-electrode interface.

- Graphene-based composite materials: Composite materials combining graphene with other materials such as metal oxides or polymers are developed to enhance battery performance. These composites can offer improved mechanical stability, higher capacity, and better cycling performance compared to traditional battery materials. The synergistic effects of graphene and other materials contribute to increased energy density and power output.

- Graphene-enabled flexible and thin-film batteries: Graphene's unique properties allow for the development of flexible and thin-film batteries with improved efficiency. These batteries can maintain high performance while being bent or stretched, making them suitable for wearable devices and flexible electronics. The use of graphene in such batteries can lead to higher energy density and faster charging capabilities in compact designs.

- Graphene-based supercapacitors and hybrid energy storage devices: Graphene is utilized in the development of high-performance supercapacitors and hybrid energy storage devices that combine features of both batteries and supercapacitors. These devices can offer rapid charging and discharging capabilities, long cycle life, and high power density. The integration of graphene in such systems can lead to improved energy storage efficiency and faster energy delivery for various applications.

02 Graphene-enhanced electrolytes

Incorporating graphene or graphene oxide into battery electrolytes can improve ionic conductivity and stability. This enhancement leads to better charge transfer, reduced internal resistance, and improved overall battery efficiency. Graphene-based electrolytes can also contribute to longer cycle life and improved safety.Expand Specific Solutions03 Graphene composite materials for battery components

Composite materials combining graphene with other substances, such as metal oxides or polymers, are used to create advanced battery components. These composites can enhance mechanical strength, conductivity, and electrochemical performance, leading to more efficient and durable batteries.Expand Specific Solutions04 Graphene-based current collectors

Utilizing graphene as a material for current collectors in batteries can significantly reduce weight while improving conductivity. This approach enhances energy density and power output, contributing to overall battery efficiency. Graphene current collectors also demonstrate better corrosion resistance and flexibility compared to traditional materials.Expand Specific Solutions05 Graphene-enhanced thermal management

Incorporating graphene into battery thermal management systems can improve heat dissipation and temperature control. This enhancement leads to more stable battery performance, increased efficiency, and improved safety. Graphene's excellent thermal conductivity properties make it an ideal material for managing heat in high-performance batteries.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery production market is in its early growth stage, characterized by rapid technological advancements and increasing commercial interest. The global market size for graphene batteries is projected to expand significantly in the coming years, driven by the growing demand for high-performance energy storage solutions. While the technology is still maturing, several key players are making substantial progress in maximizing production efficiency. Companies like Honeycomb Battery Co., Nanotek Instruments, and Global Graphene Group are at the forefront of developing innovative manufacturing processes. Academic institutions such as Northwestern University and KAIST are contributing to fundamental research, while industry giants like SABIC and Toray Industries are exploring large-scale production capabilities. The competitive landscape is diverse, with a mix of specialized startups and established corporations vying for market leadership in this promising field.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has focused on developing advanced graphene-based materials for battery applications. Their approach involves precise control of graphene synthesis at the atomic level, using chemical vapor deposition (CVD) techniques. SEL has patented a method for creating graphene-silicon composite anodes that significantly increase the energy density of lithium-ion batteries[6]. Their production process incorporates in-situ quality control measures, using real-time Raman spectroscopy to ensure consistent graphene quality throughout the manufacturing process[7].

Strengths: High-precision graphene synthesis, advanced quality control, potential for high-performance batteries. Weaknesses: CVD process can be energy-intensive, potentially higher production costs.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a scalable graphene production method based on liquid-phase exfoliation of graphite. This process allows for the production of large quantities of graphene flakes suitable for battery applications. Toray's approach focuses on optimizing the dispersion and integration of graphene into battery electrodes, using proprietary binders and coating technologies. They have reported a 20% increase in battery capacity when incorporating their graphene materials into lithium-ion batteries[8]. Toray has also invested in automated production lines that combine graphene synthesis with electrode fabrication, streamlining the overall manufacturing process[9].

Strengths: Scalable production, expertise in materials integration, established industrial presence. Weaknesses: Liquid-phase exfoliation may produce graphene with more defects compared to other methods.

Innovative Graphene Synthesis Techniques

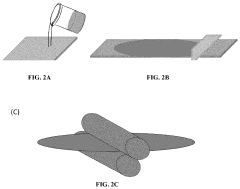

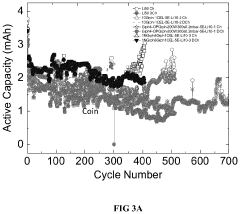

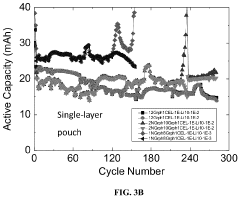

Flexible composite electrode high-rate performance lithium-ion batteries

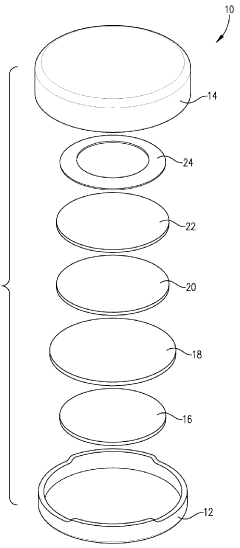

PatentActiveUS20160056451A1

Innovation

- A composite material comprising graphene or reduced graphene oxide combined with a polymer-derived ceramic material, such as SiOC, is used to form anodes that eliminate the need for copper current collectors and polymeric binders, providing enhanced electronic conductivity and structural stability, allowing for higher charge and discharge rates and improved capacity retention.

Direct-formation self-assembly graphene from cellulose nanofiber aqueous solution

PatentPendingUS20240088397A1

Innovation

- A self-assembled freestanding graphene membrane or layer is formed using an aqueous dispersion of industrial-grade graphene and cellulose nanofibers with a mass ratio of 12:1 to 20:1, which improves dispersibility and allows for low-temperature direct fabrication, enabling the formation of a stable and conductive graphene scaffold for lithium metal anodes.

Supply Chain Optimization for Graphene Production

Optimizing the supply chain for graphene production is crucial in maximizing the efficiency of graphene battery manufacturing. The complex nature of graphene synthesis and the need for high-quality materials necessitate a well-coordinated and streamlined supply chain process. To achieve this, companies must focus on several key areas of improvement.

Firstly, sourcing high-quality raw materials is essential. Graphene production requires specific precursors, such as graphite or methane, depending on the synthesis method. Establishing long-term partnerships with reliable suppliers can ensure a consistent supply of high-grade materials. Additionally, implementing rigorous quality control measures at the sourcing stage can prevent production delays and quality issues downstream.

The transportation and storage of raw materials and finished graphene products also play a critical role in supply chain optimization. Graphene is sensitive to environmental factors, so proper handling and storage conditions must be maintained throughout the supply chain. This may involve investing in specialized transportation equipment and storage facilities to preserve the material's unique properties.

Inventory management is another crucial aspect of supply chain optimization for graphene production. Given the high value and sensitivity of graphene materials, just-in-time (JIT) inventory systems can be implemented to reduce storage costs and minimize the risk of material degradation. However, this approach requires precise demand forecasting and close coordination with suppliers and customers.

Automation and digitalization of supply chain processes can significantly enhance efficiency in graphene production. Implementing advanced manufacturing execution systems (MES) and enterprise resource planning (ERP) software can provide real-time visibility into production processes, inventory levels, and supply chain operations. This enables faster decision-making and more efficient resource allocation.

Collaboration and information sharing among supply chain partners are essential for optimizing the graphene production process. Establishing a transparent and integrated supply chain network allows for better coordination, reduced lead times, and improved responsiveness to market demands. This may involve implementing blockchain technology to ensure traceability and enhance trust among supply chain participants.

Lastly, continuous improvement and innovation in supply chain practices are necessary to stay competitive in the rapidly evolving graphene industry. Regular assessments of supply chain performance, benchmarking against industry best practices, and investing in research and development of new supply chain technologies can help maintain a competitive edge in graphene battery production.

Firstly, sourcing high-quality raw materials is essential. Graphene production requires specific precursors, such as graphite or methane, depending on the synthesis method. Establishing long-term partnerships with reliable suppliers can ensure a consistent supply of high-grade materials. Additionally, implementing rigorous quality control measures at the sourcing stage can prevent production delays and quality issues downstream.

The transportation and storage of raw materials and finished graphene products also play a critical role in supply chain optimization. Graphene is sensitive to environmental factors, so proper handling and storage conditions must be maintained throughout the supply chain. This may involve investing in specialized transportation equipment and storage facilities to preserve the material's unique properties.

Inventory management is another crucial aspect of supply chain optimization for graphene production. Given the high value and sensitivity of graphene materials, just-in-time (JIT) inventory systems can be implemented to reduce storage costs and minimize the risk of material degradation. However, this approach requires precise demand forecasting and close coordination with suppliers and customers.

Automation and digitalization of supply chain processes can significantly enhance efficiency in graphene production. Implementing advanced manufacturing execution systems (MES) and enterprise resource planning (ERP) software can provide real-time visibility into production processes, inventory levels, and supply chain operations. This enables faster decision-making and more efficient resource allocation.

Collaboration and information sharing among supply chain partners are essential for optimizing the graphene production process. Establishing a transparent and integrated supply chain network allows for better coordination, reduced lead times, and improved responsiveness to market demands. This may involve implementing blockchain technology to ensure traceability and enhance trust among supply chain participants.

Lastly, continuous improvement and innovation in supply chain practices are necessary to stay competitive in the rapidly evolving graphene industry. Regular assessments of supply chain performance, benchmarking against industry best practices, and investing in research and development of new supply chain technologies can help maintain a competitive edge in graphene battery production.

Environmental Impact of Graphene Battery Manufacturing

The environmental impact of graphene battery manufacturing is a critical consideration in the pursuit of maximizing efficiency in production. As the demand for high-performance energy storage solutions grows, it is essential to evaluate and mitigate the potential environmental consequences associated with graphene battery production.

One of the primary environmental concerns in graphene battery manufacturing is the energy-intensive nature of graphene production. The synthesis of high-quality graphene often requires significant energy inputs, potentially contributing to increased carbon emissions if not managed properly. To address this issue, manufacturers are exploring more energy-efficient production methods, such as chemical vapor deposition (CVD) and electrochemical exfoliation, which can reduce the overall energy consumption and associated environmental footprint.

Water usage and contamination present another environmental challenge in graphene battery production. The manufacturing process may involve the use of various chemicals and solvents, which can lead to water pollution if not properly treated and disposed of. Implementing closed-loop water recycling systems and adopting green chemistry principles can help minimize water consumption and reduce the risk of environmental contamination.

The extraction and processing of raw materials for graphene production, such as graphite, also have environmental implications. Mining activities can lead to habitat destruction, soil erosion, and water pollution. To mitigate these impacts, manufacturers are investigating sustainable sourcing practices and exploring alternative precursor materials that have a lower environmental impact.

Air quality is another concern in graphene battery manufacturing. The production process may release particulate matter and volatile organic compounds (VOCs) into the atmosphere. Implementing advanced air filtration systems and adopting low-emission production techniques can help minimize air pollution and protect both worker health and the surrounding environment.

Waste management is a crucial aspect of environmental stewardship in graphene battery production. The manufacturing process generates various waste streams, including chemical byproducts and defective materials. Developing efficient recycling and waste recovery systems can help reduce the overall environmental impact and promote a more circular economy approach to battery production.

As the graphene battery industry continues to evolve, there is a growing emphasis on life cycle assessment (LCA) to evaluate the environmental impact of these batteries from cradle to grave. This holistic approach considers factors such as raw material extraction, manufacturing processes, transportation, use phase, and end-of-life disposal or recycling. By conducting comprehensive LCAs, manufacturers can identify hotspots in the production chain and implement targeted improvements to reduce the overall environmental footprint of graphene batteries.

One of the primary environmental concerns in graphene battery manufacturing is the energy-intensive nature of graphene production. The synthesis of high-quality graphene often requires significant energy inputs, potentially contributing to increased carbon emissions if not managed properly. To address this issue, manufacturers are exploring more energy-efficient production methods, such as chemical vapor deposition (CVD) and electrochemical exfoliation, which can reduce the overall energy consumption and associated environmental footprint.

Water usage and contamination present another environmental challenge in graphene battery production. The manufacturing process may involve the use of various chemicals and solvents, which can lead to water pollution if not properly treated and disposed of. Implementing closed-loop water recycling systems and adopting green chemistry principles can help minimize water consumption and reduce the risk of environmental contamination.

The extraction and processing of raw materials for graphene production, such as graphite, also have environmental implications. Mining activities can lead to habitat destruction, soil erosion, and water pollution. To mitigate these impacts, manufacturers are investigating sustainable sourcing practices and exploring alternative precursor materials that have a lower environmental impact.

Air quality is another concern in graphene battery manufacturing. The production process may release particulate matter and volatile organic compounds (VOCs) into the atmosphere. Implementing advanced air filtration systems and adopting low-emission production techniques can help minimize air pollution and protect both worker health and the surrounding environment.

Waste management is a crucial aspect of environmental stewardship in graphene battery production. The manufacturing process generates various waste streams, including chemical byproducts and defective materials. Developing efficient recycling and waste recovery systems can help reduce the overall environmental impact and promote a more circular economy approach to battery production.

As the graphene battery industry continues to evolve, there is a growing emphasis on life cycle assessment (LCA) to evaluate the environmental impact of these batteries from cradle to grave. This holistic approach considers factors such as raw material extraction, manufacturing processes, transportation, use phase, and end-of-life disposal or recycling. By conducting comprehensive LCAs, manufacturers can identify hotspots in the production chain and implement targeted improvements to reduce the overall environmental footprint of graphene batteries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!