How to Boost Graphene Battery Capacity for Energy Storage?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries have emerged as a promising technology in the field of energy storage, offering potential advantages over traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its applications across various industries, including energy storage.

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into battery electrodes could improve conductivity and increase the surface area for energy storage. This led to the development of graphene-enhanced lithium-ion batteries, which demonstrated improved capacity and faster charging capabilities.

As research progressed, scientists began exploring the possibility of using graphene as the primary material for battery electrodes. This shift in focus aimed to leverage graphene's unique properties, such as its high electrical conductivity, mechanical strength, and large surface area, to create batteries with significantly higher energy density and faster charging times.

The evolution of graphene batteries has been marked by several key milestones. In 2015, researchers at Manchester University developed a graphene-based supercapacitor that could charge and discharge a hundred times faster than conventional batteries. This breakthrough demonstrated the potential of graphene in high-power applications.

Another significant development came in 2017 when Samsung announced the creation of a "graphene ball" that could potentially increase battery capacity by 45% and charging speed by five times. This innovation highlighted the commercial potential of graphene-based energy storage solutions.

The primary objective in graphene battery research is to significantly boost energy storage capacity while maintaining or improving other performance metrics such as charging speed, cycle life, and safety. Researchers aim to develop graphene-based batteries that can store more energy per unit volume or weight compared to current lithium-ion technologies.

Additionally, there is a focus on improving the manufacturing processes for graphene batteries to make them more scalable and cost-effective. This includes developing methods for large-scale production of high-quality graphene and optimizing electrode fabrication techniques.

Another key objective is to enhance the stability and longevity of graphene batteries. This involves addressing challenges such as electrolyte degradation and the formation of solid-electrolyte interphase (SEI) layers, which can limit the battery's cycle life and overall performance.

As research continues, the ultimate goal is to create graphene batteries that can revolutionize energy storage across various applications, from portable electronics to electric vehicles and grid-scale storage systems. Achieving these objectives could lead to a new generation of high-performance, long-lasting, and environmentally friendly energy storage solutions.

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into battery electrodes could improve conductivity and increase the surface area for energy storage. This led to the development of graphene-enhanced lithium-ion batteries, which demonstrated improved capacity and faster charging capabilities.

As research progressed, scientists began exploring the possibility of using graphene as the primary material for battery electrodes. This shift in focus aimed to leverage graphene's unique properties, such as its high electrical conductivity, mechanical strength, and large surface area, to create batteries with significantly higher energy density and faster charging times.

The evolution of graphene batteries has been marked by several key milestones. In 2015, researchers at Manchester University developed a graphene-based supercapacitor that could charge and discharge a hundred times faster than conventional batteries. This breakthrough demonstrated the potential of graphene in high-power applications.

Another significant development came in 2017 when Samsung announced the creation of a "graphene ball" that could potentially increase battery capacity by 45% and charging speed by five times. This innovation highlighted the commercial potential of graphene-based energy storage solutions.

The primary objective in graphene battery research is to significantly boost energy storage capacity while maintaining or improving other performance metrics such as charging speed, cycle life, and safety. Researchers aim to develop graphene-based batteries that can store more energy per unit volume or weight compared to current lithium-ion technologies.

Additionally, there is a focus on improving the manufacturing processes for graphene batteries to make them more scalable and cost-effective. This includes developing methods for large-scale production of high-quality graphene and optimizing electrode fabrication techniques.

Another key objective is to enhance the stability and longevity of graphene batteries. This involves addressing challenges such as electrolyte degradation and the formation of solid-electrolyte interphase (SEI) layers, which can limit the battery's cycle life and overall performance.

As research continues, the ultimate goal is to create graphene batteries that can revolutionize energy storage across various applications, from portable electronics to electric vehicles and grid-scale storage systems. Achieving these objectives could lead to a new generation of high-performance, long-lasting, and environmentally friendly energy storage solutions.

Energy Storage Market Analysis

The energy storage market has witnessed significant growth in recent years, driven by the increasing demand for renewable energy integration and grid stability. As the world transitions towards cleaner energy sources, the need for efficient and high-capacity energy storage solutions has become paramount. The global energy storage market is expected to reach substantial value by 2030, with a compound annual growth rate (CAGR) exceeding 20% during the forecast period.

Lithium-ion batteries currently dominate the energy storage market, accounting for a majority share of installed capacity. However, the limitations of lithium-ion technology, such as energy density constraints and safety concerns, have spurred research into alternative materials and technologies. Graphene, with its exceptional electrical and thermal properties, has emerged as a promising candidate for enhancing battery performance and capacity.

The residential sector represents a rapidly growing segment of the energy storage market, driven by the increasing adoption of rooftop solar installations and the desire for energy independence. Commercial and industrial applications are also expanding, as businesses seek to reduce energy costs and improve reliability. Utility-scale energy storage projects are gaining traction, with several large-scale installations being deployed globally to support grid stability and integrate renewable energy sources.

Geographically, Asia-Pacific leads the energy storage market, with China and South Korea at the forefront of battery manufacturing and deployment. North America and Europe follow closely, with significant investments in energy storage infrastructure and supportive government policies driving market growth. Emerging markets in Latin America and Africa are also showing potential for rapid expansion in the coming years.

The competitive landscape of the energy storage market is characterized by a mix of established players and innovative startups. Major battery manufacturers, renewable energy companies, and technology giants are all vying for market share. Collaborations and partnerships between different stakeholders are becoming increasingly common, as companies seek to leverage complementary expertise and resources.

Key trends shaping the energy storage market include the development of long-duration storage technologies, the integration of artificial intelligence and machine learning for optimized energy management, and the emergence of vehicle-to-grid (V2G) solutions. The push for circular economy principles is also influencing the market, with increased focus on battery recycling and second-life applications.

As the energy storage market continues to evolve, graphene-based technologies have the potential to address many of the current limitations in battery performance. The ability of graphene to enhance energy density, improve charging speeds, and extend battery life aligns well with market demands for more efficient and sustainable energy storage solutions. However, challenges remain in scaling up graphene production and integrating it into existing battery manufacturing processes.

Lithium-ion batteries currently dominate the energy storage market, accounting for a majority share of installed capacity. However, the limitations of lithium-ion technology, such as energy density constraints and safety concerns, have spurred research into alternative materials and technologies. Graphene, with its exceptional electrical and thermal properties, has emerged as a promising candidate for enhancing battery performance and capacity.

The residential sector represents a rapidly growing segment of the energy storage market, driven by the increasing adoption of rooftop solar installations and the desire for energy independence. Commercial and industrial applications are also expanding, as businesses seek to reduce energy costs and improve reliability. Utility-scale energy storage projects are gaining traction, with several large-scale installations being deployed globally to support grid stability and integrate renewable energy sources.

Geographically, Asia-Pacific leads the energy storage market, with China and South Korea at the forefront of battery manufacturing and deployment. North America and Europe follow closely, with significant investments in energy storage infrastructure and supportive government policies driving market growth. Emerging markets in Latin America and Africa are also showing potential for rapid expansion in the coming years.

The competitive landscape of the energy storage market is characterized by a mix of established players and innovative startups. Major battery manufacturers, renewable energy companies, and technology giants are all vying for market share. Collaborations and partnerships between different stakeholders are becoming increasingly common, as companies seek to leverage complementary expertise and resources.

Key trends shaping the energy storage market include the development of long-duration storage technologies, the integration of artificial intelligence and machine learning for optimized energy management, and the emergence of vehicle-to-grid (V2G) solutions. The push for circular economy principles is also influencing the market, with increased focus on battery recycling and second-life applications.

As the energy storage market continues to evolve, graphene-based technologies have the potential to address many of the current limitations in battery performance. The ability of graphene to enhance energy density, improve charging speeds, and extend battery life aligns well with market demands for more efficient and sustainable energy storage solutions. However, challenges remain in scaling up graphene production and integrating it into existing battery manufacturing processes.

Graphene Battery Technology Challenges

Despite the promising potential of graphene in energy storage applications, several significant challenges hinder the widespread adoption and commercialization of graphene-based batteries. One of the primary obstacles is the scalability of graphene production. While laboratory-scale synthesis methods have shown impressive results, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a formidable task.

Another major challenge lies in the integration of graphene into existing battery architectures. The unique two-dimensional structure of graphene, while advantageous for electron transport, can lead to restacking and agglomeration issues when incorporated into battery electrodes. This phenomenon reduces the effective surface area and diminishes the material's performance benefits.

The stability of graphene-based electrodes in battery environments poses another significant hurdle. Graphene's high surface reactivity can lead to undesirable side reactions with electrolytes, resulting in capacity fading and reduced cycle life. Developing stable graphene-electrolyte interfaces without compromising the material's exceptional conductivity is crucial for long-term battery performance.

Cost considerations also present a substantial challenge. Although graphene production costs have decreased over the years, they remain relatively high compared to conventional battery materials. Achieving cost parity or demonstrating significantly superior performance to justify the higher cost is essential for market adoption.

Furthermore, the lack of standardization in graphene production and characterization methods complicates the development process. Variations in graphene quality, size, and properties across different production batches can lead to inconsistent battery performance, making it difficult to establish reliable manufacturing protocols.

Safety concerns associated with graphene-based batteries also need to be addressed. The high electrical conductivity of graphene can potentially lead to internal short circuits if not properly controlled. Additionally, the long-term environmental and health impacts of graphene materials are not yet fully understood, necessitating comprehensive safety studies.

Lastly, optimizing the energy density of graphene-based batteries remains a challenge. While graphene offers excellent power density due to its high conductivity, achieving energy densities that surpass current lithium-ion technologies requires further innovation in electrode design and electrolyte compatibility.

Another major challenge lies in the integration of graphene into existing battery architectures. The unique two-dimensional structure of graphene, while advantageous for electron transport, can lead to restacking and agglomeration issues when incorporated into battery electrodes. This phenomenon reduces the effective surface area and diminishes the material's performance benefits.

The stability of graphene-based electrodes in battery environments poses another significant hurdle. Graphene's high surface reactivity can lead to undesirable side reactions with electrolytes, resulting in capacity fading and reduced cycle life. Developing stable graphene-electrolyte interfaces without compromising the material's exceptional conductivity is crucial for long-term battery performance.

Cost considerations also present a substantial challenge. Although graphene production costs have decreased over the years, they remain relatively high compared to conventional battery materials. Achieving cost parity or demonstrating significantly superior performance to justify the higher cost is essential for market adoption.

Furthermore, the lack of standardization in graphene production and characterization methods complicates the development process. Variations in graphene quality, size, and properties across different production batches can lead to inconsistent battery performance, making it difficult to establish reliable manufacturing protocols.

Safety concerns associated with graphene-based batteries also need to be addressed. The high electrical conductivity of graphene can potentially lead to internal short circuits if not properly controlled. Additionally, the long-term environmental and health impacts of graphene materials are not yet fully understood, necessitating comprehensive safety studies.

Lastly, optimizing the energy density of graphene-based batteries remains a challenge. While graphene offers excellent power density due to its high conductivity, achieving energy densities that surpass current lithium-ion technologies requires further innovation in electrode design and electrolyte compatibility.

Current Graphene Battery Solutions

01 Graphene-based electrode materials for high-capacity batteries

Graphene-based materials are used as electrode components in batteries to significantly increase their capacity. The unique properties of graphene, such as high surface area and excellent conductivity, allow for improved energy storage and faster charge/discharge rates. These materials can be combined with other active materials to create composite electrodes with enhanced performance.- Graphene-based electrode materials for high-capacity batteries: Graphene-based materials are used as electrode components in batteries to significantly increase their capacity. The unique properties of graphene, such as high surface area and excellent conductivity, allow for improved energy storage and faster charge/discharge rates. These materials can be combined with other substances to create composite electrodes that enhance overall battery performance.

- Graphene-enhanced lithium-ion batteries: Incorporating graphene into lithium-ion batteries can substantially improve their capacity. Graphene can be used in both anode and cathode materials, enhancing lithium storage capacity and facilitating faster ion transport. This results in batteries with higher energy density and improved cycle life compared to conventional lithium-ion batteries.

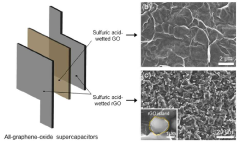

- Graphene-based supercapacitors: Graphene is utilized in the development of high-performance supercapacitors. These devices combine the high power density of traditional capacitors with the high energy density of batteries. Graphene-based supercapacitors offer rapid charge/discharge capabilities and extended cycle life, making them suitable for applications requiring both high power and high energy storage.

- Graphene-metal oxide composites for enhanced battery capacity: Combining graphene with metal oxides creates composite materials that can significantly increase battery capacity. These composites leverage the high conductivity of graphene and the high theoretical capacity of metal oxides. The synergistic effect results in improved electrochemical performance, better stability, and increased energy storage capacity compared to individual components.

- Manufacturing processes for graphene-based battery materials: Advanced manufacturing techniques are developed to produce high-quality graphene-based materials for battery applications. These processes focus on controlling the structure, morphology, and composition of graphene materials to optimize their performance in batteries. Techniques may include chemical vapor deposition, solution-based methods, and thermal treatments to create tailored graphene structures for specific battery requirements.

02 Graphene-enhanced lithium-ion batteries

Incorporating graphene into lithium-ion batteries can lead to substantial improvements in capacity. Graphene can be used as a conductive additive or as a substrate for active materials, enhancing the overall performance of the battery. This approach allows for higher energy density and better cycling stability compared to conventional lithium-ion batteries.Expand Specific Solutions03 Graphene-based supercapacitors

Graphene is utilized in the development of high-capacity supercapacitors. The large surface area of graphene enables the creation of electrodes with significantly increased capacitance. These supercapacitors can store more energy and provide higher power output compared to traditional capacitors, making them suitable for various applications requiring rapid energy storage and release.Expand Specific Solutions04 Graphene-metal oxide composites for battery electrodes

Combining graphene with metal oxides creates composite materials that can significantly enhance battery capacity. These composites leverage the high conductivity of graphene and the high theoretical capacity of metal oxides. The resulting electrodes demonstrate improved charge storage capabilities, better cycling performance, and increased overall battery capacity.Expand Specific Solutions05 Graphene-based flexible and wearable energy storage devices

Graphene's flexibility and high conductivity make it an ideal material for developing flexible and wearable energy storage devices with high capacity. These devices can be integrated into clothing or other wearable items, providing a portable power source with improved energy storage capabilities. The use of graphene allows for the creation of thin, lightweight, and high-capacity batteries suitable for various wearable applications.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery capacity enhancement market is in its early growth stage, with significant potential for expansion due to increasing demand for high-performance energy storage solutions. The market size is projected to grow substantially as research progresses and commercial applications emerge. Technologically, graphene batteries are still evolving, with companies like Northwestern University, Semiconductor Energy Laboratory, and Contemporary Amperex Technology leading research efforts. While not yet fully mature, the technology shows promise in overcoming limitations of traditional lithium-ion batteries. Key players such as SABIC Global Technologies and Panasonic Intellectual Property Management are actively developing innovative solutions, indicating a competitive landscape with both academic institutions and industry leaders vying for breakthroughs in this promising field.

Northwestern University

Technical Solution: Northwestern University has developed a novel approach to boost graphene battery capacity for energy storage. Their research focuses on creating a 3D graphene foam structure that serves as a highly conductive scaffold for lithium metal anodes. This structure allows for uniform lithium deposition and helps prevent dendrite formation, a common issue in lithium-metal batteries. The 3D graphene foam is synthesized using chemical vapor deposition (CVD) and has a high surface area, which enables faster charge transfer and improved energy density[1]. Additionally, the team has explored doping the graphene foam with nitrogen to further enhance its electrochemical properties and stability[3].

Strengths: High surface area for improved energy density, prevention of dendrite formation, and enhanced charge transfer. Weaknesses: Potential scalability issues for mass production and higher manufacturing costs compared to traditional electrode materials.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has made significant strides in graphene-enhanced battery technology for energy storage. Their approach involves incorporating graphene into lithium-ion battery cathodes and anodes to improve overall performance. CATL's graphene-based batteries utilize a proprietary graphene coating process that enhances the conductivity and stability of electrode materials. This results in faster charging rates, increased energy density, and improved cycle life[2]. The company has also developed a graphene-silicon composite anode material that significantly boosts the battery's capacity while maintaining structural integrity during charge-discharge cycles[4]. CATL's graphene batteries have shown up to 30% increase in energy density compared to conventional lithium-ion batteries[5].

Strengths: Improved energy density, faster charging rates, and enhanced cycle life. Weaknesses: Higher production costs and potential challenges in large-scale manufacturing of graphene-enhanced materials.

Graphene Battery Capacity Innovations

Reduced graphene-based material

PatentActiveUS20210230002A1

Innovation

- A reduced graphene-based material with a coating containing lithium, phosphorus, fluorine, and oxygen, derived from lithium difluorophosphate, is used for the negative electrode, improving the charge/discharge efficiency by suppressing side reactions and reducing irreversible capacity.

Method for increasing electric energy storage capability of graphine materials

PatentActiveKR1020160079334A

Innovation

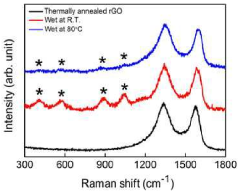

- Heat-treating graphene or graphene-containing materials at 60 to 100°C in the presence of acids like sulfuric, nitric, or hydrochloric acid modifies the surface, forming micro-sized structures to improve electrical energy storage capacity.

Environmental Impact of Graphene Batteries

The environmental impact of graphene batteries is a crucial consideration as this technology advances towards widespread adoption. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers significant advantages in energy storage applications. However, its production and use in batteries also raise important environmental concerns that must be addressed.

The manufacturing process of graphene can be energy-intensive, potentially contributing to increased carbon emissions if not managed properly. Traditional methods of graphene production, such as chemical vapor deposition, often require high temperatures and the use of harmful chemicals. However, recent advancements in eco-friendly production techniques, such as electrochemical exfoliation and green reduction methods, show promise in reducing the environmental footprint of graphene synthesis.

In terms of battery lifecycle, graphene-enhanced batteries have the potential to significantly reduce environmental impact. Their improved energy density and longer lifespan mean fewer batteries need to be produced and disposed of over time. This reduction in battery turnover can lead to decreased mining activities for raw materials and less electronic waste, both of which are significant environmental concerns associated with conventional battery technologies.

The recyclability of graphene batteries is another important factor to consider. While graphene itself is a form of carbon and theoretically recyclable, the complex composition of battery systems presents challenges. Research is ongoing to develop efficient recycling processes for graphene-based energy storage devices, which could further mitigate their environmental impact and contribute to a more circular economy in the energy sector.

Water usage and potential contamination during graphene production and battery manufacturing are additional environmental considerations. Efforts are being made to develop water-efficient production methods and to implement proper wastewater treatment processes to minimize the impact on local water resources.

When considering the end-of-life phase, graphene batteries may offer advantages in terms of reduced toxicity compared to some conventional battery chemistries. However, proper disposal and recycling infrastructure must be developed to handle these advanced materials effectively and prevent environmental contamination.

The potential for graphene batteries to enable more efficient renewable energy storage systems could indirectly contribute to significant environmental benefits. By improving the performance and reliability of energy storage solutions, graphene batteries could facilitate greater integration of intermittent renewable energy sources into the grid, potentially reducing reliance on fossil fuels and lowering overall carbon emissions in the energy sector.

The manufacturing process of graphene can be energy-intensive, potentially contributing to increased carbon emissions if not managed properly. Traditional methods of graphene production, such as chemical vapor deposition, often require high temperatures and the use of harmful chemicals. However, recent advancements in eco-friendly production techniques, such as electrochemical exfoliation and green reduction methods, show promise in reducing the environmental footprint of graphene synthesis.

In terms of battery lifecycle, graphene-enhanced batteries have the potential to significantly reduce environmental impact. Their improved energy density and longer lifespan mean fewer batteries need to be produced and disposed of over time. This reduction in battery turnover can lead to decreased mining activities for raw materials and less electronic waste, both of which are significant environmental concerns associated with conventional battery technologies.

The recyclability of graphene batteries is another important factor to consider. While graphene itself is a form of carbon and theoretically recyclable, the complex composition of battery systems presents challenges. Research is ongoing to develop efficient recycling processes for graphene-based energy storage devices, which could further mitigate their environmental impact and contribute to a more circular economy in the energy sector.

Water usage and potential contamination during graphene production and battery manufacturing are additional environmental considerations. Efforts are being made to develop water-efficient production methods and to implement proper wastewater treatment processes to minimize the impact on local water resources.

When considering the end-of-life phase, graphene batteries may offer advantages in terms of reduced toxicity compared to some conventional battery chemistries. However, proper disposal and recycling infrastructure must be developed to handle these advanced materials effectively and prevent environmental contamination.

The potential for graphene batteries to enable more efficient renewable energy storage systems could indirectly contribute to significant environmental benefits. By improving the performance and reliability of energy storage solutions, graphene batteries could facilitate greater integration of intermittent renewable energy sources into the grid, potentially reducing reliance on fossil fuels and lowering overall carbon emissions in the energy sector.

Graphene Battery Manufacturing Processes

The manufacturing processes for graphene batteries are crucial in determining their performance and capacity for energy storage. The production of graphene-based electrodes typically begins with the synthesis of high-quality graphene materials. Common methods include chemical vapor deposition (CVD), liquid-phase exfoliation, and reduction of graphene oxide. Each method has its advantages and challenges, impacting the final battery performance.

CVD allows for the growth of large-area, high-quality graphene sheets, but it is often limited by scalability and cost. Liquid-phase exfoliation offers a more scalable approach, producing graphene flakes that can be easily incorporated into battery electrodes. The reduction of graphene oxide is another widely used method, offering a balance between quality and scalability.

Once the graphene material is produced, it is typically combined with other materials to form composite electrodes. This process often involves mixing graphene with active materials such as silicon or metal oxides to enhance capacity and stability. The mixture is then coated onto current collectors, usually copper or aluminum foils, using techniques such as doctor blade coating or roll-to-roll processing.

The next critical step is the drying and calendering of the electrode material. Proper drying ensures the removal of solvents and helps in achieving the desired porosity. Calendering, which involves passing the electrode through rollers under pressure, helps in achieving the optimal density and thickness for improved performance.

Assembly of the battery cells follows, where the graphene-based electrodes are combined with separators and electrolytes. The choice of electrolyte is crucial, as it must be compatible with the graphene material and provide efficient ion transport. Advanced electrolytes, including solid-state or gel polymer electrolytes, are being explored to enhance safety and performance.

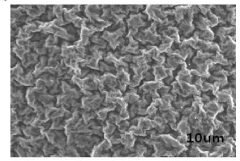

Quality control is a critical aspect of the manufacturing process. Techniques such as Raman spectroscopy, scanning electron microscopy (SEM), and X-ray diffraction (XRD) are employed to assess the quality and uniformity of the graphene materials and electrodes. These methods help in ensuring consistency and identifying potential defects that could impact battery performance.

Innovations in manufacturing processes are continually being developed to address challenges and improve performance. These include the development of 3D graphene structures, which can significantly increase the surface area and ion transport pathways. Additionally, techniques for creating defect-engineered graphene are being explored to enhance specific capacities and rate capabilities.

CVD allows for the growth of large-area, high-quality graphene sheets, but it is often limited by scalability and cost. Liquid-phase exfoliation offers a more scalable approach, producing graphene flakes that can be easily incorporated into battery electrodes. The reduction of graphene oxide is another widely used method, offering a balance between quality and scalability.

Once the graphene material is produced, it is typically combined with other materials to form composite electrodes. This process often involves mixing graphene with active materials such as silicon or metal oxides to enhance capacity and stability. The mixture is then coated onto current collectors, usually copper or aluminum foils, using techniques such as doctor blade coating or roll-to-roll processing.

The next critical step is the drying and calendering of the electrode material. Proper drying ensures the removal of solvents and helps in achieving the desired porosity. Calendering, which involves passing the electrode through rollers under pressure, helps in achieving the optimal density and thickness for improved performance.

Assembly of the battery cells follows, where the graphene-based electrodes are combined with separators and electrolytes. The choice of electrolyte is crucial, as it must be compatible with the graphene material and provide efficient ion transport. Advanced electrolytes, including solid-state or gel polymer electrolytes, are being explored to enhance safety and performance.

Quality control is a critical aspect of the manufacturing process. Techniques such as Raman spectroscopy, scanning electron microscopy (SEM), and X-ray diffraction (XRD) are employed to assess the quality and uniformity of the graphene materials and electrodes. These methods help in ensuring consistency and identifying potential defects that could impact battery performance.

Innovations in manufacturing processes are continually being developed to address challenges and improve performance. These include the development of 3D graphene structures, which can significantly increase the surface area and ion transport pathways. Additionally, techniques for creating defect-engineered graphene are being explored to enhance specific capacities and rate capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!