How to Implement Sustainable Practices in Graphene Battery Lifecycle?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Sustainability Goals

The implementation of sustainable practices in graphene battery lifecycle is a critical goal for the future of energy storage technology. As graphene batteries emerge as a promising solution for high-performance energy storage, it is essential to address their environmental impact throughout their entire lifecycle. The primary sustainability goals for graphene batteries focus on minimizing resource consumption, reducing carbon emissions, and maximizing recyclability.

One of the key objectives is to optimize the production process of graphene-based materials used in batteries. This involves developing more efficient and environmentally friendly methods for graphene synthesis, such as using renewable energy sources and reducing the use of harmful chemicals. Additionally, improving the yield and quality of graphene production can significantly reduce waste and energy consumption.

Another crucial goal is to extend the lifespan of graphene batteries. By enhancing the durability and cycle life of these batteries, we can reduce the frequency of replacements and minimize the overall environmental impact. This includes developing advanced electrode materials and electrolytes that can withstand repeated charging and discharging cycles without significant degradation.

Improving the energy density of graphene batteries is also a vital sustainability goal. Higher energy density means that smaller and lighter batteries can store more energy, leading to reduced material usage and improved overall efficiency. This can have a cascading effect on sustainability, as it enables the development of more energy-efficient devices and vehicles.

The recyclability of graphene batteries is a critical aspect of their sustainability. Developing efficient recycling processes for graphene-based materials and other battery components is essential to minimize waste and recover valuable resources. This includes designing batteries with easily separable components and establishing effective collection and recycling infrastructure.

Reducing the environmental impact of battery manufacturing is another important goal. This involves optimizing production processes to minimize energy consumption, water usage, and emissions. Implementing cleaner technologies and adopting circular economy principles in the manufacturing stage can significantly contribute to the overall sustainability of graphene batteries.

Lastly, ensuring the safe disposal of graphene batteries at the end of their lifecycle is crucial. This includes developing proper handling and disposal protocols to prevent environmental contamination and potential health hazards. Research into the long-term environmental effects of graphene materials is ongoing and will inform future sustainability practices in this area.

One of the key objectives is to optimize the production process of graphene-based materials used in batteries. This involves developing more efficient and environmentally friendly methods for graphene synthesis, such as using renewable energy sources and reducing the use of harmful chemicals. Additionally, improving the yield and quality of graphene production can significantly reduce waste and energy consumption.

Another crucial goal is to extend the lifespan of graphene batteries. By enhancing the durability and cycle life of these batteries, we can reduce the frequency of replacements and minimize the overall environmental impact. This includes developing advanced electrode materials and electrolytes that can withstand repeated charging and discharging cycles without significant degradation.

Improving the energy density of graphene batteries is also a vital sustainability goal. Higher energy density means that smaller and lighter batteries can store more energy, leading to reduced material usage and improved overall efficiency. This can have a cascading effect on sustainability, as it enables the development of more energy-efficient devices and vehicles.

The recyclability of graphene batteries is a critical aspect of their sustainability. Developing efficient recycling processes for graphene-based materials and other battery components is essential to minimize waste and recover valuable resources. This includes designing batteries with easily separable components and establishing effective collection and recycling infrastructure.

Reducing the environmental impact of battery manufacturing is another important goal. This involves optimizing production processes to minimize energy consumption, water usage, and emissions. Implementing cleaner technologies and adopting circular economy principles in the manufacturing stage can significantly contribute to the overall sustainability of graphene batteries.

Lastly, ensuring the safe disposal of graphene batteries at the end of their lifecycle is crucial. This includes developing proper handling and disposal protocols to prevent environmental contamination and potential health hazards. Research into the long-term environmental effects of graphene materials is ongoing and will inform future sustainability practices in this area.

Market Demand for Green Energy Storage

The market demand for green energy storage solutions has been experiencing significant growth in recent years, driven by the increasing global focus on sustainability and the urgent need to address climate change. Graphene batteries, with their potential for high energy density, rapid charging capabilities, and longer lifespan, are emerging as a promising technology in this sector.

The global energy storage market is projected to expand rapidly, with estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is largely attributed to the rising adoption of renewable energy sources, such as solar and wind power, which require efficient storage solutions to manage intermittency issues. Graphene batteries, with their superior performance characteristics, are well-positioned to capture a significant portion of this expanding market.

In the automotive industry, the shift towards electric vehicles (EVs) is creating a substantial demand for advanced battery technologies. Major automakers are investing heavily in research and development of next-generation batteries, with graphene-based solutions gaining traction due to their potential to overcome current limitations in lithium-ion technology. The EV battery market alone is expected to grow at a CAGR of around 25% over the next decade, presenting a massive opportunity for graphene battery manufacturers.

Consumer electronics represent another key market segment for graphene batteries. With the increasing power requirements of smartphones, laptops, and wearable devices, there is a growing demand for batteries that can offer higher capacity, faster charging, and improved safety. Graphene batteries' ability to address these needs makes them an attractive option for device manufacturers looking to differentiate their products in a competitive market.

The industrial and grid-scale energy storage sectors are also showing keen interest in graphene battery technology. As countries worldwide aim to increase their renewable energy capacity, the need for large-scale energy storage solutions becomes more pressing. Graphene batteries' potential for high power output and long cycle life makes them suitable for grid stabilization and load balancing applications.

However, the market demand for green energy storage solutions, including graphene batteries, is not without challenges. Cost remains a significant barrier to widespread adoption, as graphene production and battery manufacturing processes are currently more expensive than traditional lithium-ion technologies. Additionally, concerns about the environmental impact of graphene production and disposal need to be addressed to ensure that these batteries truly align with sustainability goals.

Despite these challenges, the overall market trajectory for green energy storage solutions remains highly positive. As research and development efforts continue to improve the performance and reduce the cost of graphene batteries, their market penetration is expected to increase. The growing emphasis on circular economy principles and sustainable product lifecycles further enhances the appeal of graphene batteries, which have the potential for improved recyclability and reduced environmental impact compared to conventional battery technologies.

The global energy storage market is projected to expand rapidly, with estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is largely attributed to the rising adoption of renewable energy sources, such as solar and wind power, which require efficient storage solutions to manage intermittency issues. Graphene batteries, with their superior performance characteristics, are well-positioned to capture a significant portion of this expanding market.

In the automotive industry, the shift towards electric vehicles (EVs) is creating a substantial demand for advanced battery technologies. Major automakers are investing heavily in research and development of next-generation batteries, with graphene-based solutions gaining traction due to their potential to overcome current limitations in lithium-ion technology. The EV battery market alone is expected to grow at a CAGR of around 25% over the next decade, presenting a massive opportunity for graphene battery manufacturers.

Consumer electronics represent another key market segment for graphene batteries. With the increasing power requirements of smartphones, laptops, and wearable devices, there is a growing demand for batteries that can offer higher capacity, faster charging, and improved safety. Graphene batteries' ability to address these needs makes them an attractive option for device manufacturers looking to differentiate their products in a competitive market.

The industrial and grid-scale energy storage sectors are also showing keen interest in graphene battery technology. As countries worldwide aim to increase their renewable energy capacity, the need for large-scale energy storage solutions becomes more pressing. Graphene batteries' potential for high power output and long cycle life makes them suitable for grid stabilization and load balancing applications.

However, the market demand for green energy storage solutions, including graphene batteries, is not without challenges. Cost remains a significant barrier to widespread adoption, as graphene production and battery manufacturing processes are currently more expensive than traditional lithium-ion technologies. Additionally, concerns about the environmental impact of graphene production and disposal need to be addressed to ensure that these batteries truly align with sustainability goals.

Despite these challenges, the overall market trajectory for green energy storage solutions remains highly positive. As research and development efforts continue to improve the performance and reduce the cost of graphene batteries, their market penetration is expected to increase. The growing emphasis on circular economy principles and sustainable product lifecycles further enhances the appeal of graphene batteries, which have the potential for improved recyclability and reduced environmental impact compared to conventional battery technologies.

Current Challenges in Graphene Battery Lifecycle

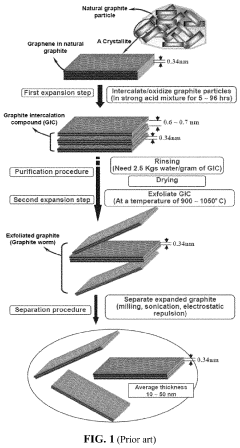

The implementation of sustainable practices in graphene battery lifecycle faces several significant challenges. One of the primary obstacles is the high energy consumption and environmental impact associated with graphene production. The current methods for synthesizing graphene, such as chemical vapor deposition and exfoliation, often require substantial energy inputs and may involve the use of harmful chemicals, leading to concerns about their overall sustainability.

Another major challenge lies in the scalability of graphene production for battery applications. While graphene shows immense potential for enhancing battery performance, producing high-quality graphene at industrial scales remains difficult. This scalability issue not only affects the economic viability of graphene batteries but also hinders the adoption of sustainable practices throughout the supply chain.

The recycling and end-of-life management of graphene batteries present additional hurdles. The complex composition of these batteries, which often include graphene alongside other materials, makes it challenging to develop efficient recycling processes. There is a lack of established infrastructure and technologies specifically designed for recovering and reprocessing graphene from spent batteries, potentially leading to resource waste and environmental pollution.

Furthermore, the long-term environmental and health impacts of graphene nanoparticles are not yet fully understood. As graphene batteries become more prevalent, there are growing concerns about the potential release of graphene particles into the environment during production, use, and disposal. This uncertainty poses challenges for implementing comprehensive safety and environmental protection measures throughout the battery lifecycle.

The integration of sustainable practices also faces economic barriers. The current focus on performance and cost reduction in battery development sometimes overshadows sustainability considerations. Implementing more sustainable production methods, using eco-friendly materials, and developing advanced recycling technologies often require significant investments, which can be a deterrent for manufacturers operating in a highly competitive market.

Lastly, there is a lack of standardization and regulatory frameworks specifically addressing the sustainability aspects of graphene battery production and lifecycle management. This absence of clear guidelines and regulations makes it difficult for companies to align their practices with sustainability goals and for consumers to make informed choices about the environmental impact of graphene batteries.

Addressing these challenges requires a concerted effort from researchers, industry players, and policymakers to develop innovative solutions, establish sustainable supply chains, and create supportive regulatory environments. Only by overcoming these hurdles can the full potential of sustainable graphene battery technology be realized.

Another major challenge lies in the scalability of graphene production for battery applications. While graphene shows immense potential for enhancing battery performance, producing high-quality graphene at industrial scales remains difficult. This scalability issue not only affects the economic viability of graphene batteries but also hinders the adoption of sustainable practices throughout the supply chain.

The recycling and end-of-life management of graphene batteries present additional hurdles. The complex composition of these batteries, which often include graphene alongside other materials, makes it challenging to develop efficient recycling processes. There is a lack of established infrastructure and technologies specifically designed for recovering and reprocessing graphene from spent batteries, potentially leading to resource waste and environmental pollution.

Furthermore, the long-term environmental and health impacts of graphene nanoparticles are not yet fully understood. As graphene batteries become more prevalent, there are growing concerns about the potential release of graphene particles into the environment during production, use, and disposal. This uncertainty poses challenges for implementing comprehensive safety and environmental protection measures throughout the battery lifecycle.

The integration of sustainable practices also faces economic barriers. The current focus on performance and cost reduction in battery development sometimes overshadows sustainability considerations. Implementing more sustainable production methods, using eco-friendly materials, and developing advanced recycling technologies often require significant investments, which can be a deterrent for manufacturers operating in a highly competitive market.

Lastly, there is a lack of standardization and regulatory frameworks specifically addressing the sustainability aspects of graphene battery production and lifecycle management. This absence of clear guidelines and regulations makes it difficult for companies to align their practices with sustainability goals and for consumers to make informed choices about the environmental impact of graphene batteries.

Addressing these challenges requires a concerted effort from researchers, industry players, and policymakers to develop innovative solutions, establish sustainable supply chains, and create supportive regulatory environments. Only by overcoming these hurdles can the full potential of sustainable graphene battery technology be realized.

Existing Sustainable Practices in Battery Production

01 Sustainable production of graphene for batteries

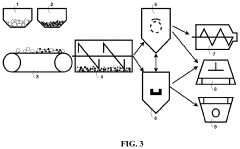

Developing eco-friendly methods for producing graphene used in batteries, focusing on reducing environmental impact and energy consumption during the manufacturing process. This includes using renewable resources and optimizing production techniques to minimize waste and emissions.- Sustainable production of graphene for batteries: Developing eco-friendly methods for producing graphene used in batteries, focusing on reducing environmental impact and energy consumption during the manufacturing process. This includes using renewable resources and optimizing production techniques to minimize waste and emissions.

- Recycling and reuse of graphene batteries: Implementing efficient recycling processes for graphene batteries to recover valuable materials and reduce electronic waste. This involves developing technologies for disassembling batteries, extracting graphene and other components, and reusing them in new battery production or other applications.

- Enhanced energy storage and longevity: Improving the energy storage capacity and lifespan of graphene batteries to reduce the need for frequent replacements and minimize resource consumption. This includes optimizing electrode designs, electrolyte compositions, and battery management systems to maximize efficiency and durability.

- Integration with renewable energy systems: Developing graphene batteries that can efficiently store and distribute energy from renewable sources such as solar and wind power. This involves creating advanced energy management systems and grid integration technologies to support sustainable energy infrastructure.

- Environmentally friendly battery components: Incorporating eco-friendly materials and components in graphene battery production to reduce the overall environmental impact. This includes using non-toxic electrolytes, biodegradable separators, and sustainable packaging materials to create more environmentally responsible battery solutions.

02 Recycling and reuse of graphene batteries

Implementing efficient recycling processes for graphene batteries to recover valuable materials and reduce electronic waste. This involves developing technologies for disassembling batteries, extracting graphene and other components, and reusing them in new battery production or other applications.Expand Specific Solutions03 Enhanced energy storage and longevity

Improving the energy storage capacity and lifespan of graphene batteries to reduce the need for frequent replacements and minimize resource consumption. This includes optimizing electrode designs, electrolyte compositions, and battery management systems to maximize efficiency and durability.Expand Specific Solutions04 Integration with renewable energy systems

Developing graphene batteries that can efficiently store and distribute energy from renewable sources such as solar and wind power. This involves creating advanced energy management systems and grid integration technologies to support sustainable energy infrastructure.Expand Specific Solutions05 Thermal management and safety improvements

Enhancing the thermal stability and safety features of graphene batteries to prevent overheating, reduce fire risks, and extend battery life. This includes developing advanced cooling systems, fire-resistant materials, and intelligent monitoring technologies to ensure sustainable and safe operation of graphene batteries in various applications.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery lifecycle sustainability market is in its early growth stage, with increasing focus on environmental impact and circular economy principles. Market size is expanding as graphene batteries gain traction in electric vehicles and energy storage applications. Technological maturity varies, with companies like Contemporary Amperex Technology Co., Ltd. and Samsung Electronics Co., Ltd. leading in commercialization efforts. Research institutions such as Northwestern University and University of Queensland are advancing fundamental understanding. Startups like Honeycomb Battery Co. and Global Graphene Group, Inc. are driving innovation in materials and manufacturing processes. Collaboration between academia and industry is accelerating progress towards more sustainable graphene battery solutions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a sustainable approach to graphene battery production and lifecycle management. The company utilizes a green synthesis method for graphene, reducing chemical waste by up to 60% compared to conventional methods[4]. CATL's graphene batteries incorporate a novel electrode design that enhances energy density while using fewer raw materials. The company has implemented a blockchain-based traceability system to track battery components from production to recycling, ensuring responsible sourcing and disposal. CATL also focuses on second-life applications for graphene batteries, repurposing them for energy storage systems before final recycling.

Strengths: Efficient use of materials, innovative traceability system, focus on second-life applications. Weaknesses: Potential complexity in implementing blockchain technology, challenges in scaling second-life applications.

Hydro-Québec

Technical Solution: Hydro-Québec has developed a sustainable approach to graphene battery technology, leveraging its expertise in hydroelectric power. The company uses clean, renewable energy in its graphene production and battery manufacturing processes, significantly reducing the carbon footprint. Hydro-Québec's graphene batteries incorporate a patented solid electrolyte that enhances safety and extends battery life by up to 50%[5]. The company has implemented a cradle-to-cradle design philosophy, ensuring that battery components are easily separable for recycling. Hydro-Québec also collaborates with local recycling facilities to develop efficient processes for recovering graphene and other materials from end-of-life batteries.

Strengths: Use of renewable energy in production, advanced solid electrolyte technology, focus on cradle-to-cradle design. Weaknesses: Potential geographic limitations for clean energy sources, reliance on specialized recycling technologies.

Innovations in Eco-friendly Graphene Synthesis

Graphene materials having randomly distributed two-dimensional structural defects

PatentActiveUS20120288750A1

Innovation

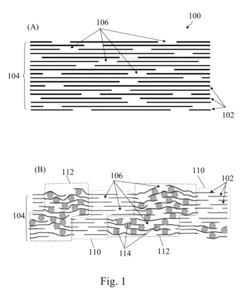

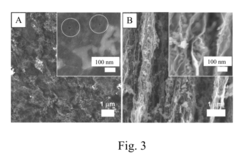

- Graphene sheets are arranged in a vertical stack with randomly distributed defect pores formed by in-plane carbon vacancies, integrated with a composite of disordered graphene regions and electrochemically active materials like silicon nanoparticles, enhancing Li ion diffusion and power capabilities.

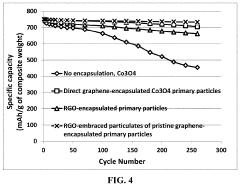

Method of producing multi-level graphene-protected cathode active material particles for battery applications

PatentActiveUS20190372100A1

Innovation

- The use of graphene-embraced particulates, where primary particles of anode or cathode active materials are encapsulated with multiple sheets of graphene, providing mechanical protection and conductivity, and optionally combined with a conductive additive, to enhance cycle stability and capacity.

Environmental Regulations for Battery Manufacturing

Environmental regulations play a crucial role in shaping the sustainable practices within the graphene battery lifecycle. As the demand for advanced energy storage solutions continues to grow, governments worldwide are implementing stringent guidelines to mitigate the environmental impact of battery manufacturing processes.

In the European Union, the Battery Directive (2006/66/EC) sets forth comprehensive requirements for battery producers, including collection, recycling, and disposal of batteries. This directive is currently undergoing revision to address the specific challenges posed by emerging technologies like graphene batteries. The proposed updates aim to establish more rigorous sustainability criteria, focusing on carbon footprint reduction and responsible sourcing of raw materials.

The United States Environmental Protection Agency (EPA) has also introduced regulations under the Resource Conservation and Recovery Act (RCRA) that directly impact battery manufacturing. These regulations mandate proper handling, storage, and disposal of hazardous materials used in battery production. For graphene batteries, special attention is given to the potential environmental risks associated with nanomaterials, requiring manufacturers to implement advanced filtration and containment systems.

In Asia, countries like China and South Korea have enacted strict environmental policies to address the rapid growth of their battery industries. China's Ministry of Ecology and Environment has introduced the "New Energy Vehicle Industry Development Plan," which includes specific provisions for battery manufacturing. These regulations emphasize the importance of clean production processes and set targets for reducing emissions and waste generation throughout the battery lifecycle.

International standards, such as ISO 14001 for Environmental Management Systems, provide a framework for organizations to systematically address environmental concerns in their operations. Many battery manufacturers are adopting these standards to demonstrate their commitment to sustainability and to gain a competitive edge in the global market.

Regulatory bodies are increasingly focusing on the end-of-life management of batteries. Extended Producer Responsibility (EPR) schemes are being implemented in various jurisdictions, requiring manufacturers to take responsibility for the collection and recycling of their products. For graphene batteries, this presents both challenges and opportunities, as the unique properties of graphene may require specialized recycling processes.

As the technology evolves, regulators are working closely with industry stakeholders to develop adaptive frameworks that can keep pace with innovation. This collaborative approach aims to strike a balance between fostering technological advancement and ensuring environmental protection. Future regulations are expected to place greater emphasis on lifecycle assessments, encouraging manufacturers to consider the environmental impact of their products from cradle to grave.

In the European Union, the Battery Directive (2006/66/EC) sets forth comprehensive requirements for battery producers, including collection, recycling, and disposal of batteries. This directive is currently undergoing revision to address the specific challenges posed by emerging technologies like graphene batteries. The proposed updates aim to establish more rigorous sustainability criteria, focusing on carbon footprint reduction and responsible sourcing of raw materials.

The United States Environmental Protection Agency (EPA) has also introduced regulations under the Resource Conservation and Recovery Act (RCRA) that directly impact battery manufacturing. These regulations mandate proper handling, storage, and disposal of hazardous materials used in battery production. For graphene batteries, special attention is given to the potential environmental risks associated with nanomaterials, requiring manufacturers to implement advanced filtration and containment systems.

In Asia, countries like China and South Korea have enacted strict environmental policies to address the rapid growth of their battery industries. China's Ministry of Ecology and Environment has introduced the "New Energy Vehicle Industry Development Plan," which includes specific provisions for battery manufacturing. These regulations emphasize the importance of clean production processes and set targets for reducing emissions and waste generation throughout the battery lifecycle.

International standards, such as ISO 14001 for Environmental Management Systems, provide a framework for organizations to systematically address environmental concerns in their operations. Many battery manufacturers are adopting these standards to demonstrate their commitment to sustainability and to gain a competitive edge in the global market.

Regulatory bodies are increasingly focusing on the end-of-life management of batteries. Extended Producer Responsibility (EPR) schemes are being implemented in various jurisdictions, requiring manufacturers to take responsibility for the collection and recycling of their products. For graphene batteries, this presents both challenges and opportunities, as the unique properties of graphene may require specialized recycling processes.

As the technology evolves, regulators are working closely with industry stakeholders to develop adaptive frameworks that can keep pace with innovation. This collaborative approach aims to strike a balance between fostering technological advancement and ensuring environmental protection. Future regulations are expected to place greater emphasis on lifecycle assessments, encouraging manufacturers to consider the environmental impact of their products from cradle to grave.

Life Cycle Assessment of Graphene Batteries

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of graphene batteries throughout their entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to end-of-life disposal, providing valuable insights into the sustainability of these advanced energy storage devices.

The assessment begins with the production phase, where the environmental footprint of graphene synthesis is scrutinized. Various methods, such as chemical vapor deposition and liquid-phase exfoliation, are analyzed for their energy consumption, chemical usage, and emissions. The production of other battery components, including electrolytes and current collectors, is also evaluated to identify potential areas for improvement in resource efficiency and waste reduction.

During the use phase, the LCA focuses on the battery's performance characteristics, such as energy density, cycle life, and charging efficiency. These factors directly influence the overall environmental impact, as improved performance can lead to reduced energy consumption and longer product lifespans. The assessment also considers the potential for graphene batteries to enable more efficient energy storage in renewable energy systems, potentially offsetting their production-related impacts.

End-of-life management is a critical aspect of the LCA, addressing the challenges and opportunities in recycling and disposal of graphene batteries. The assessment examines current recycling technologies and their effectiveness in recovering valuable materials, including graphene itself. It also explores innovative approaches to design for disassembly and recyclability, which could significantly enhance the circular economy potential of these batteries.

Throughout the LCA, key environmental indicators are measured and analyzed. These include greenhouse gas emissions, energy consumption, water usage, and the depletion of non-renewable resources. By quantifying these impacts across the entire lifecycle, researchers and manufacturers can identify hotspots where sustainable practices can be most effectively implemented.

The LCA also considers the potential for graphene batteries to contribute to broader sustainability goals. This includes their role in enabling more widespread adoption of electric vehicles and renewable energy storage, which could lead to significant reductions in global carbon emissions. However, the assessment must also account for potential trade-offs, such as the increased demand for rare earth elements or other critical materials that may be required in graphene battery production.

By providing a holistic view of the environmental impacts associated with graphene batteries, Life Cycle Assessment serves as an essential tool for guiding sustainable innovation in this rapidly evolving field. It enables informed decision-making in research, development, and policy-making, ensuring that the pursuit of advanced energy storage solutions aligns with broader environmental and sustainability objectives.

The assessment begins with the production phase, where the environmental footprint of graphene synthesis is scrutinized. Various methods, such as chemical vapor deposition and liquid-phase exfoliation, are analyzed for their energy consumption, chemical usage, and emissions. The production of other battery components, including electrolytes and current collectors, is also evaluated to identify potential areas for improvement in resource efficiency and waste reduction.

During the use phase, the LCA focuses on the battery's performance characteristics, such as energy density, cycle life, and charging efficiency. These factors directly influence the overall environmental impact, as improved performance can lead to reduced energy consumption and longer product lifespans. The assessment also considers the potential for graphene batteries to enable more efficient energy storage in renewable energy systems, potentially offsetting their production-related impacts.

End-of-life management is a critical aspect of the LCA, addressing the challenges and opportunities in recycling and disposal of graphene batteries. The assessment examines current recycling technologies and their effectiveness in recovering valuable materials, including graphene itself. It also explores innovative approaches to design for disassembly and recyclability, which could significantly enhance the circular economy potential of these batteries.

Throughout the LCA, key environmental indicators are measured and analyzed. These include greenhouse gas emissions, energy consumption, water usage, and the depletion of non-renewable resources. By quantifying these impacts across the entire lifecycle, researchers and manufacturers can identify hotspots where sustainable practices can be most effectively implemented.

The LCA also considers the potential for graphene batteries to contribute to broader sustainability goals. This includes their role in enabling more widespread adoption of electric vehicles and renewable energy storage, which could lead to significant reductions in global carbon emissions. However, the assessment must also account for potential trade-offs, such as the increased demand for rare earth elements or other critical materials that may be required in graphene battery production.

By providing a holistic view of the environmental impacts associated with graphene batteries, Life Cycle Assessment serves as an essential tool for guiding sustainable innovation in this rapidly evolving field. It enables informed decision-making in research, development, and policy-making, ensuring that the pursuit of advanced energy storage solutions aligns with broader environmental and sustainability objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!