How to Improve Graphene Battery Scalability?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries have emerged as a promising technology in the energy storage landscape, offering potential advantages over traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its applications across various fields, including energy storage.

The initial stages of graphene battery development focused on understanding the material's unique properties, such as its high electrical conductivity, mechanical strength, and large surface area. These characteristics suggested that graphene could significantly enhance battery performance by improving charge/discharge rates, energy density, and cycle life.

As research progressed, scientists began exploring different ways to incorporate graphene into battery components. Early attempts involved using graphene as an additive in electrode materials, which showed improvements in conductivity and stability. This led to the development of graphene-enhanced anodes and cathodes, demonstrating increased capacity and faster charging capabilities compared to conventional batteries.

The next phase of evolution saw the creation of graphene-based composite materials, combining graphene with other active materials to further enhance battery performance. These composites aimed to address specific challenges in battery technology, such as capacity fade and thermal management.

Recent advancements have focused on developing graphene-based electrolytes and separators, aiming to improve ion transport and overall battery safety. Researchers have also explored the potential of 3D graphene structures and graphene foams to create high-performance electrodes with enhanced surface area and conductivity.

The primary objectives in graphene battery development are centered around improving scalability, which is crucial for widespread adoption and commercialization. Key goals include:

1. Enhancing energy density to surpass current lithium-ion batteries, enabling longer-lasting devices and electric vehicles with extended range.

2. Improving power density to enable faster charging and discharging, addressing a major limitation of current battery technologies.

3. Increasing cycle life and stability to reduce battery degradation over time, leading to more sustainable and long-lasting energy storage solutions.

4. Developing cost-effective manufacturing processes to make graphene batteries economically viable for mass production and market adoption.

5. Addressing safety concerns associated with traditional lithium-ion batteries, such as thermal runaway and flammability issues.

6. Optimizing the integration of graphene materials into existing battery production lines to facilitate smoother industry transition.

As research continues, the focus remains on overcoming technical challenges and scaling up production to meet the growing demand for high-performance energy storage solutions across various sectors, including consumer electronics, electric vehicles, and grid-scale energy storage.

The initial stages of graphene battery development focused on understanding the material's unique properties, such as its high electrical conductivity, mechanical strength, and large surface area. These characteristics suggested that graphene could significantly enhance battery performance by improving charge/discharge rates, energy density, and cycle life.

As research progressed, scientists began exploring different ways to incorporate graphene into battery components. Early attempts involved using graphene as an additive in electrode materials, which showed improvements in conductivity and stability. This led to the development of graphene-enhanced anodes and cathodes, demonstrating increased capacity and faster charging capabilities compared to conventional batteries.

The next phase of evolution saw the creation of graphene-based composite materials, combining graphene with other active materials to further enhance battery performance. These composites aimed to address specific challenges in battery technology, such as capacity fade and thermal management.

Recent advancements have focused on developing graphene-based electrolytes and separators, aiming to improve ion transport and overall battery safety. Researchers have also explored the potential of 3D graphene structures and graphene foams to create high-performance electrodes with enhanced surface area and conductivity.

The primary objectives in graphene battery development are centered around improving scalability, which is crucial for widespread adoption and commercialization. Key goals include:

1. Enhancing energy density to surpass current lithium-ion batteries, enabling longer-lasting devices and electric vehicles with extended range.

2. Improving power density to enable faster charging and discharging, addressing a major limitation of current battery technologies.

3. Increasing cycle life and stability to reduce battery degradation over time, leading to more sustainable and long-lasting energy storage solutions.

4. Developing cost-effective manufacturing processes to make graphene batteries economically viable for mass production and market adoption.

5. Addressing safety concerns associated with traditional lithium-ion batteries, such as thermal runaway and flammability issues.

6. Optimizing the integration of graphene materials into existing battery production lines to facilitate smoother industry transition.

As research continues, the focus remains on overcoming technical challenges and scaling up production to meet the growing demand for high-performance energy storage solutions across various sectors, including consumer electronics, electric vehicles, and grid-scale energy storage.

Market Demand Analysis for Advanced Energy Storage

The market demand for advanced energy storage solutions, particularly those leveraging graphene technology, has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for high-performance, long-lasting, and environmentally friendly energy storage systems across various industries. The automotive sector, especially the electric vehicle (EV) market, stands at the forefront of this demand, as manufacturers seek batteries with higher energy density, faster charging capabilities, and improved longevity.

Consumer electronics represent another major market segment driving the demand for advanced energy storage. With the proliferation of smartphones, tablets, and wearable devices, there is a growing need for batteries that can provide longer usage times while maintaining compact form factors. Graphene-based batteries, with their potential for higher capacity and faster charging, are particularly attractive for these applications.

The renewable energy sector also contributes significantly to the market demand for advanced energy storage. As the world transitions towards cleaner energy sources, the need for efficient and large-scale energy storage systems to manage intermittent power generation from solar and wind sources becomes crucial. Graphene batteries, with their potential for improved energy density and cycle life, could play a pivotal role in addressing this challenge.

Industrial applications, including grid stabilization and backup power systems, represent another substantial market for advanced energy storage. The ability of graphene-enhanced batteries to handle high power outputs and rapid charge-discharge cycles makes them particularly suitable for these demanding applications.

Market analysts project robust growth for the advanced energy storage sector, with graphene batteries expected to capture an increasing share. However, the scalability of graphene battery production remains a critical factor in meeting this growing demand. Current manufacturing processes face challenges in producing graphene-based batteries at scale while maintaining consistent quality and performance.

To fully capitalize on the market potential, addressing the scalability issues of graphene battery production is paramount. This includes developing more efficient and cost-effective methods for graphene synthesis, improving the integration of graphene into battery components, and optimizing large-scale manufacturing processes. As these challenges are overcome, the market for graphene-based advanced energy storage solutions is expected to expand rapidly, potentially revolutionizing multiple industries and accelerating the transition to more sustainable energy systems.

Consumer electronics represent another major market segment driving the demand for advanced energy storage. With the proliferation of smartphones, tablets, and wearable devices, there is a growing need for batteries that can provide longer usage times while maintaining compact form factors. Graphene-based batteries, with their potential for higher capacity and faster charging, are particularly attractive for these applications.

The renewable energy sector also contributes significantly to the market demand for advanced energy storage. As the world transitions towards cleaner energy sources, the need for efficient and large-scale energy storage systems to manage intermittent power generation from solar and wind sources becomes crucial. Graphene batteries, with their potential for improved energy density and cycle life, could play a pivotal role in addressing this challenge.

Industrial applications, including grid stabilization and backup power systems, represent another substantial market for advanced energy storage. The ability of graphene-enhanced batteries to handle high power outputs and rapid charge-discharge cycles makes them particularly suitable for these demanding applications.

Market analysts project robust growth for the advanced energy storage sector, with graphene batteries expected to capture an increasing share. However, the scalability of graphene battery production remains a critical factor in meeting this growing demand. Current manufacturing processes face challenges in producing graphene-based batteries at scale while maintaining consistent quality and performance.

To fully capitalize on the market potential, addressing the scalability issues of graphene battery production is paramount. This includes developing more efficient and cost-effective methods for graphene synthesis, improving the integration of graphene into battery components, and optimizing large-scale manufacturing processes. As these challenges are overcome, the market for graphene-based advanced energy storage solutions is expected to expand rapidly, potentially revolutionizing multiple industries and accelerating the transition to more sustainable energy systems.

Current Challenges in Graphene Battery Scalability

Despite the promising potential of graphene batteries, several significant challenges hinder their scalability for widespread commercial adoption. One of the primary obstacles is the high production cost associated with graphene synthesis and battery manufacturing processes. The current methods for producing high-quality graphene at scale remain expensive and energy-intensive, making it difficult to compete with traditional lithium-ion batteries on a cost basis.

Another major challenge is the lack of standardization in graphene production and quality control. The inconsistency in graphene properties across different batches and suppliers leads to variability in battery performance, making it challenging to achieve reliable and reproducible results at scale. This inconsistency also complicates the integration of graphene into existing battery manufacturing processes.

The stability and long-term performance of graphene batteries pose additional scalability concerns. While graphene exhibits excellent theoretical properties, maintaining these characteristics over extended charge-discharge cycles in real-world applications remains a significant hurdle. Issues such as capacity fading, electrolyte degradation, and structural changes in the graphene electrodes during cycling need to be addressed to ensure the longevity and reliability required for commercial viability.

Furthermore, the integration of graphene into battery components presents technical challenges. Achieving uniform dispersion of graphene in electrode materials and electrolytes, as well as optimizing the interface between graphene and other battery components, are critical factors that impact performance and scalability. The development of scalable manufacturing techniques that can maintain the unique properties of graphene throughout the battery assembly process is essential.

Environmental and safety concerns also play a role in the scalability of graphene batteries. The potential health and environmental impacts of graphene nanoparticles are not yet fully understood, necessitating careful consideration and regulation in large-scale production and disposal processes. Additionally, ensuring the safety of graphene batteries under various operating conditions and potential failure modes is crucial for widespread adoption.

Lastly, the lack of a well-established supply chain for graphene materials and specialized battery components presents a significant barrier to scalability. The limited availability of high-quality graphene and the absence of a robust ecosystem of suppliers and manufacturers capable of meeting large-scale production demands hinder the rapid expansion of graphene battery technology.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, engineering, and manufacturing processes. Overcoming these hurdles is essential to unlock the full potential of graphene batteries and enable their scalable production for various applications, from portable electronics to electric vehicles and grid-scale energy storage systems.

Another major challenge is the lack of standardization in graphene production and quality control. The inconsistency in graphene properties across different batches and suppliers leads to variability in battery performance, making it challenging to achieve reliable and reproducible results at scale. This inconsistency also complicates the integration of graphene into existing battery manufacturing processes.

The stability and long-term performance of graphene batteries pose additional scalability concerns. While graphene exhibits excellent theoretical properties, maintaining these characteristics over extended charge-discharge cycles in real-world applications remains a significant hurdle. Issues such as capacity fading, electrolyte degradation, and structural changes in the graphene electrodes during cycling need to be addressed to ensure the longevity and reliability required for commercial viability.

Furthermore, the integration of graphene into battery components presents technical challenges. Achieving uniform dispersion of graphene in electrode materials and electrolytes, as well as optimizing the interface between graphene and other battery components, are critical factors that impact performance and scalability. The development of scalable manufacturing techniques that can maintain the unique properties of graphene throughout the battery assembly process is essential.

Environmental and safety concerns also play a role in the scalability of graphene batteries. The potential health and environmental impacts of graphene nanoparticles are not yet fully understood, necessitating careful consideration and regulation in large-scale production and disposal processes. Additionally, ensuring the safety of graphene batteries under various operating conditions and potential failure modes is crucial for widespread adoption.

Lastly, the lack of a well-established supply chain for graphene materials and specialized battery components presents a significant barrier to scalability. The limited availability of high-quality graphene and the absence of a robust ecosystem of suppliers and manufacturers capable of meeting large-scale production demands hinder the rapid expansion of graphene battery technology.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, engineering, and manufacturing processes. Overcoming these hurdles is essential to unlock the full potential of graphene batteries and enable their scalable production for various applications, from portable electronics to electric vehicles and grid-scale energy storage systems.

Existing Scalability Solutions for Graphene Batteries

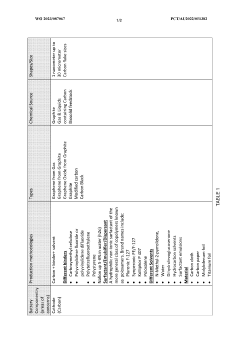

01 Mass production techniques for graphene-based electrodes

Various methods have been developed for large-scale production of graphene-based electrodes, including chemical vapor deposition, liquid-phase exfoliation, and roll-to-roll manufacturing processes. These techniques aim to increase the production capacity of graphene materials for battery applications, addressing the scalability challenge in graphene battery manufacturing.- Mass production techniques for graphene-based electrodes: Developing scalable methods for producing large quantities of graphene-based electrodes is crucial for the commercialization of graphene batteries. This includes techniques such as chemical vapor deposition, liquid-phase exfoliation, and roll-to-roll processing to manufacture high-quality graphene materials at industrial scales.

- Enhancing energy density and capacity: Improving the energy density and capacity of graphene batteries is essential for their scalability. This involves optimizing the graphene structure, increasing the active material loading, and developing novel electrode architectures to maximize the battery's performance while maintaining its scalability.

- Integration with existing battery manufacturing processes: Adapting graphene battery production to be compatible with current lithium-ion battery manufacturing processes is crucial for large-scale adoption. This includes developing methods to incorporate graphene materials into existing electrode fabrication and cell assembly lines without significant modifications to the production infrastructure.

- Addressing safety and stability concerns: Ensuring the safety and stability of graphene batteries at scale is critical for their widespread adoption. This involves developing strategies to prevent thermal runaway, improve cycle life, and enhance the overall reliability of graphene-based energy storage systems in large-scale applications.

- Cost-effective production of high-quality graphene: Developing economically viable methods for producing high-quality graphene materials is essential for the scalability of graphene batteries. This includes optimizing synthesis processes, reducing raw material costs, and improving the yield of graphene production to make graphene batteries competitive with traditional energy storage technologies.

02 Composite materials for enhanced scalability

Researchers have explored composite materials combining graphene with other materials like silicon, metal oxides, or polymers to improve the scalability of graphene batteries. These composites can enhance the mechanical stability, conductivity, and energy density of the electrodes while maintaining the benefits of graphene, making them more suitable for large-scale production.Expand Specific Solutions03 Optimization of graphene synthesis for battery applications

Efforts have been made to optimize graphene synthesis methods specifically for battery applications, focusing on controlling the thickness, defect density, and surface functionalization of graphene sheets. These optimizations aim to improve the electrochemical performance and scalability of graphene-based battery materials.Expand Specific Solutions04 Novel electrode designs for scalable graphene batteries

Innovative electrode designs have been proposed to address scalability issues in graphene batteries. These include 3D electrode structures, hierarchical porous electrodes, and hybrid electrode configurations that combine graphene with other materials. Such designs aim to maximize the surface area and improve the overall performance of graphene-based batteries at larger scales.Expand Specific Solutions05 Integration of graphene in existing battery manufacturing processes

Researchers have explored ways to integrate graphene materials into existing battery manufacturing processes to enhance scalability. This includes developing graphene-based slurries compatible with current electrode coating techniques, as well as modifying assembly processes to accommodate graphene-enhanced components without significant changes to production lines.Expand Specific Solutions

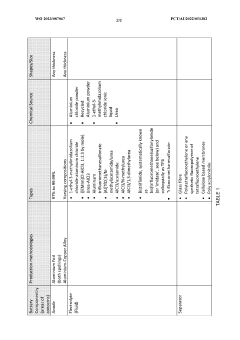

Key Players in Graphene Battery Development

The graphene battery scalability landscape is evolving rapidly, with the industry in its early growth phase. The market size is expanding, driven by increasing demand for high-performance energy storage solutions. Technological maturity varies among key players, with companies like Contemporary Amperex Technology Co., Ltd. and BYD Co., Ltd. leading in commercialization efforts. Research institutions such as Northwestern University and The University of Queensland are advancing fundamental understanding. Emerging players like NanoXplore, Inc. and Honeycomb Battery Co. are focusing on innovative production methods. The competitive field includes established materials companies like Toray Industries, Inc. and SABIC Global Technologies BV, alongside specialized graphene producers, creating a diverse ecosystem poised for significant advancements in graphene battery scalability.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL, a leading battery manufacturer, has been actively researching graphene-enhanced batteries to improve scalability and performance. Their approach involves incorporating graphene into existing lithium-ion battery technologies to enhance conductivity and structural stability. CATL has developed a graphene-based fast-charging battery that can achieve 80% charge in 15 minutes[3]. They are also working on graphene-enhanced silicon anodes to increase energy density. To address scalability, CATL has invested in advanced manufacturing processes that allow for the integration of graphene materials into their existing production lines[4]. This includes the development of specialized coating techniques and electrode fabrication methods optimized for graphene-enhanced battery components.

Strengths: Established battery manufacturing infrastructure, expertise in large-scale production, strong R&D capabilities. Weaknesses: May face challenges in sourcing high-quality graphene at scale, potential increased production costs.

BYD Co., Ltd.

Technical Solution: BYD has been exploring graphene-enhanced batteries as part of their efforts to improve electric vehicle battery technology. Their approach to improving graphene battery scalability focuses on developing cost-effective manufacturing processes and integrating graphene into their existing battery production lines. BYD has patented a method for producing graphene-oxide coated cathode materials, which can enhance the performance and lifespan of lithium-ion batteries[5]. They are also investigating the use of graphene in solid-state batteries to improve energy density and safety. To address scalability challenges, BYD is leveraging its vertically integrated supply chain and manufacturing expertise to optimize the production of graphene-enhanced battery components[6].

Strengths: Vertically integrated supply chain, extensive experience in battery manufacturing, strong presence in the electric vehicle market. Weaknesses: May face challenges in optimizing graphene integration without disrupting existing production processes.

Breakthrough Innovations in Graphene Synthesis

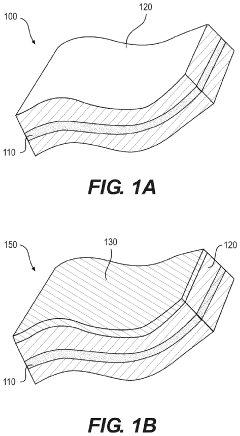

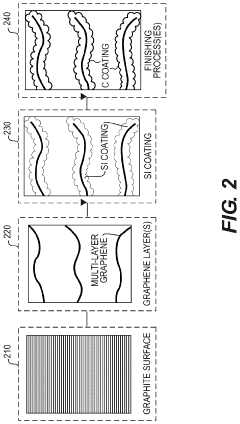

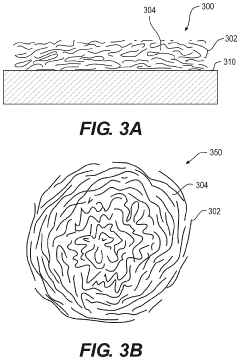

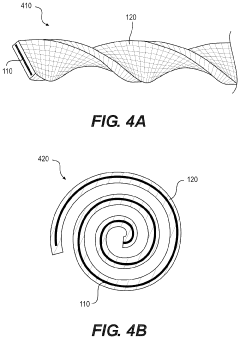

Curved two-dimensional nanocomposites for battery electrodes

PatentPendingUS20240234671A1

Innovation

- The development of curved two-dimensional nanocomposites with a planar substrate backbone and a continuous active material film, forming a three-dimensional agglomeration with internal pores to accommodate volume changes and enhance electrical conductivity.

Improved battery

PatentWO2023087067A1

Innovation

- The method involves forming graphene nano-particles from carbon-containing gases and combining them with dispersing agents and a battery part liquid, using a high shear mixer to distribute them, and assembling the battery with multiple anodes and cathodes to achieve a higher voltage and energy density.

Environmental Impact of Graphene Battery Production

The production of graphene batteries, while promising for energy storage advancements, raises significant environmental concerns that must be addressed for sustainable scalability. The extraction and processing of raw materials for graphene synthesis, particularly graphite, can lead to habitat disruption and soil contamination. Mining operations often require substantial energy inputs and may result in the release of harmful particulates into the air and water systems.

The manufacturing process of graphene itself is energy-intensive, potentially contributing to increased carbon emissions if not powered by renewable sources. Chemical vapor deposition (CVD), a common method for producing high-quality graphene, involves the use of hydrocarbon gases and metal catalysts, which can generate hazardous waste and greenhouse gas emissions if not properly managed.

Water usage is another critical environmental factor in graphene battery production. The purification and processing stages require large volumes of water, potentially straining local water resources in areas of production. Additionally, the chemicals used in these processes, if not adequately treated, can lead to water pollution and affect aquatic ecosystems.

The disposal and recycling of graphene batteries present further environmental challenges. While graphene itself is not considered toxic, the other components of the battery, such as electrolytes and metal current collectors, may pose risks if not properly handled at the end of the battery's life cycle. Developing efficient recycling methods for graphene batteries is crucial to minimize waste and recover valuable materials.

However, it's important to note that graphene batteries have the potential to offer environmental benefits in the long term. Their higher energy density and longer lifespan compared to traditional lithium-ion batteries could reduce the overall number of batteries needed, potentially decreasing the environmental impact of battery production and disposal over time.

To mitigate the environmental impact of graphene battery production, several strategies can be implemented. These include developing cleaner synthesis methods, optimizing resource use in manufacturing processes, implementing closed-loop water systems, and investing in renewable energy sources for production facilities. Additionally, designing batteries with recyclability in mind and establishing robust recycling infrastructure will be crucial for sustainable scalability.

As the technology advances, ongoing research into more environmentally friendly production methods and materials will be essential. This includes exploring bio-based precursors for graphene synthesis and developing solvent-free or water-based production techniques. By addressing these environmental concerns proactively, the graphene battery industry can work towards achieving scalability while minimizing its ecological footprint.

The manufacturing process of graphene itself is energy-intensive, potentially contributing to increased carbon emissions if not powered by renewable sources. Chemical vapor deposition (CVD), a common method for producing high-quality graphene, involves the use of hydrocarbon gases and metal catalysts, which can generate hazardous waste and greenhouse gas emissions if not properly managed.

Water usage is another critical environmental factor in graphene battery production. The purification and processing stages require large volumes of water, potentially straining local water resources in areas of production. Additionally, the chemicals used in these processes, if not adequately treated, can lead to water pollution and affect aquatic ecosystems.

The disposal and recycling of graphene batteries present further environmental challenges. While graphene itself is not considered toxic, the other components of the battery, such as electrolytes and metal current collectors, may pose risks if not properly handled at the end of the battery's life cycle. Developing efficient recycling methods for graphene batteries is crucial to minimize waste and recover valuable materials.

However, it's important to note that graphene batteries have the potential to offer environmental benefits in the long term. Their higher energy density and longer lifespan compared to traditional lithium-ion batteries could reduce the overall number of batteries needed, potentially decreasing the environmental impact of battery production and disposal over time.

To mitigate the environmental impact of graphene battery production, several strategies can be implemented. These include developing cleaner synthesis methods, optimizing resource use in manufacturing processes, implementing closed-loop water systems, and investing in renewable energy sources for production facilities. Additionally, designing batteries with recyclability in mind and establishing robust recycling infrastructure will be crucial for sustainable scalability.

As the technology advances, ongoing research into more environmentally friendly production methods and materials will be essential. This includes exploring bio-based precursors for graphene synthesis and developing solvent-free or water-based production techniques. By addressing these environmental concerns proactively, the graphene battery industry can work towards achieving scalability while minimizing its ecological footprint.

Regulatory Framework for Advanced Battery Technologies

The regulatory framework for advanced battery technologies, including graphene batteries, plays a crucial role in shaping the development, production, and commercialization of these innovative energy storage solutions. As graphene batteries emerge as a promising technology for improving energy density and charging speeds, regulatory bodies worldwide are adapting their guidelines to address the unique characteristics and potential risks associated with these advanced materials.

In the United States, the Environmental Protection Agency (EPA) and the Department of Energy (DOE) are at the forefront of developing regulations for graphene-based energy storage technologies. The EPA focuses on the environmental impact and safety aspects of graphene production and disposal, while the DOE establishes performance standards and funding initiatives to accelerate the development of scalable graphene battery technologies.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which requires manufacturers and importers of graphene materials to register their substances and provide safety data. This regulatory framework ensures that potential health and environmental risks associated with graphene production and use are thoroughly assessed and mitigated.

In Asia, countries like China, Japan, and South Korea have established their own regulatory frameworks to support the growth of advanced battery technologies. China's Ministry of Industry and Information Technology has released guidelines for the development of new energy vehicle batteries, which include provisions for graphene-based energy storage systems. These regulations aim to promote innovation while ensuring safety and environmental protection.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), are working on developing global standards for graphene materials and their applications in energy storage. These standards will help harmonize regulations across different regions and facilitate the global adoption of graphene battery technologies.

As the scalability of graphene batteries improves, regulatory bodies are focusing on addressing key challenges such as quality control, performance verification, and lifecycle management. Regulations are being developed to ensure consistent manufacturing processes, establish testing protocols for evaluating battery performance and safety, and create guidelines for the responsible disposal and recycling of graphene-based energy storage systems.

The regulatory landscape for advanced battery technologies is continuously evolving to keep pace with technological advancements. Policymakers and industry stakeholders are collaborating to create a balanced regulatory framework that promotes innovation, ensures safety, and supports the scalable production of graphene batteries. This collaborative approach aims to accelerate the commercialization of graphene-based energy storage solutions while addressing potential environmental and health concerns associated with their widespread adoption.

In the United States, the Environmental Protection Agency (EPA) and the Department of Energy (DOE) are at the forefront of developing regulations for graphene-based energy storage technologies. The EPA focuses on the environmental impact and safety aspects of graphene production and disposal, while the DOE establishes performance standards and funding initiatives to accelerate the development of scalable graphene battery technologies.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which requires manufacturers and importers of graphene materials to register their substances and provide safety data. This regulatory framework ensures that potential health and environmental risks associated with graphene production and use are thoroughly assessed and mitigated.

In Asia, countries like China, Japan, and South Korea have established their own regulatory frameworks to support the growth of advanced battery technologies. China's Ministry of Industry and Information Technology has released guidelines for the development of new energy vehicle batteries, which include provisions for graphene-based energy storage systems. These regulations aim to promote innovation while ensuring safety and environmental protection.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), are working on developing global standards for graphene materials and their applications in energy storage. These standards will help harmonize regulations across different regions and facilitate the global adoption of graphene battery technologies.

As the scalability of graphene batteries improves, regulatory bodies are focusing on addressing key challenges such as quality control, performance verification, and lifecycle management. Regulations are being developed to ensure consistent manufacturing processes, establish testing protocols for evaluating battery performance and safety, and create guidelines for the responsible disposal and recycling of graphene-based energy storage systems.

The regulatory landscape for advanced battery technologies is continuously evolving to keep pace with technological advancements. Policymakers and industry stakeholders are collaborating to create a balanced regulatory framework that promotes innovation, ensures safety, and supports the scalable production of graphene batteries. This collaborative approach aims to accelerate the commercialization of graphene-based energy storage solutions while addressing potential environmental and health concerns associated with their widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!