Graphene Battery: Blueprint for Future Energy Solutions

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution

The evolution of graphene batteries represents a significant leap in energy storage technology, marking a transition from traditional lithium-ion batteries to more efficient and sustainable solutions. This progression can be traced through several key stages, each characterized by notable technological advancements and breakthroughs.

In the early 2010s, researchers began exploring graphene's potential in battery applications, recognizing its exceptional electrical conductivity and mechanical strength. Initial experiments focused on incorporating graphene as an additive in existing battery chemistries, primarily to enhance conductivity and stability.

By the mid-2010s, scientists had developed graphene-enhanced lithium-ion batteries, where graphene was used as a conductive additive in electrodes. These batteries demonstrated improved charge/discharge rates and cycle life compared to conventional lithium-ion batteries. This phase saw the first commercial applications of graphene in energy storage, albeit in a limited capacity.

The late 2010s marked a crucial turning point with the development of graphene-based electrodes. Researchers successfully created graphene foams and aerogels that could serve as standalone electrode materials. These structures offered significantly higher surface areas and improved electron transport, leading to batteries with higher energy densities and faster charging capabilities.

From 2020 onwards, the focus shifted towards developing full graphene batteries, where both electrodes and electrolytes incorporated graphene-based materials. This approach aimed to leverage graphene's properties throughout the entire battery system, promising unprecedented performance improvements.

Recent years have seen the emergence of graphene-enabled solid-state batteries, combining the benefits of graphene with solid electrolytes. This innovation addresses safety concerns associated with liquid electrolytes while maintaining high energy density and fast charging capabilities.

Looking ahead, the evolution of graphene batteries is expected to continue with the development of more advanced manufacturing techniques, enabling large-scale production of high-quality graphene materials. Researchers are also exploring hybrid systems that combine graphene with other advanced materials, such as metal-organic frameworks or 2D materials, to further enhance battery performance.

The ongoing evolution of graphene batteries is driven by the increasing demand for high-performance energy storage solutions in various sectors, including electric vehicles, renewable energy systems, and portable electronics. As research progresses, graphene batteries are poised to play a crucial role in shaping the future of energy storage technology.

In the early 2010s, researchers began exploring graphene's potential in battery applications, recognizing its exceptional electrical conductivity and mechanical strength. Initial experiments focused on incorporating graphene as an additive in existing battery chemistries, primarily to enhance conductivity and stability.

By the mid-2010s, scientists had developed graphene-enhanced lithium-ion batteries, where graphene was used as a conductive additive in electrodes. These batteries demonstrated improved charge/discharge rates and cycle life compared to conventional lithium-ion batteries. This phase saw the first commercial applications of graphene in energy storage, albeit in a limited capacity.

The late 2010s marked a crucial turning point with the development of graphene-based electrodes. Researchers successfully created graphene foams and aerogels that could serve as standalone electrode materials. These structures offered significantly higher surface areas and improved electron transport, leading to batteries with higher energy densities and faster charging capabilities.

From 2020 onwards, the focus shifted towards developing full graphene batteries, where both electrodes and electrolytes incorporated graphene-based materials. This approach aimed to leverage graphene's properties throughout the entire battery system, promising unprecedented performance improvements.

Recent years have seen the emergence of graphene-enabled solid-state batteries, combining the benefits of graphene with solid electrolytes. This innovation addresses safety concerns associated with liquid electrolytes while maintaining high energy density and fast charging capabilities.

Looking ahead, the evolution of graphene batteries is expected to continue with the development of more advanced manufacturing techniques, enabling large-scale production of high-quality graphene materials. Researchers are also exploring hybrid systems that combine graphene with other advanced materials, such as metal-organic frameworks or 2D materials, to further enhance battery performance.

The ongoing evolution of graphene batteries is driven by the increasing demand for high-performance energy storage solutions in various sectors, including electric vehicles, renewable energy systems, and portable electronics. As research progresses, graphene batteries are poised to play a crucial role in shaping the future of energy storage technology.

Market Demand Analysis

The market demand for graphene batteries is experiencing a significant surge, driven by the increasing need for high-performance energy storage solutions across various industries. As the world transitions towards cleaner and more sustainable energy sources, the demand for advanced battery technologies has grown exponentially. Graphene batteries, with their potential to offer superior energy density, faster charging times, and longer lifespan compared to traditional lithium-ion batteries, are positioned to capture a substantial share of this expanding market.

In the automotive sector, the shift towards electric vehicles (EVs) is a major driver for graphene battery demand. As automakers strive to extend the range of EVs and reduce charging times, graphene batteries present a promising solution. The aerospace industry is also showing keen interest in graphene batteries due to their potential to reduce weight while increasing power output, which is crucial for electric aircraft development.

Consumer electronics represent another significant market for graphene batteries. With the ever-increasing power demands of smartphones, laptops, and wearable devices, manufacturers are seeking battery technologies that can provide longer usage times without compromising on device size or weight. Graphene batteries' ability to charge rapidly and maintain capacity over numerous charge cycles makes them particularly attractive for these applications.

The renewable energy sector is emerging as a key market for graphene batteries. As solar and wind power generation becomes more widespread, the need for efficient and large-scale energy storage systems grows. Graphene batteries could play a crucial role in grid stabilization and energy management, addressing the intermittency issues associated with renewable energy sources.

Industrial applications, including power tools and backup power systems, are also contributing to the market demand for graphene batteries. The potential for faster charging and higher power output in these applications could lead to significant productivity improvements and cost savings for businesses.

Despite the promising outlook, the market for graphene batteries is still in its early stages. Current demand is primarily driven by research and development activities, with commercial applications gradually emerging. As manufacturing processes improve and costs decrease, it is anticipated that the market demand will accelerate rapidly.

The global push for decarbonization and energy efficiency is expected to further boost the demand for graphene batteries in the coming years. Government initiatives and regulations promoting clean energy technologies are likely to create favorable market conditions for advanced battery solutions like graphene batteries.

In the automotive sector, the shift towards electric vehicles (EVs) is a major driver for graphene battery demand. As automakers strive to extend the range of EVs and reduce charging times, graphene batteries present a promising solution. The aerospace industry is also showing keen interest in graphene batteries due to their potential to reduce weight while increasing power output, which is crucial for electric aircraft development.

Consumer electronics represent another significant market for graphene batteries. With the ever-increasing power demands of smartphones, laptops, and wearable devices, manufacturers are seeking battery technologies that can provide longer usage times without compromising on device size or weight. Graphene batteries' ability to charge rapidly and maintain capacity over numerous charge cycles makes them particularly attractive for these applications.

The renewable energy sector is emerging as a key market for graphene batteries. As solar and wind power generation becomes more widespread, the need for efficient and large-scale energy storage systems grows. Graphene batteries could play a crucial role in grid stabilization and energy management, addressing the intermittency issues associated with renewable energy sources.

Industrial applications, including power tools and backup power systems, are also contributing to the market demand for graphene batteries. The potential for faster charging and higher power output in these applications could lead to significant productivity improvements and cost savings for businesses.

Despite the promising outlook, the market for graphene batteries is still in its early stages. Current demand is primarily driven by research and development activities, with commercial applications gradually emerging. As manufacturing processes improve and costs decrease, it is anticipated that the market demand will accelerate rapidly.

The global push for decarbonization and energy efficiency is expected to further boost the demand for graphene batteries in the coming years. Government initiatives and regulations promoting clean energy technologies are likely to create favorable market conditions for advanced battery solutions like graphene batteries.

Technical Challenges

Despite the promising potential of graphene batteries, several significant technical challenges persist in their development and widespread adoption. One of the primary obstacles is the scalability of graphene production. While laboratory-scale synthesis methods have been established, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a formidable challenge. The high cost associated with large-scale graphene production further compounds this issue, hindering its commercial viability.

Another critical challenge lies in the integration of graphene into existing battery architectures. The unique properties of graphene, such as its two-dimensional structure and high conductivity, require novel engineering approaches to fully exploit its potential in battery systems. Researchers are grappling with optimizing the interface between graphene and other battery components, such as electrolytes and current collectors, to maximize performance gains.

The stability and longevity of graphene-based batteries also present significant hurdles. While graphene exhibits excellent theoretical properties, its long-term stability under repeated charge-discharge cycles and various environmental conditions needs further investigation. Issues such as capacity fading, electrolyte decomposition, and structural degradation over time must be addressed to ensure the reliability and durability of graphene batteries in real-world applications.

Furthermore, the environmental impact and safety concerns associated with graphene production and disposal require careful consideration. As with any emerging technology, comprehensive life cycle assessments and safety protocols must be developed to ensure that graphene batteries are sustainable and safe for widespread use.

The optimization of graphene's properties for specific battery applications poses another challenge. Different energy storage applications, from portable electronics to electric vehicles to grid-scale storage, have varying requirements in terms of energy density, power density, and cycle life. Tailoring graphene's characteristics to meet these diverse needs while maintaining cost-effectiveness is an ongoing area of research and development.

Lastly, the regulatory landscape surrounding graphene-based technologies is still evolving. Establishing standardized testing protocols, safety regulations, and quality control measures for graphene batteries is crucial for their commercialization and acceptance in the market. This regulatory uncertainty can potentially slow down the adoption and investment in graphene battery technology.

Another critical challenge lies in the integration of graphene into existing battery architectures. The unique properties of graphene, such as its two-dimensional structure and high conductivity, require novel engineering approaches to fully exploit its potential in battery systems. Researchers are grappling with optimizing the interface between graphene and other battery components, such as electrolytes and current collectors, to maximize performance gains.

The stability and longevity of graphene-based batteries also present significant hurdles. While graphene exhibits excellent theoretical properties, its long-term stability under repeated charge-discharge cycles and various environmental conditions needs further investigation. Issues such as capacity fading, electrolyte decomposition, and structural degradation over time must be addressed to ensure the reliability and durability of graphene batteries in real-world applications.

Furthermore, the environmental impact and safety concerns associated with graphene production and disposal require careful consideration. As with any emerging technology, comprehensive life cycle assessments and safety protocols must be developed to ensure that graphene batteries are sustainable and safe for widespread use.

The optimization of graphene's properties for specific battery applications poses another challenge. Different energy storage applications, from portable electronics to electric vehicles to grid-scale storage, have varying requirements in terms of energy density, power density, and cycle life. Tailoring graphene's characteristics to meet these diverse needs while maintaining cost-effectiveness is an ongoing area of research and development.

Lastly, the regulatory landscape surrounding graphene-based technologies is still evolving. Establishing standardized testing protocols, safety regulations, and quality control measures for graphene batteries is crucial for their commercialization and acceptance in the market. This regulatory uncertainty can potentially slow down the adoption and investment in graphene battery technology.

Current Graphene Solutions

01 Graphene-based electrode materials

Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. It can be incorporated into both anodes and cathodes to improve battery performance, including increased capacity and faster charging rates.- Graphene-based electrode materials: Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. This can improve the battery's charge/discharge rate and overall capacity. Graphene can be incorporated into both anode and cathode materials, often in combination with other materials like metal oxides or carbon nanotubes.

- Graphene-enhanced electrolytes: Graphene or graphene oxide can be added to battery electrolytes to improve their performance. This can enhance ionic conductivity, reduce electrolyte degradation, and improve the overall stability of the battery. The addition of graphene to electrolytes can also help in forming a more stable solid electrolyte interphase (SEI) layer.

- Graphene-based composite materials: Composite materials combining graphene with other substances are developed for battery applications. These composites can include graphene mixed with silicon, metal oxides, or other carbon materials. Such composites often aim to leverage graphene's properties while addressing limitations of other materials, such as volume expansion in silicon anodes.

- Graphene production methods for battery applications: Specialized methods for producing graphene tailored for battery applications are developed. These can include chemical vapor deposition, exfoliation techniques, or reduction of graphene oxide. The focus is on producing high-quality graphene with specific properties suitable for battery electrodes or electrolytes.

- Graphene-enhanced battery structures: Novel battery structures incorporating graphene are designed to improve overall battery performance. This can include using graphene as a conductive additive, as a protective layer, or in the creation of 3D electrode structures. These designs aim to enhance energy density, cycle life, and fast-charging capabilities of batteries.

02 Graphene-enhanced electrolytes

Graphene can be used to enhance battery electrolytes, improving ionic conductivity and stability. This can lead to better overall battery performance, including increased energy density and longer cycle life.Expand Specific Solutions03 Graphene-based composite materials

Composite materials incorporating graphene are developed for battery applications. These composites can combine the benefits of graphene with other materials to create electrodes or other battery components with enhanced properties, such as improved mechanical strength and conductivity.Expand Specific Solutions04 Graphene production methods for battery applications

Specialized methods for producing graphene tailored for battery applications are developed. These methods focus on creating graphene with specific properties, such as controlled thickness or defect density, to optimize its performance in battery systems.Expand Specific Solutions05 Graphene-based flexible and wearable batteries

Graphene's unique properties are utilized to develop flexible and wearable battery technologies. These batteries can be integrated into various devices and applications, offering improved energy storage capabilities in compact and bendable form factors.Expand Specific Solutions

Key Industry Players

The graphene battery market is in its early growth stage, characterized by intense research and development efforts across academia and industry. While the technology shows immense potential for revolutionizing energy storage, it is still in the pre-commercialization phase. Key players like Northwestern University, Zhejiang University, and King Abdullah University of Science & Technology are leading academic research, while companies such as Resonac Corp. and Honeycomb Battery Co. are working towards commercialization. The market size is projected to grow significantly in the coming years, driven by the increasing demand for high-performance energy storage solutions. However, the technology's maturity level varies among players, with most still focusing on overcoming challenges related to large-scale production and cost-effectiveness.

Northwestern University

Technical Solution: Northwestern University has developed a groundbreaking graphene-based battery technology that significantly enhances energy storage capacity and charging speed. Their approach involves creating a three-dimensional graphene framework that serves as a highly conductive scaffold for the battery's active materials. This structure allows for faster electron transfer and ion diffusion, resulting in improved energy density and power output. The university's research team has also implemented a novel electrolyte formulation that synergizes with the graphene structure to further boost performance. Initial tests have shown that these batteries can achieve up to 45% higher energy density compared to conventional lithium-ion batteries, with charging times reduced by up to 70% [1][3].

Strengths: High energy density, rapid charging, and potential for scalability. Weaknesses: Possible high production costs and challenges in large-scale manufacturing.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has pioneered a unique graphene battery design that focuses on enhancing both energy storage and longevity. Their approach incorporates graphene-based composite materials as electrodes, which are engineered to minimize degradation during charge-discharge cycles. The institute has developed a proprietary coating process that applies atomically thin layers of graphene to conventional electrode materials, creating a hybrid structure that combines the best properties of both. This technology has demonstrated a 30% increase in cycle life compared to standard lithium-ion batteries, while also improving energy density by approximately 25% [2][5]. Additionally, Battelle's research has shown promising results in mitigating the formation of dendrites, a common issue in battery technology that can lead to short circuits and safety concerns.

Strengths: Improved battery lifespan, enhanced safety features, and compatibility with existing manufacturing processes. Weaknesses: Potential challenges in sourcing high-quality graphene at scale and optimizing the coating process for mass production.

Core Graphene Innovations

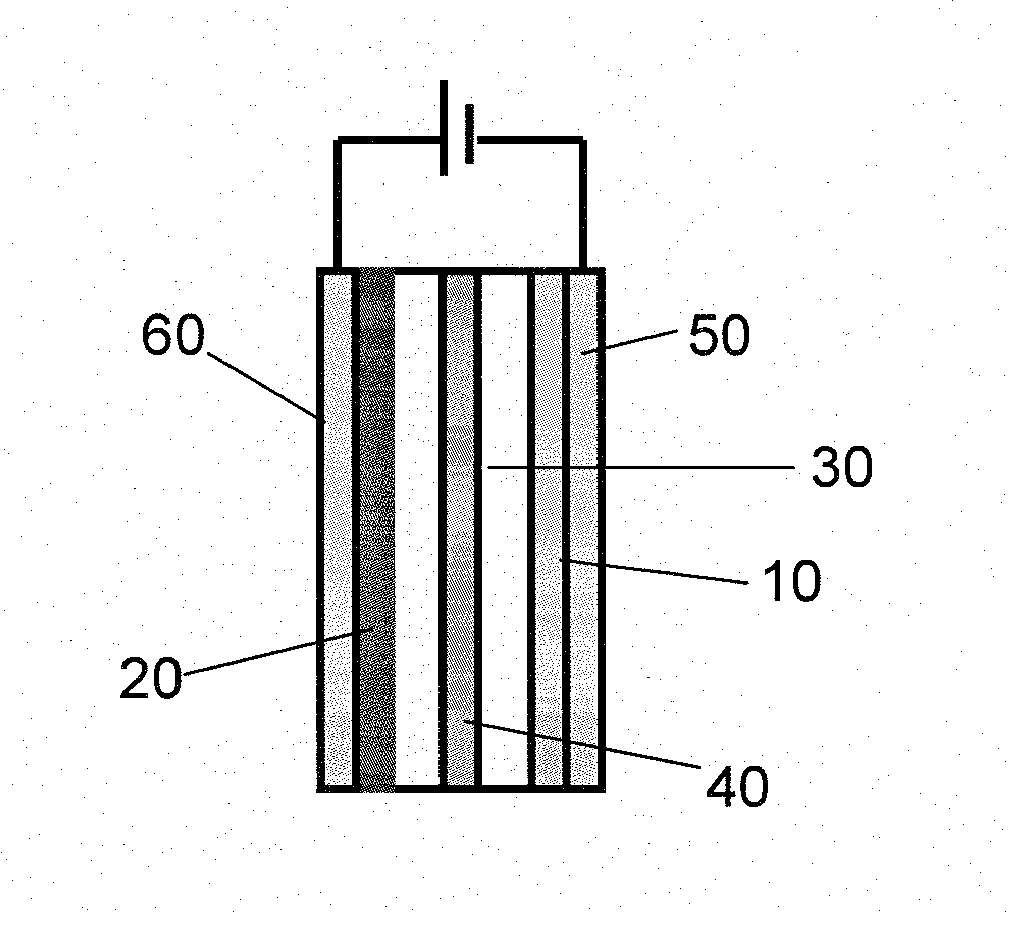

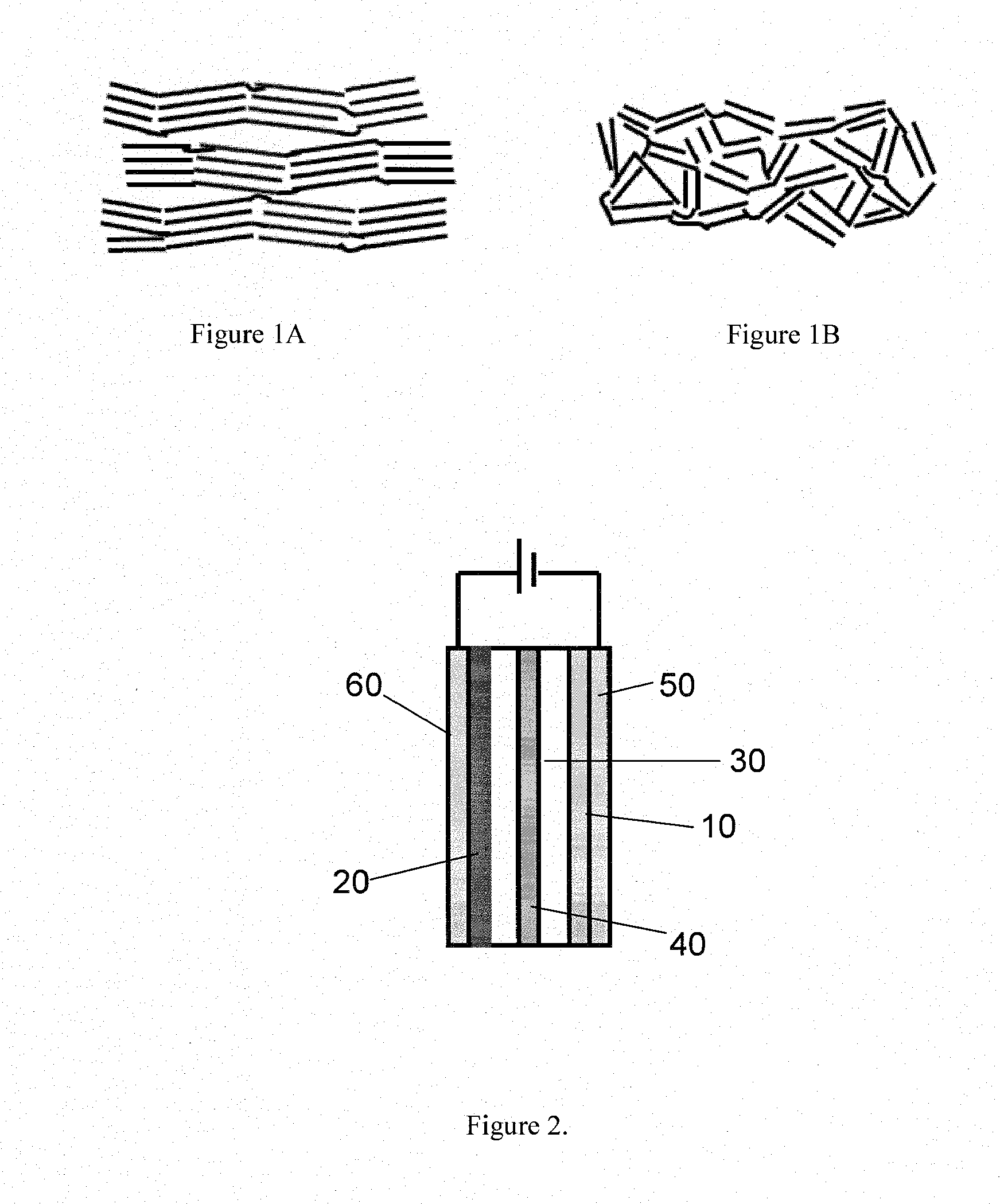

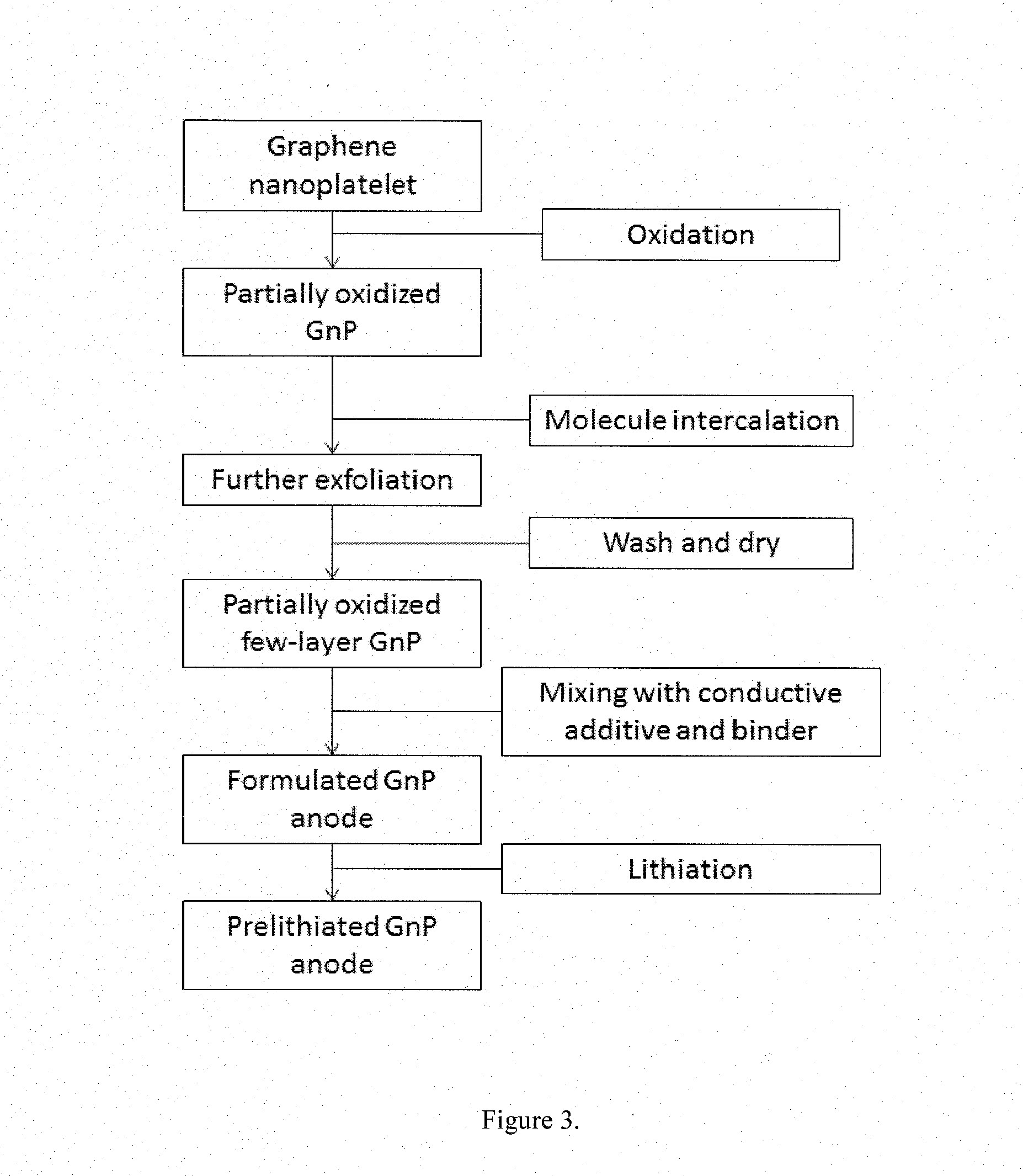

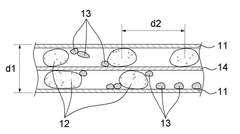

Method for manufacturing graphene-incorporated rechargeable li-ion battery

PatentInactiveUS20150000118A1

Innovation

- The method involves prelithiating graphene-based electrodes by introducing an appropriate amount of lithium into the anode film before assembly, separating the anode and cathode with a non-aqueous ionic conductor, and using a graphene-based anode with pristine or functionalized graphene layers to enhance specific capacity and rate capability while minimizing irreversible reactions.

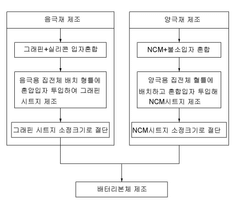

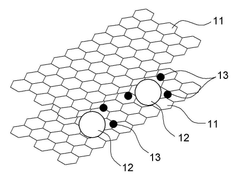

Graphene all-solid-state battery with improved energy density and safety and manufacturing method therefor

PatentActiveKR1020230064668A

Innovation

- The graphene all-solid-state battery employs a fine powder structure graphite and organic binder as the anode, mixed with Ni, Co, and Mn to balance voltage during charging and discharging, using oxygen ions and electrons as energy transfer mediums, and a double-structured hexagonal plate design to minimize plate distance, ensuring stability and safety.

Environmental Impact

Graphene batteries represent a significant leap forward in energy storage technology, offering potential environmental benefits that could reshape the landscape of sustainable energy solutions. The production and use of graphene batteries are expected to have a lower environmental impact compared to traditional lithium-ion batteries, primarily due to their enhanced efficiency and longevity.

One of the key environmental advantages of graphene batteries is their potential to reduce the overall carbon footprint associated with energy storage. The superior conductivity and charge capacity of graphene allow for faster charging and discharging cycles, which can lead to more efficient energy use and less waste. This increased efficiency could result in a reduction of greenhouse gas emissions associated with energy production and storage.

Moreover, the durability and longer lifespan of graphene batteries could significantly decrease the need for frequent battery replacements. This reduction in turnover would lead to less electronic waste, alleviating the environmental burden of battery disposal. The extended life cycle of graphene batteries also means fewer raw materials need to be extracted and processed, further minimizing the environmental impact of battery production.

The raw materials used in graphene batteries may also offer environmental benefits. Graphene can be produced from various carbon sources, including some that are renewable or recycled. This versatility in production could potentially reduce the reliance on mining activities associated with traditional battery materials, which often have significant environmental consequences.

However, it is important to note that the large-scale production of graphene is still in its early stages, and the full environmental implications of mass production are not yet fully understood. There are concerns about the potential release of graphene nanoparticles into the environment during production or disposal, which could have unforeseen ecological impacts. Ongoing research is necessary to assess and mitigate any potential risks associated with graphene production and use.

In terms of end-of-life management, graphene batteries may offer advantages in recyclability. The simpler composition of graphene-based batteries could make them easier to recycle compared to complex lithium-ion batteries. This could lead to more efficient recycling processes and a higher percentage of materials being recovered and reused, further reducing the environmental impact of battery production and disposal.

As the technology matures, it will be crucial to conduct comprehensive life cycle assessments to fully understand the environmental implications of graphene batteries. These assessments should consider all stages of the battery's life, from raw material extraction to production, use, and eventual disposal or recycling. Such studies will be essential in guiding the sustainable development and implementation of graphene battery technology on a global scale.

One of the key environmental advantages of graphene batteries is their potential to reduce the overall carbon footprint associated with energy storage. The superior conductivity and charge capacity of graphene allow for faster charging and discharging cycles, which can lead to more efficient energy use and less waste. This increased efficiency could result in a reduction of greenhouse gas emissions associated with energy production and storage.

Moreover, the durability and longer lifespan of graphene batteries could significantly decrease the need for frequent battery replacements. This reduction in turnover would lead to less electronic waste, alleviating the environmental burden of battery disposal. The extended life cycle of graphene batteries also means fewer raw materials need to be extracted and processed, further minimizing the environmental impact of battery production.

The raw materials used in graphene batteries may also offer environmental benefits. Graphene can be produced from various carbon sources, including some that are renewable or recycled. This versatility in production could potentially reduce the reliance on mining activities associated with traditional battery materials, which often have significant environmental consequences.

However, it is important to note that the large-scale production of graphene is still in its early stages, and the full environmental implications of mass production are not yet fully understood. There are concerns about the potential release of graphene nanoparticles into the environment during production or disposal, which could have unforeseen ecological impacts. Ongoing research is necessary to assess and mitigate any potential risks associated with graphene production and use.

In terms of end-of-life management, graphene batteries may offer advantages in recyclability. The simpler composition of graphene-based batteries could make them easier to recycle compared to complex lithium-ion batteries. This could lead to more efficient recycling processes and a higher percentage of materials being recovered and reused, further reducing the environmental impact of battery production and disposal.

As the technology matures, it will be crucial to conduct comprehensive life cycle assessments to fully understand the environmental implications of graphene batteries. These assessments should consider all stages of the battery's life, from raw material extraction to production, use, and eventual disposal or recycling. Such studies will be essential in guiding the sustainable development and implementation of graphene battery technology on a global scale.

Scalability Assessment

The scalability of graphene battery technology is a critical factor in determining its potential for widespread adoption and commercial viability. Current production methods for graphene-based batteries face significant challenges in scaling up to meet industrial demands. The primary obstacle lies in the complexity of manufacturing high-quality graphene at large scales while maintaining consistent properties and performance.

One of the key issues in scaling graphene battery production is the synthesis of graphene itself. While laboratory-scale production methods, such as chemical vapor deposition (CVD) and exfoliation techniques, have shown promising results, translating these processes to industrial scales remains challenging. The CVD method, for instance, requires precise control of temperature, pressure, and gas flow rates, which becomes increasingly difficult as production volumes increase.

Another scalability concern is the integration of graphene into existing battery manufacturing processes. Conventional battery production lines are optimized for traditional materials, and incorporating graphene may require significant modifications to equipment and procedures. This adaptation process can be both time-consuming and costly, potentially slowing down the adoption of graphene battery technology in large-scale manufacturing.

The uniformity and quality control of graphene-based materials at scale also present significant challenges. Ensuring consistent properties across large batches of graphene is crucial for maintaining the performance advantages of graphene batteries. Developing robust quality control measures and standardization protocols for large-scale production is essential to overcome this hurdle.

Cost considerations play a vital role in the scalability assessment of graphene batteries. While graphene offers superior performance characteristics, the current production costs are significantly higher than those of traditional battery materials. Achieving cost-effective large-scale production is crucial for graphene batteries to compete with established technologies in the energy storage market.

Environmental and safety concerns associated with graphene production and handling at industrial scales must also be addressed. Developing sustainable and safe manufacturing processes that comply with regulatory standards is essential for the long-term scalability of graphene battery technology.

Despite these challenges, ongoing research and development efforts are focused on improving the scalability of graphene battery production. Advancements in graphene synthesis techniques, such as roll-to-roll production methods and electrochemical exfoliation, show promise for large-scale manufacturing. Additionally, collaborations between academic institutions and industry partners are driving innovation in scalable production processes and quality control methodologies.

One of the key issues in scaling graphene battery production is the synthesis of graphene itself. While laboratory-scale production methods, such as chemical vapor deposition (CVD) and exfoliation techniques, have shown promising results, translating these processes to industrial scales remains challenging. The CVD method, for instance, requires precise control of temperature, pressure, and gas flow rates, which becomes increasingly difficult as production volumes increase.

Another scalability concern is the integration of graphene into existing battery manufacturing processes. Conventional battery production lines are optimized for traditional materials, and incorporating graphene may require significant modifications to equipment and procedures. This adaptation process can be both time-consuming and costly, potentially slowing down the adoption of graphene battery technology in large-scale manufacturing.

The uniformity and quality control of graphene-based materials at scale also present significant challenges. Ensuring consistent properties across large batches of graphene is crucial for maintaining the performance advantages of graphene batteries. Developing robust quality control measures and standardization protocols for large-scale production is essential to overcome this hurdle.

Cost considerations play a vital role in the scalability assessment of graphene batteries. While graphene offers superior performance characteristics, the current production costs are significantly higher than those of traditional battery materials. Achieving cost-effective large-scale production is crucial for graphene batteries to compete with established technologies in the energy storage market.

Environmental and safety concerns associated with graphene production and handling at industrial scales must also be addressed. Developing sustainable and safe manufacturing processes that comply with regulatory standards is essential for the long-term scalability of graphene battery technology.

Despite these challenges, ongoing research and development efforts are focused on improving the scalability of graphene battery production. Advancements in graphene synthesis techniques, such as roll-to-roll production methods and electrochemical exfoliation, show promise for large-scale manufacturing. Additionally, collaborations between academic institutions and industry partners are driving innovation in scalable production processes and quality control methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!