How to Optimize Graphene Battery Conductivity?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Conductivity Background and Objectives

Graphene, a two-dimensional carbon allotrope, has emerged as a revolutionary material in the field of energy storage, particularly in battery technology. The quest to optimize graphene battery conductivity has been a focal point of research and development over the past decade, driven by the increasing demand for high-performance energy storage solutions in various sectors, including electric vehicles, portable electronics, and renewable energy systems.

The evolution of graphene-based battery technology can be traced back to its discovery in 2004 by Andre Geim and Konstantin Novoselov. Since then, researchers and engineers have been exploring ways to harness graphene's exceptional properties, such as its high electrical conductivity, mechanical strength, and large surface area, to enhance battery performance. The primary objective in optimizing graphene battery conductivity is to improve energy density, charge/discharge rates, and overall battery efficiency.

As we delve into the background of graphene battery conductivity, it is crucial to understand the fundamental principles that govern its behavior. Graphene's unique electronic structure, characterized by its sp2 hybridized carbon atoms arranged in a hexagonal lattice, allows for rapid electron transport. This intrinsic property makes graphene an ideal candidate for improving battery electrode materials, particularly in terms of enhancing conductivity and reducing internal resistance.

The optimization of graphene battery conductivity involves addressing several key challenges. These include developing scalable and cost-effective methods for producing high-quality graphene, integrating graphene into existing battery architectures without compromising stability, and tailoring graphene's properties to suit specific battery chemistries. Researchers are also focusing on understanding and controlling the interfacial interactions between graphene and other battery components to maximize conductivity benefits.

Recent advancements in graphene synthesis techniques, such as chemical vapor deposition (CVD) and liquid-phase exfoliation, have paved the way for more efficient production of graphene suitable for battery applications. Additionally, the development of graphene composites and hybrid materials has opened up new avenues for optimizing battery conductivity by combining graphene's exceptional properties with those of other materials.

The objectives of optimizing graphene battery conductivity extend beyond merely improving electrical performance. They encompass enhancing overall battery life, reducing charging times, increasing energy and power densities, and ultimately developing more sustainable and environmentally friendly energy storage solutions. These goals align with the broader societal push towards cleaner energy technologies and the reduction of carbon footprints across various industries.

As we move forward, the optimization of graphene battery conductivity continues to be a dynamic and rapidly evolving field. Researchers and industry players are exploring innovative approaches, including the use of graphene derivatives, functionalized graphene, and advanced composite materials, to push the boundaries of battery performance. The ultimate aim is to unlock the full potential of graphene in revolutionizing energy storage technologies and meeting the growing global demand for efficient, high-capacity batteries.

The evolution of graphene-based battery technology can be traced back to its discovery in 2004 by Andre Geim and Konstantin Novoselov. Since then, researchers and engineers have been exploring ways to harness graphene's exceptional properties, such as its high electrical conductivity, mechanical strength, and large surface area, to enhance battery performance. The primary objective in optimizing graphene battery conductivity is to improve energy density, charge/discharge rates, and overall battery efficiency.

As we delve into the background of graphene battery conductivity, it is crucial to understand the fundamental principles that govern its behavior. Graphene's unique electronic structure, characterized by its sp2 hybridized carbon atoms arranged in a hexagonal lattice, allows for rapid electron transport. This intrinsic property makes graphene an ideal candidate for improving battery electrode materials, particularly in terms of enhancing conductivity and reducing internal resistance.

The optimization of graphene battery conductivity involves addressing several key challenges. These include developing scalable and cost-effective methods for producing high-quality graphene, integrating graphene into existing battery architectures without compromising stability, and tailoring graphene's properties to suit specific battery chemistries. Researchers are also focusing on understanding and controlling the interfacial interactions between graphene and other battery components to maximize conductivity benefits.

Recent advancements in graphene synthesis techniques, such as chemical vapor deposition (CVD) and liquid-phase exfoliation, have paved the way for more efficient production of graphene suitable for battery applications. Additionally, the development of graphene composites and hybrid materials has opened up new avenues for optimizing battery conductivity by combining graphene's exceptional properties with those of other materials.

The objectives of optimizing graphene battery conductivity extend beyond merely improving electrical performance. They encompass enhancing overall battery life, reducing charging times, increasing energy and power densities, and ultimately developing more sustainable and environmentally friendly energy storage solutions. These goals align with the broader societal push towards cleaner energy technologies and the reduction of carbon footprints across various industries.

As we move forward, the optimization of graphene battery conductivity continues to be a dynamic and rapidly evolving field. Researchers and industry players are exploring innovative approaches, including the use of graphene derivatives, functionalized graphene, and advanced composite materials, to push the boundaries of battery performance. The ultimate aim is to unlock the full potential of graphene in revolutionizing energy storage technologies and meeting the growing global demand for efficient, high-capacity batteries.

Market Analysis for High-Performance Energy Storage

The market for high-performance energy storage solutions is experiencing rapid growth, driven by increasing demand for efficient and sustainable power sources across various industries. Graphene-based batteries, with their potential for superior conductivity and energy density, are positioned at the forefront of this market evolution. The global energy storage market is projected to reach significant valuation in the coming years, with a substantial portion attributed to advanced battery technologies.

In the automotive sector, the shift towards electric vehicles (EVs) is a major driver for high-performance energy storage solutions. Graphene-enhanced batteries offer the promise of faster charging times, longer range, and improved overall performance, addressing key consumer concerns in EV adoption. This has led to increased investment and research in graphene battery technology by major automotive manufacturers and battery suppliers.

The consumer electronics industry also presents a substantial market opportunity for graphene-based energy storage. With the ever-increasing power demands of smartphones, laptops, and wearable devices, there is a growing need for batteries that can deliver higher capacity and faster charging capabilities. Graphene's potential to significantly enhance battery performance aligns well with these market requirements.

Renewable energy integration is another critical area driving demand for advanced energy storage solutions. As solar and wind power generation continues to grow, the need for efficient and high-capacity storage systems to manage intermittent supply becomes more pressing. Graphene batteries could play a crucial role in grid-scale energy storage, offering improved efficiency and longer cycle life compared to traditional battery technologies.

The industrial and aerospace sectors are also showing interest in graphene-based energy storage solutions. In industrial applications, the potential for faster charging and higher power output could lead to improved productivity and reduced downtime. In aerospace, the lightweight nature of graphene-enhanced batteries could contribute to fuel efficiency and extended flight times for electric aircraft.

Market analysis indicates that Asia-Pacific region, particularly China and South Korea, is leading in graphene battery research and development. However, North America and Europe are also making significant investments in this technology. The competitive landscape includes both established battery manufacturers exploring graphene integration and startups focused specifically on graphene-based energy storage solutions.

While the potential market for graphene batteries is substantial, challenges remain in scaling up production and reducing costs to compete with existing battery technologies. The success of graphene batteries in capturing market share will depend on overcoming these hurdles and demonstrating clear performance advantages in real-world applications.

In the automotive sector, the shift towards electric vehicles (EVs) is a major driver for high-performance energy storage solutions. Graphene-enhanced batteries offer the promise of faster charging times, longer range, and improved overall performance, addressing key consumer concerns in EV adoption. This has led to increased investment and research in graphene battery technology by major automotive manufacturers and battery suppliers.

The consumer electronics industry also presents a substantial market opportunity for graphene-based energy storage. With the ever-increasing power demands of smartphones, laptops, and wearable devices, there is a growing need for batteries that can deliver higher capacity and faster charging capabilities. Graphene's potential to significantly enhance battery performance aligns well with these market requirements.

Renewable energy integration is another critical area driving demand for advanced energy storage solutions. As solar and wind power generation continues to grow, the need for efficient and high-capacity storage systems to manage intermittent supply becomes more pressing. Graphene batteries could play a crucial role in grid-scale energy storage, offering improved efficiency and longer cycle life compared to traditional battery technologies.

The industrial and aerospace sectors are also showing interest in graphene-based energy storage solutions. In industrial applications, the potential for faster charging and higher power output could lead to improved productivity and reduced downtime. In aerospace, the lightweight nature of graphene-enhanced batteries could contribute to fuel efficiency and extended flight times for electric aircraft.

Market analysis indicates that Asia-Pacific region, particularly China and South Korea, is leading in graphene battery research and development. However, North America and Europe are also making significant investments in this technology. The competitive landscape includes both established battery manufacturers exploring graphene integration and startups focused specifically on graphene-based energy storage solutions.

While the potential market for graphene batteries is substantial, challenges remain in scaling up production and reducing costs to compete with existing battery technologies. The success of graphene batteries in capturing market share will depend on overcoming these hurdles and demonstrating clear performance advantages in real-world applications.

Current Challenges in Graphene Battery Conductivity

Despite the promising potential of graphene in battery applications, several significant challenges persist in optimizing its conductivity for practical use. One of the primary obstacles is the difficulty in maintaining graphene's exceptional intrinsic properties when integrating it into battery systems. The theoretical conductivity of pristine graphene is extraordinarily high, but this often diminishes substantially when incorporated into electrodes or other battery components.

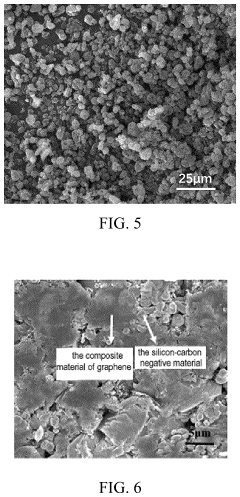

A major challenge lies in the scalable production of high-quality graphene with consistent properties. Current manufacturing processes often introduce defects and impurities that can significantly reduce conductivity. These imperfections disrupt the electron flow and create resistance points within the graphene structure, limiting its overall performance in battery applications.

Another critical issue is the interfacial resistance between graphene and other battery materials. Achieving seamless electrical contact between graphene and active materials, current collectors, or electrolytes is crucial for optimizing conductivity. However, the atomically thin nature of graphene makes it challenging to create stable and efficient interfaces without compromising its conductive properties.

The agglomeration of graphene sheets presents an additional hurdle. When used in battery electrodes, graphene tends to restack due to strong van der Waals forces, reducing the effective surface area and hindering ion transport. This restacking phenomenon not only affects conductivity but also limits the overall performance of graphene-based batteries.

Furthermore, the anisotropic nature of graphene conductivity poses challenges in battery design. While graphene exhibits excellent in-plane conductivity, its through-plane conductivity is significantly lower. This disparity complicates the design of three-dimensional battery structures that can fully leverage graphene's conductive properties.

Environmental factors also play a role in conductivity optimization. Exposure to air, moisture, and other contaminants can alter graphene's surface properties and affect its conductivity. Developing effective encapsulation or protection methods without compromising conductivity remains a significant challenge.

Lastly, the lack of standardized characterization methods for graphene conductivity in battery contexts hinders progress. Different measurement techniques and varying sample preparations make it difficult to compare results across studies and establish benchmarks for optimization efforts. Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, electrochemistry, and manufacturing technologies to unlock the full potential of graphene in battery applications.

A major challenge lies in the scalable production of high-quality graphene with consistent properties. Current manufacturing processes often introduce defects and impurities that can significantly reduce conductivity. These imperfections disrupt the electron flow and create resistance points within the graphene structure, limiting its overall performance in battery applications.

Another critical issue is the interfacial resistance between graphene and other battery materials. Achieving seamless electrical contact between graphene and active materials, current collectors, or electrolytes is crucial for optimizing conductivity. However, the atomically thin nature of graphene makes it challenging to create stable and efficient interfaces without compromising its conductive properties.

The agglomeration of graphene sheets presents an additional hurdle. When used in battery electrodes, graphene tends to restack due to strong van der Waals forces, reducing the effective surface area and hindering ion transport. This restacking phenomenon not only affects conductivity but also limits the overall performance of graphene-based batteries.

Furthermore, the anisotropic nature of graphene conductivity poses challenges in battery design. While graphene exhibits excellent in-plane conductivity, its through-plane conductivity is significantly lower. This disparity complicates the design of three-dimensional battery structures that can fully leverage graphene's conductive properties.

Environmental factors also play a role in conductivity optimization. Exposure to air, moisture, and other contaminants can alter graphene's surface properties and affect its conductivity. Developing effective encapsulation or protection methods without compromising conductivity remains a significant challenge.

Lastly, the lack of standardized characterization methods for graphene conductivity in battery contexts hinders progress. Different measurement techniques and varying sample preparations make it difficult to compare results across studies and establish benchmarks for optimization efforts. Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, electrochemistry, and manufacturing technologies to unlock the full potential of graphene in battery applications.

Existing Approaches to Enhance Graphene Conductivity

01 Graphene-based electrode materials for enhanced conductivity

Graphene-based materials are used as electrode components in batteries to improve conductivity. These materials can be functionalized or combined with other conductive substances to enhance electron transfer and overall battery performance. The high surface area and excellent electrical properties of graphene contribute to increased energy density and faster charging capabilities.- Graphene-based electrode materials for enhanced conductivity: Graphene-based materials are used as electrode components in batteries to improve conductivity. These materials can be incorporated into various battery types, including lithium-ion batteries, to enhance overall performance and energy density. The high surface area and excellent electrical properties of graphene contribute to improved charge transfer and reduced internal resistance.

- Graphene-doped electrolytes for improved ionic conductivity: Graphene or graphene oxide can be added to battery electrolytes to enhance ionic conductivity. This modification improves the movement of ions between electrodes, leading to faster charging and discharging rates. The addition of graphene to electrolytes can also contribute to better thermal stability and extended battery life.

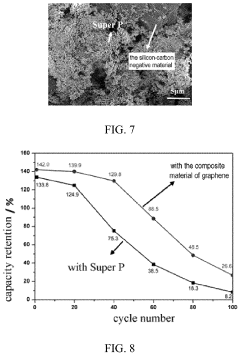

- Graphene-based composite materials for battery electrodes: Composite materials combining graphene with other conductive or active materials are developed to optimize battery performance. These composites can enhance both electronic and ionic conductivity, leading to improved capacity retention and cycle life. Examples include graphene-metal oxide composites and graphene-polymer hybrids.

- Graphene functionalization for tailored conductivity: Chemical functionalization of graphene is employed to tailor its conductivity properties for specific battery applications. This approach allows for the fine-tuning of electronic and ionic transport characteristics, potentially leading to optimized battery performance. Functionalized graphene can also improve the interface between electrode materials and electrolytes.

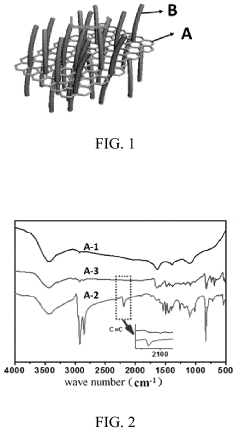

- 3D graphene structures for enhanced battery conductivity: Three-dimensional graphene structures, such as foams or aerogels, are developed to increase the effective surface area and improve conductivity in batteries. These structures can facilitate faster electron and ion transport, leading to improved power density and overall battery performance. 3D graphene architectures can also help in accommodating volume changes during charge-discharge cycles.

02 Graphene-doped electrolytes for improved ionic conductivity

Incorporating graphene or graphene oxide into battery electrolytes can significantly improve ionic conductivity. This approach enhances the movement of ions between electrodes, leading to better overall battery performance. The addition of graphene to electrolytes can also contribute to improved thermal stability and reduced electrolyte degradation.Expand Specific Solutions03 Graphene-based composite materials for battery components

Composite materials incorporating graphene are developed for various battery components, including current collectors and separators. These composites combine the high conductivity of graphene with the mechanical or chemical properties of other materials to create multifunctional components that enhance overall battery performance and durability.Expand Specific Solutions04 Graphene modification techniques for tailored conductivity

Various modification techniques are employed to tailor the conductivity of graphene for specific battery applications. These include doping, functionalization, and structural modifications. By adjusting the electronic properties of graphene, researchers can optimize its performance for different types of batteries and improve overall energy storage capabilities.Expand Specific Solutions05 Integration of graphene in solid-state batteries for enhanced conductivity

Graphene is incorporated into solid-state battery designs to address conductivity challenges. The high electron mobility of graphene helps overcome limitations in ion transport within solid electrolytes. This integration can lead to improved power density, faster charging rates, and enhanced overall performance of solid-state batteries.Expand Specific Solutions

Key Players in Graphene Battery Research and Development

The graphene battery conductivity optimization landscape is characterized by a competitive and rapidly evolving market. The industry is in an early growth stage, with significant potential for expansion as energy storage demands increase globally. Market size estimates vary but are projected to reach billions of dollars within the next decade. Technologically, graphene batteries are still in the development phase, with companies like LG Energy Solution, Honeycomb Battery, and Global Graphene Group leading research efforts. Major players such as LG Chem and Toray Industries are investing heavily in R&D to improve conductivity and commercialize graphene-enhanced batteries. Universities and research institutions, including Zhejiang University and KAIST, are also contributing to advancements in this field, indicating a collaborative ecosystem of industry and academia driving innovation.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a graphene-based conductive additive for lithium-ion batteries called TORAYCA. This material is produced using a proprietary chemical vapor deposition (CVD) process that results in high-quality, few-layer graphene sheets. TORAYCA is designed to be mixed with traditional electrode materials to form a highly conductive network. Toray's research indicates that adding just 1-2% of their graphene additive can increase the conductivity of electrode materials by up to 100 times[6]. The company has also developed a method to functionalize the graphene surface, improving its dispersion in electrode slurries and enhancing its interaction with active materials[8].

Strengths: Significant conductivity improvement with small additive amounts, high-quality graphene production, enhanced dispersion properties. Weaknesses: Potentially high production costs of CVD graphene, challenges in scaling up production to meet large-scale battery manufacturing demands.

LG Chem Ltd.

Technical Solution: LG Chem has developed a graphene-enhanced lithium-ion battery technology that focuses on improving conductivity through graphene oxide (GO) additives. Their approach involves incorporating GO into both the cathode and anode materials. For the cathode, they use a GO-coated nickel-rich layered oxide, which enhances structural stability and electron transport. In the anode, graphene is mixed with silicon particles to create a composite that offers high capacity and improved conductivity. LG Chem's research has shown that this technology can increase battery energy density by up to 30% and extend cycle life by 20% compared to conventional lithium-ion batteries[2][4].

Strengths: Improved energy density and cycle life, applicable to existing battery manufacturing processes. Weaknesses: Potential increase in production complexity, need for precise control of graphene oxide quality and quantity.

Breakthrough Innovations in Graphene Battery Design

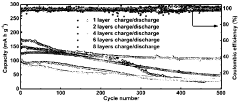

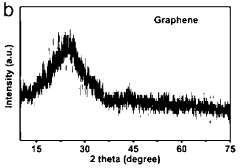

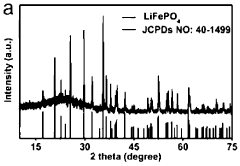

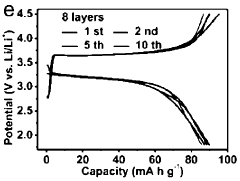

A method for improving cycle stability of cathode material for lithium-ion battery

PatentActiveZA202108331A

Innovation

- A method involving the alternating coating of lithium iron phosphate and graphene layers on the surface of cathode materials, with a preferred structure of two lithium iron phosphate layers and one graphene layer, to enhance conductivity and stability, utilizing graphene's high carrier mobility to disperse overpotential.

Conductive Composite Material of Graphene, Preparation Method Therefor, Use Thereof and Lithium-ion Battery

PatentActiveUS20230357019A1

Innovation

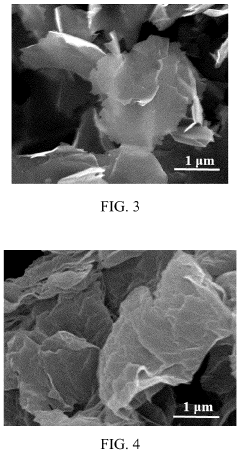

- A conductive composite material of graphene nano-sheets grafted with conjugated copolymers containing alkynyl groups, which act as a barrier to prevent aggregation and enhance electron transfer, is developed. The method involves pretreating graphene nano-sheets with 4-bromobenzenediazonium tetrafluoroborate and forming conjugated copolymers in the presence of these sheets, resulting in improved dispersion and conductivity.

Environmental Impact of Graphene Battery Production

The production of graphene batteries, while promising for energy storage advancements, raises significant environmental concerns that warrant careful consideration. The manufacturing process of graphene involves energy-intensive methods such as chemical vapor deposition or exfoliation of graphite, which can contribute to increased carbon emissions if not managed properly. Additionally, the use of harsh chemicals in graphene synthesis may lead to potential environmental contamination if proper disposal and treatment protocols are not followed.

Water usage is another critical factor in graphene battery production. The purification and processing of graphene materials often require substantial amounts of water, potentially straining local water resources in areas of production. This issue becomes particularly pressing in regions already facing water scarcity challenges.

The extraction of raw materials for graphene production, primarily graphite, can have substantial environmental impacts. Mining operations may lead to habitat destruction, soil erosion, and water pollution if not conducted with stringent environmental safeguards. Furthermore, the global supply chain for these materials can result in increased transportation-related emissions.

However, it's important to note that graphene batteries offer potential environmental benefits that could offset some of these production-related impacts. Their higher energy density and longer lifespan compared to traditional lithium-ion batteries may reduce overall resource consumption and waste generation in the long term. Additionally, the improved conductivity of graphene batteries could lead to more efficient energy storage systems, potentially reducing overall energy consumption and associated environmental impacts.

Recycling and end-of-life management of graphene batteries present both challenges and opportunities. While the recovery of graphene from used batteries could reduce the need for new raw material extraction, the process itself may require the development of new recycling technologies to effectively separate and reuse graphene components.

To mitigate the environmental impact of graphene battery production, several strategies can be employed. These include investing in cleaner energy sources for manufacturing processes, implementing closed-loop water recycling systems, and developing more environmentally friendly synthesis methods. Additionally, adopting sustainable mining practices for raw material extraction and optimizing supply chain logistics can further reduce the overall environmental footprint.

As research into graphene battery technology progresses, it is crucial to integrate life cycle assessments and environmental impact studies into the development process. This holistic approach will help identify and address potential environmental issues early in the technology's evolution, ensuring that the benefits of graphene batteries are realized without compromising environmental sustainability.

Water usage is another critical factor in graphene battery production. The purification and processing of graphene materials often require substantial amounts of water, potentially straining local water resources in areas of production. This issue becomes particularly pressing in regions already facing water scarcity challenges.

The extraction of raw materials for graphene production, primarily graphite, can have substantial environmental impacts. Mining operations may lead to habitat destruction, soil erosion, and water pollution if not conducted with stringent environmental safeguards. Furthermore, the global supply chain for these materials can result in increased transportation-related emissions.

However, it's important to note that graphene batteries offer potential environmental benefits that could offset some of these production-related impacts. Their higher energy density and longer lifespan compared to traditional lithium-ion batteries may reduce overall resource consumption and waste generation in the long term. Additionally, the improved conductivity of graphene batteries could lead to more efficient energy storage systems, potentially reducing overall energy consumption and associated environmental impacts.

Recycling and end-of-life management of graphene batteries present both challenges and opportunities. While the recovery of graphene from used batteries could reduce the need for new raw material extraction, the process itself may require the development of new recycling technologies to effectively separate and reuse graphene components.

To mitigate the environmental impact of graphene battery production, several strategies can be employed. These include investing in cleaner energy sources for manufacturing processes, implementing closed-loop water recycling systems, and developing more environmentally friendly synthesis methods. Additionally, adopting sustainable mining practices for raw material extraction and optimizing supply chain logistics can further reduce the overall environmental footprint.

As research into graphene battery technology progresses, it is crucial to integrate life cycle assessments and environmental impact studies into the development process. This holistic approach will help identify and address potential environmental issues early in the technology's evolution, ensuring that the benefits of graphene batteries are realized without compromising environmental sustainability.

Scalability and Commercialization Prospects

The scalability and commercialization prospects for graphene battery technology are promising, yet face several challenges. As research progresses in optimizing graphene battery conductivity, the potential for large-scale production and market adoption becomes increasingly feasible. The unique properties of graphene, including its high conductivity and strength-to-weight ratio, make it an attractive material for battery applications across various industries.

One of the primary factors driving the scalability of graphene batteries is the ongoing development of cost-effective production methods. As manufacturing processes improve, the cost of producing graphene-based battery components is expected to decrease, making them more competitive with traditional lithium-ion batteries. This cost reduction is crucial for widespread adoption in consumer electronics, electric vehicles, and grid-scale energy storage systems.

The automotive industry presents a significant opportunity for graphene battery commercialization. Electric vehicle manufacturers are constantly seeking ways to improve battery performance, and graphene's potential to enhance energy density and charging speeds aligns well with these goals. As graphene battery technology matures, it could become a key differentiator in the highly competitive EV market.

Another promising area for commercialization is the portable electronics sector. Graphene batteries' potential for faster charging times and longer battery life could revolutionize smartphones, laptops, and wearable devices. This market segment's rapid product cycles and consumer demand for improved battery performance create a favorable environment for early adoption of graphene battery technology.

However, scaling up graphene battery production faces several technical and logistical challenges. Ensuring consistent quality and performance across large-scale manufacturing processes remains a significant hurdle. Additionally, integrating graphene-based components into existing battery production lines may require substantial investments in new equipment and processes.

Regulatory considerations also play a crucial role in the commercialization prospects of graphene batteries. As with any new battery technology, safety standards and environmental regulations must be met. Demonstrating long-term stability, safety under various conditions, and environmental sustainability will be essential for gaining regulatory approval and consumer trust.

Collaboration between research institutions, battery manufacturers, and end-user industries will be vital in overcoming these challenges and realizing the full commercial potential of graphene batteries. As optimization techniques for graphene battery conductivity continue to advance, the path to scalability and commercialization becomes clearer, potentially reshaping the energy storage landscape in the coming years.

One of the primary factors driving the scalability of graphene batteries is the ongoing development of cost-effective production methods. As manufacturing processes improve, the cost of producing graphene-based battery components is expected to decrease, making them more competitive with traditional lithium-ion batteries. This cost reduction is crucial for widespread adoption in consumer electronics, electric vehicles, and grid-scale energy storage systems.

The automotive industry presents a significant opportunity for graphene battery commercialization. Electric vehicle manufacturers are constantly seeking ways to improve battery performance, and graphene's potential to enhance energy density and charging speeds aligns well with these goals. As graphene battery technology matures, it could become a key differentiator in the highly competitive EV market.

Another promising area for commercialization is the portable electronics sector. Graphene batteries' potential for faster charging times and longer battery life could revolutionize smartphones, laptops, and wearable devices. This market segment's rapid product cycles and consumer demand for improved battery performance create a favorable environment for early adoption of graphene battery technology.

However, scaling up graphene battery production faces several technical and logistical challenges. Ensuring consistent quality and performance across large-scale manufacturing processes remains a significant hurdle. Additionally, integrating graphene-based components into existing battery production lines may require substantial investments in new equipment and processes.

Regulatory considerations also play a crucial role in the commercialization prospects of graphene batteries. As with any new battery technology, safety standards and environmental regulations must be met. Demonstrating long-term stability, safety under various conditions, and environmental sustainability will be essential for gaining regulatory approval and consumer trust.

Collaboration between research institutions, battery manufacturers, and end-user industries will be vital in overcoming these challenges and realizing the full commercial potential of graphene batteries. As optimization techniques for graphene battery conductivity continue to advance, the path to scalability and commercialization becomes clearer, potentially reshaping the energy storage landscape in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!