Graphene Battery's Impact on Reducing Carbon Footprint

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries represent a significant leap forward in energy storage technology, with the potential to revolutionize various industries and contribute substantially to reducing carbon footprints. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which opened up new possibilities in material science and energy storage.

Initially, researchers focused on understanding the unique properties of graphene, such as its exceptional electrical conductivity, mechanical strength, and high surface area. These characteristics made graphene an ideal candidate for enhancing battery performance. The early stages of graphene battery development involved incorporating graphene into existing lithium-ion battery designs to improve their efficiency and capacity.

As research progressed, scientists began exploring the potential of graphene as a standalone electrode material. This led to the development of graphene-based supercapacitors, which offered rapid charging and discharging capabilities. However, the energy density of these early graphene energy storage devices was limited compared to traditional batteries.

The next phase of evolution focused on creating hybrid systems that combined the high power density of graphene supercapacitors with the high energy density of conventional batteries. This approach aimed to leverage the strengths of both technologies, resulting in energy storage solutions with improved overall performance.

Recent advancements have seen the development of graphene-enhanced lithium-ion batteries, where graphene is used to create more efficient electrodes and electrolytes. These innovations have led to batteries with higher capacity, faster charging times, and longer lifespans compared to traditional lithium-ion batteries.

The primary objectives of graphene battery research and development are multifaceted. Firstly, there is a strong focus on increasing energy density to enable longer-lasting and more compact energy storage solutions. This is particularly crucial for applications in electric vehicles and portable electronics, where weight and size are critical factors.

Secondly, researchers aim to improve the charging speed of graphene batteries, with the ultimate goal of achieving ultra-fast charging capabilities. This would address one of the main barriers to widespread electric vehicle adoption and revolutionize the way we use portable electronic devices.

Another key objective is to enhance the safety and stability of graphene batteries. By leveraging graphene's thermal conductivity and mechanical strength, researchers are working to create batteries that are less prone to overheating and more resistant to physical damage.

Lastly, a significant goal in graphene battery development is to reduce the environmental impact of battery production and disposal. This aligns with the broader objective of reducing carbon footprints across industries. By developing more efficient and longer-lasting batteries, graphene technology has the potential to decrease the frequency of battery replacements and reduce the overall demand for raw materials in battery production.

Initially, researchers focused on understanding the unique properties of graphene, such as its exceptional electrical conductivity, mechanical strength, and high surface area. These characteristics made graphene an ideal candidate for enhancing battery performance. The early stages of graphene battery development involved incorporating graphene into existing lithium-ion battery designs to improve their efficiency and capacity.

As research progressed, scientists began exploring the potential of graphene as a standalone electrode material. This led to the development of graphene-based supercapacitors, which offered rapid charging and discharging capabilities. However, the energy density of these early graphene energy storage devices was limited compared to traditional batteries.

The next phase of evolution focused on creating hybrid systems that combined the high power density of graphene supercapacitors with the high energy density of conventional batteries. This approach aimed to leverage the strengths of both technologies, resulting in energy storage solutions with improved overall performance.

Recent advancements have seen the development of graphene-enhanced lithium-ion batteries, where graphene is used to create more efficient electrodes and electrolytes. These innovations have led to batteries with higher capacity, faster charging times, and longer lifespans compared to traditional lithium-ion batteries.

The primary objectives of graphene battery research and development are multifaceted. Firstly, there is a strong focus on increasing energy density to enable longer-lasting and more compact energy storage solutions. This is particularly crucial for applications in electric vehicles and portable electronics, where weight and size are critical factors.

Secondly, researchers aim to improve the charging speed of graphene batteries, with the ultimate goal of achieving ultra-fast charging capabilities. This would address one of the main barriers to widespread electric vehicle adoption and revolutionize the way we use portable electronic devices.

Another key objective is to enhance the safety and stability of graphene batteries. By leveraging graphene's thermal conductivity and mechanical strength, researchers are working to create batteries that are less prone to overheating and more resistant to physical damage.

Lastly, a significant goal in graphene battery development is to reduce the environmental impact of battery production and disposal. This aligns with the broader objective of reducing carbon footprints across industries. By developing more efficient and longer-lasting batteries, graphene technology has the potential to decrease the frequency of battery replacements and reduce the overall demand for raw materials in battery production.

Market Demand for Sustainable Energy Storage

The global energy storage market is experiencing a significant shift towards sustainable solutions, driven by increasing environmental concerns and the urgent need to reduce carbon emissions. Graphene batteries have emerged as a promising technology in this context, offering potential advantages in energy density, charging speed, and environmental impact compared to traditional lithium-ion batteries.

The demand for sustainable energy storage solutions is rapidly growing across various sectors, including electric vehicles, renewable energy integration, and consumer electronics. This surge is fueled by stringent government regulations on carbon emissions, rising awareness of climate change, and the push for cleaner energy sources. The automotive industry, in particular, is a key driver of this demand, as manufacturers seek to improve the range and charging capabilities of electric vehicles to accelerate their adoption.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage systems. Graphene batteries could potentially address this challenge by offering higher capacity and faster charging capabilities, enabling better grid stability and energy management. This aligns with the global trend towards decentralized energy systems and microgrids, which require advanced storage technologies to function effectively.

The consumer electronics market also presents a significant opportunity for graphene batteries. As devices become more powerful and energy-intensive, there is a growing need for batteries that can provide longer life spans and faster charging times while minimizing environmental impact. This demand extends to portable devices, wearables, and smart home technologies, where energy efficiency and sustainability are increasingly important factors for consumers.

Industrial applications represent another substantial market for sustainable energy storage. Manufacturing facilities, data centers, and other energy-intensive operations are looking to reduce their carbon footprint and operational costs through more efficient energy storage solutions. Graphene batteries could potentially offer longer cycle life and improved performance in these high-demand environments.

The market demand for sustainable energy storage is further bolstered by increasing investments in research and development of advanced battery technologies. Governments and private sector entities are allocating significant resources to accelerate the commercialization of technologies like graphene batteries, recognizing their potential to contribute to carbon reduction goals and energy independence.

As the world transitions towards a low-carbon economy, the market for sustainable energy storage solutions is expected to expand substantially. Graphene batteries, with their potential to offer improved performance and reduced environmental impact, are well-positioned to capture a significant share of this growing market, provided they can overcome current technical and economic challenges to achieve widespread commercial viability.

The demand for sustainable energy storage solutions is rapidly growing across various sectors, including electric vehicles, renewable energy integration, and consumer electronics. This surge is fueled by stringent government regulations on carbon emissions, rising awareness of climate change, and the push for cleaner energy sources. The automotive industry, in particular, is a key driver of this demand, as manufacturers seek to improve the range and charging capabilities of electric vehicles to accelerate their adoption.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage systems. Graphene batteries could potentially address this challenge by offering higher capacity and faster charging capabilities, enabling better grid stability and energy management. This aligns with the global trend towards decentralized energy systems and microgrids, which require advanced storage technologies to function effectively.

The consumer electronics market also presents a significant opportunity for graphene batteries. As devices become more powerful and energy-intensive, there is a growing need for batteries that can provide longer life spans and faster charging times while minimizing environmental impact. This demand extends to portable devices, wearables, and smart home technologies, where energy efficiency and sustainability are increasingly important factors for consumers.

Industrial applications represent another substantial market for sustainable energy storage. Manufacturing facilities, data centers, and other energy-intensive operations are looking to reduce their carbon footprint and operational costs through more efficient energy storage solutions. Graphene batteries could potentially offer longer cycle life and improved performance in these high-demand environments.

The market demand for sustainable energy storage is further bolstered by increasing investments in research and development of advanced battery technologies. Governments and private sector entities are allocating significant resources to accelerate the commercialization of technologies like graphene batteries, recognizing their potential to contribute to carbon reduction goals and energy independence.

As the world transitions towards a low-carbon economy, the market for sustainable energy storage solutions is expected to expand substantially. Graphene batteries, with their potential to offer improved performance and reduced environmental impact, are well-positioned to capture a significant share of this growing market, provided they can overcome current technical and economic challenges to achieve widespread commercial viability.

Current Graphene Battery Technology Challenges

Despite the promising potential of graphene batteries in reducing carbon footprint, several significant challenges currently hinder their widespread adoption and commercialization. One of the primary obstacles is the high production cost associated with graphene synthesis and battery manufacturing processes. The complex and energy-intensive methods required to produce high-quality graphene materials contribute to elevated expenses, making graphene batteries less economically viable compared to traditional lithium-ion batteries.

Another major challenge lies in scaling up graphene production to meet industrial demands. While laboratory-scale production has shown promising results, translating these processes to large-scale manufacturing while maintaining consistent quality and performance remains a significant hurdle. The lack of standardized production methods and quality control measures further complicates this issue, leading to variations in graphene properties and battery performance across different manufacturers.

The integration of graphene into existing battery architectures poses additional technical difficulties. Optimizing the interface between graphene and other battery components, such as electrolytes and current collectors, is crucial for maximizing performance and stability. Researchers are still working to overcome issues related to graphene agglomeration and uniform dispersion within the battery structure, which can affect the overall efficiency and lifespan of the battery.

Stability and long-term performance of graphene batteries under various operating conditions remain areas of concern. While graphene exhibits excellent theoretical properties, practical applications have shown challenges in maintaining these characteristics over extended periods and multiple charge-discharge cycles. Issues such as capacity fading, electrolyte degradation, and structural changes in graphene-based electrodes need to be addressed to ensure the longevity and reliability of these batteries in real-world applications.

Safety considerations also present significant challenges in the development of graphene batteries. The high electrical conductivity of graphene, while beneficial for battery performance, raises concerns about potential short-circuits and thermal runaway events. Developing robust safety mechanisms and optimizing battery design to mitigate these risks is crucial for widespread adoption, particularly in sensitive applications such as electric vehicles and portable electronics.

Environmental and health impacts of graphene production and disposal are additional areas requiring further investigation. While graphene batteries aim to reduce carbon footprint, the environmental implications of large-scale graphene synthesis and the end-of-life management of graphene-containing batteries need to be thoroughly assessed to ensure a truly sustainable technology solution.

Addressing these multifaceted challenges requires collaborative efforts across academia, industry, and regulatory bodies. Continued research and development, along with strategic investments in manufacturing infrastructure and safety protocols, are essential to overcome these hurdles and realize the full potential of graphene batteries in reducing global carbon footprint.

Another major challenge lies in scaling up graphene production to meet industrial demands. While laboratory-scale production has shown promising results, translating these processes to large-scale manufacturing while maintaining consistent quality and performance remains a significant hurdle. The lack of standardized production methods and quality control measures further complicates this issue, leading to variations in graphene properties and battery performance across different manufacturers.

The integration of graphene into existing battery architectures poses additional technical difficulties. Optimizing the interface between graphene and other battery components, such as electrolytes and current collectors, is crucial for maximizing performance and stability. Researchers are still working to overcome issues related to graphene agglomeration and uniform dispersion within the battery structure, which can affect the overall efficiency and lifespan of the battery.

Stability and long-term performance of graphene batteries under various operating conditions remain areas of concern. While graphene exhibits excellent theoretical properties, practical applications have shown challenges in maintaining these characteristics over extended periods and multiple charge-discharge cycles. Issues such as capacity fading, electrolyte degradation, and structural changes in graphene-based electrodes need to be addressed to ensure the longevity and reliability of these batteries in real-world applications.

Safety considerations also present significant challenges in the development of graphene batteries. The high electrical conductivity of graphene, while beneficial for battery performance, raises concerns about potential short-circuits and thermal runaway events. Developing robust safety mechanisms and optimizing battery design to mitigate these risks is crucial for widespread adoption, particularly in sensitive applications such as electric vehicles and portable electronics.

Environmental and health impacts of graphene production and disposal are additional areas requiring further investigation. While graphene batteries aim to reduce carbon footprint, the environmental implications of large-scale graphene synthesis and the end-of-life management of graphene-containing batteries need to be thoroughly assessed to ensure a truly sustainable technology solution.

Addressing these multifaceted challenges requires collaborative efforts across academia, industry, and regulatory bodies. Continued research and development, along with strategic investments in manufacturing infrastructure and safety protocols, are essential to overcome these hurdles and realize the full potential of graphene batteries in reducing global carbon footprint.

Existing Graphene Battery Solutions

01 Graphene-based electrode materials for reduced carbon footprint

Graphene-based materials are used in battery electrodes to improve energy density and reduce the overall carbon footprint of battery production. These materials can enhance the battery's performance while requiring less raw material, potentially lowering the environmental impact of manufacturing processes.- Graphene-based electrode materials for reduced carbon footprint: Graphene-based materials are used in battery electrodes to improve energy density and reduce the overall carbon footprint of battery production. These materials can enhance the battery's performance while minimizing environmental impact due to their high conductivity and lightweight nature.

- Sustainable production methods for graphene batteries: Innovative manufacturing processes are developed to produce graphene batteries with a lower carbon footprint. These methods focus on reducing energy consumption during production, utilizing eco-friendly materials, and optimizing the use of resources to minimize environmental impact.

- Life cycle assessment of graphene batteries: Comprehensive life cycle assessments are conducted to evaluate the carbon footprint of graphene batteries from production to disposal. These assessments consider factors such as raw material extraction, manufacturing processes, use phase, and end-of-life management to provide a holistic view of the environmental impact.

- Recycling and circular economy approaches for graphene batteries: Strategies are developed to implement recycling and circular economy principles for graphene batteries. These approaches aim to recover and reuse valuable materials, reduce waste, and minimize the overall carbon footprint associated with battery production and disposal.

- Integration of renewable energy in graphene battery production: Efforts are made to incorporate renewable energy sources in the production of graphene batteries to reduce their carbon footprint. This includes the use of solar, wind, or other clean energy technologies in manufacturing facilities and throughout the supply chain.

02 Sustainable production methods for graphene batteries

Innovative production techniques are developed to manufacture graphene batteries with a reduced carbon footprint. These methods focus on using eco-friendly precursors, optimizing energy consumption during production, and implementing recycling processes to minimize waste and environmental impact.Expand Specific Solutions03 Life cycle assessment of graphene batteries

Comprehensive life cycle assessments are conducted to evaluate the carbon footprint of graphene batteries from raw material extraction to end-of-life disposal. These assessments help identify areas for improvement in the battery's environmental performance and guide the development of more sustainable battery technologies.Expand Specific Solutions04 Integration of renewable energy in graphene battery production

The use of renewable energy sources in the production of graphene batteries is explored to further reduce their carbon footprint. This approach involves incorporating solar, wind, or other clean energy technologies into manufacturing processes, potentially offsetting the energy-intensive steps of graphene synthesis and battery assembly.Expand Specific Solutions05 Recycling and circular economy strategies for graphene batteries

Advanced recycling techniques and circular economy principles are applied to graphene batteries to minimize their environmental impact. These strategies focus on recovering and reusing graphene and other valuable materials from spent batteries, reducing the need for raw material extraction and lowering the overall carbon footprint of the battery lifecycle.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market is in its early growth stage, with significant potential for reducing carbon footprints in various industries. The market size is expanding rapidly, driven by increasing demand for sustainable energy storage solutions. Technological maturity varies among key players, with companies like Honeycomb Battery Co., NEC Corp., and Western Digital Corp. leading in research and development. Universities such as Northwestern, Porto, and Eastern Finland are contributing to advancements in graphene battery technology. Collaboration between academic institutions and industry leaders like Semiconductor Energy Laboratory and GlobalWafers is accelerating innovation. While the technology shows promise, challenges in scalability and cost-effectiveness remain, indicating a competitive landscape with ample room for growth and differentiation.

NEC Corp.

Technical Solution: NEC Corporation has been actively researching and developing graphene-based technologies for energy storage applications. Their focus has been on creating high-performance supercapacitors using graphene materials. NEC's approach involves using a unique graphene synthesis method that allows for the production of high-quality, large-area graphene sheets suitable for energy storage devices [10]. They have reported achieving energy densities in graphene supercapacitors that are up to 5 times higher than conventional activated carbon supercapacitors [11]. Additionally, NEC has explored the integration of graphene into lithium-ion battery electrodes, demonstrating improved conductivity and faster charge/discharge rates [12].

Strengths: Strong focus on practical applications and integration with existing technologies, potential for rapid commercialization. Weaknesses: May face competition from other established battery technologies and manufacturers.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: The Dalian Institute has made significant strides in graphene battery technology, particularly focusing on improving the performance of lithium-sulfur batteries. Their research has led to the development of a graphene-based interlayer that effectively traps polysulfides, a common issue in lithium-sulfur batteries that leads to capacity fade [7]. This innovation has shown to increase the cycle life of lithium-sulfur batteries by up to 300% [8]. The institute has also explored the use of nitrogen-doped graphene as a catalyst for metal-air batteries, which could potentially offer higher energy densities and lower environmental impact compared to traditional lithium-ion batteries [9].

Strengths: Addressing key challenges in next-generation battery technologies, potential for significant improvements in battery lifespan and performance. Weaknesses: May require further development for practical implementation in commercial products.

Core Graphene Battery Innovations

Negative electrode material, secondary battery and electronic device

PatentPendingEP4579815A1

Innovation

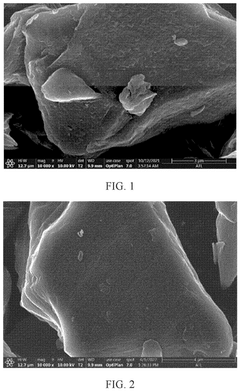

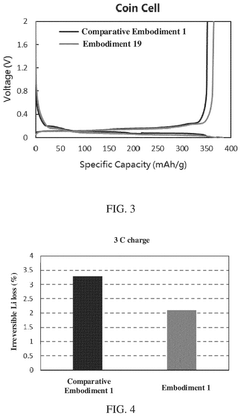

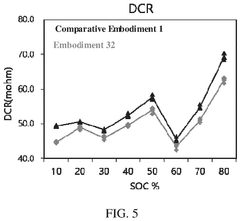

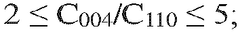

- A carbon-based negative electrode material with a controlled average surface roughness (1.2 nm ≤ R a ≤ 30 nm) and specific crystal plane orientation (2 ≤ C 004 /C 110 ≤ 7) is developed, featuring a wrinkled structure that enhances lithium ion adsorption and diffusion, along with optimized graphitization and particle sizes (6 nm ≤ D v50 ≤ 15 nm, 15 nm ≤ D v99 ≤ 42 nm) to improve gravimetric capacity and kinetic properties.

Environmental Impact Assessment

The environmental impact assessment of graphene batteries in reducing carbon footprint reveals significant potential for positive change across multiple sectors. Graphene batteries, with their superior energy density and faster charging capabilities, offer a promising alternative to traditional lithium-ion batteries, potentially revolutionizing energy storage and utilization.

In the transportation sector, the adoption of graphene batteries in electric vehicles (EVs) could lead to a substantial reduction in carbon emissions. The increased energy density allows for longer driving ranges, addressing one of the primary concerns of EV adoption. This improvement could accelerate the transition from fossil fuel-powered vehicles to electric alternatives, resulting in a notable decrease in greenhouse gas emissions from the transportation sector.

The manufacturing process of graphene batteries also presents opportunities for reducing environmental impact. Compared to traditional lithium-ion batteries, graphene batteries require fewer raw materials and can be produced using more environmentally friendly methods. This reduction in material usage and the potential for cleaner production processes contribute to a lower carbon footprint throughout the battery lifecycle.

In the renewable energy sector, graphene batteries could play a crucial role in enhancing the efficiency and reliability of energy storage systems. Their ability to charge and discharge rapidly makes them ideal for storing excess energy from intermittent renewable sources like solar and wind. This improved energy storage capacity could lead to a more stable and efficient renewable energy grid, further reducing reliance on fossil fuels and decreasing overall carbon emissions.

The longevity of graphene batteries is another factor contributing to their positive environmental impact. With a significantly longer lifespan compared to traditional batteries, graphene batteries reduce the need for frequent replacements. This durability translates to less electronic waste and a reduced demand for new battery production, both of which contribute to lowering the overall carbon footprint associated with energy storage solutions.

However, it is important to note that the full environmental impact of graphene batteries is still being studied. While the potential benefits are significant, factors such as the scalability of production, the environmental impact of graphene extraction or synthesis, and end-of-life recycling processes need to be thoroughly assessed to ensure a comprehensive understanding of their long-term environmental implications.

In the transportation sector, the adoption of graphene batteries in electric vehicles (EVs) could lead to a substantial reduction in carbon emissions. The increased energy density allows for longer driving ranges, addressing one of the primary concerns of EV adoption. This improvement could accelerate the transition from fossil fuel-powered vehicles to electric alternatives, resulting in a notable decrease in greenhouse gas emissions from the transportation sector.

The manufacturing process of graphene batteries also presents opportunities for reducing environmental impact. Compared to traditional lithium-ion batteries, graphene batteries require fewer raw materials and can be produced using more environmentally friendly methods. This reduction in material usage and the potential for cleaner production processes contribute to a lower carbon footprint throughout the battery lifecycle.

In the renewable energy sector, graphene batteries could play a crucial role in enhancing the efficiency and reliability of energy storage systems. Their ability to charge and discharge rapidly makes them ideal for storing excess energy from intermittent renewable sources like solar and wind. This improved energy storage capacity could lead to a more stable and efficient renewable energy grid, further reducing reliance on fossil fuels and decreasing overall carbon emissions.

The longevity of graphene batteries is another factor contributing to their positive environmental impact. With a significantly longer lifespan compared to traditional batteries, graphene batteries reduce the need for frequent replacements. This durability translates to less electronic waste and a reduced demand for new battery production, both of which contribute to lowering the overall carbon footprint associated with energy storage solutions.

However, it is important to note that the full environmental impact of graphene batteries is still being studied. While the potential benefits are significant, factors such as the scalability of production, the environmental impact of graphene extraction or synthesis, and end-of-life recycling processes need to be thoroughly assessed to ensure a comprehensive understanding of their long-term environmental implications.

Graphene Battery Manufacturing Processes

The manufacturing processes for graphene batteries are crucial in determining their potential to reduce carbon footprints. These processes involve several key steps, each contributing to the overall environmental impact and efficiency of the battery production.

The first stage in graphene battery manufacturing is the synthesis of graphene itself. This can be achieved through various methods, including chemical vapor deposition (CVD), exfoliation of graphite, and reduction of graphene oxide. Among these, CVD is widely used for large-scale production due to its ability to produce high-quality graphene sheets. However, this process often requires high temperatures and energy-intensive conditions, which can contribute to carbon emissions.

Once graphene is synthesized, it needs to be incorporated into the battery structure. This typically involves creating a composite material by combining graphene with other battery components such as electrolytes and current collectors. The integration process often requires precise control of material properties and may involve techniques like solution processing or vacuum filtration.

The assembly of graphene batteries follows, which includes the layering of anode, cathode, and separator materials. This step is critical for ensuring proper ion flow and overall battery performance. Advanced manufacturing techniques, such as roll-to-roll processing, are being developed to enhance the efficiency and scalability of this stage.

Surface treatment and functionalization of graphene are essential steps that can significantly impact battery performance. These processes involve modifying the graphene surface to improve its interaction with electrolytes and other battery components. Techniques such as plasma treatment or chemical functionalization are commonly employed, but their environmental impact varies depending on the specific methods and chemicals used.

Quality control and testing are integral parts of the manufacturing process, ensuring that each battery meets the required specifications. This involves various analytical techniques and performance tests, which may consume additional energy but are crucial for producing reliable and efficient batteries.

The final stages of manufacturing include packaging and sealing of the batteries. This step is important not only for protecting the battery components but also for ensuring safety during transportation and use. The choice of packaging materials can have implications for the overall environmental footprint of the battery.

Throughout the manufacturing process, there are opportunities to implement sustainable practices and reduce carbon emissions. This includes using renewable energy sources for power-intensive steps, optimizing material usage to minimize waste, and developing closed-loop recycling systems for battery components. Advancements in these areas are crucial for maximizing the potential of graphene batteries to contribute to carbon footprint reduction.

The first stage in graphene battery manufacturing is the synthesis of graphene itself. This can be achieved through various methods, including chemical vapor deposition (CVD), exfoliation of graphite, and reduction of graphene oxide. Among these, CVD is widely used for large-scale production due to its ability to produce high-quality graphene sheets. However, this process often requires high temperatures and energy-intensive conditions, which can contribute to carbon emissions.

Once graphene is synthesized, it needs to be incorporated into the battery structure. This typically involves creating a composite material by combining graphene with other battery components such as electrolytes and current collectors. The integration process often requires precise control of material properties and may involve techniques like solution processing or vacuum filtration.

The assembly of graphene batteries follows, which includes the layering of anode, cathode, and separator materials. This step is critical for ensuring proper ion flow and overall battery performance. Advanced manufacturing techniques, such as roll-to-roll processing, are being developed to enhance the efficiency and scalability of this stage.

Surface treatment and functionalization of graphene are essential steps that can significantly impact battery performance. These processes involve modifying the graphene surface to improve its interaction with electrolytes and other battery components. Techniques such as plasma treatment or chemical functionalization are commonly employed, but their environmental impact varies depending on the specific methods and chemicals used.

Quality control and testing are integral parts of the manufacturing process, ensuring that each battery meets the required specifications. This involves various analytical techniques and performance tests, which may consume additional energy but are crucial for producing reliable and efficient batteries.

The final stages of manufacturing include packaging and sealing of the batteries. This step is important not only for protecting the battery components but also for ensuring safety during transportation and use. The choice of packaging materials can have implications for the overall environmental footprint of the battery.

Throughout the manufacturing process, there are opportunities to implement sustainable practices and reduce carbon emissions. This includes using renewable energy sources for power-intensive steps, optimizing material usage to minimize waste, and developing closed-loop recycling systems for battery components. Advancements in these areas are crucial for maximizing the potential of graphene batteries to contribute to carbon footprint reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!