Examining Polypropylene's Fire Safety Applications in Construction

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Fire Safety Evolution and Objectives

Polypropylene's journey in fire safety applications within the construction industry has been marked by significant advancements and evolving objectives. The development of fire-resistant polypropylene materials has been driven by the increasing demand for safer building materials and stricter fire safety regulations in the construction sector.

Initially, polypropylene was primarily used in construction for its durability, cost-effectiveness, and versatility. However, its inherent flammability posed significant challenges in meeting fire safety standards. This limitation spurred research and development efforts to enhance the fire-resistant properties of polypropylene, leading to the creation of flame-retardant additives and innovative manufacturing processes.

The evolution of polypropylene's fire safety features can be traced through several key milestones. In the 1980s, the introduction of halogenated flame retardants marked a significant improvement in the material's fire resistance. However, environmental concerns led to a shift towards more sustainable solutions. The 1990s saw the development of intumescent systems, which form a protective char layer when exposed to heat, significantly improving the material's fire performance.

Recent years have witnessed a focus on nanotechnology-based solutions, incorporating materials like nano-clays and carbon nanotubes to enhance fire resistance without compromising other desirable properties of polypropylene. This approach has opened new possibilities for creating high-performance, fire-resistant polypropylene composites suitable for various construction applications.

The primary objectives in the ongoing development of fire-safe polypropylene for construction include improving flame spread resistance, reducing smoke production, and minimizing toxic gas emissions during combustion. Additionally, there is a growing emphasis on maintaining the material's structural integrity under fire conditions, particularly for load-bearing applications.

Another critical goal is to achieve these fire safety improvements while preserving polypropylene's other beneficial properties, such as its lightweight nature, chemical resistance, and ease of processing. This balancing act between fire safety and material performance continues to drive innovation in the field.

Looking forward, the industry aims to develop polypropylene-based materials that not only meet but exceed current fire safety standards. This includes creating self-extinguishing variants and exploring synergistic combinations of different flame-retardant mechanisms. The ultimate objective is to position polypropylene as a preferred material in construction, capable of enhancing overall building safety while offering the sustainability and performance benefits inherent to polymers.

Initially, polypropylene was primarily used in construction for its durability, cost-effectiveness, and versatility. However, its inherent flammability posed significant challenges in meeting fire safety standards. This limitation spurred research and development efforts to enhance the fire-resistant properties of polypropylene, leading to the creation of flame-retardant additives and innovative manufacturing processes.

The evolution of polypropylene's fire safety features can be traced through several key milestones. In the 1980s, the introduction of halogenated flame retardants marked a significant improvement in the material's fire resistance. However, environmental concerns led to a shift towards more sustainable solutions. The 1990s saw the development of intumescent systems, which form a protective char layer when exposed to heat, significantly improving the material's fire performance.

Recent years have witnessed a focus on nanotechnology-based solutions, incorporating materials like nano-clays and carbon nanotubes to enhance fire resistance without compromising other desirable properties of polypropylene. This approach has opened new possibilities for creating high-performance, fire-resistant polypropylene composites suitable for various construction applications.

The primary objectives in the ongoing development of fire-safe polypropylene for construction include improving flame spread resistance, reducing smoke production, and minimizing toxic gas emissions during combustion. Additionally, there is a growing emphasis on maintaining the material's structural integrity under fire conditions, particularly for load-bearing applications.

Another critical goal is to achieve these fire safety improvements while preserving polypropylene's other beneficial properties, such as its lightweight nature, chemical resistance, and ease of processing. This balancing act between fire safety and material performance continues to drive innovation in the field.

Looking forward, the industry aims to develop polypropylene-based materials that not only meet but exceed current fire safety standards. This includes creating self-extinguishing variants and exploring synergistic combinations of different flame-retardant mechanisms. The ultimate objective is to position polypropylene as a preferred material in construction, capable of enhancing overall building safety while offering the sustainability and performance benefits inherent to polymers.

Construction Industry Demand for Fire-Resistant Materials

The construction industry has witnessed a growing demand for fire-resistant materials, driven by increasingly stringent safety regulations and a heightened awareness of fire hazards in buildings. This trend is particularly evident in high-rise structures, commercial complexes, and public facilities where fire safety is paramount. The global market for fire-resistant building materials is experiencing significant growth, with projections indicating a steady increase in the coming years.

Polypropylene, a versatile thermoplastic polymer, has emerged as a promising material for fire safety applications in construction. Its inherent properties, such as low density, high strength-to-weight ratio, and excellent chemical resistance, make it an attractive option for various building components. When modified with fire-retardant additives, polypropylene can achieve enhanced fire resistance, meeting or exceeding industry standards.

The demand for fire-resistant polypropylene in construction is primarily driven by its application in insulation materials, electrical wiring, piping systems, and structural components. In the insulation sector, fire-resistant polypropylene foams are gaining traction as an alternative to traditional materials, offering improved thermal performance and fire safety. The electrical industry is adopting fire-resistant polypropylene for cable insulation and conduits, reducing the risk of fire propagation in building electrical systems.

Building codes and regulations play a crucial role in shaping the demand for fire-resistant materials. Many countries have implemented stricter fire safety standards, requiring construction materials to meet specific fire resistance ratings. This regulatory environment has spurred innovation in fire-resistant polypropylene formulations, with manufacturers investing in research and development to create products that comply with these standards.

The construction industry's shift towards sustainable and environmentally friendly materials has also influenced the demand for fire-resistant polypropylene. As a recyclable material, polypropylene aligns with green building initiatives, offering a more sustainable alternative to some traditional fire-resistant materials. This aspect has become increasingly important for architects and builders seeking to balance safety requirements with environmental considerations.

Despite the growing demand, challenges remain in the widespread adoption of fire-resistant polypropylene in construction. These include the need for extensive testing and certification to meet diverse regional standards, as well as the higher cost compared to some conventional materials. However, ongoing research and development efforts are focused on addressing these challenges, aiming to improve the cost-effectiveness and performance of fire-resistant polypropylene products.

Polypropylene, a versatile thermoplastic polymer, has emerged as a promising material for fire safety applications in construction. Its inherent properties, such as low density, high strength-to-weight ratio, and excellent chemical resistance, make it an attractive option for various building components. When modified with fire-retardant additives, polypropylene can achieve enhanced fire resistance, meeting or exceeding industry standards.

The demand for fire-resistant polypropylene in construction is primarily driven by its application in insulation materials, electrical wiring, piping systems, and structural components. In the insulation sector, fire-resistant polypropylene foams are gaining traction as an alternative to traditional materials, offering improved thermal performance and fire safety. The electrical industry is adopting fire-resistant polypropylene for cable insulation and conduits, reducing the risk of fire propagation in building electrical systems.

Building codes and regulations play a crucial role in shaping the demand for fire-resistant materials. Many countries have implemented stricter fire safety standards, requiring construction materials to meet specific fire resistance ratings. This regulatory environment has spurred innovation in fire-resistant polypropylene formulations, with manufacturers investing in research and development to create products that comply with these standards.

The construction industry's shift towards sustainable and environmentally friendly materials has also influenced the demand for fire-resistant polypropylene. As a recyclable material, polypropylene aligns with green building initiatives, offering a more sustainable alternative to some traditional fire-resistant materials. This aspect has become increasingly important for architects and builders seeking to balance safety requirements with environmental considerations.

Despite the growing demand, challenges remain in the widespread adoption of fire-resistant polypropylene in construction. These include the need for extensive testing and certification to meet diverse regional standards, as well as the higher cost compared to some conventional materials. However, ongoing research and development efforts are focused on addressing these challenges, aiming to improve the cost-effectiveness and performance of fire-resistant polypropylene products.

Current Polypropylene Fire Safety Challenges

Polypropylene, despite its widespread use in construction, faces significant fire safety challenges that need to be addressed. One of the primary concerns is its inherent flammability. When exposed to high temperatures, polypropylene tends to melt and drip, potentially spreading fire to other areas. This characteristic makes it particularly problematic in vertical applications, such as wall claddings or insulation systems, where the risk of fire propagation is higher.

Another challenge is the release of toxic gases during combustion. When polypropylene burns, it can emit harmful substances, including carbon monoxide and various hydrocarbons. These emissions not only pose immediate health risks to building occupants but also complicate firefighting efforts and evacuation procedures.

The material's low thermal stability is an additional concern. Polypropylene begins to degrade at relatively low temperatures compared to other construction materials, which can compromise its structural integrity in fire scenarios. This degradation can lead to the collapse of building components, further exacerbating the fire hazard.

Fire retardancy is another area where polypropylene faces challenges. While fire retardants can be added to improve its fire performance, these additives often come with their own set of issues. They may negatively impact the material's mechanical properties, increase production costs, or raise environmental concerns due to the potential release of harmful chemicals over time.

The recyclability of fire-retardant polypropylene is also a growing concern in the construction industry's push towards sustainability. The presence of fire retardants can complicate recycling processes, potentially limiting the material's end-of-life options and overall environmental footprint.

Regulatory compliance presents another hurdle. As building codes and fire safety standards become increasingly stringent, polypropylene manufacturers and construction professionals must continually adapt their products and practices to meet these evolving requirements. This ongoing process of adaptation can be both technically challenging and economically demanding.

Lastly, there is the challenge of public perception. High-profile fire incidents involving plastic materials have raised concerns among the general public and stakeholders in the construction industry. Overcoming these perceptions and demonstrating the safe use of polypropylene in construction applications requires extensive testing, documentation, and education efforts.

Another challenge is the release of toxic gases during combustion. When polypropylene burns, it can emit harmful substances, including carbon monoxide and various hydrocarbons. These emissions not only pose immediate health risks to building occupants but also complicate firefighting efforts and evacuation procedures.

The material's low thermal stability is an additional concern. Polypropylene begins to degrade at relatively low temperatures compared to other construction materials, which can compromise its structural integrity in fire scenarios. This degradation can lead to the collapse of building components, further exacerbating the fire hazard.

Fire retardancy is another area where polypropylene faces challenges. While fire retardants can be added to improve its fire performance, these additives often come with their own set of issues. They may negatively impact the material's mechanical properties, increase production costs, or raise environmental concerns due to the potential release of harmful chemicals over time.

The recyclability of fire-retardant polypropylene is also a growing concern in the construction industry's push towards sustainability. The presence of fire retardants can complicate recycling processes, potentially limiting the material's end-of-life options and overall environmental footprint.

Regulatory compliance presents another hurdle. As building codes and fire safety standards become increasingly stringent, polypropylene manufacturers and construction professionals must continually adapt their products and practices to meet these evolving requirements. This ongoing process of adaptation can be both technically challenging and economically demanding.

Lastly, there is the challenge of public perception. High-profile fire incidents involving plastic materials have raised concerns among the general public and stakeholders in the construction industry. Overcoming these perceptions and demonstrating the safe use of polypropylene in construction applications requires extensive testing, documentation, and education efforts.

Existing Polypropylene Fire Safety Solutions

01 Flame retardant additives for polypropylene

Various flame retardant additives can be incorporated into polypropylene to enhance its fire safety properties. These additives work by inhibiting combustion, reducing flame spread, or promoting char formation. Common flame retardants used in polypropylene include halogenated compounds, phosphorus-based additives, and mineral fillers.- Flame retardant additives for polypropylene: Various flame retardant additives can be incorporated into polypropylene to enhance its fire safety properties. These additives work by different mechanisms, such as forming a protective char layer, releasing flame-inhibiting gases, or promoting intumescence. Common flame retardants used in polypropylene include halogenated compounds, phosphorus-based additives, and mineral fillers.

- Fire-resistant polypropylene composites: Developing fire-resistant polypropylene composites involves combining polypropylene with other materials to improve its fire safety characteristics. These composites may include reinforcing fibers, nanoparticles, or other polymers that contribute to enhanced flame resistance, reduced heat release, and improved mechanical properties under fire conditions.

- Surface treatments for improved fire safety: Surface treatments can be applied to polypropylene products to enhance their fire safety properties. These treatments may include coatings, plasma treatments, or chemical modifications of the surface layer. Such treatments can create a protective barrier that improves flame resistance and reduces the spread of fire on polypropylene surfaces.

- Fire safety testing and standards for polypropylene: Developing and implementing fire safety testing methods and standards specific to polypropylene materials is crucial for ensuring their safe use in various applications. These tests may evaluate parameters such as flame spread, smoke generation, heat release rate, and time to ignition. Compliance with established fire safety standards is essential for the use of polypropylene in construction, automotive, and other industries.

- Fire-resistant polypropylene fiber and textile applications: Developing fire-resistant polypropylene fibers and textiles involves modifying the polymer structure or incorporating flame retardant additives during fiber production. These fire-resistant fibers can be used in various applications, including protective clothing, upholstery, and industrial textiles, where fire safety is a critical requirement.

02 Fire-resistant polypropylene composites

Developing fire-resistant polypropylene composites involves combining polypropylene with other materials to improve its fire safety characteristics. These composites may include reinforcing fibers, nanoparticles, or other polymers that contribute to enhanced flame resistance and reduced heat release rates during combustion.Expand Specific Solutions03 Surface treatments for improved fire safety

Surface treatments can be applied to polypropylene products to enhance their fire safety properties. These treatments may include coatings, plasma treatments, or chemical modifications that create a protective barrier on the surface of the material, reducing its flammability and improving its resistance to ignition.Expand Specific Solutions04 Fire safety testing and standards for polypropylene

Developing and implementing fire safety testing methods and standards specific to polypropylene materials is crucial for ensuring their safe use in various applications. These tests may evaluate parameters such as flame spread, smoke generation, and heat release rates to assess the overall fire performance of polypropylene products.Expand Specific Solutions05 Fire-resistant polypropylene fiber and textile applications

Developing fire-resistant polypropylene fibers and textiles involves modifying the polymer structure or incorporating flame retardant additives during fiber production. These fire-resistant fibers can be used in various applications, including protective clothing, upholstery, and industrial textiles, where fire safety is a critical requirement.Expand Specific Solutions

Key Players in Fire-Resistant Polypropylene Development

The fire safety applications of polypropylene in construction are at a mature stage of development, with a substantial market size driven by stringent building regulations and increasing safety awareness. The technology's maturity is evident from the involvement of major industry players like Borealis AG, Kingfa Sci. & Tech. Co., Ltd., and Dow Global Technologies LLC, who have established expertise in developing flame-retardant polypropylene formulations. These companies, along with others such as SABIC and Mitsui Chemicals, are continuously innovating to improve the fire resistance properties of polypropylene while maintaining its desirable characteristics for construction applications. The competitive landscape is characterized by a mix of large multinational corporations and specialized chemical companies, indicating a well-developed market with ongoing research and development efforts.

Borealis AG

Technical Solution: Borealis AG has developed a range of flame-retardant polypropylene (PP) compounds for construction applications. Their Daploy™ HMS PP technology enhances the fire safety of PP by incorporating high melt strength properties[1]. This allows for the production of low-density foams with improved flame retardancy. The company has also introduced Fibremod™, a long glass fiber-reinforced PP that combines mechanical strength with flame-retardant properties[2]. These materials are engineered to meet stringent fire safety standards such as UL94 V-0 and achieve low smoke density and toxicity levels[3].

Strengths: Advanced polymer technology, wide range of tailored solutions. Weaknesses: Potential higher cost compared to standard PP, may require specialized processing.

Dow Global Technologies LLC

Technical Solution: Dow has developed INTUNE™ PP-based Olefin Block Copolymers (OBCs) that can be used in flame-retardant PP compounds for construction applications. These OBCs enhance the compatibility between PP and flame retardants, improving overall fire performance[4]. Dow's AFFINITY™ polyolefin elastomers are also used in flame-retardant PP formulations to maintain flexibility and impact resistance while meeting fire safety requirements[5]. The company's EMERGE™ Advanced Resins include halogen-free flame-retardant grades specifically designed for building and construction applications, offering both fire safety and environmental benefits[6].

Strengths: Diverse product portfolio, strong R&D capabilities. Weaknesses: Some solutions may be more expensive than traditional materials, potential for reduced mechanical properties in highly flame-retardant grades.

Innovative Fire-Resistant Polypropylene Technologies

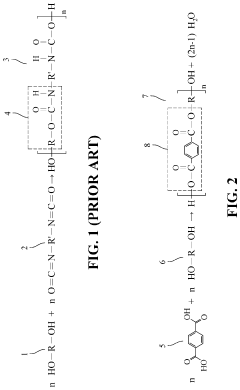

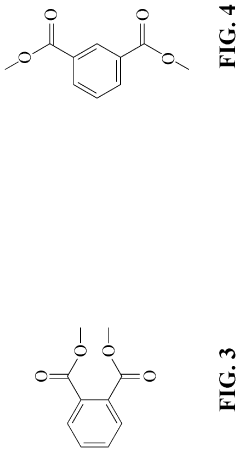

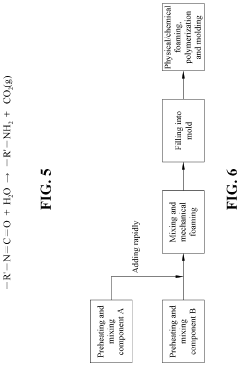

Flame-resistant polyurethane foam material

PatentInactiveUS20210122872A1

Innovation

- A flame-resistant polyurethane foam material is developed using a polyester polyol with a high content of terephthalic acid structure and a phosphate ester with a benzene structure as a flame retardant, improving structural strength, hardness, and flame resistance through a condensation polymerization reaction and addition of a foaming agent, catalyst, and optional additives.

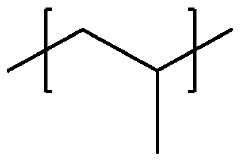

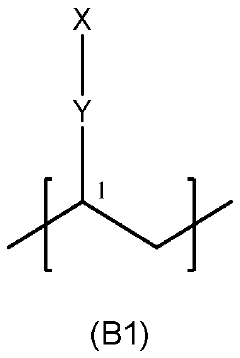

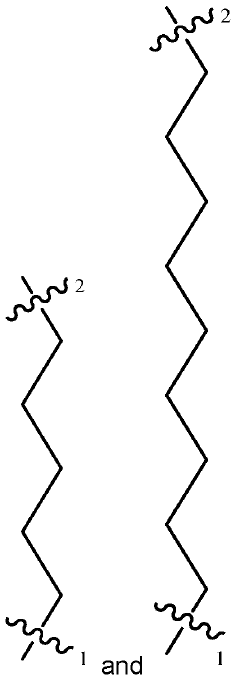

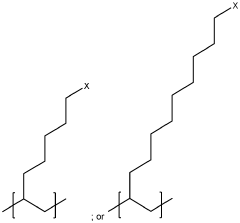

Flame retardant polypropylene

PatentWO2024121541A1

Innovation

- A polymer comprising propylene repeating units and phosphonated ethylene repeating units, prepared through a two-step process involving the phosphonation of LG-functionalised ethylene units, which are then blended with poly(propylene) to enhance flame retardancy and thermal stability.

Building Codes and Fire Safety Regulations

Building codes and fire safety regulations play a crucial role in ensuring the safety of occupants and structures in the construction industry. These regulations are continuously evolving to incorporate new materials and technologies, including the use of polypropylene in fire safety applications. The implementation of stringent building codes and fire safety regulations has significantly contributed to reducing fire-related incidents and improving overall building safety.

In many jurisdictions, building codes and fire safety regulations are based on performance-based standards, which allow for the use of innovative materials and technologies that can meet or exceed the required safety levels. This approach has opened doors for the integration of polypropylene-based fire safety solutions in construction projects. Polypropylene's unique properties, such as its low smoke emission and high heat resistance, make it an attractive option for various fire safety applications.

The International Building Code (IBC) and the National Fire Protection Association (NFPA) standards are widely recognized and adopted in many countries. These codes provide comprehensive guidelines for fire safety in buildings, including requirements for fire-resistant materials, fire suppression systems, and evacuation procedures. The inclusion of polypropylene-based products in these codes has been gradual, with ongoing research and testing supporting their effectiveness in fire safety applications.

One of the key areas where polypropylene has gained acceptance in building codes is in fire-resistant coatings and insulation materials. These applications leverage polypropylene's ability to form a protective char layer when exposed to high temperatures, effectively slowing down the spread of fire. Building codes now often specify the use of such materials in critical areas of a structure, such as load-bearing elements and escape routes.

The adoption of polypropylene in fire safety applications has also led to the development of specific testing and certification procedures. These procedures ensure that polypropylene-based products meet the stringent requirements set forth in building codes and fire safety regulations. Standardized tests, such as the ASTM E84 for surface burning characteristics and the UL 94 for flammability of plastic materials, are commonly used to evaluate the performance of polypropylene-based fire safety products.

As the construction industry continues to embrace sustainable and energy-efficient building practices, building codes and fire safety regulations are adapting to accommodate new materials and technologies. Polypropylene's recyclability and durability align well with these sustainability goals, further supporting its integration into modern building codes. However, it is essential to note that the use of polypropylene in fire safety applications must always be balanced with other fire safety measures to ensure comprehensive protection.

In many jurisdictions, building codes and fire safety regulations are based on performance-based standards, which allow for the use of innovative materials and technologies that can meet or exceed the required safety levels. This approach has opened doors for the integration of polypropylene-based fire safety solutions in construction projects. Polypropylene's unique properties, such as its low smoke emission and high heat resistance, make it an attractive option for various fire safety applications.

The International Building Code (IBC) and the National Fire Protection Association (NFPA) standards are widely recognized and adopted in many countries. These codes provide comprehensive guidelines for fire safety in buildings, including requirements for fire-resistant materials, fire suppression systems, and evacuation procedures. The inclusion of polypropylene-based products in these codes has been gradual, with ongoing research and testing supporting their effectiveness in fire safety applications.

One of the key areas where polypropylene has gained acceptance in building codes is in fire-resistant coatings and insulation materials. These applications leverage polypropylene's ability to form a protective char layer when exposed to high temperatures, effectively slowing down the spread of fire. Building codes now often specify the use of such materials in critical areas of a structure, such as load-bearing elements and escape routes.

The adoption of polypropylene in fire safety applications has also led to the development of specific testing and certification procedures. These procedures ensure that polypropylene-based products meet the stringent requirements set forth in building codes and fire safety regulations. Standardized tests, such as the ASTM E84 for surface burning characteristics and the UL 94 for flammability of plastic materials, are commonly used to evaluate the performance of polypropylene-based fire safety products.

As the construction industry continues to embrace sustainable and energy-efficient building practices, building codes and fire safety regulations are adapting to accommodate new materials and technologies. Polypropylene's recyclability and durability align well with these sustainability goals, further supporting its integration into modern building codes. However, it is essential to note that the use of polypropylene in fire safety applications must always be balanced with other fire safety measures to ensure comprehensive protection.

Environmental Impact of Fire-Resistant Polypropylene

The environmental impact of fire-resistant polypropylene in construction applications is a critical consideration as the industry seeks to balance safety requirements with sustainability goals. Fire-resistant polypropylene offers significant advantages in terms of fire safety, but its production and use also have environmental implications that must be carefully evaluated.

The manufacturing process of fire-resistant polypropylene typically involves the addition of flame retardants, which can include halogenated compounds, phosphorus-based additives, or mineral fillers. While these additives enhance the material's fire resistance, they may also increase the overall environmental footprint of the product. The production of these additives often requires additional energy and resources, potentially contributing to increased greenhouse gas emissions and resource depletion.

However, it is important to note that the use of fire-resistant polypropylene in construction can lead to positive environmental outcomes. By improving fire safety in buildings, these materials can reduce the likelihood and severity of fires, thereby preventing the release of toxic fumes and particulates that result from burning structures. This indirect environmental benefit should be weighed against the production impacts when assessing the overall environmental profile of fire-resistant polypropylene.

End-of-life considerations are another crucial aspect of the environmental impact assessment. Fire-resistant polypropylene may pose challenges in recycling due to the presence of flame retardant additives. Some additives can make the material more difficult to recycle or may require specialized recycling processes, potentially leading to increased waste if proper recycling infrastructure is not in place.

On the other hand, the durability and longevity of fire-resistant polypropylene in construction applications can contribute to reduced material replacement rates and lower overall resource consumption over the lifecycle of a building. This extended service life can offset some of the initial environmental costs associated with production.

Water pollution is another potential concern, particularly if halogenated flame retardants are used. These compounds can leach into the environment during the product's lifecycle, potentially affecting aquatic ecosystems. However, the development of more environmentally friendly flame retardants, such as non-halogenated alternatives, is an active area of research that may mitigate these concerns in the future.

In conclusion, while fire-resistant polypropylene offers important safety benefits in construction, its environmental impact is complex and multifaceted. Ongoing research and development efforts are focused on improving the sustainability of these materials, including the exploration of bio-based flame retardants and more efficient production processes. As the construction industry continues to prioritize both safety and sustainability, a holistic approach to assessing and minimizing the environmental impact of fire-resistant polypropylene will be essential.

The manufacturing process of fire-resistant polypropylene typically involves the addition of flame retardants, which can include halogenated compounds, phosphorus-based additives, or mineral fillers. While these additives enhance the material's fire resistance, they may also increase the overall environmental footprint of the product. The production of these additives often requires additional energy and resources, potentially contributing to increased greenhouse gas emissions and resource depletion.

However, it is important to note that the use of fire-resistant polypropylene in construction can lead to positive environmental outcomes. By improving fire safety in buildings, these materials can reduce the likelihood and severity of fires, thereby preventing the release of toxic fumes and particulates that result from burning structures. This indirect environmental benefit should be weighed against the production impacts when assessing the overall environmental profile of fire-resistant polypropylene.

End-of-life considerations are another crucial aspect of the environmental impact assessment. Fire-resistant polypropylene may pose challenges in recycling due to the presence of flame retardant additives. Some additives can make the material more difficult to recycle or may require specialized recycling processes, potentially leading to increased waste if proper recycling infrastructure is not in place.

On the other hand, the durability and longevity of fire-resistant polypropylene in construction applications can contribute to reduced material replacement rates and lower overall resource consumption over the lifecycle of a building. This extended service life can offset some of the initial environmental costs associated with production.

Water pollution is another potential concern, particularly if halogenated flame retardants are used. These compounds can leach into the environment during the product's lifecycle, potentially affecting aquatic ecosystems. However, the development of more environmentally friendly flame retardants, such as non-halogenated alternatives, is an active area of research that may mitigate these concerns in the future.

In conclusion, while fire-resistant polypropylene offers important safety benefits in construction, its environmental impact is complex and multifaceted. Ongoing research and development efforts are focused on improving the sustainability of these materials, including the exploration of bio-based flame retardants and more efficient production processes. As the construction industry continues to prioritize both safety and sustainability, a holistic approach to assessing and minimizing the environmental impact of fire-resistant polypropylene will be essential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!