Exploring Ferrofluid's Potential in Improved Waste Management Systems

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid in Waste Management: Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have garnered significant attention in recent years due to their potential applications across various industries. In the context of waste management, these remarkable substances offer promising avenues for innovation and improvement. The evolution of ferrofluid technology can be traced back to the 1960s when NASA first developed them for controlling liquids in zero gravity. Since then, their applications have expanded into diverse fields, including engineering, medicine, and environmental sciences.

The waste management sector faces numerous challenges, including the need for more efficient separation techniques, improved contaminant removal, and enhanced resource recovery. Ferrofluids, with their unique magnetic properties and fluid characteristics, present an opportunity to address these issues. The primary objective of exploring ferrofluids in waste management is to leverage their magnetic responsiveness and fluid dynamics to develop novel solutions for waste separation, treatment, and recycling processes.

One of the key technological trends driving this exploration is the increasing focus on sustainable and environmentally friendly waste management practices. As global concerns about pollution and resource depletion grow, there is a pressing need for innovative approaches that can minimize environmental impact while maximizing resource recovery. Ferrofluids, being non-toxic and highly controllable, align well with these sustainability goals.

The potential applications of ferrofluids in waste management are diverse and promising. They could be used to enhance the separation of different types of waste materials, particularly in scenarios where traditional methods struggle. For instance, ferrofluids might be employed to separate plastics of varying densities or to extract valuable metals from electronic waste more efficiently. Additionally, their unique properties could be harnessed to create advanced filtration systems for wastewater treatment or to develop more effective oil spill cleanup technologies.

As research in this field progresses, several technological objectives have emerged. These include developing ferrofluid formulations specifically tailored for waste management applications, designing systems that can effectively integrate ferrofluids into existing waste processing infrastructure, and creating scalable solutions that can be implemented in both small-scale and industrial settings. The ultimate goal is to create a new paradigm in waste management that is more efficient, cost-effective, and environmentally sustainable.

The waste management sector faces numerous challenges, including the need for more efficient separation techniques, improved contaminant removal, and enhanced resource recovery. Ferrofluids, with their unique magnetic properties and fluid characteristics, present an opportunity to address these issues. The primary objective of exploring ferrofluids in waste management is to leverage their magnetic responsiveness and fluid dynamics to develop novel solutions for waste separation, treatment, and recycling processes.

One of the key technological trends driving this exploration is the increasing focus on sustainable and environmentally friendly waste management practices. As global concerns about pollution and resource depletion grow, there is a pressing need for innovative approaches that can minimize environmental impact while maximizing resource recovery. Ferrofluids, being non-toxic and highly controllable, align well with these sustainability goals.

The potential applications of ferrofluids in waste management are diverse and promising. They could be used to enhance the separation of different types of waste materials, particularly in scenarios where traditional methods struggle. For instance, ferrofluids might be employed to separate plastics of varying densities or to extract valuable metals from electronic waste more efficiently. Additionally, their unique properties could be harnessed to create advanced filtration systems for wastewater treatment or to develop more effective oil spill cleanup technologies.

As research in this field progresses, several technological objectives have emerged. These include developing ferrofluid formulations specifically tailored for waste management applications, designing systems that can effectively integrate ferrofluids into existing waste processing infrastructure, and creating scalable solutions that can be implemented in both small-scale and industrial settings. The ultimate goal is to create a new paradigm in waste management that is more efficient, cost-effective, and environmentally sustainable.

Market Analysis for Ferrofluid-Based Waste Solutions

The market for ferrofluid-based waste management solutions is experiencing significant growth potential as industries and municipalities seek more efficient and environmentally friendly waste treatment methods. The global waste management market, valued at $423.4 billion in 2021, is projected to reach $642.7 billion by 2032, with a compound annual growth rate (CAGR) of 3.9%. Within this broader market, ferrofluid technology presents a promising niche with unique advantages in waste separation and purification processes.

Ferrofluids, which are colloidal liquids containing magnetic nanoparticles, offer innovative solutions for waste management challenges. Their ability to be precisely controlled by magnetic fields enables more effective separation of contaminants from water and other waste streams. This technology is particularly appealing in industries such as mining, oil and gas, and manufacturing, where the removal of fine particulates and heavy metals from wastewater is crucial.

The demand for ferrofluid-based waste solutions is driven by several factors. Stringent environmental regulations worldwide are pushing industries to adopt more effective waste treatment technologies. The increasing focus on water conservation and recycling in water-scarce regions is also boosting the market for advanced purification methods. Additionally, the growing awareness of the environmental impact of industrial waste is encouraging companies to invest in more sustainable waste management practices.

In the industrial sector, ferrofluid technology shows promise in treating industrial effluents, particularly in removing oil and grease from wastewater. The oil and gas industry, which generates large volumes of contaminated water, represents a significant market opportunity. The mining sector is another key target, where ferrofluids can be used to separate valuable minerals from waste materials more efficiently than traditional methods.

Municipal waste management is another area where ferrofluid-based solutions could gain traction. As cities grapple with increasing waste volumes and the need for more sustainable disposal methods, technologies that can improve recycling rates and reduce landfill usage are in high demand. Ferrofluids could potentially enhance the sorting and separation of recyclable materials, improving the efficiency of recycling plants.

The market for ferrofluid waste management solutions is still in its early stages, with significant room for growth and innovation. As research and development in this field progress, new applications and improved efficiencies are likely to emerge, further expanding the market potential. However, challenges such as high initial costs and the need for specialized equipment may initially limit widespread adoption, particularly in smaller-scale operations or developing regions.

Ferrofluids, which are colloidal liquids containing magnetic nanoparticles, offer innovative solutions for waste management challenges. Their ability to be precisely controlled by magnetic fields enables more effective separation of contaminants from water and other waste streams. This technology is particularly appealing in industries such as mining, oil and gas, and manufacturing, where the removal of fine particulates and heavy metals from wastewater is crucial.

The demand for ferrofluid-based waste solutions is driven by several factors. Stringent environmental regulations worldwide are pushing industries to adopt more effective waste treatment technologies. The increasing focus on water conservation and recycling in water-scarce regions is also boosting the market for advanced purification methods. Additionally, the growing awareness of the environmental impact of industrial waste is encouraging companies to invest in more sustainable waste management practices.

In the industrial sector, ferrofluid technology shows promise in treating industrial effluents, particularly in removing oil and grease from wastewater. The oil and gas industry, which generates large volumes of contaminated water, represents a significant market opportunity. The mining sector is another key target, where ferrofluids can be used to separate valuable minerals from waste materials more efficiently than traditional methods.

Municipal waste management is another area where ferrofluid-based solutions could gain traction. As cities grapple with increasing waste volumes and the need for more sustainable disposal methods, technologies that can improve recycling rates and reduce landfill usage are in high demand. Ferrofluids could potentially enhance the sorting and separation of recyclable materials, improving the efficiency of recycling plants.

The market for ferrofluid waste management solutions is still in its early stages, with significant room for growth and innovation. As research and development in this field progress, new applications and improved efficiencies are likely to emerge, further expanding the market potential. However, challenges such as high initial costs and the need for specialized equipment may initially limit widespread adoption, particularly in smaller-scale operations or developing regions.

Current Challenges in Ferrofluid Waste Management Applications

The integration of ferrofluids into waste management systems presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the long-term stability of ferrofluids in diverse waste environments. Waste streams often contain a wide range of chemical compounds, varying pH levels, and different temperatures, which can potentially degrade or alter the properties of ferrofluids over time. This instability may lead to reduced effectiveness in waste separation and treatment processes.

Another critical challenge is the development of efficient separation techniques to recover ferrofluids from treated waste. While ferrofluids can be manipulated using magnetic fields, designing systems that can effectively separate and recycle these materials from complex waste mixtures remains a technical hurdle. The presence of other magnetic particles or debris in the waste stream can interfere with the separation process, necessitating more sophisticated sorting mechanisms.

The potential environmental impact of ferrofluids in waste management applications is also a concern. Although ferrofluids are generally considered non-toxic, their long-term effects on ecosystems when released into the environment are not fully understood. There is a need for comprehensive studies on the biodegradability and bioaccumulation of ferrofluid nanoparticles in various environmental conditions.

Scaling up ferrofluid-based waste management systems from laboratory experiments to industrial-scale applications poses significant engineering challenges. Designing large-scale magnetic field generators and containment systems that can handle high volumes of waste while maintaining the precise control needed for ferrofluid manipulation is a complex task. Additionally, ensuring uniform distribution and behavior of ferrofluids in large-scale systems is crucial for consistent performance.

The cost-effectiveness of ferrofluid-based waste management solutions is another hurdle. While ferrofluids offer unique capabilities, their production and maintenance costs may be higher compared to conventional waste treatment methods. Developing economically viable processes that can compete with or complement existing technologies is essential for widespread adoption in the waste management industry.

Regulatory compliance and safety standards for the use of ferrofluids in waste management are yet to be fully established. As a relatively new technology in this field, there is a lack of specific guidelines and regulations governing the use, handling, and disposal of ferrofluids in waste treatment processes. This regulatory uncertainty can hinder the adoption and implementation of ferrofluid-based solutions in commercial waste management operations.

Another critical challenge is the development of efficient separation techniques to recover ferrofluids from treated waste. While ferrofluids can be manipulated using magnetic fields, designing systems that can effectively separate and recycle these materials from complex waste mixtures remains a technical hurdle. The presence of other magnetic particles or debris in the waste stream can interfere with the separation process, necessitating more sophisticated sorting mechanisms.

The potential environmental impact of ferrofluids in waste management applications is also a concern. Although ferrofluids are generally considered non-toxic, their long-term effects on ecosystems when released into the environment are not fully understood. There is a need for comprehensive studies on the biodegradability and bioaccumulation of ferrofluid nanoparticles in various environmental conditions.

Scaling up ferrofluid-based waste management systems from laboratory experiments to industrial-scale applications poses significant engineering challenges. Designing large-scale magnetic field generators and containment systems that can handle high volumes of waste while maintaining the precise control needed for ferrofluid manipulation is a complex task. Additionally, ensuring uniform distribution and behavior of ferrofluids in large-scale systems is crucial for consistent performance.

The cost-effectiveness of ferrofluid-based waste management solutions is another hurdle. While ferrofluids offer unique capabilities, their production and maintenance costs may be higher compared to conventional waste treatment methods. Developing economically viable processes that can compete with or complement existing technologies is essential for widespread adoption in the waste management industry.

Regulatory compliance and safety standards for the use of ferrofluids in waste management are yet to be fully established. As a relatively new technology in this field, there is a lack of specific guidelines and regulations governing the use, handling, and disposal of ferrofluids in waste treatment processes. This regulatory uncertainty can hinder the adoption and implementation of ferrofluid-based solutions in commercial waste management operations.

Existing Ferrofluid-Based Waste Management Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size, surfactant selection, and carrier fluid properties to achieve stable and responsive ferrofluids.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly in electronic cooling systems. Their unique properties allow for efficient heat transfer and the ability to be directed by magnetic fields, making them useful in targeted cooling applications for components like processors and power electronics.

- Damping and vibration control: The viscoelastic properties of ferrofluids make them suitable for damping applications. They can be used in shock absorbers, vibration isolators, and inertial dampers. The ability to change their properties in response to magnetic fields allows for adaptive damping systems.

- Sensing and measurement applications: Ferrofluids are utilized in various sensing and measurement devices. Their response to magnetic fields and ability to change shape or position makes them useful in applications such as accelerometers, inclinometers, and pressure sensors. They can also be used in magnetic field visualization and measurement tools.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear in mechanical systems.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The ability to manipulate ferrofluids with magnetic fields allows for targeted and efficient heat removal in various applications.Expand Specific Solutions04 Sensor and actuator technologies

Ferrofluids are employed in various sensor and actuator designs, leveraging their responsiveness to magnetic fields. They are used in accelerometers, tilt sensors, and position sensors. In actuators, ferrofluids can be used to create controllable damping systems and adaptive structures for vibration control and precision positioning.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have potential applications in medicine and biomedical research. They are being investigated for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to manipulate ferrofluids externally using magnetic fields makes them attractive for minimally invasive medical procedures.Expand Specific Solutions

Key Players in Ferrofluid and Waste Management Industries

The exploration of ferrofluid's potential in improved waste management systems is in its early stages, with the market still developing. The technology's maturity varies across different applications, but overall, it remains in the research and development phase. Companies like Commissariat à l´énergie atomique et aux énergies Alternatives, Delft University of Technology, and Nanyang Technological University are at the forefront of this research, leveraging their expertise in materials science and environmental engineering. The market size is currently limited but shows promise for growth as the technology advances and its applications in waste management become more defined. As environmental concerns increase globally, the demand for innovative waste management solutions using ferrofluids is expected to rise, potentially attracting more players and investment in the coming years.

Stena Recycling International AB

Technical Solution: Stena Recycling International AB has pioneered a ferrofluid-based waste sorting and recycling system that revolutionizes the processing of complex waste streams. Their technology employs a series of ferrofluid-filled channels and magnetic field generators to achieve high-precision separation of materials based on their density and magnetic properties. This approach enables the efficient sorting of mixed waste, including plastics, metals, and electronic components, with minimal manual intervention[7]. The system's adaptability allows for real-time adjustments to accommodate varying waste compositions, ensuring optimal performance across different recycling scenarios. Stena's innovation also includes a closed-loop ferrofluid recovery and purification process, which minimizes environmental impact and operational costs[9]. The company has successfully deployed this technology in several large-scale recycling facilities across Europe, demonstrating its effectiveness in improving recycling rates and reducing landfill waste[11].

Strengths: Highly efficient in sorting complex waste mixtures, adaptable to various waste streams, and potential for high-volume processing. Weaknesses: Initial setup costs may be high, and requires careful management of ferrofluid to prevent environmental contamination.

European Metal Recycling Ltd.

Technical Solution: European Metal Recycling Ltd. has developed an innovative ferrofluid-based system for enhanced metal recovery from waste streams. Their technology utilizes a specially formulated ferrofluid that selectively binds to metal particles, allowing for efficient separation even in complex waste mixtures. The system employs a series of magnetic separators and ferrofluid regeneration units to continuously process large volumes of waste material. EMR's approach has shown particular promise in recovering valuable metals from electronic waste and industrial by-products, significantly improving recycling rates for these challenging waste streams[8]. The company has also integrated advanced sensing and control systems to optimize the ferrofluid's composition and magnetic field strengths in real-time, ensuring maximum recovery efficiency across varying waste inputs[10]. EMR has successfully implemented this technology at several of its recycling facilities, demonstrating substantial improvements in metal recovery rates and purity of recovered materials[12].

Strengths: Highly effective for metal recovery from complex waste streams, potential for recovering high-value materials, and scalable to large operations. Weaknesses: May require significant initial investment and ongoing optimization to maintain peak performance.

Innovative Ferrofluid Applications in Waste Treatment

Method for moving a fluid of interest in a capillary tube and fluidic microsystem

PatentWO2003026798A1

Innovation

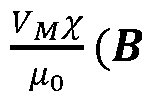

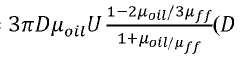

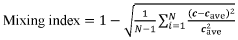

- A method involving a train of ferrofluid with a plug of ferrofluid and a plug of liquid immiscible with the fluid of interest, controlled by a magnetic field generated outside the capillary, is used to manage fluid movement within the microchannel, utilizing ionic ferrofluids and hydrophobic capillary walls to prevent contamination and ensure precise flow control.

Electronically-controlled digital ferrofluidic device and method for scalable and addressable bioanalytical operations

PatentWO2021081103A1

Innovation

- An electronically-controlled digital ferrofluidic device using an electromagnetic induction-coil matrix and moveable permanent magnets to create addressable magnetic fields for manipulating nanoliter or microliter volumes of magnetic droplets, enabling advanced tasks like droplet generation, dispensing, and sorting.

Environmental Impact Assessment of Ferrofluid Use

The environmental impact assessment of ferrofluid use in waste management systems is a critical aspect of evaluating the technology's potential for widespread adoption. Ferrofluids, being a unique class of magnetic nanomaterials, present both opportunities and challenges in terms of their environmental footprint.

One of the primary environmental benefits of incorporating ferrofluids into waste management systems is the potential for improved separation and recovery of materials. By leveraging the magnetic properties of ferrofluids, it becomes possible to enhance the efficiency of sorting processes, particularly for metal-containing waste streams. This increased efficiency can lead to higher recycling rates and a reduction in the amount of waste sent to landfills, thereby mitigating the environmental impact associated with waste disposal.

However, the production and use of ferrofluids also raise concerns regarding their potential release into the environment. The nanoparticles present in ferrofluids, typically iron oxide particles coated with surfactants, may pose risks to aquatic ecosystems if not properly contained. Studies have shown that nanoparticles can accumulate in organisms and potentially disrupt food chains. Therefore, stringent containment measures and proper disposal protocols must be implemented to prevent unintended environmental contamination.

The life cycle assessment of ferrofluid-based waste management systems is another crucial consideration. While the operational phase may offer environmental benefits through improved waste sorting and recovery, the production of ferrofluids involves energy-intensive processes and the use of potentially hazardous chemicals. A comprehensive analysis of the entire life cycle, from raw material extraction to end-of-life disposal, is necessary to determine the net environmental impact of ferrofluid implementation in waste management.

Energy consumption is a key factor in assessing the environmental impact of ferrofluid-based systems. The magnetic manipulation of ferrofluids requires energy input, which must be weighed against the energy savings achieved through improved waste sorting efficiency. Optimizing the energy balance of these systems is essential for minimizing their carbon footprint and ensuring overall environmental sustainability.

Lastly, the potential for ferrofluid recovery and reuse within waste management systems should be explored. Developing closed-loop systems that allow for the continuous recycling of ferrofluids can significantly reduce the environmental impact associated with their production and disposal. This approach aligns with circular economy principles and could enhance the long-term sustainability of ferrofluid-based waste management technologies.

One of the primary environmental benefits of incorporating ferrofluids into waste management systems is the potential for improved separation and recovery of materials. By leveraging the magnetic properties of ferrofluids, it becomes possible to enhance the efficiency of sorting processes, particularly for metal-containing waste streams. This increased efficiency can lead to higher recycling rates and a reduction in the amount of waste sent to landfills, thereby mitigating the environmental impact associated with waste disposal.

However, the production and use of ferrofluids also raise concerns regarding their potential release into the environment. The nanoparticles present in ferrofluids, typically iron oxide particles coated with surfactants, may pose risks to aquatic ecosystems if not properly contained. Studies have shown that nanoparticles can accumulate in organisms and potentially disrupt food chains. Therefore, stringent containment measures and proper disposal protocols must be implemented to prevent unintended environmental contamination.

The life cycle assessment of ferrofluid-based waste management systems is another crucial consideration. While the operational phase may offer environmental benefits through improved waste sorting and recovery, the production of ferrofluids involves energy-intensive processes and the use of potentially hazardous chemicals. A comprehensive analysis of the entire life cycle, from raw material extraction to end-of-life disposal, is necessary to determine the net environmental impact of ferrofluid implementation in waste management.

Energy consumption is a key factor in assessing the environmental impact of ferrofluid-based systems. The magnetic manipulation of ferrofluids requires energy input, which must be weighed against the energy savings achieved through improved waste sorting efficiency. Optimizing the energy balance of these systems is essential for minimizing their carbon footprint and ensuring overall environmental sustainability.

Lastly, the potential for ferrofluid recovery and reuse within waste management systems should be explored. Developing closed-loop systems that allow for the continuous recycling of ferrofluids can significantly reduce the environmental impact associated with their production and disposal. This approach aligns with circular economy principles and could enhance the long-term sustainability of ferrofluid-based waste management technologies.

Regulatory Framework for Ferrofluid in Waste Management

The regulatory framework for ferrofluid in waste management is a complex and evolving landscape. As ferrofluid technology gains traction in waste management applications, governments and regulatory bodies are working to establish guidelines and standards to ensure its safe and effective use.

At the federal level, the Environmental Protection Agency (EPA) plays a crucial role in overseeing the implementation of ferrofluid-based waste management systems. The EPA has initiated a review process to assess the potential environmental impacts and safety considerations of ferrofluid use in waste treatment facilities. This process aims to develop specific regulations and permitting requirements for ferrofluid applications in waste management.

State-level environmental agencies are also actively involved in shaping the regulatory framework. Several states have formed task forces to study the implications of ferrofluid technology and draft state-specific guidelines. These efforts focus on addressing local environmental concerns and aligning ferrofluid use with existing waste management regulations.

The Occupational Safety and Health Administration (OSHA) is developing safety protocols for workers handling ferrofluids in waste management facilities. These protocols will cover proper handling procedures, personal protective equipment requirements, and emergency response measures.

International organizations, such as the International Organization for Standardization (ISO), are working on establishing global standards for ferrofluid use in waste management. These standards aim to facilitate international cooperation and ensure consistency in safety and performance across different countries.

Industry associations, including the Waste Management Association and the Environmental Technology Council, are collaborating with regulatory bodies to provide input on practical considerations and best practices for ferrofluid implementation. This collaboration helps ensure that regulations are both effective and feasible for industry adoption.

The regulatory framework also addresses the disposal and recycling of ferrofluids after their use in waste management systems. Guidelines are being developed to ensure proper handling and treatment of used ferrofluids to prevent potential environmental contamination.

As research on ferrofluid applications in waste management progresses, regulatory bodies are adopting an adaptive approach. They are establishing mechanisms for regular review and updates to the regulatory framework, allowing for the incorporation of new scientific findings and technological advancements.

At the federal level, the Environmental Protection Agency (EPA) plays a crucial role in overseeing the implementation of ferrofluid-based waste management systems. The EPA has initiated a review process to assess the potential environmental impacts and safety considerations of ferrofluid use in waste treatment facilities. This process aims to develop specific regulations and permitting requirements for ferrofluid applications in waste management.

State-level environmental agencies are also actively involved in shaping the regulatory framework. Several states have formed task forces to study the implications of ferrofluid technology and draft state-specific guidelines. These efforts focus on addressing local environmental concerns and aligning ferrofluid use with existing waste management regulations.

The Occupational Safety and Health Administration (OSHA) is developing safety protocols for workers handling ferrofluids in waste management facilities. These protocols will cover proper handling procedures, personal protective equipment requirements, and emergency response measures.

International organizations, such as the International Organization for Standardization (ISO), are working on establishing global standards for ferrofluid use in waste management. These standards aim to facilitate international cooperation and ensure consistency in safety and performance across different countries.

Industry associations, including the Waste Management Association and the Environmental Technology Council, are collaborating with regulatory bodies to provide input on practical considerations and best practices for ferrofluid implementation. This collaboration helps ensure that regulations are both effective and feasible for industry adoption.

The regulatory framework also addresses the disposal and recycling of ferrofluids after their use in waste management systems. Guidelines are being developed to ensure proper handling and treatment of used ferrofluids to prevent potential environmental contamination.

As research on ferrofluid applications in waste management progresses, regulatory bodies are adopting an adaptive approach. They are establishing mechanisms for regular review and updates to the regulatory framework, allowing for the incorporation of new scientific findings and technological advancements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!