Leading Ferrofluid Technologies in Advanced Scientific Exploration

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Evolution

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution over the past six decades. Initially conceived for controlling fluids in zero gravity, these magnetic liquids have since found applications across various scientific and industrial domains. The evolution of ferrofluids can be traced through several key stages, each marked by technological advancements and expanding applications.

In the early stages, ferrofluids were primarily used in sealing and damping applications. The 1970s and 1980s saw the development of more stable ferrofluid compositions, enabling their use in computer hard drives and loudspeakers. This period also witnessed the exploration of ferrofluids in biomedical applications, particularly in targeted drug delivery and magnetic hyperthermia for cancer treatment.

The 1990s brought about a surge in nanotechnology research, which significantly impacted ferrofluid development. Enhanced synthesis methods led to the production of ferrofluids with more uniform particle sizes and improved magnetic properties. This advancement opened up new possibilities in microfluidics and lab-on-a-chip technologies, where ferrofluids could be precisely manipulated at the microscale.

The turn of the millennium marked the beginning of ferrofluids' integration into advanced scientific exploration. Researchers began investigating their potential in space propulsion systems, utilizing their unique behavior in microgravity environments. Concurrently, the field of magnetorheological fluids, closely related to ferrofluids, saw rapid development, leading to applications in adaptive suspension systems and earthquake-resistant buildings.

In recent years, the evolution of ferrofluids has been characterized by their convergence with other cutting-edge technologies. The integration of ferrofluids with smart materials has led to the development of self-healing composites and adaptive optical systems. Moreover, the advent of 3D printing technologies has enabled the fabrication of complex ferrofluid-based structures, pushing the boundaries of material science and engineering.

Looking towards the future, the evolution of ferrofluids is poised to continue its upward trajectory. Emerging research areas include the development of bio-inspired ferrofluids for soft robotics, the exploration of quantum effects in nanoscale ferrofluids, and the application of machine learning algorithms to optimize ferrofluid compositions for specific tasks. As our understanding of these remarkable materials deepens, their potential applications in advanced scientific exploration are bound to expand, promising exciting breakthroughs in fields ranging from space technology to nanomedicine.

In the early stages, ferrofluids were primarily used in sealing and damping applications. The 1970s and 1980s saw the development of more stable ferrofluid compositions, enabling their use in computer hard drives and loudspeakers. This period also witnessed the exploration of ferrofluids in biomedical applications, particularly in targeted drug delivery and magnetic hyperthermia for cancer treatment.

The 1990s brought about a surge in nanotechnology research, which significantly impacted ferrofluid development. Enhanced synthesis methods led to the production of ferrofluids with more uniform particle sizes and improved magnetic properties. This advancement opened up new possibilities in microfluidics and lab-on-a-chip technologies, where ferrofluids could be precisely manipulated at the microscale.

The turn of the millennium marked the beginning of ferrofluids' integration into advanced scientific exploration. Researchers began investigating their potential in space propulsion systems, utilizing their unique behavior in microgravity environments. Concurrently, the field of magnetorheological fluids, closely related to ferrofluids, saw rapid development, leading to applications in adaptive suspension systems and earthquake-resistant buildings.

In recent years, the evolution of ferrofluids has been characterized by their convergence with other cutting-edge technologies. The integration of ferrofluids with smart materials has led to the development of self-healing composites and adaptive optical systems. Moreover, the advent of 3D printing technologies has enabled the fabrication of complex ferrofluid-based structures, pushing the boundaries of material science and engineering.

Looking towards the future, the evolution of ferrofluids is poised to continue its upward trajectory. Emerging research areas include the development of bio-inspired ferrofluids for soft robotics, the exploration of quantum effects in nanoscale ferrofluids, and the application of machine learning algorithms to optimize ferrofluid compositions for specific tasks. As our understanding of these remarkable materials deepens, their potential applications in advanced scientific exploration are bound to expand, promising exciting breakthroughs in fields ranging from space technology to nanomedicine.

Market Applications

Ferrofluids, with their unique magnetic properties and fluid characteristics, have found diverse applications across various industries, driving market growth and technological advancements. In the field of advanced scientific exploration, ferrofluids play a crucial role in enhancing research capabilities and enabling innovative solutions.

One of the primary market applications for ferrofluids in scientific exploration is in the development of advanced sensors and measurement devices. These magnetic fluids can be used to create highly sensitive magnetometers, which are essential for detecting and measuring weak magnetic fields in space exploration, geophysical surveys, and materials science research. The ability of ferrofluids to respond to minute changes in magnetic fields makes them invaluable in precision instrumentation for scientific investigations.

In the aerospace industry, ferrofluids have gained traction for their potential in microgravity experiments and space-based manufacturing processes. Their unique behavior in zero-gravity environments allows for novel approaches to fluid handling, heat transfer, and material processing in space. This has opened up new possibilities for conducting scientific experiments and developing manufacturing techniques that were previously impossible in traditional Earth-bound settings.

The biomedical research sector has also embraced ferrofluid technologies for various applications. These include targeted drug delivery systems, where ferrofluids can be used as carriers for therapeutic agents, allowing for precise control and localization of treatments. Additionally, ferrofluids have shown promise in magnetic hyperthermia treatments for cancer, where they can be used to generate localized heat in tumor cells when exposed to an alternating magnetic field.

Environmental monitoring and remediation represent another significant market application for ferrofluids in scientific exploration. These magnetic fluids can be employed in the development of advanced water purification systems, capable of removing contaminants and pollutants with high efficiency. Ferrofluids also show potential in oil spill cleanup operations, where they can be used to separate oil from water more effectively than traditional methods.

In the field of materials science, ferrofluids are being explored for their potential in creating smart materials and adaptive structures. These applications range from self-healing materials that can respond to external stimuli to dynamic optical devices that can change their properties based on magnetic field variations. Such innovations have far-reaching implications for the development of next-generation materials and devices across multiple industries.

The market for ferrofluid technologies in advanced scientific exploration continues to expand as researchers and industries discover new applications and refine existing ones. The unique properties of ferrofluids, combined with ongoing advancements in their synthesis and manipulation, ensure their relevance in pushing the boundaries of scientific discovery and technological innovation across various sectors.

One of the primary market applications for ferrofluids in scientific exploration is in the development of advanced sensors and measurement devices. These magnetic fluids can be used to create highly sensitive magnetometers, which are essential for detecting and measuring weak magnetic fields in space exploration, geophysical surveys, and materials science research. The ability of ferrofluids to respond to minute changes in magnetic fields makes them invaluable in precision instrumentation for scientific investigations.

In the aerospace industry, ferrofluids have gained traction for their potential in microgravity experiments and space-based manufacturing processes. Their unique behavior in zero-gravity environments allows for novel approaches to fluid handling, heat transfer, and material processing in space. This has opened up new possibilities for conducting scientific experiments and developing manufacturing techniques that were previously impossible in traditional Earth-bound settings.

The biomedical research sector has also embraced ferrofluid technologies for various applications. These include targeted drug delivery systems, where ferrofluids can be used as carriers for therapeutic agents, allowing for precise control and localization of treatments. Additionally, ferrofluids have shown promise in magnetic hyperthermia treatments for cancer, where they can be used to generate localized heat in tumor cells when exposed to an alternating magnetic field.

Environmental monitoring and remediation represent another significant market application for ferrofluids in scientific exploration. These magnetic fluids can be employed in the development of advanced water purification systems, capable of removing contaminants and pollutants with high efficiency. Ferrofluids also show potential in oil spill cleanup operations, where they can be used to separate oil from water more effectively than traditional methods.

In the field of materials science, ferrofluids are being explored for their potential in creating smart materials and adaptive structures. These applications range from self-healing materials that can respond to external stimuli to dynamic optical devices that can change their properties based on magnetic field variations. Such innovations have far-reaching implications for the development of next-generation materials and devices across multiple industries.

The market for ferrofluid technologies in advanced scientific exploration continues to expand as researchers and industries discover new applications and refine existing ones. The unique properties of ferrofluids, combined with ongoing advancements in their synthesis and manipulation, ensure their relevance in pushing the boundaries of scientific discovery and technological innovation across various sectors.

Technical Challenges

Ferrofluid technology, while promising, faces several significant challenges in its application to advanced scientific exploration. One of the primary obstacles is the stability of ferrofluids in extreme environments. In space exploration or deep-sea research, ferrofluids may encounter extreme temperatures, pressures, and radiation levels that can alter their magnetic properties or cause degradation of the fluid itself. Developing ferrofluids that maintain their unique characteristics under such conditions remains a critical challenge.

Another major hurdle is the precise control of ferrofluid behavior in complex magnetic fields. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for intricate scientific applications requires advanced magnetization techniques and sophisticated field generation systems. This becomes particularly challenging when dealing with dynamic or rapidly changing environments, where real-time adjustments are necessary.

The biocompatibility of ferrofluids presents a significant challenge for their use in medical and biological research. While some progress has been made in developing biocompatible ferrofluids, concerns remain about potential long-term effects and interactions with living tissues. This is especially crucial for applications such as targeted drug delivery or in vivo imaging, where the ferrofluid comes into direct contact with biological systems.

Scaling up ferrofluid production for large-scale scientific applications is another technical challenge. Current manufacturing processes can be complex and costly, particularly when producing high-quality ferrofluids with consistent properties. Developing more efficient and cost-effective production methods is essential for broader adoption in scientific research and exploration.

The long-term stability of ferrofluids is also a concern. Over time, ferrofluids can experience particle agglomeration or separation, which can alter their magnetic properties and overall performance. This is particularly problematic for long-duration scientific missions or experiments where consistent behavior over extended periods is crucial.

Additionally, the integration of ferrofluids with other advanced materials and technologies poses significant challenges. For instance, combining ferrofluids with smart materials or nanotechnology for enhanced functionality requires overcoming issues of compatibility, interface design, and maintaining the unique properties of each component.

Lastly, there is a need for more advanced modeling and simulation tools to predict ferrofluid behavior in complex systems accurately. Current models often struggle to capture the full range of ferrofluid dynamics, especially in multiphysics environments. Developing more sophisticated computational methods is essential for designing and optimizing ferrofluid-based systems for advanced scientific exploration.

Another major hurdle is the precise control of ferrofluid behavior in complex magnetic fields. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for intricate scientific applications requires advanced magnetization techniques and sophisticated field generation systems. This becomes particularly challenging when dealing with dynamic or rapidly changing environments, where real-time adjustments are necessary.

The biocompatibility of ferrofluids presents a significant challenge for their use in medical and biological research. While some progress has been made in developing biocompatible ferrofluids, concerns remain about potential long-term effects and interactions with living tissues. This is especially crucial for applications such as targeted drug delivery or in vivo imaging, where the ferrofluid comes into direct contact with biological systems.

Scaling up ferrofluid production for large-scale scientific applications is another technical challenge. Current manufacturing processes can be complex and costly, particularly when producing high-quality ferrofluids with consistent properties. Developing more efficient and cost-effective production methods is essential for broader adoption in scientific research and exploration.

The long-term stability of ferrofluids is also a concern. Over time, ferrofluids can experience particle agglomeration or separation, which can alter their magnetic properties and overall performance. This is particularly problematic for long-duration scientific missions or experiments where consistent behavior over extended periods is crucial.

Additionally, the integration of ferrofluids with other advanced materials and technologies poses significant challenges. For instance, combining ferrofluids with smart materials or nanotechnology for enhanced functionality requires overcoming issues of compatibility, interface design, and maintaining the unique properties of each component.

Lastly, there is a need for more advanced modeling and simulation tools to predict ferrofluid behavior in complex systems accurately. Current models often struggle to capture the full range of ferrofluid dynamics, especially in multiphysics environments. Developing more sophisticated computational methods is essential for designing and optimizing ferrofluid-based systems for advanced scientific exploration.

Current Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size, distribution, and stability to maintain the fluid's unique magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, contamination-resistant barriers that can be controlled by magnetic fields. These properties make them ideal for use in various industrial and mechanical systems.

- Thermal management and heat transfer: Ferrofluids exhibit unique heat transfer properties due to their ability to be manipulated by magnetic fields. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The magnetic nanoparticles enhance thermal conductivity and allow for targeted heat dissipation.

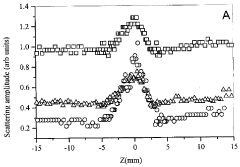

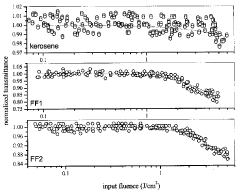

- Magnetic field sensing and measurement: Ferrofluids are employed in various sensing and measurement applications, including magnetometers and inertial sensors. Their response to magnetic fields allows for precise detection and quantification of magnetic field strength and direction. This property is utilized in scientific instruments and industrial monitoring systems.

- Medical and biomedical applications: Ferrofluids have emerging applications in medicine and biotechnology. They are being researched for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids with external magnetic fields makes them promising for minimally invasive medical procedures.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals and bearings. Their ability to be controlled by magnetic fields allows for dynamic sealing and reduced friction in various mechanical applications, improving efficiency and longevity of equipment.Expand Specific Solutions03 Magnetic field sensing and control

Ferrofluids are utilized in sensors and control systems that rely on magnetic field detection and manipulation. These applications include position sensors, accelerometers, and magnetic field visualizers, leveraging the fluid's responsiveness to external magnetic fields for precise measurements and control.Expand Specific Solutions04 Thermal management applications

Ferrofluids are employed in thermal management systems, particularly in electronics cooling. Their unique properties allow for efficient heat transfer when subjected to magnetic fields, enabling the development of novel cooling solutions for high-performance electronic devices and power systems.Expand Specific Solutions05 Damping and vibration control

Ferrofluids are used in damping systems and vibration control applications. Their ability to change viscosity in response to magnetic fields allows for adaptive damping in various mechanical systems, improving stability and reducing unwanted vibrations in structures and machinery.Expand Specific Solutions

Industry Leaders

The ferrofluid technology market for advanced scientific exploration is in a growth phase, with increasing applications across various scientific fields. The market size is expanding as research institutions and companies recognize the potential of ferrofluids in areas such as biomedicine, materials science, and space exploration. While the technology is maturing, there is still room for innovation and refinement. Key players like Schlumberger Technologies, Inc. and Yale University are driving advancements in ferrofluid applications for scientific research. Companies such as Ferrotec (USA) Corp. are specializing in ferrofluid production and development, while research institutions like Cornell University and East China Normal University are exploring novel uses in cutting-edge scientific experiments.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced ferrofluid technologies for enhanced oil recovery and well logging applications. Their ferrofluid-based sensors can detect minute changes in magnetic fields, allowing for precise measurements of reservoir properties. The company has also created ferrofluid-enhanced drilling fluids that improve borehole stability and reduce friction during drilling operations[1][3]. Schlumberger's ferrofluid technologies incorporate nanoparticle engineering to optimize magnetic properties and fluid stability in extreme downhole conditions, enabling more accurate data acquisition and improved oil recovery rates[2].

Strengths: Extensive experience in oilfield applications, robust R&D capabilities, and global market presence. Weaknesses: Highly dependent on oil industry cycles, potential environmental concerns related to nanoparticle use in subsurface applications.

Cornell University

Technical Solution: Cornell University has been a pioneer in ferrofluid research, with contributions spanning fundamental science and applied technologies. The university's researchers have developed novel ferrofluid synthesis methods, including the creation of biocompatible ferrofluids for medical applications[14]. Cornell's work in ferrohydrodynamics has led to breakthroughs in understanding the behavior of ferrofluids under complex magnetic fields, enabling new applications in microfluidics and soft robotics[15]. The university has also made significant advances in using ferrofluids for environmental remediation, developing magnetically-controlled ferrofluid systems for the removal of pollutants from water and soil[16]. Additionally, Cornell researchers are exploring the use of ferrofluids in advanced optical systems, leveraging their tunable refractive properties for adaptive lenses and displays[17].

Strengths: Strong interdisciplinary research environment, cutting-edge facilities for nanomaterial synthesis and characterization, and a track record of successful technology transfer. Weaknesses: As an academic institution, may face challenges in scaling up technologies for commercial production.

Key Innovations

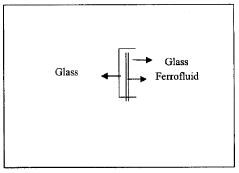

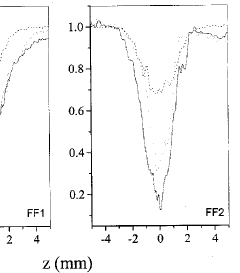

Optical limiting ferromagnetic nanoparticles and device thereof

PatentInactiveIN1981CHE2007A

Innovation

- Synthesizing ferromagnetic nanoparticles of specific sizes (4-6 nm) using an optimized co-precipitation technique and incorporating them into a ferrofluid, which is then encapsulated between glass plates without air gaps for enhanced thermal stability and optical limiting performance.

Label-free cellular manipulation and sorting via biocompatible ferrofluids

PatentWO2011071912A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with programmable magnetic field gradients generated by electrodes, allowing for the efficient separation and sorting of microparticles and live cells based on size, shape, and elasticity, with high resolution and rapid processing times.

Environmental Impact

The environmental impact of ferrofluid technologies in advanced scientific exploration is a critical consideration that requires thorough assessment. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable for various scientific applications. However, their potential environmental effects must be carefully evaluated.

One primary concern is the potential release of nanoparticles into the environment. The small size of these particles allows them to easily disperse and potentially interact with ecosystems in unforeseen ways. Studies have shown that nanoparticles can accumulate in organisms, potentially causing toxicity or disrupting biological processes. The long-term effects of such accumulation on food chains and ecosystem balance are not yet fully understood, necessitating ongoing research and monitoring.

Water contamination is another significant environmental consideration. Ferrofluids used in scientific exploration may come into contact with water bodies, potentially leading to the dispersion of magnetic nanoparticles in aquatic environments. This could affect water quality and pose risks to aquatic life. Proper containment and disposal protocols are essential to mitigate these risks.

The production process of ferrofluids also has environmental implications. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste. Ensuring responsible manufacturing practices and waste management is crucial to minimize the environmental footprint of ferrofluid production.

On the positive side, ferrofluid technologies can contribute to environmental protection efforts. Their unique properties make them valuable for environmental sensing and remediation applications. For instance, ferrofluids can be used in the development of highly sensitive pollution detectors or in the cleanup of oil spills, potentially mitigating environmental damage.

The recyclability and reusability of ferrofluids are important factors in assessing their overall environmental impact. Developing efficient recycling methods for used ferrofluids can significantly reduce waste and the need for new production, thereby lessening the environmental burden.

As ferrofluid technologies advance, it is crucial to conduct comprehensive life cycle assessments to fully understand their environmental implications. This includes evaluating the environmental costs of raw material extraction, production, use, and disposal. Such assessments will guide the development of more sustainable practices in the use of ferrofluids for scientific exploration.

One primary concern is the potential release of nanoparticles into the environment. The small size of these particles allows them to easily disperse and potentially interact with ecosystems in unforeseen ways. Studies have shown that nanoparticles can accumulate in organisms, potentially causing toxicity or disrupting biological processes. The long-term effects of such accumulation on food chains and ecosystem balance are not yet fully understood, necessitating ongoing research and monitoring.

Water contamination is another significant environmental consideration. Ferrofluids used in scientific exploration may come into contact with water bodies, potentially leading to the dispersion of magnetic nanoparticles in aquatic environments. This could affect water quality and pose risks to aquatic life. Proper containment and disposal protocols are essential to mitigate these risks.

The production process of ferrofluids also has environmental implications. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste. Ensuring responsible manufacturing practices and waste management is crucial to minimize the environmental footprint of ferrofluid production.

On the positive side, ferrofluid technologies can contribute to environmental protection efforts. Their unique properties make them valuable for environmental sensing and remediation applications. For instance, ferrofluids can be used in the development of highly sensitive pollution detectors or in the cleanup of oil spills, potentially mitigating environmental damage.

The recyclability and reusability of ferrofluids are important factors in assessing their overall environmental impact. Developing efficient recycling methods for used ferrofluids can significantly reduce waste and the need for new production, thereby lessening the environmental burden.

As ferrofluid technologies advance, it is crucial to conduct comprehensive life cycle assessments to fully understand their environmental implications. This includes evaluating the environmental costs of raw material extraction, production, use, and disposal. Such assessments will guide the development of more sustainable practices in the use of ferrofluids for scientific exploration.

Safety Regulations

Safety regulations play a crucial role in the development and application of ferrofluid technologies in advanced scientific exploration. As these innovative materials continue to push the boundaries of scientific research, it is imperative to establish and maintain comprehensive safety protocols to protect researchers, laboratory personnel, and the environment.

Ferrofluids, being composed of nanoscale magnetic particles suspended in a carrier fluid, present unique safety challenges that must be addressed. The primary concern is the potential health risks associated with exposure to nanoparticles. Inhalation or skin contact with these particles may lead to adverse health effects, necessitating stringent safety measures in handling and storage procedures.

To mitigate these risks, regulatory bodies have implemented guidelines for the safe use of ferrofluids in research settings. These regulations typically mandate the use of appropriate personal protective equipment (PPE), including respiratory protection, gloves, and protective eyewear. Additionally, specialized ventilation systems and containment measures are often required to prevent the release of nanoparticles into the environment.

Environmental considerations are also a key aspect of safety regulations for ferrofluid technologies. Proper disposal protocols must be followed to prevent contamination of water sources or soil. Many jurisdictions require specific waste management procedures for nanomaterials, including ferrofluids, to ensure they do not pose a threat to ecosystems or human health.

As ferrofluid applications expand into new areas of scientific exploration, safety regulations must evolve to keep pace with technological advancements. This includes developing new testing methods to assess the long-term effects of exposure to ferrofluids and establishing exposure limits based on the latest scientific evidence.

International collaboration in safety regulation development is essential to ensure consistent standards across different research institutions and countries. Organizations such as the International Organization for Standardization (ISO) and the Organization for Economic Co-operation and Development (OECD) play pivotal roles in harmonizing safety guidelines for nanomaterials, including ferrofluids.

Researchers and institutions working with ferrofluids must stay informed about the latest safety regulations and best practices. Regular training programs and safety audits are crucial to maintaining a culture of safety in laboratories and research facilities. Furthermore, transparent reporting of safety incidents and near-misses can contribute to the continuous improvement of safety protocols in the field.

As the field of ferrofluid technology continues to advance, it is likely that safety regulations will become more sophisticated and tailored to specific applications. This may include the development of application-specific safety guidelines for ferrofluids used in medical research, space exploration, or environmental monitoring. By prioritizing safety and adhering to robust regulations, the scientific community can ensure that the potential of ferrofluid technologies is fully realized while minimizing risks to human health and the environment.

Ferrofluids, being composed of nanoscale magnetic particles suspended in a carrier fluid, present unique safety challenges that must be addressed. The primary concern is the potential health risks associated with exposure to nanoparticles. Inhalation or skin contact with these particles may lead to adverse health effects, necessitating stringent safety measures in handling and storage procedures.

To mitigate these risks, regulatory bodies have implemented guidelines for the safe use of ferrofluids in research settings. These regulations typically mandate the use of appropriate personal protective equipment (PPE), including respiratory protection, gloves, and protective eyewear. Additionally, specialized ventilation systems and containment measures are often required to prevent the release of nanoparticles into the environment.

Environmental considerations are also a key aspect of safety regulations for ferrofluid technologies. Proper disposal protocols must be followed to prevent contamination of water sources or soil. Many jurisdictions require specific waste management procedures for nanomaterials, including ferrofluids, to ensure they do not pose a threat to ecosystems or human health.

As ferrofluid applications expand into new areas of scientific exploration, safety regulations must evolve to keep pace with technological advancements. This includes developing new testing methods to assess the long-term effects of exposure to ferrofluids and establishing exposure limits based on the latest scientific evidence.

International collaboration in safety regulation development is essential to ensure consistent standards across different research institutions and countries. Organizations such as the International Organization for Standardization (ISO) and the Organization for Economic Co-operation and Development (OECD) play pivotal roles in harmonizing safety guidelines for nanomaterials, including ferrofluids.

Researchers and institutions working with ferrofluids must stay informed about the latest safety regulations and best practices. Regular training programs and safety audits are crucial to maintaining a culture of safety in laboratories and research facilities. Furthermore, transparent reporting of safety incidents and near-misses can contribute to the continuous improvement of safety protocols in the field.

As the field of ferrofluid technology continues to advance, it is likely that safety regulations will become more sophisticated and tailored to specific applications. This may include the development of application-specific safety guidelines for ferrofluids used in medical research, space exploration, or environmental monitoring. By prioritizing safety and adhering to robust regulations, the scientific community can ensure that the potential of ferrofluid technologies is fully realized while minimizing risks to human health and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!