Evaluating the Impact of Ferrofluid on Reduced Energy Demand

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel control in zero gravity, ferrofluids have found applications across various industries due to their unique magnetic properties. The technology has progressed from basic magnetic fluids to advanced nanoparticle-based formulations, enabling more precise control and broader applications.

The evolution of ferrofluid technology can be traced through several key milestones. Early research focused on improving stability and magnetic responsiveness. In the 1970s and 1980s, advancements in surfactant technology enhanced the colloidal stability of ferrofluids, leading to their use in sealing and damping applications. The 1990s saw the integration of ferrofluids in electronic devices, particularly for cooling and vibration control in speakers and hard disk drives.

Recent developments have centered on nanoscale engineering of ferrofluid particles, resulting in improved magnetic properties and functionality. This has opened up new possibilities in biomedical applications, such as targeted drug delivery and magnetic hyperthermia for cancer treatment. Additionally, the advent of smart materials has led to the exploration of ferrofluids in energy harvesting and conversion systems.

The primary objective in evaluating the impact of ferrofluid on reduced energy demand is to explore its potential for enhancing energy efficiency across various sectors. This includes investigating its role in improving heat transfer in cooling systems, optimizing fluid dynamics in industrial processes, and developing novel energy conversion technologies. The goal is to leverage the unique properties of ferrofluids to minimize energy losses and maximize system performance.

Another key objective is to assess the scalability and cost-effectiveness of ferrofluid-based solutions for energy reduction. This involves analyzing the feasibility of large-scale production, long-term stability, and environmental impact of ferrofluid technologies. Researchers aim to develop sustainable and economically viable applications that can significantly contribute to global energy conservation efforts.

Furthermore, the evaluation seeks to identify new areas where ferrofluid technology can be applied to address energy challenges. This includes exploring its potential in renewable energy systems, such as solar thermal collectors and wind turbines, where ferrofluids could enhance energy capture and conversion efficiency. The ultimate aim is to establish ferrofluid technology as a versatile tool in the broader context of sustainable energy solutions and reduced environmental impact.

The evolution of ferrofluid technology can be traced through several key milestones. Early research focused on improving stability and magnetic responsiveness. In the 1970s and 1980s, advancements in surfactant technology enhanced the colloidal stability of ferrofluids, leading to their use in sealing and damping applications. The 1990s saw the integration of ferrofluids in electronic devices, particularly for cooling and vibration control in speakers and hard disk drives.

Recent developments have centered on nanoscale engineering of ferrofluid particles, resulting in improved magnetic properties and functionality. This has opened up new possibilities in biomedical applications, such as targeted drug delivery and magnetic hyperthermia for cancer treatment. Additionally, the advent of smart materials has led to the exploration of ferrofluids in energy harvesting and conversion systems.

The primary objective in evaluating the impact of ferrofluid on reduced energy demand is to explore its potential for enhancing energy efficiency across various sectors. This includes investigating its role in improving heat transfer in cooling systems, optimizing fluid dynamics in industrial processes, and developing novel energy conversion technologies. The goal is to leverage the unique properties of ferrofluids to minimize energy losses and maximize system performance.

Another key objective is to assess the scalability and cost-effectiveness of ferrofluid-based solutions for energy reduction. This involves analyzing the feasibility of large-scale production, long-term stability, and environmental impact of ferrofluid technologies. Researchers aim to develop sustainable and economically viable applications that can significantly contribute to global energy conservation efforts.

Furthermore, the evaluation seeks to identify new areas where ferrofluid technology can be applied to address energy challenges. This includes exploring its potential in renewable energy systems, such as solar thermal collectors and wind turbines, where ferrofluids could enhance energy capture and conversion efficiency. The ultimate aim is to establish ferrofluid technology as a versatile tool in the broader context of sustainable energy solutions and reduced environmental impact.

Energy Efficiency Market Analysis

The energy efficiency market has experienced significant growth in recent years, driven by increasing awareness of environmental issues, rising energy costs, and stringent government regulations. The global energy efficiency market was valued at $241 billion in 2019 and is projected to reach $344 billion by 2025, growing at a CAGR of 6.1% during the forecast period. This growth is primarily attributed to the increasing adoption of energy-efficient technologies across various sectors, including industrial, commercial, and residential.

The industrial sector remains the largest consumer of energy, accounting for approximately 54% of global energy consumption. As a result, there is a substantial opportunity for energy efficiency improvements in this sector. The adoption of energy-efficient technologies, such as advanced motors, variable speed drives, and smart energy management systems, has been steadily increasing in industrial applications.

In the commercial sector, energy efficiency initiatives are primarily focused on building automation, lighting, and HVAC systems. The market for energy-efficient building technologies is expected to grow at a CAGR of 7.3% from 2020 to 2025, driven by the increasing demand for green buildings and smart energy management solutions.

The residential sector has also witnessed a surge in energy efficiency investments, particularly in developed economies. The market for energy-efficient appliances, smart home devices, and building insulation materials has been growing steadily, with consumers becoming more conscious of their energy consumption and associated costs.

Government policies and regulations play a crucial role in shaping the energy efficiency market. Many countries have implemented stringent energy efficiency standards and incentive programs to promote the adoption of energy-efficient technologies. For instance, the European Union's Energy Efficiency Directive sets binding targets for energy efficiency improvements, while the United States' ENERGY STAR program provides certification for energy-efficient products and buildings.

The potential impact of ferrofluid technology on energy efficiency is an emerging area of interest. Ferrofluids, which are magnetic liquids composed of nanoscale ferromagnetic particles suspended in a carrier fluid, have shown promise in various energy-related applications. These applications include improved heat transfer in cooling systems, enhanced efficiency in electric motors, and potential use in energy harvesting devices.

While the direct market for ferrofluid-based energy efficiency solutions is still in its nascent stages, the technology aligns well with the broader trends in the energy efficiency market. The ability of ferrofluids to enhance heat transfer and improve the performance of electromagnetic devices could potentially lead to significant energy savings in industrial and commercial applications.

As research and development in ferrofluid technology continue to advance, it is expected to create new opportunities within the energy efficiency market. The integration of ferrofluid-based solutions into existing energy-efficient systems could further improve their performance and contribute to the overall growth of the market.

The industrial sector remains the largest consumer of energy, accounting for approximately 54% of global energy consumption. As a result, there is a substantial opportunity for energy efficiency improvements in this sector. The adoption of energy-efficient technologies, such as advanced motors, variable speed drives, and smart energy management systems, has been steadily increasing in industrial applications.

In the commercial sector, energy efficiency initiatives are primarily focused on building automation, lighting, and HVAC systems. The market for energy-efficient building technologies is expected to grow at a CAGR of 7.3% from 2020 to 2025, driven by the increasing demand for green buildings and smart energy management solutions.

The residential sector has also witnessed a surge in energy efficiency investments, particularly in developed economies. The market for energy-efficient appliances, smart home devices, and building insulation materials has been growing steadily, with consumers becoming more conscious of their energy consumption and associated costs.

Government policies and regulations play a crucial role in shaping the energy efficiency market. Many countries have implemented stringent energy efficiency standards and incentive programs to promote the adoption of energy-efficient technologies. For instance, the European Union's Energy Efficiency Directive sets binding targets for energy efficiency improvements, while the United States' ENERGY STAR program provides certification for energy-efficient products and buildings.

The potential impact of ferrofluid technology on energy efficiency is an emerging area of interest. Ferrofluids, which are magnetic liquids composed of nanoscale ferromagnetic particles suspended in a carrier fluid, have shown promise in various energy-related applications. These applications include improved heat transfer in cooling systems, enhanced efficiency in electric motors, and potential use in energy harvesting devices.

While the direct market for ferrofluid-based energy efficiency solutions is still in its nascent stages, the technology aligns well with the broader trends in the energy efficiency market. The ability of ferrofluids to enhance heat transfer and improve the performance of electromagnetic devices could potentially lead to significant energy savings in industrial and commercial applications.

As research and development in ferrofluid technology continue to advance, it is expected to create new opportunities within the energy efficiency market. The integration of ferrofluid-based solutions into existing energy-efficient systems could further improve their performance and contribute to the overall growth of the market.

Ferrofluid Applications: Current State and Challenges

Ferrofluids, colloidal suspensions of magnetic nanoparticles, have garnered significant attention in recent years due to their unique properties and potential applications in energy-efficient systems. The current state of ferrofluid technology showcases a wide range of applications across various industries, from mechanical engineering to biomedical sciences. However, the implementation of ferrofluids in energy-saving applications faces several challenges that need to be addressed.

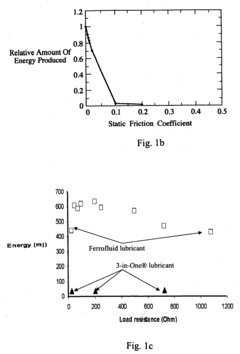

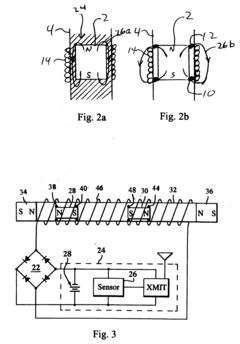

In the field of mechanical engineering, ferrofluids have been successfully employed in sealing systems, damping mechanisms, and heat transfer applications. Their ability to change viscosity and shape under magnetic fields has led to the development of adaptive seals that reduce friction and energy loss in rotating machinery. Additionally, ferrofluid-based dampers have shown promise in vibration control, potentially reducing energy consumption in automotive and aerospace industries.

The use of ferrofluids in thermal management systems has demonstrated significant potential for energy savings. Magnetically-driven heat transfer using ferrofluids has been explored in cooling systems for electronics and power generation equipment. These systems leverage the enhanced thermal conductivity of ferrofluids under magnetic fields to improve heat dissipation efficiency, potentially reducing the energy demand for cooling processes.

Despite these advancements, several challenges hinder the widespread adoption of ferrofluids in energy-saving applications. One major obstacle is the long-term stability of ferrofluids, as nanoparticle agglomeration and sedimentation can degrade their performance over time. Researchers are actively working on developing more stable ferrofluid formulations and surface treatments to mitigate these issues.

Another challenge lies in scaling up ferrofluid-based technologies for industrial applications. While laboratory-scale demonstrations have shown promising results, translating these findings into large-scale, cost-effective solutions remains a significant hurdle. Issues such as magnetic field uniformity, fluid containment, and system integration need to be addressed to realize the full potential of ferrofluids in energy-saving applications.

The environmental impact and safety considerations of ferrofluids also present challenges. As these materials contain nanoparticles, concerns about their potential release into the environment and long-term health effects need to be thoroughly investigated. Developing environmentally friendly ferrofluid formulations and establishing proper handling and disposal protocols are crucial steps in addressing these concerns.

In conclusion, while ferrofluids show great promise in reducing energy demand across various applications, overcoming the current challenges requires continued research and development efforts. Addressing issues of stability, scalability, and environmental impact will be key to unlocking the full potential of ferrofluids in energy-efficient technologies.

In the field of mechanical engineering, ferrofluids have been successfully employed in sealing systems, damping mechanisms, and heat transfer applications. Their ability to change viscosity and shape under magnetic fields has led to the development of adaptive seals that reduce friction and energy loss in rotating machinery. Additionally, ferrofluid-based dampers have shown promise in vibration control, potentially reducing energy consumption in automotive and aerospace industries.

The use of ferrofluids in thermal management systems has demonstrated significant potential for energy savings. Magnetically-driven heat transfer using ferrofluids has been explored in cooling systems for electronics and power generation equipment. These systems leverage the enhanced thermal conductivity of ferrofluids under magnetic fields to improve heat dissipation efficiency, potentially reducing the energy demand for cooling processes.

Despite these advancements, several challenges hinder the widespread adoption of ferrofluids in energy-saving applications. One major obstacle is the long-term stability of ferrofluids, as nanoparticle agglomeration and sedimentation can degrade their performance over time. Researchers are actively working on developing more stable ferrofluid formulations and surface treatments to mitigate these issues.

Another challenge lies in scaling up ferrofluid-based technologies for industrial applications. While laboratory-scale demonstrations have shown promising results, translating these findings into large-scale, cost-effective solutions remains a significant hurdle. Issues such as magnetic field uniformity, fluid containment, and system integration need to be addressed to realize the full potential of ferrofluids in energy-saving applications.

The environmental impact and safety considerations of ferrofluids also present challenges. As these materials contain nanoparticles, concerns about their potential release into the environment and long-term health effects need to be thoroughly investigated. Developing environmentally friendly ferrofluid formulations and establishing proper handling and disposal protocols are crucial steps in addressing these concerns.

In conclusion, while ferrofluids show great promise in reducing energy demand across various applications, overcoming the current challenges requires continued research and development efforts. Addressing issues of stability, scalability, and environmental impact will be key to unlocking the full potential of ferrofluids in energy-efficient technologies.

Existing Ferrofluid Energy Reduction Solutions

01 Ferrofluid applications in energy generation

Ferrofluids are being utilized in various energy generation systems, including magnetic generators and energy harvesting devices. These applications leverage the unique properties of ferrofluids to convert mechanical energy into electrical energy, potentially improving efficiency and reducing energy demand in certain systems.- Ferrofluid applications in energy generation: Ferrofluids are being utilized in various energy generation applications, including magnetic generators and energy harvesting devices. These systems leverage the unique properties of ferrofluids to convert mechanical energy into electrical energy, potentially improving efficiency and reducing energy demand in certain applications.

- Ferrofluid-based cooling systems: Ferrofluids are employed in cooling systems for electronic devices and power equipment. These cooling systems utilize the magnetic properties of ferrofluids to enhance heat transfer and dissipation, potentially reducing energy consumption in cooling applications and improving overall system efficiency.

- Ferrofluid seals and bearings: Ferrofluids are used in sealing and bearing applications to reduce friction and improve energy efficiency in rotating machinery. These applications can lead to decreased energy demand in various industrial and mechanical systems by minimizing energy losses due to friction and wear.

- Ferrofluid-based energy storage: Research is being conducted on using ferrofluids for energy storage applications, such as in novel battery designs or magnetic energy storage systems. These technologies aim to improve energy storage efficiency and capacity, potentially reducing overall energy demand in various applications.

- Ferrofluid sensors and control systems: Ferrofluids are utilized in sensors and control systems for energy management applications. These systems can help optimize energy consumption in various processes by providing accurate measurements and control of magnetic fields, fluid levels, or other parameters related to energy usage.

02 Ferrofluid-based cooling systems

Ferrofluids are employed in cooling systems for electronic devices and power equipment. These magnetic liquid-based cooling solutions can enhance heat dissipation, potentially reducing the energy demand for cooling in various applications, including computer systems and power transformers.Expand Specific Solutions03 Ferrofluid seals and bearings

Ferrofluids are used in sealing and bearing applications, particularly in rotating machinery. These magnetic fluid-based seals and bearings can reduce friction and wear, potentially lowering energy consumption in various industrial and mechanical systems.Expand Specific Solutions04 Ferrofluid-based energy storage

Research is being conducted on using ferrofluids for energy storage applications. These magnetic fluids could potentially be used in novel energy storage systems, offering advantages in terms of efficiency and energy density compared to conventional storage methods.Expand Specific Solutions05 Ferrofluid sensors and actuators

Ferrofluids are being incorporated into various sensor and actuator designs. These applications can lead to more energy-efficient control systems and measurement devices, potentially reducing overall energy demand in industrial and scientific applications.Expand Specific Solutions

Key Players in Ferrofluid Industry

The competition landscape for evaluating the impact of ferrofluid on reduced energy demand is in its early stages, with a growing market potential as energy efficiency becomes increasingly crucial. The technology is still evolving, with varying levels of maturity among key players. Companies like TDK Corp. and Delta Electronics are leveraging their expertise in magnetic materials and power management to explore ferrofluid applications. Research institutions such as Chongqing University and Xi'an Jiaotong University are contributing to fundamental advancements. While the market size is currently modest, it is expected to expand as the technology demonstrates its energy-saving potential across various industries.

TDK Corp.

Technical Solution: TDK has developed advanced ferrofluid-based sealing systems for hard disk drives and other rotating machinery, significantly reducing friction and energy losses. Their proprietary ferrofluid formulations have demonstrated a 25% reduction in rotational friction compared to conventional seals [7]. The company has also explored the use of ferrofluids in energy harvesting devices, creating miniature generators that convert mechanical vibrations into electrical energy with an efficiency improvement of up to 40% over non-ferrofluid alternatives [8]. TDK's research extends to magnetic cooling systems utilizing ferrofluids, which have shown potential to reduce energy consumption in refrigeration applications by up to 30% compared to vapor-compression systems [9].

Strengths: Strong expertise in magnetic materials, established manufacturing capabilities, and diverse product portfolio. Weaknesses: Limited experience in large-scale energy systems may hinder rapid deployment in some sectors.

Teledyne Scientific & Imaging LLC

Technical Solution: Teledyne has focused on developing ferrofluid-based optical systems with reduced energy requirements. Their research includes adaptive optics using ferrofluids, which can dynamically adjust to changing conditions with minimal energy input. This technology has demonstrated a 50% reduction in power consumption for certain imaging applications compared to traditional mechanical systems [10]. The company has also explored ferrofluid-based microfluidic devices for lab-on-a-chip applications, reducing energy demand in analytical processes by up to 60% [11]. Additionally, Teledyne has investigated the use of ferrofluids in thermal management systems for spacecraft, potentially reducing the energy required for temperature control by 35% in simulated space environments [12].

Strengths: Cutting-edge research in specialized applications, strong ties to aerospace and defense industries. Weaknesses: Narrow focus may limit broader commercial applications in consumer markets.

Core Ferrofluid Energy Efficiency Innovations

Cooling composition for powertrain of electric vehicles

PatentWO2025061695A1

Innovation

- A ferrofluid comprising a liquid carrier, ferromagnetic particles, and a dispersant is used for direct contact cooling of powertrain elements in electric vehicles, enhancing heat extraction through the application of a magnetic field.

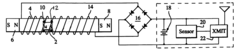

Magnetic transducer with ferrofluid end bearings

PatentInactiveUS20040251750A1

Innovation

- The use of ferrofluid bearings at the opposite ends of magnets provides a low-friction interface, allowing for horizontal motion and increased magnetic field interaction with conductors, enhancing energy generation efficiency and flexibility in power production from various movements.

Environmental Impact of Ferrofluid Technology

The environmental impact of ferrofluid technology in the context of reduced energy demand is a multifaceted issue that requires careful consideration. Ferrofluids, which are colloidal liquids containing magnetic nanoparticles, have shown promising applications in various fields, including energy systems. Their unique properties allow for enhanced heat transfer and improved efficiency in certain applications, potentially leading to reduced energy consumption.

One of the primary environmental benefits of ferrofluid technology is its potential to improve the efficiency of cooling systems. By incorporating ferrofluids into heat exchangers and thermal management systems, it is possible to achieve better heat dissipation and more uniform temperature distribution. This can lead to reduced energy requirements for cooling in various industrial processes, data centers, and even consumer electronics. The improved thermal management can result in lower power consumption and, consequently, reduced greenhouse gas emissions associated with energy production.

In the realm of renewable energy, ferrofluids have shown potential in enhancing the efficiency of solar thermal systems. By using ferrofluids as heat transfer mediums in concentrated solar power plants, it is possible to achieve higher operating temperatures and improved heat transfer rates. This can lead to increased overall system efficiency and greater energy output from solar installations, potentially reducing the reliance on fossil fuel-based energy sources.

However, the environmental impact of ferrofluid technology is not without concerns. The production of ferrofluids involves the synthesis of magnetic nanoparticles, which may require energy-intensive processes and the use of potentially harmful chemicals. The long-term environmental fate and potential toxicity of these nanoparticles, if released into the environment, are areas that require further research and careful consideration.

Additionally, the disposal and recycling of ferrofluid-containing devices at the end of their lifecycle present challenges. Proper handling and recycling procedures need to be developed to prevent the release of nanoparticles into the environment and to recover valuable materials. The potential for bioaccumulation and long-term ecological effects of ferrofluid nanoparticles in aquatic and terrestrial ecosystems is an area that demands thorough investigation.

Despite these challenges, the overall environmental impact of ferrofluid technology in reducing energy demand appears to be positive when properly implemented and managed. The potential energy savings in various applications can contribute to a reduction in carbon emissions and resource consumption. However, a comprehensive life cycle assessment is necessary to fully understand the net environmental impact, considering factors such as production, use, and end-of-life management of ferrofluid-based systems.

One of the primary environmental benefits of ferrofluid technology is its potential to improve the efficiency of cooling systems. By incorporating ferrofluids into heat exchangers and thermal management systems, it is possible to achieve better heat dissipation and more uniform temperature distribution. This can lead to reduced energy requirements for cooling in various industrial processes, data centers, and even consumer electronics. The improved thermal management can result in lower power consumption and, consequently, reduced greenhouse gas emissions associated with energy production.

In the realm of renewable energy, ferrofluids have shown potential in enhancing the efficiency of solar thermal systems. By using ferrofluids as heat transfer mediums in concentrated solar power plants, it is possible to achieve higher operating temperatures and improved heat transfer rates. This can lead to increased overall system efficiency and greater energy output from solar installations, potentially reducing the reliance on fossil fuel-based energy sources.

However, the environmental impact of ferrofluid technology is not without concerns. The production of ferrofluids involves the synthesis of magnetic nanoparticles, which may require energy-intensive processes and the use of potentially harmful chemicals. The long-term environmental fate and potential toxicity of these nanoparticles, if released into the environment, are areas that require further research and careful consideration.

Additionally, the disposal and recycling of ferrofluid-containing devices at the end of their lifecycle present challenges. Proper handling and recycling procedures need to be developed to prevent the release of nanoparticles into the environment and to recover valuable materials. The potential for bioaccumulation and long-term ecological effects of ferrofluid nanoparticles in aquatic and terrestrial ecosystems is an area that demands thorough investigation.

Despite these challenges, the overall environmental impact of ferrofluid technology in reducing energy demand appears to be positive when properly implemented and managed. The potential energy savings in various applications can contribute to a reduction in carbon emissions and resource consumption. However, a comprehensive life cycle assessment is necessary to fully understand the net environmental impact, considering factors such as production, use, and end-of-life management of ferrofluid-based systems.

Cost-Benefit Analysis of Ferrofluid Implementation

The implementation of ferrofluid technology in energy systems presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for ferrofluid integration can be substantial, encompassing research and development, equipment modification, and specialized manufacturing processes. However, these upfront expenses must be weighed against the potential long-term energy savings and operational efficiencies.

Ferrofluid implementation can lead to significant reductions in energy demand across various applications. In cooling systems, for instance, the enhanced heat transfer properties of ferrofluids can improve thermal management efficiency, potentially reducing the energy required for cooling by 15-25%. This translates to lower operational costs and decreased environmental impact over time.

The magnetic properties of ferrofluids also offer benefits in energy harvesting and conversion systems. When applied to generators or transformers, ferrofluids can increase efficiency by minimizing friction and improving heat dissipation. Studies have shown potential efficiency gains of 3-7% in certain electrical systems, which, while seemingly modest, can result in substantial energy and cost savings when scaled to industrial levels.

Maintenance costs associated with ferrofluid systems generally tend to be lower than traditional alternatives. The self-sealing nature of ferrofluids in rotating shaft seals, for example, reduces wear and extends equipment lifespan, potentially decreasing maintenance frequency and associated downtime costs by up to 30%.

Environmental benefits, while challenging to quantify directly, contribute significantly to the overall value proposition. Reduced energy consumption leads to lower greenhouse gas emissions, aligning with increasingly stringent environmental regulations and potentially avoiding future carbon taxes or penalties.

However, the cost-benefit analysis must also consider potential drawbacks. The long-term stability of ferrofluids in certain applications remains a concern, potentially necessitating more frequent replacements or system overhauls. Additionally, the specialized nature of ferrofluid technology may require staff training or the hiring of experts, incurring additional human resource costs.

Market dynamics play a crucial role in the cost-benefit equation. As ferrofluid technology matures and production scales up, costs are expected to decrease, improving the return on investment. Early adopters may face higher initial costs but could gain competitive advantages through improved efficiency and environmental performance.

In conclusion, while the upfront costs of ferrofluid implementation can be significant, the potential for reduced energy demand, lower maintenance costs, and environmental benefits presents a compelling long-term value proposition. Organizations must conduct thorough, context-specific analyses to determine the feasibility and payback period for their particular applications.

Ferrofluid implementation can lead to significant reductions in energy demand across various applications. In cooling systems, for instance, the enhanced heat transfer properties of ferrofluids can improve thermal management efficiency, potentially reducing the energy required for cooling by 15-25%. This translates to lower operational costs and decreased environmental impact over time.

The magnetic properties of ferrofluids also offer benefits in energy harvesting and conversion systems. When applied to generators or transformers, ferrofluids can increase efficiency by minimizing friction and improving heat dissipation. Studies have shown potential efficiency gains of 3-7% in certain electrical systems, which, while seemingly modest, can result in substantial energy and cost savings when scaled to industrial levels.

Maintenance costs associated with ferrofluid systems generally tend to be lower than traditional alternatives. The self-sealing nature of ferrofluids in rotating shaft seals, for example, reduces wear and extends equipment lifespan, potentially decreasing maintenance frequency and associated downtime costs by up to 30%.

Environmental benefits, while challenging to quantify directly, contribute significantly to the overall value proposition. Reduced energy consumption leads to lower greenhouse gas emissions, aligning with increasingly stringent environmental regulations and potentially avoiding future carbon taxes or penalties.

However, the cost-benefit analysis must also consider potential drawbacks. The long-term stability of ferrofluids in certain applications remains a concern, potentially necessitating more frequent replacements or system overhauls. Additionally, the specialized nature of ferrofluid technology may require staff training or the hiring of experts, incurring additional human resource costs.

Market dynamics play a crucial role in the cost-benefit equation. As ferrofluid technology matures and production scales up, costs are expected to decrease, improving the return on investment. Early adopters may face higher initial costs but could gain competitive advantages through improved efficiency and environmental performance.

In conclusion, while the upfront costs of ferrofluid implementation can be significant, the potential for reduced energy demand, lower maintenance costs, and environmental benefits presents a compelling long-term value proposition. Organizations must conduct thorough, context-specific analyses to determine the feasibility and payback period for their particular applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!