Ferrofluid's Influence on Next-Gen Power Transmission Technologies

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids have undergone significant technological evolution since their initial discovery in the 1960s. The development trajectory of ferrofluid technology can be traced through several key phases, each marked by important breakthroughs and applications.

In the early stages, ferrofluids were primarily used in simple mechanical applications, such as seals for rotating shafts. The 1970s and 1980s saw an expansion of ferrofluid applications into various fields, including aerospace and biomedical industries. During this period, researchers focused on improving the stability and magnetic properties of ferrofluids, leading to more diverse applications.

The 1990s marked a turning point in ferrofluid technology with the advent of nanotechnology. This enabled the production of more stable and uniform ferrofluids with enhanced magnetic properties. Concurrently, advances in computational modeling allowed for better prediction and control of ferrofluid behavior, opening up new possibilities in microfluidics and thermal management systems.

The early 2000s witnessed a surge in ferrofluid research for biomedical applications. Magnetic drug targeting, hyperthermia treatment for cancer, and contrast agents for magnetic resonance imaging became prominent areas of study. This period also saw the emergence of ferrofluid-based actuators and sensors, laying the groundwork for their potential use in power transmission technologies.

From 2010 onwards, ferrofluid technology has increasingly intersected with the field of energy and power systems. Researchers began exploring the use of ferrofluids in cooling systems for high-power electronics and transformers. The unique thermal and magnetic properties of ferrofluids showed promise in enhancing heat transfer efficiency in these applications.

Most recently, the focus has shifted towards integrating ferrofluids into next-generation power transmission technologies. Studies have explored their potential in improving the efficiency of power transformers, developing novel types of circuit breakers, and enhancing the cooling systems of high-voltage direct current (HVDC) transmission equipment. The ability of ferrofluids to respond to magnetic fields while maintaining fluid properties has opened up innovative approaches to managing thermal and electrical challenges in power systems.

Looking ahead, the evolution of ferrofluid technology in power transmission is likely to continue along several paths. These include the development of smart ferrofluids with tunable properties, integration with advanced materials for enhanced performance, and exploration of ferrofluid-based systems for renewable energy applications. As research progresses, ferrofluids are poised to play an increasingly significant role in shaping the future of power transmission technologies.

In the early stages, ferrofluids were primarily used in simple mechanical applications, such as seals for rotating shafts. The 1970s and 1980s saw an expansion of ferrofluid applications into various fields, including aerospace and biomedical industries. During this period, researchers focused on improving the stability and magnetic properties of ferrofluids, leading to more diverse applications.

The 1990s marked a turning point in ferrofluid technology with the advent of nanotechnology. This enabled the production of more stable and uniform ferrofluids with enhanced magnetic properties. Concurrently, advances in computational modeling allowed for better prediction and control of ferrofluid behavior, opening up new possibilities in microfluidics and thermal management systems.

The early 2000s witnessed a surge in ferrofluid research for biomedical applications. Magnetic drug targeting, hyperthermia treatment for cancer, and contrast agents for magnetic resonance imaging became prominent areas of study. This period also saw the emergence of ferrofluid-based actuators and sensors, laying the groundwork for their potential use in power transmission technologies.

From 2010 onwards, ferrofluid technology has increasingly intersected with the field of energy and power systems. Researchers began exploring the use of ferrofluids in cooling systems for high-power electronics and transformers. The unique thermal and magnetic properties of ferrofluids showed promise in enhancing heat transfer efficiency in these applications.

Most recently, the focus has shifted towards integrating ferrofluids into next-generation power transmission technologies. Studies have explored their potential in improving the efficiency of power transformers, developing novel types of circuit breakers, and enhancing the cooling systems of high-voltage direct current (HVDC) transmission equipment. The ability of ferrofluids to respond to magnetic fields while maintaining fluid properties has opened up innovative approaches to managing thermal and electrical challenges in power systems.

Looking ahead, the evolution of ferrofluid technology in power transmission is likely to continue along several paths. These include the development of smart ferrofluids with tunable properties, integration with advanced materials for enhanced performance, and exploration of ferrofluid-based systems for renewable energy applications. As research progresses, ferrofluids are poised to play an increasingly significant role in shaping the future of power transmission technologies.

Power Trans Market Trends

The power transmission market is experiencing significant growth and transformation, driven by increasing energy demands, the integration of renewable sources, and the need for more efficient and reliable transmission systems. The global power transmission market is projected to reach substantial growth in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the rapid industrialization and urbanization in developing economies, as well as the modernization of aging infrastructure in developed nations.

One of the key trends shaping the power transmission market is the shift towards smart grid technologies. Smart grids incorporate advanced sensors, communication networks, and data analytics to improve the efficiency, reliability, and sustainability of power transmission systems. This trend is driving investments in grid modernization projects worldwide, with utilities and governments allocating substantial budgets to upgrade their transmission infrastructure.

Another significant trend is the increasing adoption of high-voltage direct current (HVDC) transmission systems. HVDC technology offers advantages over traditional alternating current (AC) systems, including lower transmission losses over long distances and improved grid stability. As countries seek to connect remote renewable energy sources to urban load centers, HVDC transmission is becoming increasingly prevalent, particularly for offshore wind farms and large-scale solar projects.

The integration of renewable energy sources into the power grid is also driving market growth. As the share of wind, solar, and other intermittent renewable sources increases, power transmission systems must adapt to handle the variability and unpredictability of these energy sources. This has led to investments in flexible AC transmission systems (FACTS) and other advanced technologies that can enhance grid stability and power quality.

Emerging technologies, such as superconducting transmission lines and ferrofluid-based systems, are gaining attention for their potential to revolutionize power transmission. These technologies promise to significantly reduce transmission losses and increase power carrying capacity, addressing key challenges in the industry. While still in early stages of development and commercialization, they represent potential game-changers for the future of power transmission.

The market is also witnessing a trend towards increased cross-border power transmission, particularly in regions like Europe and Southeast Asia. This trend is driven by the need to balance supply and demand across different geographical areas and to improve overall grid resilience. As a result, there is growing investment in interconnectors and regional power pools.

One of the key trends shaping the power transmission market is the shift towards smart grid technologies. Smart grids incorporate advanced sensors, communication networks, and data analytics to improve the efficiency, reliability, and sustainability of power transmission systems. This trend is driving investments in grid modernization projects worldwide, with utilities and governments allocating substantial budgets to upgrade their transmission infrastructure.

Another significant trend is the increasing adoption of high-voltage direct current (HVDC) transmission systems. HVDC technology offers advantages over traditional alternating current (AC) systems, including lower transmission losses over long distances and improved grid stability. As countries seek to connect remote renewable energy sources to urban load centers, HVDC transmission is becoming increasingly prevalent, particularly for offshore wind farms and large-scale solar projects.

The integration of renewable energy sources into the power grid is also driving market growth. As the share of wind, solar, and other intermittent renewable sources increases, power transmission systems must adapt to handle the variability and unpredictability of these energy sources. This has led to investments in flexible AC transmission systems (FACTS) and other advanced technologies that can enhance grid stability and power quality.

Emerging technologies, such as superconducting transmission lines and ferrofluid-based systems, are gaining attention for their potential to revolutionize power transmission. These technologies promise to significantly reduce transmission losses and increase power carrying capacity, addressing key challenges in the industry. While still in early stages of development and commercialization, they represent potential game-changers for the future of power transmission.

The market is also witnessing a trend towards increased cross-border power transmission, particularly in regions like Europe and Southeast Asia. This trend is driven by the need to balance supply and demand across different geographical areas and to improve overall grid resilience. As a result, there is growing investment in interconnectors and regional power pools.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in next-generation power transmission technologies, several significant challenges hinder their widespread adoption and implementation. One of the primary obstacles is the long-term stability of ferrofluids under operational conditions. When exposed to strong magnetic fields and high temperatures, ferrofluids tend to degrade over time, leading to a reduction in their magnetic properties and overall performance. This degradation can result in decreased efficiency and reliability of power transmission systems, limiting their practical applications.

Another critical challenge is the precise control and manipulation of ferrofluids in dynamic environments. While ferrofluids respond to magnetic fields, achieving fine-tuned control over their behavior in complex power transmission systems remains a significant hurdle. This lack of precise control can lead to inconsistencies in performance and potential safety concerns, particularly in high-voltage applications.

The scalability of ferrofluid-based technologies also presents a considerable challenge. While ferrofluids have shown promise in small-scale laboratory experiments, translating these results to large-scale industrial applications has proven difficult. Issues such as maintaining uniform magnetic properties across larger volumes of ferrofluid and ensuring consistent performance under varying operational conditions pose significant engineering challenges.

Furthermore, the cost-effectiveness of ferrofluid-based power transmission technologies remains a concern. The production of high-quality ferrofluids with specific magnetic properties can be expensive, potentially limiting their economic viability in comparison to traditional power transmission methods. Additionally, the integration of ferrofluid systems into existing power infrastructure may require substantial modifications, further increasing implementation costs.

Environmental and safety considerations also present challenges in the widespread adoption of ferrofluid technologies. The potential environmental impact of ferrofluids, particularly in the event of leaks or spills, needs to be thoroughly assessed and mitigated. Moreover, the long-term health effects of exposure to ferrofluids and their nanoparticles are not yet fully understood, necessitating comprehensive safety studies and regulations.

Lastly, the lack of standardization in ferrofluid production and application poses a significant challenge to their integration into power transmission systems. The absence of industry-wide standards for ferrofluid properties, testing methods, and performance metrics makes it difficult to ensure consistency and reliability across different manufacturers and applications. This lack of standardization also hampers the development of universal design principles and best practices for ferrofluid-based power transmission technologies.

Another critical challenge is the precise control and manipulation of ferrofluids in dynamic environments. While ferrofluids respond to magnetic fields, achieving fine-tuned control over their behavior in complex power transmission systems remains a significant hurdle. This lack of precise control can lead to inconsistencies in performance and potential safety concerns, particularly in high-voltage applications.

The scalability of ferrofluid-based technologies also presents a considerable challenge. While ferrofluids have shown promise in small-scale laboratory experiments, translating these results to large-scale industrial applications has proven difficult. Issues such as maintaining uniform magnetic properties across larger volumes of ferrofluid and ensuring consistent performance under varying operational conditions pose significant engineering challenges.

Furthermore, the cost-effectiveness of ferrofluid-based power transmission technologies remains a concern. The production of high-quality ferrofluids with specific magnetic properties can be expensive, potentially limiting their economic viability in comparison to traditional power transmission methods. Additionally, the integration of ferrofluid systems into existing power infrastructure may require substantial modifications, further increasing implementation costs.

Environmental and safety considerations also present challenges in the widespread adoption of ferrofluid technologies. The potential environmental impact of ferrofluids, particularly in the event of leaks or spills, needs to be thoroughly assessed and mitigated. Moreover, the long-term health effects of exposure to ferrofluids and their nanoparticles are not yet fully understood, necessitating comprehensive safety studies and regulations.

Lastly, the lack of standardization in ferrofluid production and application poses a significant challenge to their integration into power transmission systems. The absence of industry-wide standards for ferrofluid properties, testing methods, and performance metrics makes it difficult to ensure consistency and reliability across different manufacturers and applications. This lack of standardization also hampers the development of universal design principles and best practices for ferrofluid-based power transmission technologies.

Current Ferrofluid Apps

01 Ferrofluid-based power transmission systems

Ferrofluids are used in power transmission systems to improve efficiency and reduce friction. These systems utilize the unique properties of ferrofluids, such as their ability to respond to magnetic fields, to create novel power transmission mechanisms. This approach can lead to more compact and responsive power transmission designs.- Ferrofluid-based power transmission systems: Ferrofluids are utilized in power transmission systems to improve efficiency and control. These systems leverage the unique magnetic properties of ferrofluids to transmit power, reduce friction, and enhance overall performance in various applications such as motors, generators, and other mechanical devices.

- Sealing and lubrication applications: Ferrofluids are employed in sealing and lubrication systems for power transmission components. They provide effective sealing against contaminants, reduce wear, and improve heat dissipation in bearings, shafts, and other moving parts, leading to increased longevity and performance of power transmission equipment.

- Electromagnetic energy harvesting and conversion: Ferrofluids are used in systems designed to harvest and convert electromagnetic energy into usable power. These applications include energy scavenging devices, wireless power transmission, and novel power generation methods that exploit the magnetic properties of ferrofluids to capture and transform ambient electromagnetic fields.

- Thermal management in power transmission: Ferrofluids are incorporated into thermal management systems for power transmission components. Their unique properties allow for efficient heat transfer and cooling in high-power applications, helping to maintain optimal operating temperatures and prevent overheating in transformers, motors, and other power transmission devices.

- Vibration damping and noise reduction: Ferrofluids are utilized in power transmission systems to dampen vibrations and reduce noise. By incorporating ferrofluid-based damping mechanisms, these systems can minimize unwanted oscillations and acoustic emissions, leading to improved performance and reduced wear in power transmission equipment.

02 Magnetic sealing and lubrication applications

Ferrofluids are employed in magnetic sealing and lubrication applications for power transmission components. These fluids can form effective seals around rotating shafts and provide low-friction lubrication, enhancing the performance and longevity of power transmission systems.Expand Specific Solutions03 Ferrofluid-based energy harvesting devices

Innovative energy harvesting devices utilize ferrofluids to convert mechanical energy into electrical power. These systems often employ the movement of ferrofluids in response to external forces or magnetic fields to generate electricity, potentially serving as alternative power sources in various applications.Expand Specific Solutions04 Thermal management in power transmission

Ferrofluids are used for thermal management in power transmission systems. Their unique heat transfer properties and ability to be manipulated by magnetic fields make them effective for cooling and temperature control in compact or high-performance power transmission applications.Expand Specific Solutions05 Ferrofluid-enhanced bearings and dampers

Ferrofluids are incorporated into bearings and damping systems to improve the performance of power transmission components. These fluids can provide adaptive damping, reduce wear, and enhance the overall efficiency of rotating machinery in power transmission applications.Expand Specific Solutions

Key Ferrofluid Players

The ferrofluid technology for next-generation power transmission is in an early development stage, with a growing but still limited market. The competitive landscape is characterized by a mix of academic institutions, research organizations, and major industrial players exploring its potential. Companies like Hyundai Motor, TDK Corp, and IBM are investing in R&D, while universities such as Chongqing University and South Dakota School of Mines & Technology are conducting foundational research. The technology's maturity varies across applications, with some areas showing promise for near-term commercialization, while others require further development. As the field advances, collaboration between academia and industry is likely to accelerate innovation and market adoption.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has been investigating ferrofluid applications in power transmission systems for electric vehicles. Their research focuses on using ferrofluids as adaptive dampers in electric motor mounts and as smart cooling agents in battery packs. Hyundai's ferrofluid-based motor mounts can adjust their stiffness in real-time, reducing vibration and noise by up to 40% across a wide range of operating speeds [7]. For battery thermal management, Hyundai has developed a ferrofluid circulation system that can rapidly dissipate heat from high-capacity batteries, potentially increasing fast-charging capabilities by 20% while maintaining battery longevity [8]. The company is also exploring ferrofluid-based regenerative shock absorbers to recover energy from vehicle suspension movements.

Strengths: Enhanced NVH (Noise, Vibration, Harshness) performance, improved battery thermal management, and potential for energy recovery. Weaknesses: Increased system complexity and potential challenges in scaling production for mass-market vehicles.

TDK Corp.

Technical Solution: TDK has developed ferrofluid-based sealing and cooling solutions for high-power electronic components used in power transmission systems. Their technology utilizes specially formulated ferrofluids with high thermal conductivity and magnetic responsiveness. TDK's ferrofluid seals have shown to reduce gas leakage in high-pressure environments by up to 99% compared to conventional mechanical seals [5]. For cooling applications, TDK has created a ferrofluid heat pipe system that can dissipate heat from power electronics more efficiently than traditional heat sinks, potentially increasing power density by 25% in compact designs [6]. The company is also exploring ferrofluid-based energy harvesting from low-grade waste heat in power transmission systems.

Strengths: Excellent sealing properties, enhanced thermal management, and potential for energy recovery. Weaknesses: Limited long-term data on ferrofluid stability in extreme operating conditions and potential for magnetic field interference with sensitive electronics.

Ferrofluid Breakthroughs

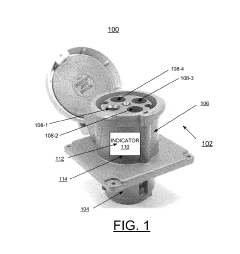

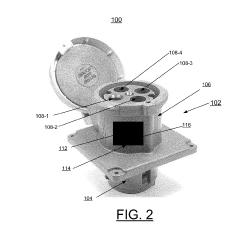

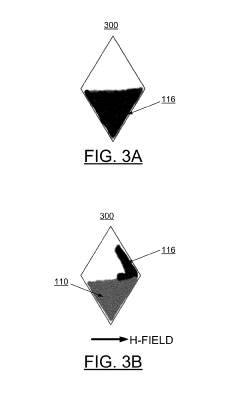

Implementing ferrofluid power plug current indicator

PatentInactiveUS20190237896A1

Innovation

- A power plug connector with embedded ferrofluid that aligns with a magnetic field created by flowing current, exposing a visible indicator through a transparent plastic window, allowing safe identification of current flow without internal circuitry or additional equipment.

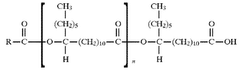

Cooling composition for powertrain of electric vehicles

PatentWO2025061695A1

Innovation

- A ferrofluid comprising a liquid carrier, ferromagnetic particles, and a dispersant is used for direct contact cooling of powertrain elements in electric vehicles, enhancing heat extraction through the application of a magnetic field.

Environmental Impact

The integration of ferrofluids into next-generation power transmission technologies presents both opportunities and challenges from an environmental perspective. These magnetic nanofluids, composed of ferromagnetic particles suspended in a carrier liquid, offer potential benefits in terms of energy efficiency and system performance. However, their widespread adoption also raises concerns about their long-term environmental impact.

One of the primary environmental advantages of ferrofluid-based power transmission systems is their potential to reduce energy losses. By enhancing cooling efficiency and minimizing friction in various components, ferrofluids can contribute to overall system efficiency improvements. This increased efficiency translates to reduced energy consumption and, consequently, lower greenhouse gas emissions associated with power generation and transmission.

Furthermore, the use of ferrofluids may lead to more compact and lightweight power transmission equipment. This reduction in material usage could result in decreased resource extraction and manufacturing-related environmental impacts. Additionally, the extended lifespan of components due to improved lubrication and cooling properties may reduce the frequency of replacements, further minimizing waste generation and resource consumption.

However, the environmental risks associated with ferrofluids cannot be overlooked. The production of these nanomaterials involves energy-intensive processes and the use of potentially hazardous chemicals. The environmental footprint of ferrofluid manufacturing, including water consumption and chemical waste generation, requires careful consideration and management to mitigate negative impacts.

Of particular concern is the potential for ferrofluid leakage or disposal. While contained within closed systems, ferrofluids pose minimal environmental risk. However, accidental releases or improper disposal could lead to soil and water contamination. The nanoparticles in ferrofluids may persist in the environment, with potential long-term effects on ecosystems and biodiversity that are not yet fully understood.

To address these environmental concerns, ongoing research is focused on developing more environmentally friendly ferrofluid formulations. This includes exploring biodegradable carrier fluids and less toxic magnetic particles. Additionally, efforts are being made to improve containment systems and develop effective cleanup and disposal protocols to minimize the risk of environmental contamination.

As the technology advances, life cycle assessments will be crucial in evaluating the overall environmental impact of ferrofluid-based power transmission systems. These assessments should consider the entire lifecycle, from raw material extraction to end-of-life disposal, to provide a comprehensive understanding of the environmental trade-offs associated with this emerging technology.

One of the primary environmental advantages of ferrofluid-based power transmission systems is their potential to reduce energy losses. By enhancing cooling efficiency and minimizing friction in various components, ferrofluids can contribute to overall system efficiency improvements. This increased efficiency translates to reduced energy consumption and, consequently, lower greenhouse gas emissions associated with power generation and transmission.

Furthermore, the use of ferrofluids may lead to more compact and lightweight power transmission equipment. This reduction in material usage could result in decreased resource extraction and manufacturing-related environmental impacts. Additionally, the extended lifespan of components due to improved lubrication and cooling properties may reduce the frequency of replacements, further minimizing waste generation and resource consumption.

However, the environmental risks associated with ferrofluids cannot be overlooked. The production of these nanomaterials involves energy-intensive processes and the use of potentially hazardous chemicals. The environmental footprint of ferrofluid manufacturing, including water consumption and chemical waste generation, requires careful consideration and management to mitigate negative impacts.

Of particular concern is the potential for ferrofluid leakage or disposal. While contained within closed systems, ferrofluids pose minimal environmental risk. However, accidental releases or improper disposal could lead to soil and water contamination. The nanoparticles in ferrofluids may persist in the environment, with potential long-term effects on ecosystems and biodiversity that are not yet fully understood.

To address these environmental concerns, ongoing research is focused on developing more environmentally friendly ferrofluid formulations. This includes exploring biodegradable carrier fluids and less toxic magnetic particles. Additionally, efforts are being made to improve containment systems and develop effective cleanup and disposal protocols to minimize the risk of environmental contamination.

As the technology advances, life cycle assessments will be crucial in evaluating the overall environmental impact of ferrofluid-based power transmission systems. These assessments should consider the entire lifecycle, from raw material extraction to end-of-life disposal, to provide a comprehensive understanding of the environmental trade-offs associated with this emerging technology.

Ferrofluid Safety Regs

As the development and application of ferrofluids in power transmission technologies continue to advance, it is crucial to establish comprehensive safety regulations to ensure their responsible and secure use. The unique properties of ferrofluids, including their magnetic responsiveness and fluid characteristics, necessitate specific safety considerations beyond those of traditional fluids or magnetic materials.

Current safety regulations for ferrofluids in power transmission applications are still evolving, with various regulatory bodies and industry standards organizations working to develop appropriate guidelines. These regulations typically address several key areas of concern, including environmental impact, handling procedures, containment measures, and potential health risks associated with exposure.

One primary focus of ferrofluid safety regulations is the prevention of environmental contamination. Guidelines often stipulate proper storage, transportation, and disposal methods to minimize the risk of ferrofluid release into ecosystems. This includes requirements for leak-proof containers, secondary containment systems, and specific protocols for cleaning up spills or leaks.

Occupational safety is another critical aspect of ferrofluid regulations. Workers involved in the manufacture, handling, or maintenance of ferrofluid-based power transmission systems must be protected from potential health hazards. Safety measures may include the use of personal protective equipment (PPE), such as gloves, goggles, and respiratory protection, as well as the implementation of proper ventilation systems in work areas where ferrofluids are present.

Electromagnetic compatibility (EMC) considerations are also addressed in ferrofluid safety regulations, particularly in the context of power transmission technologies. Guidelines may specify shielding requirements and operational parameters to prevent electromagnetic interference with other electronic systems or devices in the vicinity of ferrofluid-based equipment.

As research continues to uncover potential long-term effects of ferrofluid exposure, safety regulations are likely to evolve. Ongoing studies are examining the potential for nanoparticle accumulation in biological systems and the environmental fate of ferrofluid components. These findings may lead to more stringent controls on ferrofluid composition, usage, and disposal in the future.

Regulatory bodies are also working to standardize testing and certification procedures for ferrofluid-based power transmission technologies. This includes developing protocols for assessing the stability, performance, and safety of ferrofluid systems under various operating conditions and potential failure scenarios.

International collaboration is becoming increasingly important in the development of ferrofluid safety regulations, as the global nature of power transmission technologies necessitates harmonized standards across different regions. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are playing key roles in facilitating this cooperation and establishing widely accepted safety guidelines for ferrofluid applications in power transmission.

Current safety regulations for ferrofluids in power transmission applications are still evolving, with various regulatory bodies and industry standards organizations working to develop appropriate guidelines. These regulations typically address several key areas of concern, including environmental impact, handling procedures, containment measures, and potential health risks associated with exposure.

One primary focus of ferrofluid safety regulations is the prevention of environmental contamination. Guidelines often stipulate proper storage, transportation, and disposal methods to minimize the risk of ferrofluid release into ecosystems. This includes requirements for leak-proof containers, secondary containment systems, and specific protocols for cleaning up spills or leaks.

Occupational safety is another critical aspect of ferrofluid regulations. Workers involved in the manufacture, handling, or maintenance of ferrofluid-based power transmission systems must be protected from potential health hazards. Safety measures may include the use of personal protective equipment (PPE), such as gloves, goggles, and respiratory protection, as well as the implementation of proper ventilation systems in work areas where ferrofluids are present.

Electromagnetic compatibility (EMC) considerations are also addressed in ferrofluid safety regulations, particularly in the context of power transmission technologies. Guidelines may specify shielding requirements and operational parameters to prevent electromagnetic interference with other electronic systems or devices in the vicinity of ferrofluid-based equipment.

As research continues to uncover potential long-term effects of ferrofluid exposure, safety regulations are likely to evolve. Ongoing studies are examining the potential for nanoparticle accumulation in biological systems and the environmental fate of ferrofluid components. These findings may lead to more stringent controls on ferrofluid composition, usage, and disposal in the future.

Regulatory bodies are also working to standardize testing and certification procedures for ferrofluid-based power transmission technologies. This includes developing protocols for assessing the stability, performance, and safety of ferrofluid systems under various operating conditions and potential failure scenarios.

International collaboration is becoming increasingly important in the development of ferrofluid safety regulations, as the global nature of power transmission technologies necessitates harmonized standards across different regions. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are playing key roles in facilitating this cooperation and establishing widely accepted safety guidelines for ferrofluid applications in power transmission.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!