Leading Techniques for Ferrofluid Application in Environmental Engineering

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids, first developed in the 1960s by NASA, have undergone significant technological evolution over the past six decades. Initially conceived for space applications, these magnetic nanofluids have found their way into various environmental engineering applications, marking a remarkable journey of technological advancement.

The early stages of ferrofluid development focused primarily on improving stability and magnetic responsiveness. Scientists worked on perfecting the synthesis of magnetic nanoparticles and their suspension in carrier fluids. This period saw the emergence of surfactant-based stabilization techniques, which became crucial for preventing particle agglomeration and maintaining long-term stability.

In the 1980s and 1990s, research shifted towards enhancing the physical and chemical properties of ferrofluids. This era witnessed the development of ferrofluids with higher magnetic saturation, improved thermal stability, and enhanced resistance to oxidation. These advancements broadened the potential applications of ferrofluids in environmental engineering, particularly in areas such as wastewater treatment and oil spill cleanup.

The turn of the millennium marked a significant leap in ferrofluid technology. The advent of nanotechnology enabled precise control over particle size and distribution, leading to ferrofluids with superior magnetic properties and stability. This period also saw the integration of ferrofluids with other materials, such as polymers and ceramics, creating novel composite materials with unique environmental applications.

Recent years have witnessed a focus on developing "smart" ferrofluids capable of responding to multiple stimuli beyond magnetic fields. These advanced ferrofluids can react to changes in pH, temperature, or light, opening up new possibilities in environmental sensing and remediation. The incorporation of biocompatible and biodegradable components has also gained traction, aligning ferrofluid technology with sustainable environmental practices.

In the context of environmental engineering, ferrofluid technology has evolved to address specific challenges. For instance, magnetically guided ferrofluids have been developed for targeted pollutant removal in water treatment processes. Similarly, advances in ferrofluid-based membranes have led to more efficient separation techniques for various environmental applications.

The latest frontier in ferrofluid evolution involves the integration of artificial intelligence and machine learning. These technologies are being employed to optimize ferrofluid compositions and predict their behavior in complex environmental systems, paving the way for more effective and efficient environmental engineering solutions.

The early stages of ferrofluid development focused primarily on improving stability and magnetic responsiveness. Scientists worked on perfecting the synthesis of magnetic nanoparticles and their suspension in carrier fluids. This period saw the emergence of surfactant-based stabilization techniques, which became crucial for preventing particle agglomeration and maintaining long-term stability.

In the 1980s and 1990s, research shifted towards enhancing the physical and chemical properties of ferrofluids. This era witnessed the development of ferrofluids with higher magnetic saturation, improved thermal stability, and enhanced resistance to oxidation. These advancements broadened the potential applications of ferrofluids in environmental engineering, particularly in areas such as wastewater treatment and oil spill cleanup.

The turn of the millennium marked a significant leap in ferrofluid technology. The advent of nanotechnology enabled precise control over particle size and distribution, leading to ferrofluids with superior magnetic properties and stability. This period also saw the integration of ferrofluids with other materials, such as polymers and ceramics, creating novel composite materials with unique environmental applications.

Recent years have witnessed a focus on developing "smart" ferrofluids capable of responding to multiple stimuli beyond magnetic fields. These advanced ferrofluids can react to changes in pH, temperature, or light, opening up new possibilities in environmental sensing and remediation. The incorporation of biocompatible and biodegradable components has also gained traction, aligning ferrofluid technology with sustainable environmental practices.

In the context of environmental engineering, ferrofluid technology has evolved to address specific challenges. For instance, magnetically guided ferrofluids have been developed for targeted pollutant removal in water treatment processes. Similarly, advances in ferrofluid-based membranes have led to more efficient separation techniques for various environmental applications.

The latest frontier in ferrofluid evolution involves the integration of artificial intelligence and machine learning. These technologies are being employed to optimize ferrofluid compositions and predict their behavior in complex environmental systems, paving the way for more effective and efficient environmental engineering solutions.

Environmental Market Needs

The environmental engineering sector is experiencing a growing demand for innovative solutions to address pressing ecological challenges. Ferrofluids, with their unique magnetic properties and adaptability, are emerging as a promising technology in this field. The market for environmental applications of ferrofluids is driven by several key factors, including the need for more efficient water treatment processes, soil remediation techniques, and air pollution control methods.

In the water treatment sector, there is a significant demand for advanced filtration and separation technologies. Ferrofluids offer potential solutions for removing contaminants such as heavy metals, organic pollutants, and microplastics from water sources. The ability of ferrofluids to be manipulated by magnetic fields allows for precise control in separation processes, potentially leading to more efficient and cost-effective water purification systems.

Soil remediation is another area where ferrofluids show promise. As industrial activities and urbanization continue to impact soil quality, there is an increasing need for effective soil decontamination techniques. Ferrofluids could be used to target and extract specific pollutants from soil, offering a less invasive and more targeted approach compared to traditional remediation methods.

Air pollution control is a critical concern in many urban and industrial areas. The market is seeking innovative solutions to capture and neutralize airborne pollutants. Ferrofluids could potentially be used in advanced air filtration systems, leveraging their magnetic properties to trap and remove particulate matter and other contaminants from the air.

The oil spill cleanup sector also presents a significant market opportunity for ferrofluid applications. With the ongoing risk of oil spills in marine environments, there is a constant demand for more effective cleanup technologies. Ferrofluids could be used to develop advanced oil-water separation techniques, potentially improving the speed and efficiency of oil spill response efforts.

Additionally, there is a growing interest in sustainable and environmentally friendly technologies across various industries. Ferrofluids, being potentially reusable and requiring minimal chemical additives, align well with this trend. This creates opportunities for ferrofluid applications in green technologies and circular economy initiatives.

The market demand for ferrofluid applications in environmental engineering is further bolstered by increasingly stringent environmental regulations worldwide. As governments and international bodies impose stricter standards for pollution control and environmental protection, industries are compelled to seek out more advanced and efficient solutions, creating a favorable market environment for innovative technologies like ferrofluids.

In the water treatment sector, there is a significant demand for advanced filtration and separation technologies. Ferrofluids offer potential solutions for removing contaminants such as heavy metals, organic pollutants, and microplastics from water sources. The ability of ferrofluids to be manipulated by magnetic fields allows for precise control in separation processes, potentially leading to more efficient and cost-effective water purification systems.

Soil remediation is another area where ferrofluids show promise. As industrial activities and urbanization continue to impact soil quality, there is an increasing need for effective soil decontamination techniques. Ferrofluids could be used to target and extract specific pollutants from soil, offering a less invasive and more targeted approach compared to traditional remediation methods.

Air pollution control is a critical concern in many urban and industrial areas. The market is seeking innovative solutions to capture and neutralize airborne pollutants. Ferrofluids could potentially be used in advanced air filtration systems, leveraging their magnetic properties to trap and remove particulate matter and other contaminants from the air.

The oil spill cleanup sector also presents a significant market opportunity for ferrofluid applications. With the ongoing risk of oil spills in marine environments, there is a constant demand for more effective cleanup technologies. Ferrofluids could be used to develop advanced oil-water separation techniques, potentially improving the speed and efficiency of oil spill response efforts.

Additionally, there is a growing interest in sustainable and environmentally friendly technologies across various industries. Ferrofluids, being potentially reusable and requiring minimal chemical additives, align well with this trend. This creates opportunities for ferrofluid applications in green technologies and circular economy initiatives.

The market demand for ferrofluid applications in environmental engineering is further bolstered by increasingly stringent environmental regulations worldwide. As governments and international bodies impose stricter standards for pollution control and environmental protection, industries are compelled to seek out more advanced and efficient solutions, creating a favorable market environment for innovative technologies like ferrofluids.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in environmental engineering applications, several significant challenges hinder their widespread adoption and effectiveness. One of the primary obstacles is the long-term stability of ferrofluids in complex environmental matrices. When exposed to diverse pollutants, varying pH levels, and heterogeneous aqueous environments, ferrofluids may experience aggregation, sedimentation, or loss of magnetic properties, compromising their performance and reusability.

Another critical challenge lies in the selective capture and removal of specific contaminants. While ferrofluids demonstrate high adsorption capacities for various pollutants, achieving selectivity in mixed-contaminant scenarios remains difficult. This limitation affects the efficiency of ferrofluid-based treatment processes, particularly in real-world environmental remediation applications where multiple pollutants coexist.

The scalability of ferrofluid-based technologies presents a significant hurdle in their practical implementation. Laboratory-scale successes often face obstacles when scaled up to industrial levels, primarily due to issues related to uniform dispersion, magnetic field distribution, and recovery of ferrofluids in large-scale systems. These scaling challenges impact the economic viability and operational feasibility of ferrofluid applications in environmental engineering.

Environmental concerns regarding the potential ecological impacts of ferrofluids themselves pose another challenge. The long-term effects of nanoparticle release into ecosystems, potential bioaccumulation, and toxicity to aquatic organisms are areas that require extensive research and risk assessment before widespread deployment of ferrofluid-based environmental solutions.

The optimization of magnetic separation and recovery processes for ferrofluids in complex environmental matrices remains a technical challenge. Efficient separation and recovery are crucial for the economic feasibility and environmental sustainability of ferrofluid applications, yet achieving high recovery rates without compromising the treated effluent quality is often difficult in practice.

Lastly, the regulatory landscape surrounding the use of nanomaterials in environmental applications presents a challenge for the adoption of ferrofluid technologies. The lack of standardized protocols for safety assessment, disposal, and environmental impact evaluation of ferrofluids creates uncertainty and potential barriers to their implementation in large-scale environmental engineering projects.

Another critical challenge lies in the selective capture and removal of specific contaminants. While ferrofluids demonstrate high adsorption capacities for various pollutants, achieving selectivity in mixed-contaminant scenarios remains difficult. This limitation affects the efficiency of ferrofluid-based treatment processes, particularly in real-world environmental remediation applications where multiple pollutants coexist.

The scalability of ferrofluid-based technologies presents a significant hurdle in their practical implementation. Laboratory-scale successes often face obstacles when scaled up to industrial levels, primarily due to issues related to uniform dispersion, magnetic field distribution, and recovery of ferrofluids in large-scale systems. These scaling challenges impact the economic viability and operational feasibility of ferrofluid applications in environmental engineering.

Environmental concerns regarding the potential ecological impacts of ferrofluids themselves pose another challenge. The long-term effects of nanoparticle release into ecosystems, potential bioaccumulation, and toxicity to aquatic organisms are areas that require extensive research and risk assessment before widespread deployment of ferrofluid-based environmental solutions.

The optimization of magnetic separation and recovery processes for ferrofluids in complex environmental matrices remains a technical challenge. Efficient separation and recovery are crucial for the economic feasibility and environmental sustainability of ferrofluid applications, yet achieving high recovery rates without compromising the treated effluent quality is often difficult in practice.

Lastly, the regulatory landscape surrounding the use of nanomaterials in environmental applications presents a challenge for the adoption of ferrofluid technologies. The lack of standardized protocols for safety assessment, disposal, and environmental impact evaluation of ferrofluids creates uncertainty and potential barriers to their implementation in large-scale environmental engineering projects.

Current Ferrofluid Apps

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, minimal leakage, and long service life. These properties make them ideal for use in various industrial and mechanical systems.

- Thermal management and cooling systems: Ferrofluids have unique heat transfer properties that make them suitable for thermal management applications. They can be used in cooling systems for electronic devices, where their ability to be manipulated by magnetic fields allows for targeted heat dissipation. This property is particularly valuable in compact or high-performance electronic systems.

- Damping and vibration control: The magnetic properties of ferrofluids make them effective in damping and vibration control applications. They can be used in shock absorbers, vibration isolators, and other mechanical systems to reduce unwanted motion and improve stability. The ability to change their viscosity in response to magnetic fields allows for adaptive damping solutions.

- Sensing and measurement applications: Ferrofluids are employed in various sensing and measurement devices. Their response to magnetic fields and ability to change shape or position makes them useful in accelerometers, inclinometers, and other instruments. They can also be used in magnetic field visualization and in specialized optical systems for precise measurements.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, zero-leakage seals that can operate under high pressure differentials and in vacuum environments. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining liquid properties.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, speakers, and transformers. When subjected to a magnetic field, the fluid's thermal conductivity can be controlled, allowing for efficient heat dissipation in various applications.Expand Specific Solutions04 Damping and vibration control

The unique properties of ferrofluids make them excellent for damping and vibration control applications. They can be used in shock absorbers, inertial dampers, and acoustic devices. The fluid's viscosity can be controlled by applying magnetic fields, allowing for adaptive damping in various mechanical systems.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids are employed in various sensing and measurement devices. They are used in accelerometers, inclinometers, and pressure sensors. The fluid's response to magnetic fields and its ability to change shape and position make it suitable for detecting and measuring physical quantities in a wide range of applications.Expand Specific Solutions

Key Ferrofluid Players

The ferrofluid application in environmental engineering is in an emerging stage, with a growing market driven by increasing environmental concerns and technological advancements. The global market size for ferrofluid applications is expanding, though still relatively niche. Technologically, the field is progressing rapidly, with varying levels of maturity across different applications. Key players like Yale University, Ferrotec (USA) Corp., and Teledyne Scientific & Imaging LLC are at the forefront of research and development. Universities such as Université Laval and Chongqing University are contributing significantly to academic research, while companies like Ecopetrol SA and Koninklijke Philips NV are exploring practical applications. The involvement of diverse institutions indicates a competitive landscape with potential for further innovation and market growth.

Yale University

Technical Solution: Yale University has conducted extensive research on ferrofluid applications in environmental engineering. Their work includes the development of novel magnetic nanocomposites for water treatment, capable of removing both organic and inorganic contaminants with high efficiency[1]. Yale researchers have also explored the use of ferrofluids in atmospheric carbon capture, utilizing magnetic properties to enhance the absorption and separation of greenhouse gases[2]. Additionally, the university has investigated the potential of ferrofluid-based membranes for advanced desalination processes, aiming to improve water purification techniques while reducing energy consumption[3].

Strengths: Cutting-edge research capabilities; interdisciplinary approach combining materials science and environmental engineering. Weaknesses: May face challenges in translating academic research into commercially viable technologies.

Ferrotec (USA) Corp.

Technical Solution: Ferrotec has developed advanced ferrofluid-based solutions for environmental engineering applications. Their technology focuses on magnetic separation techniques for water treatment, utilizing nano-sized magnetic particles to remove contaminants from wastewater[1]. The company has also pioneered the use of ferrofluids in oil spill cleanup, where magnetic nanoparticles are dispersed in oil slicks and then collected using magnetic fields[2]. Additionally, Ferrotec has explored the application of ferrofluids in soil remediation, using magnetically-guided nanoparticles to target and extract heavy metals and other pollutants from contaminated soil[3].

Strengths: Extensive experience in ferrofluid manufacturing and applications; diverse range of environmental solutions. Weaknesses: May face challenges in scaling up technologies for large-scale environmental projects.

Ferrofluid Innovations

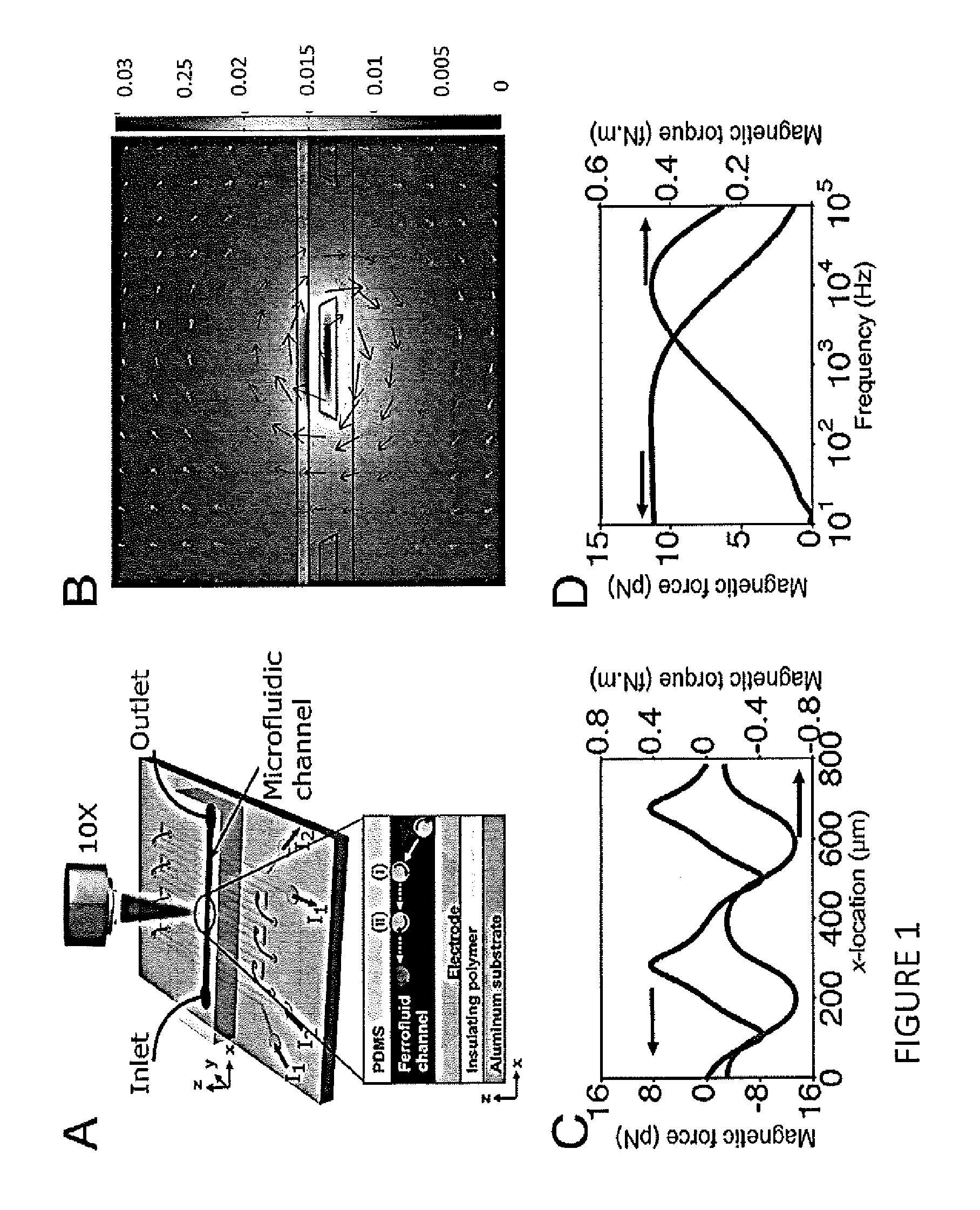

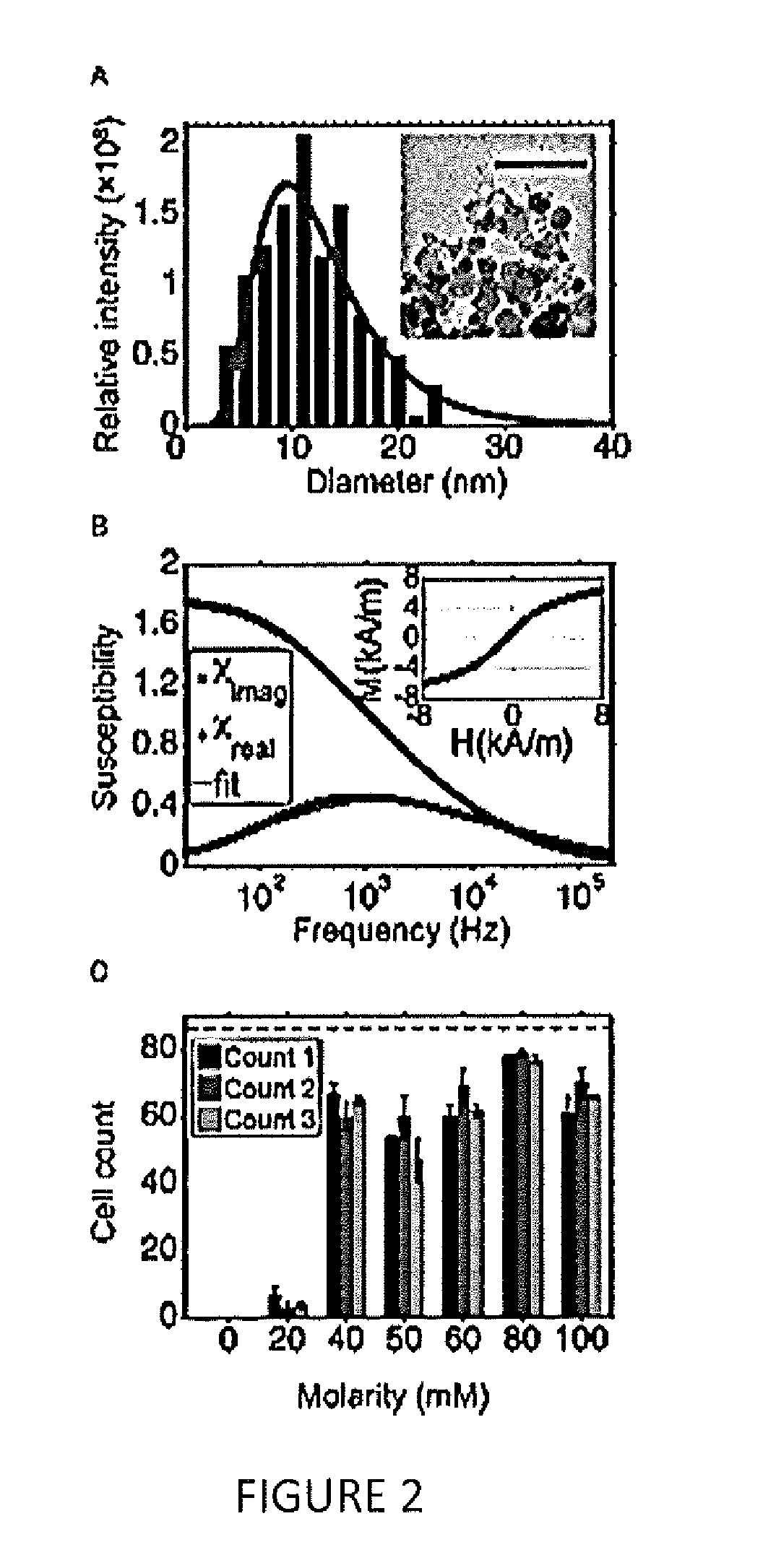

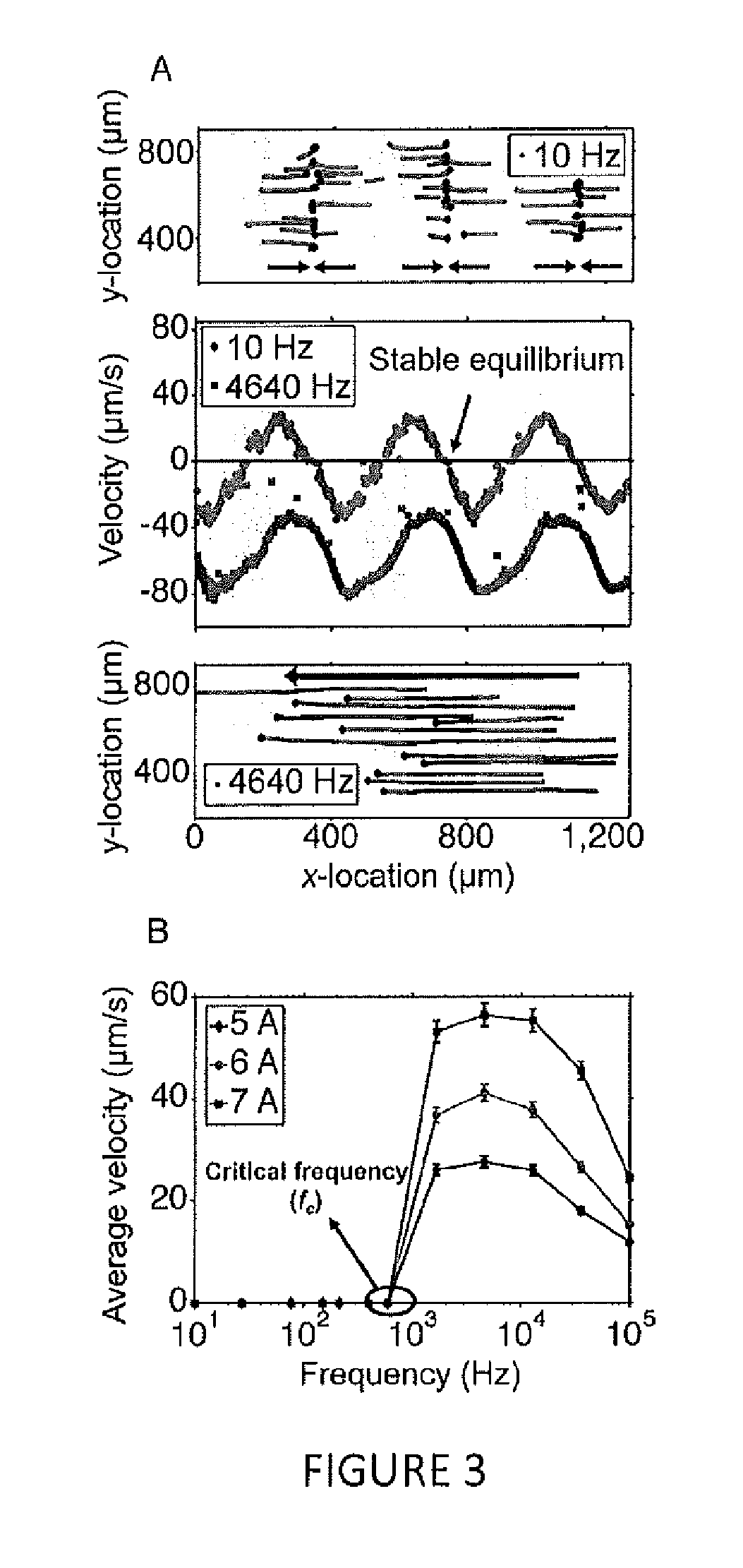

Label-free cellular manipulation and sorting via biocompatible ferrofluids

PatentActiveUS20120237997A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

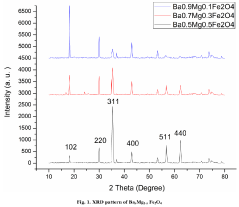

Development of water based ferrofluid for efficient heat transfer

PatentUndeterminedIN202021015289A

Innovation

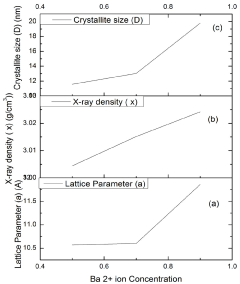

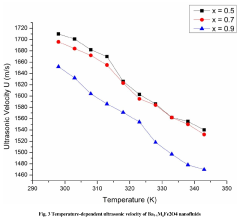

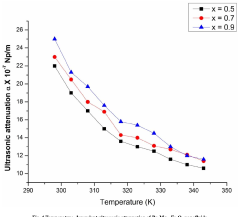

- The synthesis of Ba substituted Mg ferrite nanoparticles and their incorporation into water-based ferrofluids using ultrasonication to enhance thermal conductivity, ensuring stable single-phase formation and optimized thermoacoustical properties.

Eco-Impact Assessment

The application of ferrofluids in environmental engineering has garnered significant attention due to its potential for addressing various ecological challenges. Assessing the eco-impact of ferrofluid-based techniques is crucial for understanding their long-term sustainability and environmental compatibility. This evaluation encompasses several key aspects that require thorough examination.

Firstly, the production process of ferrofluids must be scrutinized for its environmental footprint. The synthesis of magnetic nanoparticles and their subsequent suspension in carrier fluids often involves chemical processes that may generate waste or consume significant energy. Analyzing the life cycle of ferrofluid production, from raw material extraction to final product formulation, provides insights into the overall environmental cost associated with these materials.

The application phase of ferrofluids in environmental engineering solutions presents both opportunities and challenges from an ecological perspective. On one hand, ferrofluids offer innovative approaches to pollution control, waste treatment, and resource recovery, potentially reducing the environmental impact of traditional methods. For instance, their use in oil spill cleanup can significantly enhance the efficiency of containment and recovery operations, minimizing damage to marine ecosystems.

However, the introduction of engineered nanomaterials into the environment raises concerns about their potential ecological effects. The fate and behavior of ferrofluid nanoparticles in natural systems must be carefully studied to assess any risks of bioaccumulation or ecosystem disruption. This includes examining their interactions with various organisms, their potential for entering food chains, and their long-term persistence in different environmental compartments.

Water and soil quality impacts are particularly important considerations. While ferrofluids can be effective in removing contaminants from these media, the possibility of secondary pollution through the release of nanoparticles or their degradation products must be evaluated. Comprehensive toxicity studies on aquatic and terrestrial organisms are essential to understand the potential ecological consequences of ferrofluid applications.

Energy efficiency and carbon footprint analyses are also integral to the eco-impact assessment. Ferrofluid-based technologies often promise enhanced performance and reduced energy consumption compared to conventional methods. Quantifying these benefits in terms of reduced greenhouse gas emissions and overall environmental burden is crucial for justifying their adoption from a sustainability standpoint.

Lastly, the end-of-life management of ferrofluids and associated equipment requires careful consideration. Developing effective recycling or disposal methods for used ferrofluids is essential to prevent environmental contamination and ensure the closure of material loops. This aspect of the assessment should also explore the potential for recovering valuable components from spent ferrofluids, contributing to resource conservation efforts.

Firstly, the production process of ferrofluids must be scrutinized for its environmental footprint. The synthesis of magnetic nanoparticles and their subsequent suspension in carrier fluids often involves chemical processes that may generate waste or consume significant energy. Analyzing the life cycle of ferrofluid production, from raw material extraction to final product formulation, provides insights into the overall environmental cost associated with these materials.

The application phase of ferrofluids in environmental engineering solutions presents both opportunities and challenges from an ecological perspective. On one hand, ferrofluids offer innovative approaches to pollution control, waste treatment, and resource recovery, potentially reducing the environmental impact of traditional methods. For instance, their use in oil spill cleanup can significantly enhance the efficiency of containment and recovery operations, minimizing damage to marine ecosystems.

However, the introduction of engineered nanomaterials into the environment raises concerns about their potential ecological effects. The fate and behavior of ferrofluid nanoparticles in natural systems must be carefully studied to assess any risks of bioaccumulation or ecosystem disruption. This includes examining their interactions with various organisms, their potential for entering food chains, and their long-term persistence in different environmental compartments.

Water and soil quality impacts are particularly important considerations. While ferrofluids can be effective in removing contaminants from these media, the possibility of secondary pollution through the release of nanoparticles or their degradation products must be evaluated. Comprehensive toxicity studies on aquatic and terrestrial organisms are essential to understand the potential ecological consequences of ferrofluid applications.

Energy efficiency and carbon footprint analyses are also integral to the eco-impact assessment. Ferrofluid-based technologies often promise enhanced performance and reduced energy consumption compared to conventional methods. Quantifying these benefits in terms of reduced greenhouse gas emissions and overall environmental burden is crucial for justifying their adoption from a sustainability standpoint.

Lastly, the end-of-life management of ferrofluids and associated equipment requires careful consideration. Developing effective recycling or disposal methods for used ferrofluids is essential to prevent environmental contamination and ensure the closure of material loops. This aspect of the assessment should also explore the potential for recovering valuable components from spent ferrofluids, contributing to resource conservation efforts.

Regulatory Framework

The regulatory framework surrounding ferrofluid applications in environmental engineering is complex and multifaceted, reflecting the diverse nature of potential uses and associated risks. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and recommendations for the safe handling and disposal of nanomaterials, including ferrofluids. These guidelines often serve as a basis for national and regional regulations.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating ferrofluid applications under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers and importers to submit premanufacture notices for new chemical substances, including engineered nanomaterials like ferrofluids. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for worker safety when handling these materials.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to ferrofluids and other nanomaterials. REACH requires companies to register substances manufactured or imported in quantities over one tonne per year and provide safety data. The EU has also established specific regulations for nanomaterials in cosmetics, food, and biocidal products, which may impact certain environmental applications of ferrofluids.

In Asia, countries like Japan and South Korea have developed their own regulatory frameworks for nanomaterials. Japan's approach focuses on voluntary reporting and risk assessment, while South Korea has implemented mandatory registration requirements similar to REACH. China has also been developing regulations for new chemical substances, including nanomaterials, under its Measures for Environmental Management of New Chemical Substances.

Despite these regulatory efforts, there remain significant challenges in the governance of ferrofluid applications. The rapid pace of technological advancement often outstrips regulatory processes, leading to potential gaps in oversight. Moreover, the unique properties of ferrofluids at the nanoscale present difficulties in risk assessment and management, as traditional toxicological methods may not always be applicable.

To address these challenges, many jurisdictions are adopting adaptive and flexible regulatory approaches. These include the use of soft law instruments, such as guidelines and best practices, alongside traditional hard law regulations. Additionally, there is a growing emphasis on stakeholder engagement and international cooperation to ensure that regulatory frameworks remain effective and up-to-date in the face of evolving technologies and applications in environmental engineering.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating ferrofluid applications under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers and importers to submit premanufacture notices for new chemical substances, including engineered nanomaterials like ferrofluids. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for worker safety when handling these materials.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to ferrofluids and other nanomaterials. REACH requires companies to register substances manufactured or imported in quantities over one tonne per year and provide safety data. The EU has also established specific regulations for nanomaterials in cosmetics, food, and biocidal products, which may impact certain environmental applications of ferrofluids.

In Asia, countries like Japan and South Korea have developed their own regulatory frameworks for nanomaterials. Japan's approach focuses on voluntary reporting and risk assessment, while South Korea has implemented mandatory registration requirements similar to REACH. China has also been developing regulations for new chemical substances, including nanomaterials, under its Measures for Environmental Management of New Chemical Substances.

Despite these regulatory efforts, there remain significant challenges in the governance of ferrofluid applications. The rapid pace of technological advancement often outstrips regulatory processes, leading to potential gaps in oversight. Moreover, the unique properties of ferrofluids at the nanoscale present difficulties in risk assessment and management, as traditional toxicological methods may not always be applicable.

To address these challenges, many jurisdictions are adopting adaptive and flexible regulatory approaches. These include the use of soft law instruments, such as guidelines and best practices, alongside traditional hard law regulations. Additionally, there is a growing emphasis on stakeholder engagement and international cooperation to ensure that regulatory frameworks remain effective and up-to-date in the face of evolving technologies and applications in environmental engineering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!