Ferrofluid's Contribution to Revolutionary Digital Imaging Methods

JUL 9, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Imaging Evolution

The evolution of ferrofluid imaging represents a significant milestone in the field of digital imaging methods. This innovative approach harnesses the unique properties of ferrofluids, colloidal suspensions of magnetic nanoparticles, to create dynamic and responsive imaging systems.

The journey of ferrofluid imaging began in the early 2000s when researchers first explored the potential of manipulating ferrofluids using magnetic fields for imaging applications. Initially, these experiments focused on creating simple patterns and shapes, demonstrating the basic principle of controlled ferrofluid movement.

As the technology progressed, scientists developed more sophisticated methods to manipulate ferrofluids with greater precision. By 2010, researchers had successfully created complex, high-resolution images using ferrofluid displays. These early systems utilized electromagnetic arrays to control the distribution of ferrofluid, allowing for the formation of intricate patterns and grayscale images.

The next significant breakthrough came in the mid-2010s with the integration of computer vision and machine learning algorithms. This advancement enabled real-time tracking and response to external stimuli, paving the way for interactive ferrofluid displays. These systems could dynamically adjust their appearance based on user input or environmental changes, opening up new possibilities in adaptive imaging.

By 2018, miniaturization techniques had advanced sufficiently to allow for the development of micro-scale ferrofluid imaging devices. These compact systems offered higher resolution and faster response times, making them suitable for a wider range of applications, including medical imaging and microscopy.

Recent years have seen a focus on enhancing the color capabilities of ferrofluid imaging. Researchers have experimented with multi-layered ferrofluid systems and the incorporation of fluorescent nanoparticles to achieve a broader color spectrum. This development has significantly expanded the potential applications of ferrofluid imaging in fields such as display technology and artistic visualization.

The latest advancements in ferrofluid imaging involve the integration of 3D printing techniques. By precisely depositing ferrofluid-infused materials, researchers have created three-dimensional structures that can change shape or appearance in response to magnetic fields. This breakthrough has opened up new avenues in 4D printing and responsive materials.

Looking ahead, the future of ferrofluid imaging appears promising, with ongoing research into nanoscale manipulation, quantum effects in ferrofluids, and the development of biocompatible ferrofluids for in vivo imaging applications. These advancements continue to push the boundaries of what is possible in digital imaging, offering new tools for scientific visualization, artistic expression, and technological innovation.

The journey of ferrofluid imaging began in the early 2000s when researchers first explored the potential of manipulating ferrofluids using magnetic fields for imaging applications. Initially, these experiments focused on creating simple patterns and shapes, demonstrating the basic principle of controlled ferrofluid movement.

As the technology progressed, scientists developed more sophisticated methods to manipulate ferrofluids with greater precision. By 2010, researchers had successfully created complex, high-resolution images using ferrofluid displays. These early systems utilized electromagnetic arrays to control the distribution of ferrofluid, allowing for the formation of intricate patterns and grayscale images.

The next significant breakthrough came in the mid-2010s with the integration of computer vision and machine learning algorithms. This advancement enabled real-time tracking and response to external stimuli, paving the way for interactive ferrofluid displays. These systems could dynamically adjust their appearance based on user input or environmental changes, opening up new possibilities in adaptive imaging.

By 2018, miniaturization techniques had advanced sufficiently to allow for the development of micro-scale ferrofluid imaging devices. These compact systems offered higher resolution and faster response times, making them suitable for a wider range of applications, including medical imaging and microscopy.

Recent years have seen a focus on enhancing the color capabilities of ferrofluid imaging. Researchers have experimented with multi-layered ferrofluid systems and the incorporation of fluorescent nanoparticles to achieve a broader color spectrum. This development has significantly expanded the potential applications of ferrofluid imaging in fields such as display technology and artistic visualization.

The latest advancements in ferrofluid imaging involve the integration of 3D printing techniques. By precisely depositing ferrofluid-infused materials, researchers have created three-dimensional structures that can change shape or appearance in response to magnetic fields. This breakthrough has opened up new avenues in 4D printing and responsive materials.

Looking ahead, the future of ferrofluid imaging appears promising, with ongoing research into nanoscale manipulation, quantum effects in ferrofluids, and the development of biocompatible ferrofluids for in vivo imaging applications. These advancements continue to push the boundaries of what is possible in digital imaging, offering new tools for scientific visualization, artistic expression, and technological innovation.

Digital Imaging Market Trends

The digital imaging market has experienced significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. The global digital imaging market size was valued at $26.3 billion in 2020 and is projected to reach $42.8 billion by 2027, growing at a CAGR of 7.8% during the forecast period. This growth is primarily attributed to the increasing adoption of digital cameras, smartphones with advanced imaging capabilities, and the rising demand for high-quality visual content across various industries.

One of the key trends shaping the digital imaging market is the integration of artificial intelligence (AI) and machine learning algorithms. These technologies are revolutionizing image processing, enhancing image quality, and enabling advanced features such as object recognition and scene understanding. The AI-powered imaging solutions market is expected to grow at a CAGR of 25.3% from 2021 to 2028, indicating a strong demand for intelligent imaging technologies.

Another significant trend is the shift towards 3D imaging and sensing technologies. The 3D imaging market is forecasted to reach $36.4 billion by 2025, growing at a CAGR of 23.2% from 2020 to 2025. This growth is driven by applications in healthcare, automotive, and consumer electronics sectors, where 3D imaging enables improved diagnostics, autonomous driving capabilities, and enhanced user experiences in augmented reality (AR) and virtual reality (VR) applications.

The emergence of computational photography is also reshaping the digital imaging landscape. This technology leverages software algorithms and multiple image sensors to produce high-quality images beyond the limitations of traditional optical systems. The computational camera market is expected to grow at a CAGR of 18.5% from 2021 to 2026, reflecting the increasing adoption of advanced imaging techniques in smartphones and professional cameras.

In the professional photography and videography segment, there is a growing demand for high-resolution imaging solutions. The 4K and 8K camera market is projected to reach $11.7 billion by 2026, growing at a CAGR of 9.8% from 2021 to 2026. This trend is driven by the increasing production of high-quality content for streaming platforms, cinema, and broadcast applications.

The medical imaging sector is also experiencing significant growth, with a focus on advanced diagnostic technologies. The global medical imaging market size is expected to reach $45.0 billion by 2026, growing at a CAGR of 5.2% from 2021 to 2026. This growth is fueled by the increasing prevalence of chronic diseases and the adoption of AI-powered diagnostic tools.

One of the key trends shaping the digital imaging market is the integration of artificial intelligence (AI) and machine learning algorithms. These technologies are revolutionizing image processing, enhancing image quality, and enabling advanced features such as object recognition and scene understanding. The AI-powered imaging solutions market is expected to grow at a CAGR of 25.3% from 2021 to 2028, indicating a strong demand for intelligent imaging technologies.

Another significant trend is the shift towards 3D imaging and sensing technologies. The 3D imaging market is forecasted to reach $36.4 billion by 2025, growing at a CAGR of 23.2% from 2020 to 2025. This growth is driven by applications in healthcare, automotive, and consumer electronics sectors, where 3D imaging enables improved diagnostics, autonomous driving capabilities, and enhanced user experiences in augmented reality (AR) and virtual reality (VR) applications.

The emergence of computational photography is also reshaping the digital imaging landscape. This technology leverages software algorithms and multiple image sensors to produce high-quality images beyond the limitations of traditional optical systems. The computational camera market is expected to grow at a CAGR of 18.5% from 2021 to 2026, reflecting the increasing adoption of advanced imaging techniques in smartphones and professional cameras.

In the professional photography and videography segment, there is a growing demand for high-resolution imaging solutions. The 4K and 8K camera market is projected to reach $11.7 billion by 2026, growing at a CAGR of 9.8% from 2021 to 2026. This trend is driven by the increasing production of high-quality content for streaming platforms, cinema, and broadcast applications.

The medical imaging sector is also experiencing significant growth, with a focus on advanced diagnostic technologies. The global medical imaging market size is expected to reach $45.0 billion by 2026, growing at a CAGR of 5.2% from 2021 to 2026. This growth is fueled by the increasing prevalence of chronic diseases and the adoption of AI-powered diagnostic tools.

Ferrofluid Tech Challenges

Ferrofluids, while promising for digital imaging applications, face several significant technical challenges that hinder their widespread adoption. One of the primary obstacles is the stability of the colloidal suspension. Ferrofluids consist of magnetic nanoparticles suspended in a carrier fluid, and maintaining this suspension over extended periods is crucial for consistent performance. Environmental factors such as temperature fluctuations, exposure to strong magnetic fields, and mechanical stress can cause particle aggregation or separation, compromising the fluid's properties and functionality.

Another major challenge lies in controlling the precise behavior of ferrofluids under applied magnetic fields. While the general response of ferrofluids to magnetic stimuli is well understood, achieving fine-grained control for high-resolution imaging applications remains difficult. This is particularly problematic when attempting to create complex, dynamic patterns or structures necessary for advanced imaging techniques. The non-linear response of ferrofluids to magnetic fields of varying strengths further complicates their predictable manipulation.

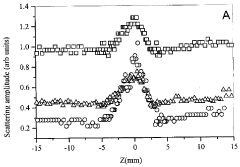

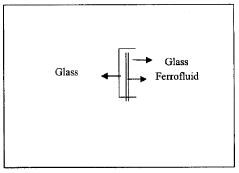

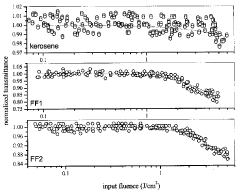

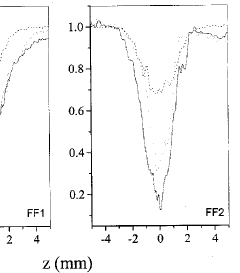

The optical properties of ferrofluids present another set of challenges. While their unique light-scattering and absorption characteristics make them interesting for imaging applications, these properties can also interfere with desired imaging outcomes. Achieving the right balance between opacity and transparency, as well as managing reflectivity and color consistency across different magnetic field strengths, poses significant technical hurdles.

Scalability and manufacturing consistency are additional concerns. Producing ferrofluids with uniform properties at scale is challenging, as slight variations in particle size, distribution, or carrier fluid composition can lead to significant differences in performance. This inconsistency can result in unreliable imaging results and difficulties in standardizing ferrofluid-based imaging systems.

Lastly, the long-term stability and durability of ferrofluid-based imaging systems remain a concern. Exposure to air, moisture, or other contaminants can degrade the ferrofluid over time, altering its magnetic and optical properties. Developing effective sealing and containment solutions that do not interfere with the fluid's functionality is a critical challenge that must be addressed for practical, long-lasting applications in digital imaging.

Another major challenge lies in controlling the precise behavior of ferrofluids under applied magnetic fields. While the general response of ferrofluids to magnetic stimuli is well understood, achieving fine-grained control for high-resolution imaging applications remains difficult. This is particularly problematic when attempting to create complex, dynamic patterns or structures necessary for advanced imaging techniques. The non-linear response of ferrofluids to magnetic fields of varying strengths further complicates their predictable manipulation.

The optical properties of ferrofluids present another set of challenges. While their unique light-scattering and absorption characteristics make them interesting for imaging applications, these properties can also interfere with desired imaging outcomes. Achieving the right balance between opacity and transparency, as well as managing reflectivity and color consistency across different magnetic field strengths, poses significant technical hurdles.

Scalability and manufacturing consistency are additional concerns. Producing ferrofluids with uniform properties at scale is challenging, as slight variations in particle size, distribution, or carrier fluid composition can lead to significant differences in performance. This inconsistency can result in unreliable imaging results and difficulties in standardizing ferrofluid-based imaging systems.

Lastly, the long-term stability and durability of ferrofluid-based imaging systems remain a concern. Exposure to air, moisture, or other contaminants can degrade the ferrofluid over time, altering its magnetic and optical properties. Developing effective sealing and containment solutions that do not interfere with the fluid's functionality is a critical challenge that must be addressed for practical, long-lasting applications in digital imaging.

Current Ferrofluid Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, zero-leakage seals that can operate under high pressure differentials and in vacuum environments. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining liquid properties.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, speakers, and transformers. When subjected to a magnetic field, the fluid's thermal conductivity can be controlled, allowing for adaptive thermal management in various applications.

- Damping and vibration control: The unique properties of ferrofluids make them excellent for damping and vibration control applications. They can be used in shock absorbers, inertial dampers, and acoustic devices. The fluid's viscosity can be controlled by applying magnetic fields, allowing for adaptive damping in response to varying conditions.

- Sensing and measurement applications: Ferrofluids are employed in various sensing and measurement devices. They are used in accelerometers, inclinometers, and pressure sensors. The fluid's response to magnetic fields and its ability to change shape or position under these fields make it suitable for precise measurements in different environments.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.Expand Specific Solutions03 Magnetic field-responsive devices

Ferrofluids are utilized in various devices that respond to magnetic fields. These include sensors, actuators, and dampers. The unique properties of ferrofluids allow for precise control and manipulation of fluid behavior using external magnetic fields, enabling novel applications in areas such as vibration control and energy harvesting.Expand Specific Solutions04 Heat transfer and cooling applications

Ferrofluids have thermal management applications, particularly in electronic cooling. Their ability to be directed and controlled by magnetic fields allows for targeted cooling of specific components. This property is exploited in the design of heat sinks and thermal management systems for high-performance electronics.Expand Specific Solutions05 Measurement and analysis techniques

Various techniques have been developed for measuring and analyzing the properties of ferrofluids. These include methods for determining particle size distribution, magnetic susceptibility, and rheological properties. Advanced imaging and spectroscopic techniques are also employed to study the behavior of ferrofluids under different conditions.Expand Specific Solutions

Key Ferrofluid Innovators

The ferrofluid-based digital imaging technology market is in its early growth stage, characterized by rapid innovation and expanding applications. The market size is projected to increase significantly due to growing demand in medical imaging, data storage, and display technologies. While the technology is still evolving, several key players are driving advancements. Companies like Koninklijke Philips NV and Siemens Healthineers AG are leveraging ferrofluids in medical imaging, while Western Digital Corp. explores applications in data storage. Research institutions such as Yale University and the University of Minnesota are contributing to fundamental breakthroughs. The technology's maturity varies across applications, with some areas nearing commercialization while others remain in experimental stages.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced ferrofluid-based imaging techniques for medical applications. Their approach utilizes ferrofluids as contrast agents in magnetic resonance imaging (MRI), enhancing image quality and diagnostic accuracy. The company has implemented a novel method of synthesizing biocompatible ferrofluids with optimized magnetic properties, allowing for improved visualization of soft tissues and blood vessels[1]. Additionally, Philips has integrated ferrofluid technology into their latest generation of MRI scanners, enabling real-time tracking of ferrofluid distribution in the body, which has significant implications for cancer diagnosis and treatment monitoring[2].

Strengths: Improved image contrast and resolution in MRI; Enhanced diagnostic capabilities for various medical conditions. Weaknesses: Potential biocompatibility concerns; Limited application outside of medical imaging.

Siemens Healthineers AG

Technical Solution: Siemens Healthineers has pioneered the use of ferrofluids in their advanced imaging systems, particularly in magnetic particle imaging (MPI). Their proprietary ferrofluid formulation consists of superparamagnetic iron oxide nanoparticles (SPIONs) with carefully controlled size distribution and surface functionalization[3]. This allows for high-resolution, real-time 3D imaging of physiological processes. The company has also developed a dual-modality approach combining MPI with MRI, leveraging ferrofluids as both contrast agents and tracers. This innovation has led to significant improvements in cardiovascular and cancer imaging, with spatial resolution reaching sub-millimeter levels and temporal resolution in the millisecond range[4].

Strengths: High-resolution, real-time 3D imaging capabilities; Dual-modality approach enhancing diagnostic accuracy. Weaknesses: High cost of implementation; Requires specialized equipment and expertise.

Ferrofluid Imaging Patents

Instruments coated with iron oxide nanoparticles for invasive medicine

PatentActiveEP2240546A2

Innovation

- Instruments for invasive medicine are coated with ferrofluids containing iron oxide nanoparticles, which are suspended in a carrier liquid and applied as a stable dispersion, providing high-quality visualization in MRI without releasing harmful components.

Optical limiting ferromagnetic nanoparticles and device thereof

PatentInactiveIN1981CHE2007A

Innovation

- Synthesizing ferromagnetic nanoparticles of specific sizes (4-6 nm) using an optimized co-precipitation technique and incorporating them into a ferrofluid, which is then encapsulated between glass plates without air gaps for enhanced thermal stability and optical limiting performance.

Nanoparticle Safety Concerns

The use of ferrofluids in digital imaging methods introduces potential safety concerns related to nanoparticles. Ferrofluids contain magnetic nanoparticles, typically iron oxide, suspended in a carrier fluid. While these nanoparticles enable unique imaging capabilities, their small size and potential for interaction with biological systems raise important safety considerations.

One primary concern is the potential for nanoparticle exposure during the manufacturing, handling, and disposal of ferrofluid-based imaging devices. Inhalation of nanoparticles can lead to respiratory issues, as these particles may penetrate deep into the lungs. Skin contact is another potential route of exposure, which could result in dermal absorption or irritation.

The long-term effects of nanoparticle exposure are not fully understood, necessitating careful risk assessment and management. Studies have shown that some nanoparticles can cross biological barriers, including the blood-brain barrier, raising concerns about potential neurological impacts. Additionally, the accumulation of nanoparticles in organs and tissues over time could lead to unforeseen health consequences.

Environmental safety is another critical aspect to consider. The release of nanoparticles into the environment, either through improper disposal or accidental spills, could have ecological implications. These particles may persist in the environment, potentially affecting aquatic and terrestrial ecosystems.

To address these safety concerns, stringent protocols for handling and containment of ferrofluids in imaging applications must be developed and implemented. This includes proper personal protective equipment for workers, controlled manufacturing environments, and secure disposal methods to prevent environmental contamination.

Research into the biocompatibility and toxicity of ferrofluid nanoparticles is ongoing. Some studies suggest that surface modifications of nanoparticles can reduce their potential toxicity and improve their safety profile. However, more comprehensive long-term studies are needed to fully understand the health and environmental impacts of these materials.

Regulatory bodies are increasingly focusing on nanoparticle safety, with guidelines and standards being developed to ensure the safe use of nanomaterials in various applications, including medical imaging. Compliance with these regulations will be crucial for the widespread adoption of ferrofluid-based imaging technologies.

One primary concern is the potential for nanoparticle exposure during the manufacturing, handling, and disposal of ferrofluid-based imaging devices. Inhalation of nanoparticles can lead to respiratory issues, as these particles may penetrate deep into the lungs. Skin contact is another potential route of exposure, which could result in dermal absorption or irritation.

The long-term effects of nanoparticle exposure are not fully understood, necessitating careful risk assessment and management. Studies have shown that some nanoparticles can cross biological barriers, including the blood-brain barrier, raising concerns about potential neurological impacts. Additionally, the accumulation of nanoparticles in organs and tissues over time could lead to unforeseen health consequences.

Environmental safety is another critical aspect to consider. The release of nanoparticles into the environment, either through improper disposal or accidental spills, could have ecological implications. These particles may persist in the environment, potentially affecting aquatic and terrestrial ecosystems.

To address these safety concerns, stringent protocols for handling and containment of ferrofluids in imaging applications must be developed and implemented. This includes proper personal protective equipment for workers, controlled manufacturing environments, and secure disposal methods to prevent environmental contamination.

Research into the biocompatibility and toxicity of ferrofluid nanoparticles is ongoing. Some studies suggest that surface modifications of nanoparticles can reduce their potential toxicity and improve their safety profile. However, more comprehensive long-term studies are needed to fully understand the health and environmental impacts of these materials.

Regulatory bodies are increasingly focusing on nanoparticle safety, with guidelines and standards being developed to ensure the safe use of nanomaterials in various applications, including medical imaging. Compliance with these regulations will be crucial for the widespread adoption of ferrofluid-based imaging technologies.

Ferrofluid Imaging Standards

The development of ferrofluid imaging standards is crucial for ensuring consistency, reliability, and reproducibility in the emerging field of ferrofluid-based digital imaging methods. These standards aim to establish guidelines for the preparation, characterization, and application of ferrofluids in imaging systems, as well as define protocols for image acquisition, processing, and analysis.

One key aspect of ferrofluid imaging standards is the standardization of ferrofluid composition and properties. This includes specifications for particle size distribution, magnetic susceptibility, and viscosity, which directly impact the imaging performance. By defining acceptable ranges for these parameters, researchers and manufacturers can ensure that ferrofluids used in imaging applications meet consistent quality criteria.

Another important component of these standards is the establishment of calibration procedures for ferrofluid-based imaging systems. This involves developing reference materials and methods to assess the accuracy and precision of measurements obtained through ferrofluid imaging techniques. Such calibration standards enable comparisons between different imaging systems and facilitate the validation of experimental results across laboratories.

Ferrofluid imaging standards also address the need for standardized image acquisition protocols. This includes guidelines for sample preparation, magnetic field application, and imaging conditions. By defining these parameters, the standards help minimize variability in image quality and ensure that results obtained from different imaging setups can be meaningfully compared.

Data processing and analysis techniques form another critical aspect of ferrofluid imaging standards. These standards outline recommended algorithms and software tools for image enhancement, feature extraction, and quantitative analysis of ferrofluid-based images. By promoting the use of standardized data processing methods, the field can achieve greater consistency in interpreting and reporting imaging results.

Safety considerations are also an integral part of ferrofluid imaging standards. These guidelines address the proper handling, storage, and disposal of ferrofluids, as well as safety measures for operating imaging equipment in the presence of magnetic fields. By incorporating safety standards, the field can ensure responsible and sustainable development of ferrofluid imaging technologies.

The development of ferrofluid imaging standards is an ongoing process that requires collaboration between researchers, industry experts, and regulatory bodies. As the field continues to evolve, these standards will need to be regularly updated to incorporate new technological advancements and address emerging challenges in ferrofluid-based digital imaging methods.

One key aspect of ferrofluid imaging standards is the standardization of ferrofluid composition and properties. This includes specifications for particle size distribution, magnetic susceptibility, and viscosity, which directly impact the imaging performance. By defining acceptable ranges for these parameters, researchers and manufacturers can ensure that ferrofluids used in imaging applications meet consistent quality criteria.

Another important component of these standards is the establishment of calibration procedures for ferrofluid-based imaging systems. This involves developing reference materials and methods to assess the accuracy and precision of measurements obtained through ferrofluid imaging techniques. Such calibration standards enable comparisons between different imaging systems and facilitate the validation of experimental results across laboratories.

Ferrofluid imaging standards also address the need for standardized image acquisition protocols. This includes guidelines for sample preparation, magnetic field application, and imaging conditions. By defining these parameters, the standards help minimize variability in image quality and ensure that results obtained from different imaging setups can be meaningfully compared.

Data processing and analysis techniques form another critical aspect of ferrofluid imaging standards. These standards outline recommended algorithms and software tools for image enhancement, feature extraction, and quantitative analysis of ferrofluid-based images. By promoting the use of standardized data processing methods, the field can achieve greater consistency in interpreting and reporting imaging results.

Safety considerations are also an integral part of ferrofluid imaging standards. These guidelines address the proper handling, storage, and disposal of ferrofluids, as well as safety measures for operating imaging equipment in the presence of magnetic fields. By incorporating safety standards, the field can ensure responsible and sustainable development of ferrofluid imaging technologies.

The development of ferrofluid imaging standards is an ongoing process that requires collaboration between researchers, industry experts, and regulatory bodies. As the field continues to evolve, these standards will need to be regularly updated to incorporate new technological advancements and address emerging challenges in ferrofluid-based digital imaging methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!