Ferrofluid's Impact on Revolutionizing Industrial Water Treatment

JUL 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have undergone significant evolution since their inception in the 1960s. Initially developed for NASA space applications, these colloidal suspensions of magnetic nanoparticles have found their way into various industrial sectors, including water treatment. The technological progression of ferrofluids has been marked by advancements in synthesis methods, particle stabilization, and functionalization techniques.

The early stages of ferrofluid development focused on improving stability and magnetic responsiveness. Researchers worked on optimizing particle size distribution and surfactant coatings to prevent agglomeration and maintain fluid properties. As the technology matured, attention shifted towards enhancing the specificity and efficiency of ferrofluids for targeted applications, particularly in environmental remediation and water treatment.

In the context of industrial water treatment, ferrofluid technology has evolved to address critical challenges such as the removal of heavy metals, organic pollutants, and microorganisms from wastewater streams. The objectives of ferrofluid application in this field have expanded to include not only contaminant removal but also resource recovery and process intensification.

Recent technological advancements have focused on developing smart ferrofluids with multi-functional capabilities. These advanced materials combine magnetic properties with other functionalities such as catalytic activity, selective adsorption, and stimuli-responsiveness. The goal is to create versatile systems that can simultaneously remove multiple types of pollutants while allowing for easy separation and regeneration.

The evolution of ferrofluid technology in water treatment is also closely tied to the development of novel reactor designs and process configurations. Magnetic separation systems, magnetically assisted flocculation, and ferrofluid-enhanced membrane processes are among the innovative approaches being explored to leverage the unique properties of these materials.

Looking forward, the objectives of ferrofluid technology in revolutionizing industrial water treatment are multifaceted. Key aims include improving treatment efficiency, reducing energy consumption, minimizing chemical usage, and enabling the recovery of valuable resources from wastewater. There is also a growing emphasis on developing sustainable and environmentally friendly ferrofluid formulations to align with circular economy principles.

As research continues, the integration of ferrofluid technology with other advanced water treatment methods, such as advanced oxidation processes and electrochemical systems, is expected to unlock new possibilities for tackling complex water pollution challenges. The ultimate goal is to establish ferrofluids as a cornerstone technology in next-generation water treatment systems, capable of addressing the diverse and evolving needs of industrial water management.

The early stages of ferrofluid development focused on improving stability and magnetic responsiveness. Researchers worked on optimizing particle size distribution and surfactant coatings to prevent agglomeration and maintain fluid properties. As the technology matured, attention shifted towards enhancing the specificity and efficiency of ferrofluids for targeted applications, particularly in environmental remediation and water treatment.

In the context of industrial water treatment, ferrofluid technology has evolved to address critical challenges such as the removal of heavy metals, organic pollutants, and microorganisms from wastewater streams. The objectives of ferrofluid application in this field have expanded to include not only contaminant removal but also resource recovery and process intensification.

Recent technological advancements have focused on developing smart ferrofluids with multi-functional capabilities. These advanced materials combine magnetic properties with other functionalities such as catalytic activity, selective adsorption, and stimuli-responsiveness. The goal is to create versatile systems that can simultaneously remove multiple types of pollutants while allowing for easy separation and regeneration.

The evolution of ferrofluid technology in water treatment is also closely tied to the development of novel reactor designs and process configurations. Magnetic separation systems, magnetically assisted flocculation, and ferrofluid-enhanced membrane processes are among the innovative approaches being explored to leverage the unique properties of these materials.

Looking forward, the objectives of ferrofluid technology in revolutionizing industrial water treatment are multifaceted. Key aims include improving treatment efficiency, reducing energy consumption, minimizing chemical usage, and enabling the recovery of valuable resources from wastewater. There is also a growing emphasis on developing sustainable and environmentally friendly ferrofluid formulations to align with circular economy principles.

As research continues, the integration of ferrofluid technology with other advanced water treatment methods, such as advanced oxidation processes and electrochemical systems, is expected to unlock new possibilities for tackling complex water pollution challenges. The ultimate goal is to establish ferrofluids as a cornerstone technology in next-generation water treatment systems, capable of addressing the diverse and evolving needs of industrial water management.

Industrial Water Treatment Market Analysis

The industrial water treatment market has been experiencing significant growth in recent years, driven by increasing water scarcity, stringent environmental regulations, and the need for sustainable water management practices across various industries. This market encompasses a wide range of technologies and solutions designed to purify, recycle, and reuse water in industrial processes, making it a critical sector for both environmental sustainability and economic efficiency.

The global industrial water treatment market was valued at approximately $15 billion in 2020 and is projected to reach $26 billion by 2026, growing at a compound annual growth rate (CAGR) of around 7% during the forecast period. This growth is primarily attributed to the rising demand for clean water in industrial applications, particularly in sectors such as power generation, oil and gas, chemical manufacturing, and food and beverage processing.

Key drivers of market growth include the increasing adoption of zero liquid discharge (ZLD) systems, which aim to eliminate wastewater discharge and maximize water reuse. Additionally, the implementation of advanced treatment technologies such as membrane filtration, UV disinfection, and electrodeionization is contributing to market expansion. These technologies offer improved efficiency, reduced operational costs, and enhanced water quality, making them attractive options for industrial users.

Geographically, Asia-Pacific is expected to witness the highest growth rate in the industrial water treatment market, driven by rapid industrialization, urbanization, and stringent water quality regulations in countries like China and India. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and implementing advanced treatment solutions.

The market is characterized by intense competition among key players, including Suez, Veolia, Ecolab, and Evoqua Water Technologies. These companies are investing heavily in research and development to introduce innovative solutions and gain a competitive edge. Mergers, acquisitions, and strategic partnerships are also common strategies employed by market players to expand their product portfolios and geographical presence.

Emerging trends in the industrial water treatment market include the integration of digital technologies such as artificial intelligence, Internet of Things (IoT), and data analytics for real-time monitoring and optimization of water treatment processes. These smart water management solutions are expected to drive efficiency and cost-effectiveness in industrial water treatment operations.

The introduction of ferrofluid technology in industrial water treatment represents a potentially disruptive innovation in this market. Ferrofluids, which are colloidal liquids containing magnetic nanoparticles, offer unique properties that could revolutionize water purification processes. Their ability to be manipulated by magnetic fields presents opportunities for enhanced separation of contaminants, improved filtration efficiency, and novel approaches to water treatment that could address current limitations in conventional technologies.

The global industrial water treatment market was valued at approximately $15 billion in 2020 and is projected to reach $26 billion by 2026, growing at a compound annual growth rate (CAGR) of around 7% during the forecast period. This growth is primarily attributed to the rising demand for clean water in industrial applications, particularly in sectors such as power generation, oil and gas, chemical manufacturing, and food and beverage processing.

Key drivers of market growth include the increasing adoption of zero liquid discharge (ZLD) systems, which aim to eliminate wastewater discharge and maximize water reuse. Additionally, the implementation of advanced treatment technologies such as membrane filtration, UV disinfection, and electrodeionization is contributing to market expansion. These technologies offer improved efficiency, reduced operational costs, and enhanced water quality, making them attractive options for industrial users.

Geographically, Asia-Pacific is expected to witness the highest growth rate in the industrial water treatment market, driven by rapid industrialization, urbanization, and stringent water quality regulations in countries like China and India. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and implementing advanced treatment solutions.

The market is characterized by intense competition among key players, including Suez, Veolia, Ecolab, and Evoqua Water Technologies. These companies are investing heavily in research and development to introduce innovative solutions and gain a competitive edge. Mergers, acquisitions, and strategic partnerships are also common strategies employed by market players to expand their product portfolios and geographical presence.

Emerging trends in the industrial water treatment market include the integration of digital technologies such as artificial intelligence, Internet of Things (IoT), and data analytics for real-time monitoring and optimization of water treatment processes. These smart water management solutions are expected to drive efficiency and cost-effectiveness in industrial water treatment operations.

The introduction of ferrofluid technology in industrial water treatment represents a potentially disruptive innovation in this market. Ferrofluids, which are colloidal liquids containing magnetic nanoparticles, offer unique properties that could revolutionize water purification processes. Their ability to be manipulated by magnetic fields presents opportunities for enhanced separation of contaminants, improved filtration efficiency, and novel approaches to water treatment that could address current limitations in conventional technologies.

Ferrofluid Challenges in Water Treatment

The integration of ferrofluids into industrial water treatment processes presents several significant challenges that must be addressed for successful implementation. One of the primary obstacles is the stability of ferrofluids in complex aqueous environments. Industrial wastewater often contains a diverse array of contaminants, including dissolved salts, organic compounds, and suspended solids, which can potentially destabilize the ferrofluid emulsion. Maintaining the colloidal stability of ferrofluids under these varied conditions is crucial for their effective operation in water treatment applications.

Another major challenge lies in the separation and recovery of ferrofluids after the treatment process. While the magnetic properties of ferrofluids offer a potential advantage for their removal, achieving complete separation from treated water can be difficult, especially when dealing with large volumes of water in industrial settings. Residual ferrofluid particles in the treated water could lead to secondary contamination, necessitating the development of efficient and scalable separation techniques.

The long-term environmental impact of ferrofluids in water treatment systems is also a concern that requires thorough investigation. The potential release of nanoparticles into the environment, even in small quantities, raises questions about their fate and potential effects on aquatic ecosystems. Ensuring the biodegradability or safe disposal of spent ferrofluids is essential for the sustainable implementation of this technology.

Cost-effectiveness presents another hurdle in the widespread adoption of ferrofluid-based water treatment solutions. The production of high-quality ferrofluids with specific properties tailored for water treatment applications can be expensive. Balancing the enhanced treatment efficiency against the increased operational costs is crucial for making this technology economically viable for industrial-scale implementation.

Furthermore, the optimization of ferrofluid properties for specific water treatment applications poses a significant challenge. Different industrial processes generate wastewater with varying characteristics, requiring ferrofluids to be customized for optimal performance. This includes tailoring the magnetic susceptibility, surface chemistry, and particle size distribution to achieve the desired treatment outcomes while maintaining stability and ease of separation.

Lastly, the integration of ferrofluid technology into existing water treatment infrastructure presents both technical and operational challenges. Retrofitting current systems to accommodate ferrofluid-based processes may require significant modifications to equipment and operational procedures. Developing standardized protocols for the handling, storage, and application of ferrofluids in industrial settings is essential for ensuring safety and efficiency in their use.

Another major challenge lies in the separation and recovery of ferrofluids after the treatment process. While the magnetic properties of ferrofluids offer a potential advantage for their removal, achieving complete separation from treated water can be difficult, especially when dealing with large volumes of water in industrial settings. Residual ferrofluid particles in the treated water could lead to secondary contamination, necessitating the development of efficient and scalable separation techniques.

The long-term environmental impact of ferrofluids in water treatment systems is also a concern that requires thorough investigation. The potential release of nanoparticles into the environment, even in small quantities, raises questions about their fate and potential effects on aquatic ecosystems. Ensuring the biodegradability or safe disposal of spent ferrofluids is essential for the sustainable implementation of this technology.

Cost-effectiveness presents another hurdle in the widespread adoption of ferrofluid-based water treatment solutions. The production of high-quality ferrofluids with specific properties tailored for water treatment applications can be expensive. Balancing the enhanced treatment efficiency against the increased operational costs is crucial for making this technology economically viable for industrial-scale implementation.

Furthermore, the optimization of ferrofluid properties for specific water treatment applications poses a significant challenge. Different industrial processes generate wastewater with varying characteristics, requiring ferrofluids to be customized for optimal performance. This includes tailoring the magnetic susceptibility, surface chemistry, and particle size distribution to achieve the desired treatment outcomes while maintaining stability and ease of separation.

Lastly, the integration of ferrofluid technology into existing water treatment infrastructure presents both technical and operational challenges. Retrofitting current systems to accommodate ferrofluid-based processes may require significant modifications to equipment and operational procedures. Developing standardized protocols for the handling, storage, and application of ferrofluids in industrial settings is essential for ensuring safety and efficiency in their use.

Current Ferrofluid Water Treatment Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They typically consist of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size, surfactant selection, and carrier fluid properties to achieve stable and responsive ferrofluids.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They typically consist of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size, surfactant selection, and carrier fluid properties to achieve stable and responsive ferrofluids.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear in mechanical systems.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The ability to manipulate ferrofluids with magnetic fields allows for targeted cooling and improved thermal management in various applications.

- Magnetic field sensing and measurement: Ferrofluids are employed in various sensing and measurement devices that rely on magnetic field detection. These applications include accelerometers, inclinometers, and magnetic field sensors. The response of ferrofluids to magnetic fields allows for precise measurements and detection of changes in orientation or field strength.

- Biomedical and therapeutic applications: Ferrofluids have emerging applications in biomedicine and therapeutics. They are being investigated for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids with external magnetic fields offers potential for localized treatments and improved diagnostic imaging.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear in mechanical systems.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The ability to manipulate ferrofluids with magnetic fields allows for targeted cooling and improved thermal management in various applications.Expand Specific Solutions04 Sensing and measurement applications

The magnetic properties of ferrofluids make them useful in various sensing and measurement applications. They are employed in accelerometers, inclinometers, and other devices that rely on fluid movement in response to external forces or magnetic fields. Ferrofluids can provide high sensitivity and rapid response in these applications.Expand Specific Solutions05 Biomedical and therapeutic uses

Ferrofluids have potential applications in biomedicine and therapeutics. They can be used as contrast agents in magnetic resonance imaging (MRI), for targeted drug delivery, and in hyperthermia treatments for cancer. The ability to control ferrofluids with external magnetic fields allows for precise manipulation within the body.Expand Specific Solutions

Key Players in Ferrofluid Water Treatment

The ferrofluid technology for industrial water treatment is in an early development stage, with significant potential for growth. The market size is expanding as industries seek more efficient and sustainable water treatment solutions. While the technology shows promise, it is still evolving towards full commercial maturity. Key players like Kurita Water Industries, ChemTreat, and Eastman Chemical are investing in research and development to advance ferrofluid applications. Universities such as Delft University of Technology and King Fahd University of Petroleum & Minerals are contributing to the fundamental understanding of ferrofluid behavior in water treatment processes. As the technology progresses, collaboration between academic institutions and industry leaders will be crucial for overcoming technical challenges and scaling up ferrofluid-based water treatment systems.

Kurita Water Industries Ltd.

Technical Solution: Kurita Water Industries Ltd. has developed an innovative ferrofluid-based water treatment system that leverages the unique properties of magnetic nanoparticles. Their technology utilizes ferrofluids to create a highly efficient separation process for removing contaminants from industrial wastewater. The system employs a combination of magnetic fields and specially designed ferrofluid formulations to attract and capture pollutants, including heavy metals, organic compounds, and suspended solids. This approach allows for rapid and effective treatment of large volumes of water, with the ability to remove particles as small as 10 nanometers [1]. The company has also integrated smart sensors and AI-driven control systems to optimize the treatment process in real-time, adjusting magnetic field strength and ferrofluid concentration based on water quality parameters [3].

Strengths: High efficiency in removing a wide range of contaminants, including nano-scale particles; Adaptable to various industrial applications; Reduced chemical usage compared to traditional methods. Weaknesses: Initial setup costs may be higher than conventional systems; Requires careful handling and disposal of used ferrofluids.

ChemTreat, Inc.

Technical Solution: ChemTreat, Inc. has pioneered a ferrofluid-enhanced membrane filtration system for industrial water treatment. Their approach combines the principles of membrane technology with the unique properties of ferrofluids to create a highly effective and fouling-resistant filtration process. The company's proprietary ferrofluid formulation is designed to form a thin, dynamic layer on the membrane surface, which enhances selectivity and flux while preventing membrane fouling. This innovative system utilizes controlled magnetic fields to manipulate the ferrofluid layer, allowing for in-situ membrane cleaning and regeneration without the need for harsh chemicals or frequent replacements [2]. ChemTreat's technology has demonstrated a 30% increase in water recovery rates and a 40% reduction in energy consumption compared to conventional membrane systems [5].

Strengths: Significantly reduced membrane fouling and extended membrane life; Lower operational costs due to reduced energy consumption and chemical usage. Weaknesses: May require specialized training for operators; Limited to applications where magnetic fields can be safely applied.

Innovative Ferrofluid Patents for Water Purification

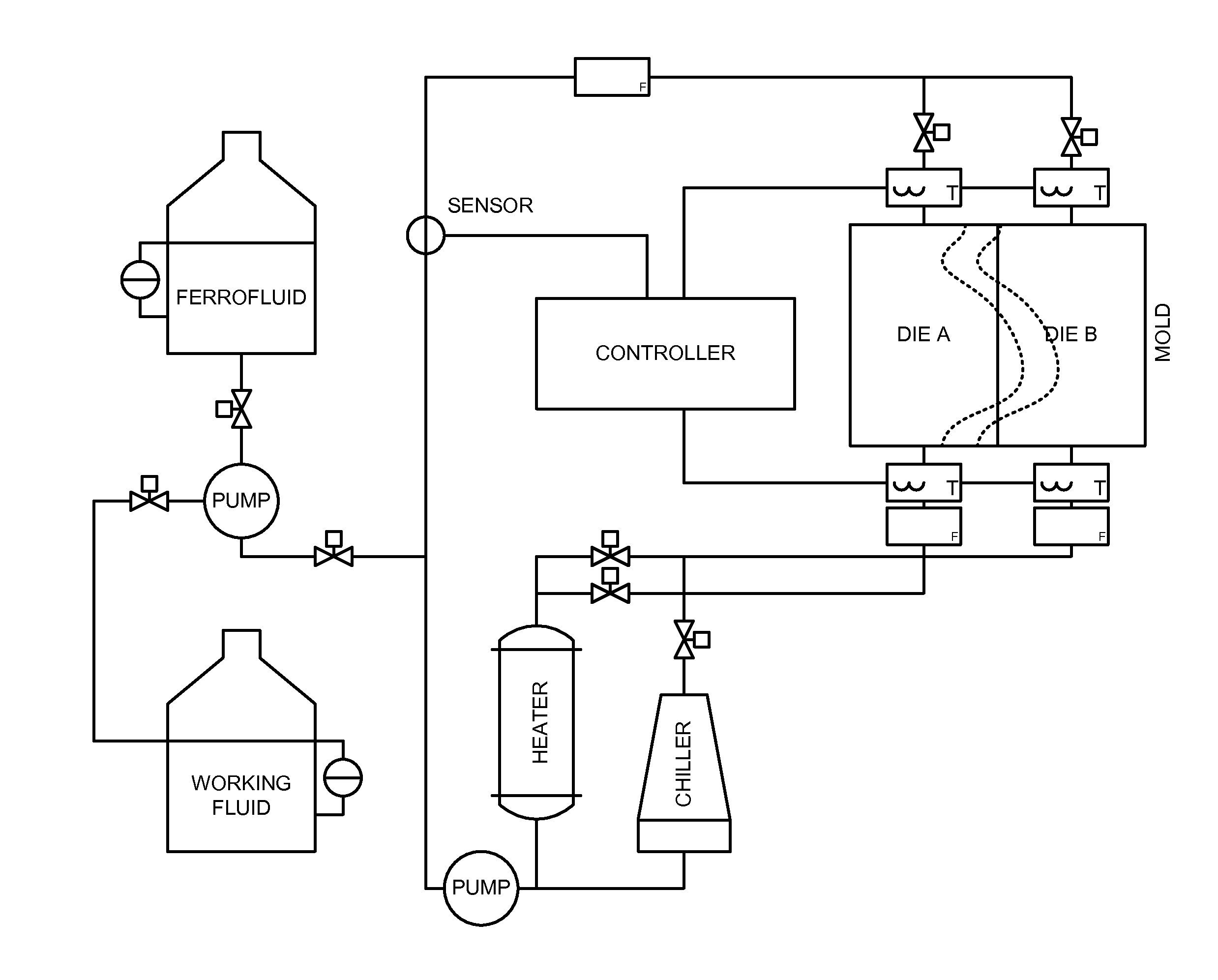

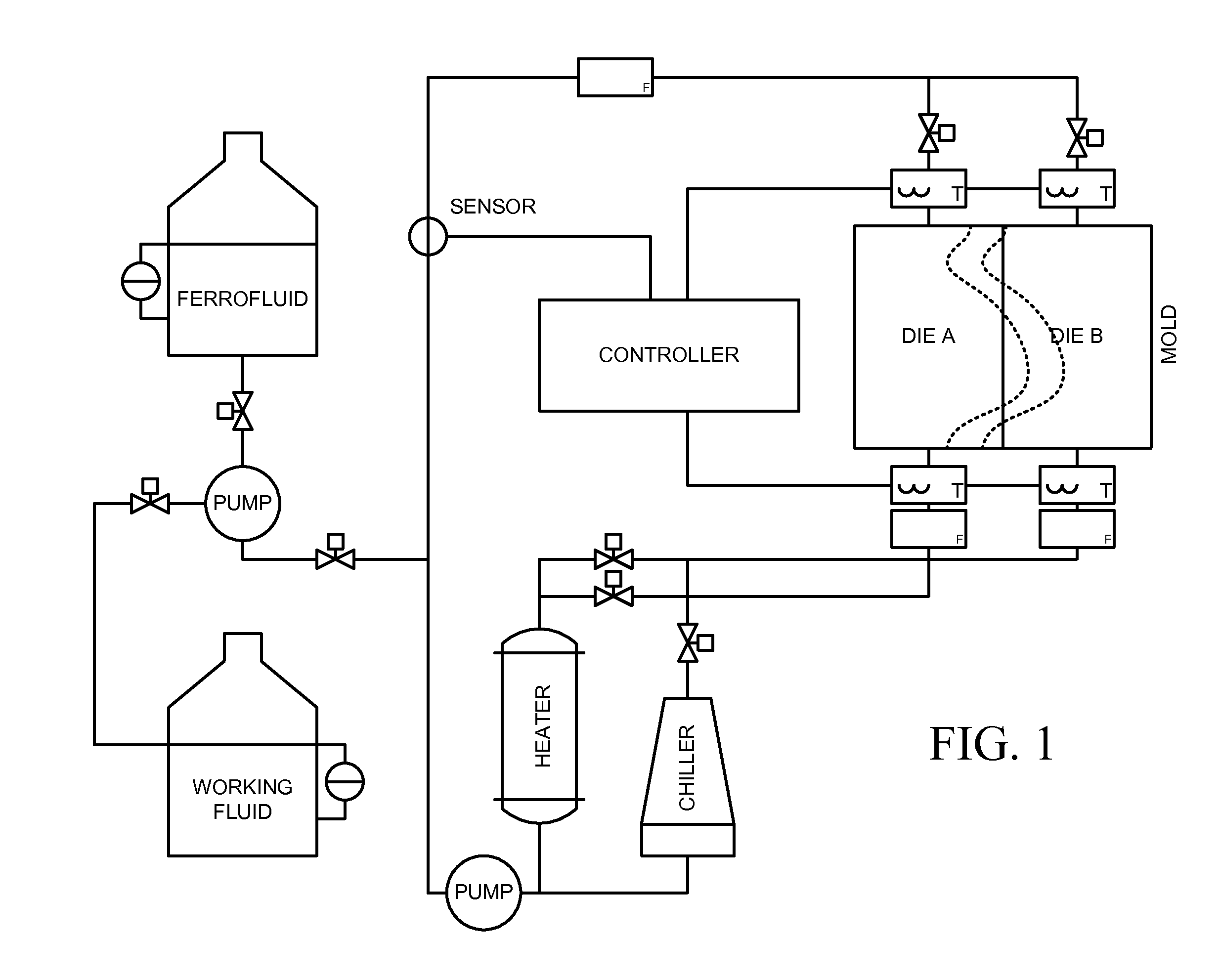

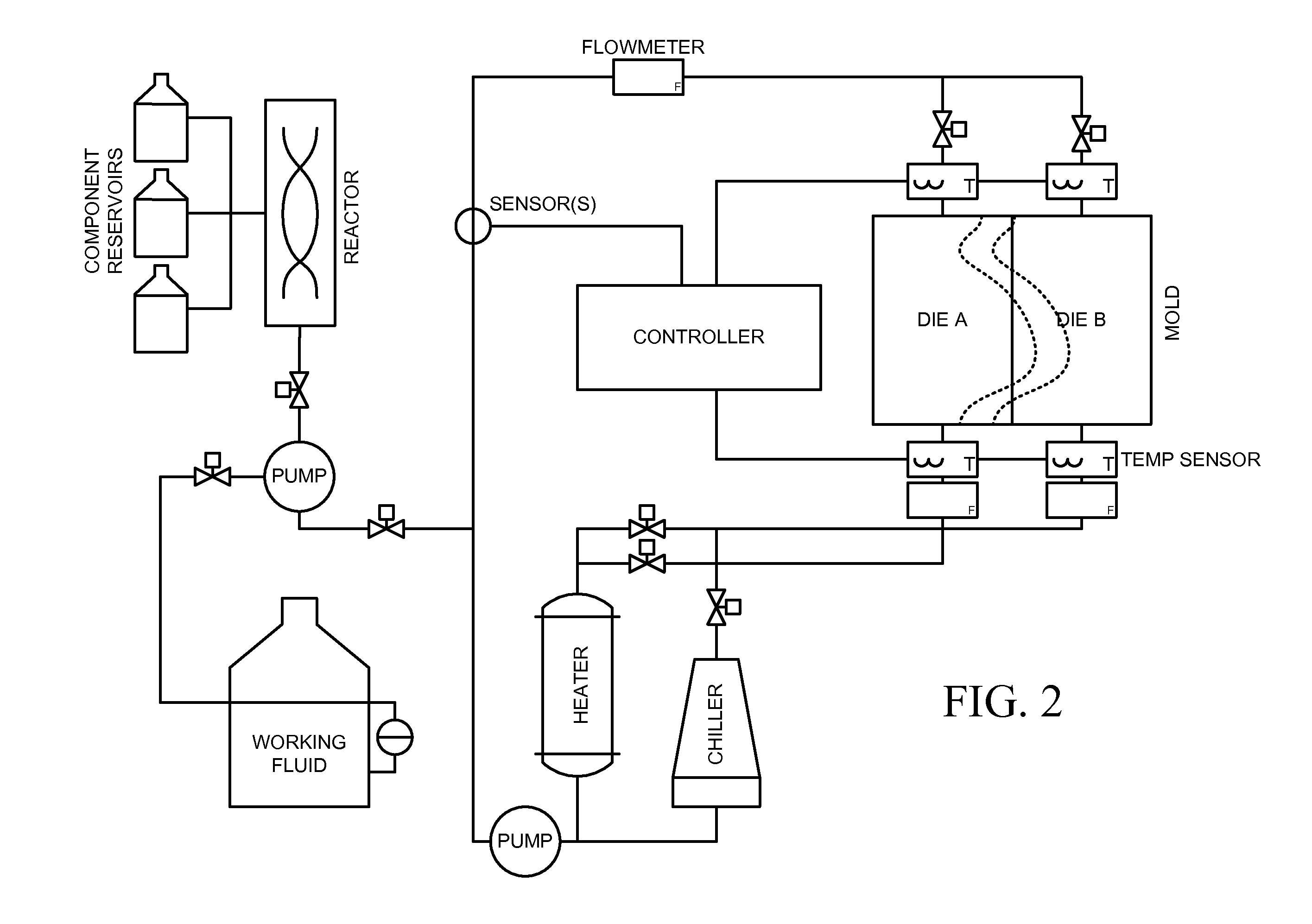

Method and apparatus for improving heat transfer in industrial water systems with ferrofluids

PatentActiveUS20120199320A1

Innovation

- A method involving the preparation of a consistent ferrofluid with particles less than 5 nm in diameter, which can be economically added to heat transfer fluids and monitored/controlled using direct measurement techniques to achieve enhanced heat transfer efficiency, utilizing an in-line reactor for cost-effective manufacturing and compatibility with existing water treatment additives.

A novel method for wastewater treatment

PatentActiveIN202121037343A

Innovation

- A process involving the in-situ generation of hypochlorous acid by purging chlorine gas into a reactor with a FeSO4 solution, which reacts with iron (II) in an aqueous solution to form highly reactive hydroxyl radicals, effectively reducing COD and ammoniacal nitrogen content in effluents, eliminating the need for hazardous hydrogen peroxide and costly sodium hypochlorite.

Environmental Impact of Ferrofluid Technology

The environmental impact of ferrofluid technology in industrial water treatment is a critical consideration as this innovative approach gains traction. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can significantly enhance water treatment processes while potentially reducing environmental footprints.

One of the primary environmental benefits of ferrofluid-based water treatment is the potential reduction in chemical usage. Traditional water treatment methods often rely heavily on chemical additives for coagulation, flocculation, and disinfection. Ferrofluids can potentially replace or reduce the need for some of these chemicals by leveraging their magnetic properties to aggregate and remove contaminants. This reduction in chemical usage not only minimizes the introduction of synthetic compounds into water systems but also decreases the environmental impact associated with the production and transportation of these chemicals.

Furthermore, ferrofluid technology may contribute to energy savings in water treatment facilities. The magnetic properties of ferrofluids can be harnessed to create more efficient separation processes, potentially reducing the energy required for filtration and pumping. This energy reduction translates to lower greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change.

The application of ferrofluids in water treatment also holds promise for improving the removal of emerging contaminants, such as pharmaceuticals and microplastics. These pollutants pose significant challenges to conventional treatment methods and can have far-reaching ecological consequences. Ferrofluids' unique interaction with these contaminants may lead to more effective removal, thereby reducing the release of harmful substances into aquatic ecosystems.

However, the environmental impact of ferrofluid technology is not without potential concerns. The production and disposal of ferrofluids must be carefully managed to prevent the release of nanoparticles into the environment. While research suggests that properly engineered ferrofluids can be safely contained and recycled, long-term studies on their ecological effects are still ongoing. Ensuring the complete removal of ferrofluid particles from treated water is crucial to prevent any unintended consequences on aquatic life or human health.

Additionally, the lifecycle assessment of ferrofluid production and application in water treatment must be considered. While the technology may offer environmental benefits in its use phase, the environmental costs of manufacturing and eventual disposal of ferrofluids need to be carefully evaluated to ensure a net positive impact.

As ferrofluid technology continues to evolve, ongoing research and development efforts are focused on optimizing its environmental performance. This includes improving the recyclability of ferrofluids, enhancing their stability to prevent particle leaching, and developing more sustainable production methods. The potential for ferrofluids to be integrated into closed-loop water treatment systems presents an exciting opportunity for further reducing the environmental footprint of industrial water management.

One of the primary environmental benefits of ferrofluid-based water treatment is the potential reduction in chemical usage. Traditional water treatment methods often rely heavily on chemical additives for coagulation, flocculation, and disinfection. Ferrofluids can potentially replace or reduce the need for some of these chemicals by leveraging their magnetic properties to aggregate and remove contaminants. This reduction in chemical usage not only minimizes the introduction of synthetic compounds into water systems but also decreases the environmental impact associated with the production and transportation of these chemicals.

Furthermore, ferrofluid technology may contribute to energy savings in water treatment facilities. The magnetic properties of ferrofluids can be harnessed to create more efficient separation processes, potentially reducing the energy required for filtration and pumping. This energy reduction translates to lower greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change.

The application of ferrofluids in water treatment also holds promise for improving the removal of emerging contaminants, such as pharmaceuticals and microplastics. These pollutants pose significant challenges to conventional treatment methods and can have far-reaching ecological consequences. Ferrofluids' unique interaction with these contaminants may lead to more effective removal, thereby reducing the release of harmful substances into aquatic ecosystems.

However, the environmental impact of ferrofluid technology is not without potential concerns. The production and disposal of ferrofluids must be carefully managed to prevent the release of nanoparticles into the environment. While research suggests that properly engineered ferrofluids can be safely contained and recycled, long-term studies on their ecological effects are still ongoing. Ensuring the complete removal of ferrofluid particles from treated water is crucial to prevent any unintended consequences on aquatic life or human health.

Additionally, the lifecycle assessment of ferrofluid production and application in water treatment must be considered. While the technology may offer environmental benefits in its use phase, the environmental costs of manufacturing and eventual disposal of ferrofluids need to be carefully evaluated to ensure a net positive impact.

As ferrofluid technology continues to evolve, ongoing research and development efforts are focused on optimizing its environmental performance. This includes improving the recyclability of ferrofluids, enhancing their stability to prevent particle leaching, and developing more sustainable production methods. The potential for ferrofluids to be integrated into closed-loop water treatment systems presents an exciting opportunity for further reducing the environmental footprint of industrial water management.

Regulatory Framework for Ferrofluid in Water Treatment

The regulatory framework for ferrofluid in water treatment is a complex and evolving landscape that requires careful consideration. As ferrofluid technology gains traction in industrial water treatment applications, regulatory bodies are working to establish guidelines and standards to ensure its safe and effective use.

At the federal level, the Environmental Protection Agency (EPA) plays a crucial role in overseeing water treatment technologies. While specific regulations for ferrofluid use in water treatment are still in development, the EPA's existing frameworks for water quality and treatment processes serve as a foundation. The agency's National Primary Drinking Water Regulations and National Secondary Drinking Water Regulations set standards for contaminant levels and treatment techniques, which ferrofluid-based systems must adhere to.

State-level regulations add another layer of complexity to the regulatory landscape. Many states have their own environmental protection agencies that may impose additional requirements or restrictions on the use of novel water treatment technologies. These state-level regulations often focus on local water quality concerns and may vary significantly across different regions.

The Safe Drinking Water Act (SDWA) provides a federal framework for ensuring the safety of drinking water supplies. As ferrofluid technology is integrated into water treatment processes, it must demonstrate compliance with SDWA standards and regulations. This includes proving its effectiveness in removing contaminants and ensuring that the treatment process itself does not introduce harmful substances into the water supply.

International regulations also play a role, particularly for companies operating in multiple countries. Organizations such as the World Health Organization (WHO) provide guidelines for water quality and treatment that influence regulatory approaches worldwide. As ferrofluid technology gains global attention, harmonization of international standards may become increasingly important.

The regulatory framework must also address the potential environmental impacts of ferrofluid use in water treatment. This includes considerations for the disposal of spent ferrofluids and any byproducts generated during the treatment process. The Resource Conservation and Recovery Act (RCRA) may come into play, governing the management and disposal of hazardous waste materials.

As the technology advances, regulatory bodies are likely to develop more specific guidelines for ferrofluid use in water treatment. This may include requirements for safety testing, performance validation, and long-term monitoring of treated water supplies. Industry stakeholders, including ferrofluid manufacturers and water treatment facility operators, will need to stay informed about evolving regulations and actively participate in shaping future regulatory frameworks.

At the federal level, the Environmental Protection Agency (EPA) plays a crucial role in overseeing water treatment technologies. While specific regulations for ferrofluid use in water treatment are still in development, the EPA's existing frameworks for water quality and treatment processes serve as a foundation. The agency's National Primary Drinking Water Regulations and National Secondary Drinking Water Regulations set standards for contaminant levels and treatment techniques, which ferrofluid-based systems must adhere to.

State-level regulations add another layer of complexity to the regulatory landscape. Many states have their own environmental protection agencies that may impose additional requirements or restrictions on the use of novel water treatment technologies. These state-level regulations often focus on local water quality concerns and may vary significantly across different regions.

The Safe Drinking Water Act (SDWA) provides a federal framework for ensuring the safety of drinking water supplies. As ferrofluid technology is integrated into water treatment processes, it must demonstrate compliance with SDWA standards and regulations. This includes proving its effectiveness in removing contaminants and ensuring that the treatment process itself does not introduce harmful substances into the water supply.

International regulations also play a role, particularly for companies operating in multiple countries. Organizations such as the World Health Organization (WHO) provide guidelines for water quality and treatment that influence regulatory approaches worldwide. As ferrofluid technology gains global attention, harmonization of international standards may become increasingly important.

The regulatory framework must also address the potential environmental impacts of ferrofluid use in water treatment. This includes considerations for the disposal of spent ferrofluids and any byproducts generated during the treatment process. The Resource Conservation and Recovery Act (RCRA) may come into play, governing the management and disposal of hazardous waste materials.

As the technology advances, regulatory bodies are likely to develop more specific guidelines for ferrofluid use in water treatment. This may include requirements for safety testing, performance validation, and long-term monitoring of treated water supplies. Industry stakeholders, including ferrofluid manufacturers and water treatment facility operators, will need to stay informed about evolving regulations and actively participate in shaping future regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!