Key Techniques for Ferrofluid Application in Pharmaceutical Research

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Pharma Tech Evolution

The evolution of ferrofluid technology in pharmaceutical research has been marked by significant milestones and breakthroughs over the past few decades. Initially developed in the 1960s by NASA for rocket fuel applications, ferrofluids have since found their way into various fields, including medicine and pharmaceuticals.

In the 1980s, researchers began exploring the potential of ferrofluids in drug delivery systems. The unique properties of these magnetic nanoparticles, particularly their ability to be manipulated by external magnetic fields, sparked interest in targeted drug delivery applications. Early studies focused on using ferrofluids as contrast agents for magnetic resonance imaging (MRI), laying the groundwork for more advanced pharmaceutical applications.

The 1990s saw a surge in research on ferrofluid-based drug carriers. Scientists developed methods to functionalize magnetic nanoparticles with biocompatible coatings, enabling better drug encapsulation and reduced toxicity. This period also marked the beginning of in vitro and in vivo studies to assess the efficacy and safety of ferrofluid-based drug delivery systems.

The turn of the millennium brought about significant advancements in nanotechnology, which greatly benefited ferrofluid research in pharmaceuticals. Improved synthesis techniques allowed for better control over particle size, shape, and magnetic properties. This led to the development of more sophisticated drug delivery vehicles, capable of responding to multiple stimuli such as pH, temperature, and magnetic fields.

In the 2010s, the focus shifted towards theranostic applications, combining diagnostic and therapeutic capabilities in a single ferrofluid-based platform. Researchers explored the use of ferrofluids for simultaneous imaging and drug delivery, particularly in cancer treatment. This period also saw increased efforts in developing ferrofluid-based biosensors for rapid and sensitive detection of various biomarkers.

Recent years have witnessed a growing interest in using ferrofluids for tissue engineering and regenerative medicine. Studies have shown promising results in using magnetically actuated scaffolds for controlled cell growth and differentiation. Additionally, researchers are exploring the potential of ferrofluids in hyperthermia treatments, leveraging their ability to generate heat under alternating magnetic fields.

The latest trends in ferrofluid pharmaceutical research include the development of smart drug delivery systems that can navigate through complex biological environments, overcome physiological barriers, and release drugs with precise spatiotemporal control. There is also a growing emphasis on personalized medicine, with ferrofluid-based technologies being tailored to individual patient needs and genetic profiles.

In the 1980s, researchers began exploring the potential of ferrofluids in drug delivery systems. The unique properties of these magnetic nanoparticles, particularly their ability to be manipulated by external magnetic fields, sparked interest in targeted drug delivery applications. Early studies focused on using ferrofluids as contrast agents for magnetic resonance imaging (MRI), laying the groundwork for more advanced pharmaceutical applications.

The 1990s saw a surge in research on ferrofluid-based drug carriers. Scientists developed methods to functionalize magnetic nanoparticles with biocompatible coatings, enabling better drug encapsulation and reduced toxicity. This period also marked the beginning of in vitro and in vivo studies to assess the efficacy and safety of ferrofluid-based drug delivery systems.

The turn of the millennium brought about significant advancements in nanotechnology, which greatly benefited ferrofluid research in pharmaceuticals. Improved synthesis techniques allowed for better control over particle size, shape, and magnetic properties. This led to the development of more sophisticated drug delivery vehicles, capable of responding to multiple stimuli such as pH, temperature, and magnetic fields.

In the 2010s, the focus shifted towards theranostic applications, combining diagnostic and therapeutic capabilities in a single ferrofluid-based platform. Researchers explored the use of ferrofluids for simultaneous imaging and drug delivery, particularly in cancer treatment. This period also saw increased efforts in developing ferrofluid-based biosensors for rapid and sensitive detection of various biomarkers.

Recent years have witnessed a growing interest in using ferrofluids for tissue engineering and regenerative medicine. Studies have shown promising results in using magnetically actuated scaffolds for controlled cell growth and differentiation. Additionally, researchers are exploring the potential of ferrofluids in hyperthermia treatments, leveraging their ability to generate heat under alternating magnetic fields.

The latest trends in ferrofluid pharmaceutical research include the development of smart drug delivery systems that can navigate through complex biological environments, overcome physiological barriers, and release drugs with precise spatiotemporal control. There is also a growing emphasis on personalized medicine, with ferrofluid-based technologies being tailored to individual patient needs and genetic profiles.

Market Demand Analysis

The market demand for ferrofluid applications in pharmaceutical research has been steadily growing in recent years, driven by the increasing need for innovative drug delivery systems and advanced diagnostic tools. Ferrofluids, which are colloidal suspensions of magnetic nanoparticles, offer unique properties that make them particularly attractive for various pharmaceutical applications.

One of the primary areas of market demand is in targeted drug delivery. Ferrofluids can be manipulated using external magnetic fields, allowing for precise control over the distribution and release of drugs within the body. This capability is especially valuable in cancer treatment, where localized drug delivery can significantly reduce side effects and improve therapeutic efficacy. The global market for targeted drug delivery systems is projected to expand rapidly, with ferrofluid-based solutions poised to capture a significant share.

Another key area of market demand is in magnetic resonance imaging (MRI) contrast agents. Ferrofluids can enhance the contrast and resolution of MRI scans, enabling more accurate diagnoses of various medical conditions. As the prevalence of chronic diseases and the aging population increases worldwide, the demand for advanced diagnostic imaging techniques is expected to rise, driving the adoption of ferrofluid-based contrast agents.

In the field of biosensors and diagnostic devices, ferrofluids are gaining traction due to their ability to detect and quantify specific biomolecules with high sensitivity. This application is particularly relevant in the development of point-of-care diagnostic tools, which are in high demand for rapid and accurate disease detection, especially in resource-limited settings.

The pharmaceutical industry's increasing focus on personalized medicine and nanotechnology-based therapies is also contributing to the growing market demand for ferrofluid applications. These advanced materials offer the potential for developing tailored treatments that can be precisely controlled and monitored within the body, aligning with the trend towards more individualized healthcare solutions.

Furthermore, the ongoing COVID-19 pandemic has highlighted the need for innovative diagnostic and therapeutic approaches, potentially accelerating the adoption of ferrofluid-based technologies in viral detection and vaccine development. This unexpected market driver has opened up new opportunities for ferrofluid applications in pharmaceutical research and development.

As regulatory bodies become more familiar with ferrofluid-based technologies and their safety profiles, the approval process for related pharmaceutical products is expected to become more streamlined. This regulatory progress is likely to further stimulate market demand and investment in ferrofluid research and development within the pharmaceutical sector.

One of the primary areas of market demand is in targeted drug delivery. Ferrofluids can be manipulated using external magnetic fields, allowing for precise control over the distribution and release of drugs within the body. This capability is especially valuable in cancer treatment, where localized drug delivery can significantly reduce side effects and improve therapeutic efficacy. The global market for targeted drug delivery systems is projected to expand rapidly, with ferrofluid-based solutions poised to capture a significant share.

Another key area of market demand is in magnetic resonance imaging (MRI) contrast agents. Ferrofluids can enhance the contrast and resolution of MRI scans, enabling more accurate diagnoses of various medical conditions. As the prevalence of chronic diseases and the aging population increases worldwide, the demand for advanced diagnostic imaging techniques is expected to rise, driving the adoption of ferrofluid-based contrast agents.

In the field of biosensors and diagnostic devices, ferrofluids are gaining traction due to their ability to detect and quantify specific biomolecules with high sensitivity. This application is particularly relevant in the development of point-of-care diagnostic tools, which are in high demand for rapid and accurate disease detection, especially in resource-limited settings.

The pharmaceutical industry's increasing focus on personalized medicine and nanotechnology-based therapies is also contributing to the growing market demand for ferrofluid applications. These advanced materials offer the potential for developing tailored treatments that can be precisely controlled and monitored within the body, aligning with the trend towards more individualized healthcare solutions.

Furthermore, the ongoing COVID-19 pandemic has highlighted the need for innovative diagnostic and therapeutic approaches, potentially accelerating the adoption of ferrofluid-based technologies in viral detection and vaccine development. This unexpected market driver has opened up new opportunities for ferrofluid applications in pharmaceutical research and development.

As regulatory bodies become more familiar with ferrofluid-based technologies and their safety profiles, the approval process for related pharmaceutical products is expected to become more streamlined. This regulatory progress is likely to further stimulate market demand and investment in ferrofluid research and development within the pharmaceutical sector.

Current Challenges

The application of ferrofluids in pharmaceutical research faces several significant challenges that hinder its widespread adoption and full potential realization. One of the primary obstacles is the complexity of synthesizing stable and biocompatible ferrofluids suitable for pharmaceutical applications. The magnetic nanoparticles used in ferrofluids must be carefully engineered to maintain their stability in biological environments while retaining their magnetic properties. This requires precise control over particle size, shape, and surface chemistry, which can be difficult to achieve consistently at scale.

Another major challenge lies in the long-term stability of ferrofluids in physiological conditions. The high salt concentrations and protein-rich environment of the human body can lead to aggregation or degradation of the magnetic nanoparticles, potentially compromising their effectiveness and safety. Researchers are still working to develop robust coating strategies that can protect the nanoparticles without interfering with their magnetic properties or biocompatibility.

The potential toxicity of ferrofluids remains a significant concern in pharmaceutical applications. While many studies have shown promising results regarding the safety of certain ferrofluid formulations, the long-term effects of exposure to magnetic nanoparticles in the human body are not yet fully understood. This uncertainty poses challenges for regulatory approval and clinical translation of ferrofluid-based pharmaceutical products.

Controlling the behavior of ferrofluids in complex biological systems presents another set of challenges. The interaction between magnetic fields, ferrofluids, and living tissues is highly complex and can be influenced by numerous factors. Achieving precise control over ferrofluid movement, localization, and drug release in vivo requires sophisticated modeling and experimental techniques that are still being developed.

Furthermore, the scalability of ferrofluid production for pharmaceutical applications remains a significant hurdle. Current synthesis methods often yield small quantities of high-quality ferrofluids, but scaling up these processes while maintaining consistent quality and properties is challenging. This limitation impacts the feasibility of large-scale clinical trials and commercial production of ferrofluid-based pharmaceuticals.

Lastly, the integration of ferrofluids into existing drug delivery systems and medical devices poses technical challenges. Compatibility issues between ferrofluids and other materials used in pharmaceutical formulations or medical devices must be carefully addressed to ensure the overall efficacy and safety of the final product. This often requires interdisciplinary collaboration and innovative engineering solutions to overcome material and design constraints.

Another major challenge lies in the long-term stability of ferrofluids in physiological conditions. The high salt concentrations and protein-rich environment of the human body can lead to aggregation or degradation of the magnetic nanoparticles, potentially compromising their effectiveness and safety. Researchers are still working to develop robust coating strategies that can protect the nanoparticles without interfering with their magnetic properties or biocompatibility.

The potential toxicity of ferrofluids remains a significant concern in pharmaceutical applications. While many studies have shown promising results regarding the safety of certain ferrofluid formulations, the long-term effects of exposure to magnetic nanoparticles in the human body are not yet fully understood. This uncertainty poses challenges for regulatory approval and clinical translation of ferrofluid-based pharmaceutical products.

Controlling the behavior of ferrofluids in complex biological systems presents another set of challenges. The interaction between magnetic fields, ferrofluids, and living tissues is highly complex and can be influenced by numerous factors. Achieving precise control over ferrofluid movement, localization, and drug release in vivo requires sophisticated modeling and experimental techniques that are still being developed.

Furthermore, the scalability of ferrofluid production for pharmaceutical applications remains a significant hurdle. Current synthesis methods often yield small quantities of high-quality ferrofluids, but scaling up these processes while maintaining consistent quality and properties is challenging. This limitation impacts the feasibility of large-scale clinical trials and commercial production of ferrofluid-based pharmaceuticals.

Lastly, the integration of ferrofluids into existing drug delivery systems and medical devices poses technical challenges. Compatibility issues between ferrofluids and other materials used in pharmaceutical formulations or medical devices must be carefully addressed to ensure the overall efficacy and safety of the final product. This often requires interdisciplinary collaboration and innovative engineering solutions to overcome material and design constraints.

Existing Pharma Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, contamination-resistant seals that can operate in high-vacuum or high-pressure environments. The magnetic properties of ferrofluids allow them to be retained in place while providing excellent lubrication.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their ability to be manipulated by magnetic fields. They are used in cooling systems for electronic devices, speakers, and other heat-generating equipment. The magnetic nanoparticles in ferrofluids can be directed to areas of high heat generation, improving overall thermal management efficiency.

- Magnetic field sensing and measurement: Ferrofluids are employed in various sensing and measurement applications, including magnetic field sensors, accelerometers, and inclinometers. Their unique response to magnetic fields allows for precise detection and measurement of field strength and direction. These properties are utilized in scientific instruments and industrial equipment for accurate magnetic field analysis.

- Medical and biomedical applications: Ferrofluids have emerging applications in the medical and biomedical fields. They are being researched for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids using external magnetic fields makes them promising for minimally invasive medical procedures and diagnostics.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide effective sealing against pressure differentials and contaminants while reducing friction. These properties make them valuable in various industries, including aerospace, automotive, and manufacturing.Expand Specific Solutions03 Magnetic field-responsive devices

Ferrofluids are utilized in devices that respond to magnetic fields, such as sensors, actuators, and dampers. Their unique ability to change properties under magnetic influence allows for precise control and manipulation in various applications, including vibration damping, position sensing, and fluid control systems.Expand Specific Solutions04 Heat transfer and cooling applications

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic components, transformers, and other high-heat applications. The ability to manipulate ferrofluids with magnetic fields allows for targeted cooling and improved thermal management in compact designs.Expand Specific Solutions05 Novel applications and emerging technologies

Ferrofluids are finding new applications in emerging technologies. These include use in microfluidic devices, biomedical applications such as targeted drug delivery, magnetic separation processes, and energy harvesting systems. Ongoing research explores their potential in areas like magnetic hyperthermia for cancer treatment and magnetically controlled soft robotics.Expand Specific Solutions

Key Industry Players

The ferrofluid application in pharmaceutical research is in an emerging stage, with a growing market driven by innovative drug delivery systems and diagnostic tools. The technology's maturity is advancing rapidly, as evidenced by the involvement of prestigious institutions like Yale University, Peking University, and the California Institute of Technology. Companies such as Advanced Liquid Logic and CFD Research Corp. are at the forefront, developing microfluidic platforms and simulation technologies. The competitive landscape is diverse, with academic institutions, biotech firms, and established pharmaceutical companies collaborating and competing to harness ferrofluid's potential in areas like targeted drug delivery, biosensors, and magnetic hyperthermia for cancer treatment.

Yale University

Technical Solution: Yale University has developed innovative ferrofluid applications in pharmaceutical research, focusing on targeted drug delivery systems. Their approach utilizes magnetic nanoparticles coated with biocompatible materials to create ferrofluids that can be precisely controlled using external magnetic fields. This allows for localized drug delivery to specific tissues or organs, potentially reducing side effects and improving treatment efficacy[1]. The university has also explored the use of ferrofluids in microfluidic devices for drug screening and analysis, enabling high-throughput testing of pharmaceutical compounds[3]. Additionally, Yale researchers have investigated the potential of ferrofluids in magnetic hyperthermia for cancer treatment, where the nanoparticles generate heat when exposed to alternating magnetic fields, selectively destroying tumor cells[5].

Strengths: Cutting-edge research in targeted drug delivery and microfluidic applications. Strong interdisciplinary collaboration between engineering and medical departments. Weaknesses: Potential challenges in scaling up laboratory-scale techniques for clinical applications. Limited commercial partnerships for technology transfer.

The Regents of the University of California

Technical Solution: The University of California system has made significant advancements in ferrofluid applications for pharmaceutical research. Their approach focuses on developing multifunctional ferrofluids that combine drug delivery capabilities with diagnostic imaging properties. These "theranostic" nanoparticles allow for simultaneous treatment and real-time monitoring of drug distribution and efficacy[2]. UC researchers have also pioneered the use of ferrofluids in magnetic particle imaging (MPI) for non-invasive tracking of drug-loaded nanoparticles in the body[4]. Furthermore, the university has explored the application of ferrofluids in microfluidic devices for high-precision drug formulation and encapsulation, enabling the production of complex drug delivery systems with enhanced stability and bioavailability[6].

Strengths: Comprehensive research program covering multiple aspects of ferrofluid applications in pharmaceuticals. Strong track record of translating research into clinical trials. Weaknesses: Complex intellectual property landscape due to multiple campuses and research groups. Potential challenges in coordinating large-scale, multi-institution projects.

Core Ferrofluid Innovations

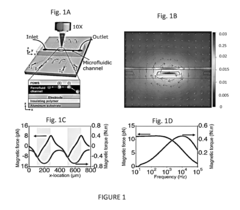

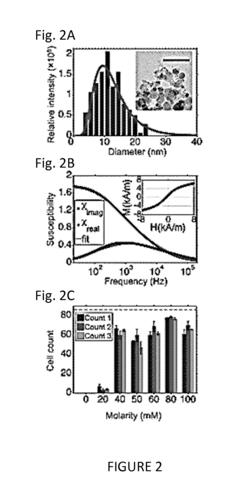

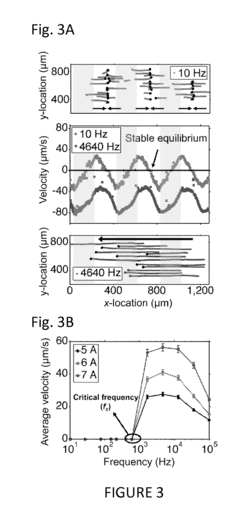

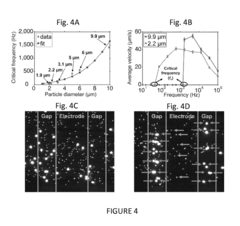

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

System for transporting active substances in a biological system

PatentInactiveUS20100330159A1

Innovation

- A stabilizer-free system where magnetic particles are directly loaded with active substances on their surface or enveloped by them, allowing for targeted transport and concentration in biological systems without the need for surface coatings or additional excipients, utilizing superparamagnetic particles of sizes 1-300 nm for enhanced loading capacity.

Regulatory Considerations

The application of ferrofluids in pharmaceutical research is subject to stringent regulatory oversight to ensure safety, efficacy, and quality standards are met. Regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) play crucial roles in evaluating and approving ferrofluid-based pharmaceutical products.

One of the primary regulatory considerations is the classification of ferrofluid-containing products. Depending on their intended use and mechanism of action, these products may be categorized as drugs, medical devices, or combination products. This classification determines the specific regulatory pathway and requirements for approval.

Safety assessment is a critical aspect of regulatory compliance. Manufacturers must conduct comprehensive toxicology studies to evaluate the potential risks associated with ferrofluid exposure. This includes assessing the biocompatibility of the nanoparticles, their potential for accumulation in tissues, and any long-term effects on organ systems.

Quality control and manufacturing processes are subject to rigorous regulatory scrutiny. Good Manufacturing Practices (GMP) must be adhered to throughout the production of ferrofluid-based pharmaceuticals. This involves implementing robust quality management systems, validating production processes, and ensuring consistent product quality.

Regulatory bodies also focus on the characterization and stability of ferrofluids used in pharmaceutical applications. Manufacturers must provide detailed information on the physicochemical properties of the ferrofluids, including particle size distribution, magnetic properties, and colloidal stability. Stability studies are required to demonstrate the shelf life and storage conditions of the final product.

Clinical trials involving ferrofluid-based pharmaceuticals are subject to additional regulatory considerations. Protocols must be designed to address specific safety concerns related to the use of magnetic nanoparticles in vivo. This may include monitoring for potential immune responses, assessing the biodistribution of nanoparticles, and evaluating long-term safety profiles.

Post-market surveillance is another crucial regulatory aspect. Manufacturers are required to implement pharmacovigilance systems to monitor and report any adverse events associated with ferrofluid-containing products. This ongoing surveillance helps identify potential safety issues and informs regulatory decisions regarding product labeling or market withdrawal if necessary.

Regulatory requirements may vary across different regions and countries. Manufacturers seeking global market access must navigate these diverse regulatory landscapes, which may involve submitting multiple applications and adhering to region-specific guidelines. Harmonization efforts, such as the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), aim to streamline regulatory processes and reduce redundancy in global pharmaceutical development.

One of the primary regulatory considerations is the classification of ferrofluid-containing products. Depending on their intended use and mechanism of action, these products may be categorized as drugs, medical devices, or combination products. This classification determines the specific regulatory pathway and requirements for approval.

Safety assessment is a critical aspect of regulatory compliance. Manufacturers must conduct comprehensive toxicology studies to evaluate the potential risks associated with ferrofluid exposure. This includes assessing the biocompatibility of the nanoparticles, their potential for accumulation in tissues, and any long-term effects on organ systems.

Quality control and manufacturing processes are subject to rigorous regulatory scrutiny. Good Manufacturing Practices (GMP) must be adhered to throughout the production of ferrofluid-based pharmaceuticals. This involves implementing robust quality management systems, validating production processes, and ensuring consistent product quality.

Regulatory bodies also focus on the characterization and stability of ferrofluids used in pharmaceutical applications. Manufacturers must provide detailed information on the physicochemical properties of the ferrofluids, including particle size distribution, magnetic properties, and colloidal stability. Stability studies are required to demonstrate the shelf life and storage conditions of the final product.

Clinical trials involving ferrofluid-based pharmaceuticals are subject to additional regulatory considerations. Protocols must be designed to address specific safety concerns related to the use of magnetic nanoparticles in vivo. This may include monitoring for potential immune responses, assessing the biodistribution of nanoparticles, and evaluating long-term safety profiles.

Post-market surveillance is another crucial regulatory aspect. Manufacturers are required to implement pharmacovigilance systems to monitor and report any adverse events associated with ferrofluid-containing products. This ongoing surveillance helps identify potential safety issues and informs regulatory decisions regarding product labeling or market withdrawal if necessary.

Regulatory requirements may vary across different regions and countries. Manufacturers seeking global market access must navigate these diverse regulatory landscapes, which may involve submitting multiple applications and adhering to region-specific guidelines. Harmonization efforts, such as the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), aim to streamline regulatory processes and reduce redundancy in global pharmaceutical development.

Biocompatibility Assessment

Biocompatibility assessment is a critical aspect of ferrofluid application in pharmaceutical research. The evaluation of ferrofluids' compatibility with biological systems is essential to ensure their safety and efficacy in drug delivery and other medical applications.

One of the primary considerations in biocompatibility assessment is the potential toxicity of ferrofluid components. Magnetic nanoparticles, typically iron oxide, must be carefully evaluated for their effects on cellular viability and function. In vitro studies using various cell lines are commonly employed to assess cytotoxicity, genotoxicity, and potential inflammatory responses.

The surface coating of ferrofluid nanoparticles plays a crucial role in their biocompatibility. Researchers often utilize biocompatible polymers such as polyethylene glycol (PEG) or dextran to enhance the stability and reduce the immunogenicity of ferrofluids. The choice of coating material can significantly influence the nanoparticles' interaction with biological systems and their overall biocompatibility profile.

In vivo studies are essential for comprehensive biocompatibility assessment. Animal models are used to evaluate the biodistribution, pharmacokinetics, and potential long-term effects of ferrofluids. These studies help researchers understand how ferrofluids interact with various organs and tissues, as well as their clearance mechanisms from the body.

Hemocompatibility is another critical aspect of biocompatibility assessment for ferrofluids intended for intravenous administration. Evaluating the interaction between ferrofluids and blood components, including potential hemolysis or coagulation effects, is crucial for ensuring their safety in systemic applications.

The immune response to ferrofluids is a key consideration in biocompatibility assessment. Researchers must evaluate the potential for immunogenicity and complement activation, which could lead to adverse reactions or reduced efficacy of the ferrofluid-based pharmaceutical formulations.

Standardized testing protocols and regulatory guidelines play a vital role in ensuring consistent and reliable biocompatibility assessments. Adherence to international standards, such as those set by ISO 10993 for the biological evaluation of medical devices, provides a framework for comprehensive biocompatibility testing of ferrofluids in pharmaceutical applications.

Advanced imaging techniques, such as magnetic resonance imaging (MRI) and electron microscopy, are employed to visualize the interaction between ferrofluids and biological systems at the cellular and tissue levels. These methods provide valuable insights into the distribution and potential accumulation of ferrofluid nanoparticles in various organs and tissues.

One of the primary considerations in biocompatibility assessment is the potential toxicity of ferrofluid components. Magnetic nanoparticles, typically iron oxide, must be carefully evaluated for their effects on cellular viability and function. In vitro studies using various cell lines are commonly employed to assess cytotoxicity, genotoxicity, and potential inflammatory responses.

The surface coating of ferrofluid nanoparticles plays a crucial role in their biocompatibility. Researchers often utilize biocompatible polymers such as polyethylene glycol (PEG) or dextran to enhance the stability and reduce the immunogenicity of ferrofluids. The choice of coating material can significantly influence the nanoparticles' interaction with biological systems and their overall biocompatibility profile.

In vivo studies are essential for comprehensive biocompatibility assessment. Animal models are used to evaluate the biodistribution, pharmacokinetics, and potential long-term effects of ferrofluids. These studies help researchers understand how ferrofluids interact with various organs and tissues, as well as their clearance mechanisms from the body.

Hemocompatibility is another critical aspect of biocompatibility assessment for ferrofluids intended for intravenous administration. Evaluating the interaction between ferrofluids and blood components, including potential hemolysis or coagulation effects, is crucial for ensuring their safety in systemic applications.

The immune response to ferrofluids is a key consideration in biocompatibility assessment. Researchers must evaluate the potential for immunogenicity and complement activation, which could lead to adverse reactions or reduced efficacy of the ferrofluid-based pharmaceutical formulations.

Standardized testing protocols and regulatory guidelines play a vital role in ensuring consistent and reliable biocompatibility assessments. Adherence to international standards, such as those set by ISO 10993 for the biological evaluation of medical devices, provides a framework for comprehensive biocompatibility testing of ferrofluids in pharmaceutical applications.

Advanced imaging techniques, such as magnetic resonance imaging (MRI) and electron microscopy, are employed to visualize the interaction between ferrofluids and biological systems at the cellular and tissue levels. These methods provide valuable insights into the distribution and potential accumulation of ferrofluid nanoparticles in various organs and tissues.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!