How to Use Ferrofluid in Efficient Magnetic Field Control Systems?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel control in zero gravity, ferrofluids have found diverse applications across various industries. The technology's progression has been marked by advancements in synthesis methods, particle size control, and stability enhancement.

Early ferrofluids faced challenges with long-term stability and limited magnetic responsiveness. However, continuous research has led to the development of more sophisticated ferrofluids with improved colloidal stability and magnetic properties. The introduction of surfactant coatings and the optimization of carrier fluids have played crucial roles in enhancing the performance and longevity of ferrofluids.

The evolution of ferrofluid technology has been closely tied to advancements in nanotechnology and materials science. The ability to produce uniform, nanoscale magnetic particles has significantly improved the overall quality and consistency of ferrofluids. This has opened up new possibilities for their application in precision engineering and microfluidic systems.

In recent years, there has been a growing interest in using ferrofluids for magnetic field control systems. The unique properties of ferrofluids, such as their ability to change shape and viscosity in response to magnetic fields, make them ideal candidates for dynamic and adaptive control mechanisms. This has led to increased research focus on optimizing ferrofluid compositions and developing novel control algorithms.

The primary objectives in the field of ferrofluid technology for magnetic field control systems include enhancing magnetic responsiveness, improving thermal stability, and developing more precise control mechanisms. Researchers aim to create ferrofluids that can respond rapidly to changing magnetic fields while maintaining their properties over a wide range of temperatures and operating conditions.

Another key objective is the integration of ferrofluids into miniaturized systems, particularly in the realm of microelectromechanical systems (MEMS) and nanoelectromechanical systems (NEMS). This requires overcoming challenges related to fluid containment, interface interactions, and long-term reliability in confined spaces.

Furthermore, there is a growing emphasis on developing environmentally friendly and biocompatible ferrofluids. This is particularly important for applications in biomedical engineering and environmental sensing. The goal is to create ferrofluids that are not only efficient in magnetic field control but also safe for use in sensitive environments.

As the technology continues to mature, the objectives extend to scaling up production processes while maintaining quality and consistency. This is crucial for the widespread adoption of ferrofluid-based magnetic field control systems in industrial applications. Additionally, there is a focus on developing standardized testing and characterization methods to ensure the reliability and reproducibility of ferrofluid performance across different applications and environments.

Early ferrofluids faced challenges with long-term stability and limited magnetic responsiveness. However, continuous research has led to the development of more sophisticated ferrofluids with improved colloidal stability and magnetic properties. The introduction of surfactant coatings and the optimization of carrier fluids have played crucial roles in enhancing the performance and longevity of ferrofluids.

The evolution of ferrofluid technology has been closely tied to advancements in nanotechnology and materials science. The ability to produce uniform, nanoscale magnetic particles has significantly improved the overall quality and consistency of ferrofluids. This has opened up new possibilities for their application in precision engineering and microfluidic systems.

In recent years, there has been a growing interest in using ferrofluids for magnetic field control systems. The unique properties of ferrofluids, such as their ability to change shape and viscosity in response to magnetic fields, make them ideal candidates for dynamic and adaptive control mechanisms. This has led to increased research focus on optimizing ferrofluid compositions and developing novel control algorithms.

The primary objectives in the field of ferrofluid technology for magnetic field control systems include enhancing magnetic responsiveness, improving thermal stability, and developing more precise control mechanisms. Researchers aim to create ferrofluids that can respond rapidly to changing magnetic fields while maintaining their properties over a wide range of temperatures and operating conditions.

Another key objective is the integration of ferrofluids into miniaturized systems, particularly in the realm of microelectromechanical systems (MEMS) and nanoelectromechanical systems (NEMS). This requires overcoming challenges related to fluid containment, interface interactions, and long-term reliability in confined spaces.

Furthermore, there is a growing emphasis on developing environmentally friendly and biocompatible ferrofluids. This is particularly important for applications in biomedical engineering and environmental sensing. The goal is to create ferrofluids that are not only efficient in magnetic field control but also safe for use in sensitive environments.

As the technology continues to mature, the objectives extend to scaling up production processes while maintaining quality and consistency. This is crucial for the widespread adoption of ferrofluid-based magnetic field control systems in industrial applications. Additionally, there is a focus on developing standardized testing and characterization methods to ensure the reliability and reproducibility of ferrofluid performance across different applications and environments.

Market Analysis for Magnetic Field Control Systems

The market for magnetic field control systems utilizing ferrofluid technology is experiencing significant growth, driven by increasing demand across various industries. The global market for magnetic field control systems is projected to reach $5.2 billion by 2026, with a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026. This growth is primarily attributed to the expanding applications of magnetic field control systems in sectors such as healthcare, aerospace, automotive, and electronics.

In the healthcare sector, ferrofluid-based magnetic field control systems are gaining traction in medical imaging technologies, particularly in MRI machines. The enhanced precision and efficiency offered by these systems are driving their adoption, with the medical imaging market expected to grow at a CAGR of 5.2% from 2021 to 2026.

The aerospace industry is another key market for ferrofluid-based magnetic field control systems. These systems are increasingly used in satellite attitude control and vibration damping applications. The global aerospace market is forecasted to grow at a CAGR of 7.1% from 2021 to 2026, presenting significant opportunities for magnetic field control system manufacturers.

In the automotive sector, ferrofluid technology is being explored for applications in suspension systems and engine mounts. The automotive magnetic field control systems market is expected to grow at a CAGR of 5.9% from 2021 to 2026, driven by the increasing demand for advanced vehicle performance and comfort features.

The electronics industry is also a major consumer of magnetic field control systems, particularly in the development of advanced sensors and actuators. The global sensor market is projected to grow at a CAGR of 8.9% from 2021 to 2026, with magnetic field sensors being a significant contributor to this growth.

Geographically, North America and Europe are the leading markets for magnetic field control systems, accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate, with a CAGR of 8.2% from 2021 to 2026, driven by rapid industrialization and increasing investments in research and development.

Key players in the magnetic field control systems market include Magneto Rheological Devices, Lord Corporation, and Ferrotec Holdings Corporation. These companies are focusing on developing innovative ferrofluid-based solutions to cater to the growing demand across various industries.

In the healthcare sector, ferrofluid-based magnetic field control systems are gaining traction in medical imaging technologies, particularly in MRI machines. The enhanced precision and efficiency offered by these systems are driving their adoption, with the medical imaging market expected to grow at a CAGR of 5.2% from 2021 to 2026.

The aerospace industry is another key market for ferrofluid-based magnetic field control systems. These systems are increasingly used in satellite attitude control and vibration damping applications. The global aerospace market is forecasted to grow at a CAGR of 7.1% from 2021 to 2026, presenting significant opportunities for magnetic field control system manufacturers.

In the automotive sector, ferrofluid technology is being explored for applications in suspension systems and engine mounts. The automotive magnetic field control systems market is expected to grow at a CAGR of 5.9% from 2021 to 2026, driven by the increasing demand for advanced vehicle performance and comfort features.

The electronics industry is also a major consumer of magnetic field control systems, particularly in the development of advanced sensors and actuators. The global sensor market is projected to grow at a CAGR of 8.9% from 2021 to 2026, with magnetic field sensors being a significant contributor to this growth.

Geographically, North America and Europe are the leading markets for magnetic field control systems, accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate, with a CAGR of 8.2% from 2021 to 2026, driven by rapid industrialization and increasing investments in research and development.

Key players in the magnetic field control systems market include Magneto Rheological Devices, Lord Corporation, and Ferrotec Holdings Corporation. These companies are focusing on developing innovative ferrofluid-based solutions to cater to the growing demand across various industries.

Current Challenges in Ferrofluid-based Control Systems

Ferrofluid-based control systems have shown great potential in various applications, yet they face several significant challenges that hinder their widespread adoption and efficiency. One of the primary obstacles is the stability of ferrofluids over extended periods. These colloidal suspensions tend to aggregate and settle over time, leading to reduced performance and potential system failures. This instability is particularly problematic in long-term applications or in environments with varying temperatures and magnetic field strengths.

Another critical challenge lies in the precise control of ferrofluid behavior within complex magnetic field geometries. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for intricate tasks remains difficult. This is especially true in systems requiring rapid changes in fluid properties or precise spatial manipulation. The non-linear response of ferrofluids to magnetic fields further complicates the development of accurate control algorithms.

The thermal management of ferrofluid-based systems presents another significant hurdle. As these fluids interact with magnetic fields, they generate heat through magnetic hysteresis and fluid friction. This heat generation can lead to changes in fluid properties and potentially compromise the integrity of the entire system. Developing effective cooling mechanisms without interfering with the magnetic field control is a complex engineering challenge.

Compatibility issues between ferrofluids and other materials used in control systems also pose difficulties. The corrosive nature of some ferrofluids can lead to degradation of system components over time, necessitating the use of specialized, often expensive, materials. This compatibility concern extends to sealing technologies, as preventing ferrofluid leakage while maintaining system functionality is crucial for many applications.

Scaling ferrofluid-based control systems for industrial applications presents its own set of challenges. While small-scale demonstrations have shown promise, translating these successes to larger, more complex systems often reveals unforeseen issues. These can include magnetic field inhomogeneities, fluid property variations across larger volumes, and increased system complexity that complicates control and maintenance.

Lastly, the environmental and health implications of ferrofluids, particularly in the event of leaks or system failures, remain a concern. The long-term effects of nanoparticle exposure and the potential for environmental contamination necessitate careful consideration in system design and risk assessment. Addressing these safety concerns is crucial for the broader acceptance and implementation of ferrofluid-based control systems across various industries.

Another critical challenge lies in the precise control of ferrofluid behavior within complex magnetic field geometries. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for intricate tasks remains difficult. This is especially true in systems requiring rapid changes in fluid properties or precise spatial manipulation. The non-linear response of ferrofluids to magnetic fields further complicates the development of accurate control algorithms.

The thermal management of ferrofluid-based systems presents another significant hurdle. As these fluids interact with magnetic fields, they generate heat through magnetic hysteresis and fluid friction. This heat generation can lead to changes in fluid properties and potentially compromise the integrity of the entire system. Developing effective cooling mechanisms without interfering with the magnetic field control is a complex engineering challenge.

Compatibility issues between ferrofluids and other materials used in control systems also pose difficulties. The corrosive nature of some ferrofluids can lead to degradation of system components over time, necessitating the use of specialized, often expensive, materials. This compatibility concern extends to sealing technologies, as preventing ferrofluid leakage while maintaining system functionality is crucial for many applications.

Scaling ferrofluid-based control systems for industrial applications presents its own set of challenges. While small-scale demonstrations have shown promise, translating these successes to larger, more complex systems often reveals unforeseen issues. These can include magnetic field inhomogeneities, fluid property variations across larger volumes, and increased system complexity that complicates control and maintenance.

Lastly, the environmental and health implications of ferrofluids, particularly in the event of leaks or system failures, remain a concern. The long-term effects of nanoparticle exposure and the potential for environmental contamination necessitate careful consideration in system design and risk assessment. Addressing these safety concerns is crucial for the broader acceptance and implementation of ferrofluid-based control systems across various industries.

Existing Ferrofluid Control System Solutions

01 Magnetic field optimization for ferrofluid efficiency

Optimizing magnetic field strength and distribution can significantly enhance ferrofluid efficiency. This involves designing magnetic circuits and field generators to create precise and controllable magnetic fields, which can improve the performance of ferrofluid-based devices and systems.- Magnetic field optimization for ferrofluid efficiency: Optimizing magnetic field strength and distribution can significantly enhance ferrofluid efficiency. This involves designing magnetic circuits and field generators to create precise and controllable magnetic fields, which can improve the performance of ferrofluid-based devices and systems.

- Ferrofluid composition and particle size control: The efficiency of ferrofluids can be improved by carefully controlling their composition and magnetic particle size distribution. This includes selecting appropriate carrier fluids, surfactants, and magnetic materials, as well as optimizing the synthesis process to achieve desired particle sizes and magnetic properties.

- Ferrofluid sealing and lubrication applications: Ferrofluids can be efficiently used in sealing and lubrication applications, such as in rotary shaft seals and bearings. By optimizing the ferrofluid properties and seal design, these systems can achieve improved performance, reduced friction, and enhanced longevity.

- Thermal management and heat transfer enhancement: Ferrofluids can be utilized to improve thermal management and heat transfer in various systems. By leveraging their unique magnetic and thermal properties, ferrofluids can enhance cooling efficiency in electronic devices, power systems, and other heat-generating applications.

- Ferrofluid-based sensors and actuators: The efficiency of ferrofluid-based sensors and actuators can be improved through innovative designs and control mechanisms. This includes developing precise measurement techniques, optimizing response times, and enhancing the sensitivity and accuracy of ferrofluid-based devices for various sensing and actuation applications.

02 Ferrofluid composition and particle size control

The efficiency of ferrofluids can be improved by carefully controlling their composition and the size of magnetic particles. This includes selecting appropriate carrier fluids, surfactants, and magnetic materials, as well as optimizing particle size distribution to enhance stability and magnetic response.Expand Specific Solutions03 Ferrofluid sealing and lubrication applications

Ferrofluids can be efficiently used in sealing and lubrication applications, such as in rotary shaft seals and bearings. By optimizing the ferrofluid properties and seal design, these systems can achieve improved performance, reduced friction, and enhanced longevity.Expand Specific Solutions04 Thermal management and heat transfer using ferrofluids

Ferrofluids can be utilized for efficient thermal management and heat transfer in various applications. By leveraging their unique magnetic and thermal properties, ferrofluids can enhance cooling systems, improve heat dissipation, and enable novel thermal management solutions in electronic and mechanical systems.Expand Specific Solutions05 Ferrofluid-based sensing and measurement techniques

Ferrofluids can be employed in various sensing and measurement applications to improve efficiency and accuracy. This includes using ferrofluids in accelerometers, gyroscopes, and other sensors to enhance sensitivity and response time, as well as in measurement devices for magnetic fields and fluid properties.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The ferrofluid-based magnetic field control systems market is in its early growth stage, with increasing research and development activities. The market size is relatively small but expanding, driven by applications in various industries. The technology's maturity is progressing, with key players like Yale University, Japan Science & Technology Agency, and Koninklijke Philips NV leading research efforts. Companies such as Hitachi Ltd. and Advanced Industrial Science & Technology are also contributing to advancements in this field. While the technology shows promise, it is still evolving, with ongoing efforts to improve efficiency, reliability, and scalability for widespread commercial adoption.

Koninklijke Philips NV

Technical Solution: Philips has developed innovative applications of ferrofluids in magnetic field control systems, particularly in the realm of medical imaging and diagnostics. Their approach focuses on using ferrofluids to enhance the contrast and resolution of magnetic resonance imaging (MRI) scans[9]. The system employs specially designed ferrofluids as contrast agents that can be precisely controlled and directed within the body using external magnetic fields. This allows for more targeted imaging and potentially reduces the need for invasive procedures. Additionally, Philips has explored the use of ferrofluid-based actuators in medical devices, enabling precise and controlled movements in minimally invasive surgical tools[10].

Strengths: Enhanced medical imaging capabilities, potential for non-invasive diagnostics, and precise control in medical devices. Weaknesses: Regulatory challenges for medical applications and potential biocompatibility concerns with long-term use of ferrofluids in the body.

Hitachi Ltd.

Technical Solution: Hitachi has developed a novel approach to using ferrofluids in magnetic field control systems, particularly for applications in electronics cooling and vibration damping. Their system utilizes specially formulated ferrofluids with enhanced thermal conductivity and magnetic responsiveness[5]. Hitachi's technology incorporates a network of micro-channels filled with ferrofluid, which can be dynamically controlled to redirect magnetic fields and heat flow. This allows for precise thermal management in compact electronic devices. Additionally, Hitachi has explored the use of ferrofluids in adaptive damping systems for industrial machinery, where magnetic field control can adjust damping characteristics in real-time based on operational conditions[6].

Strengths: Excellent thermal management capabilities, adaptability to compact designs, and dual functionality for cooling and vibration control. Weaknesses: Potential limitations in high-temperature environments and complexity in manufacturing process.

Innovative Ferrofluid Control Mechanisms

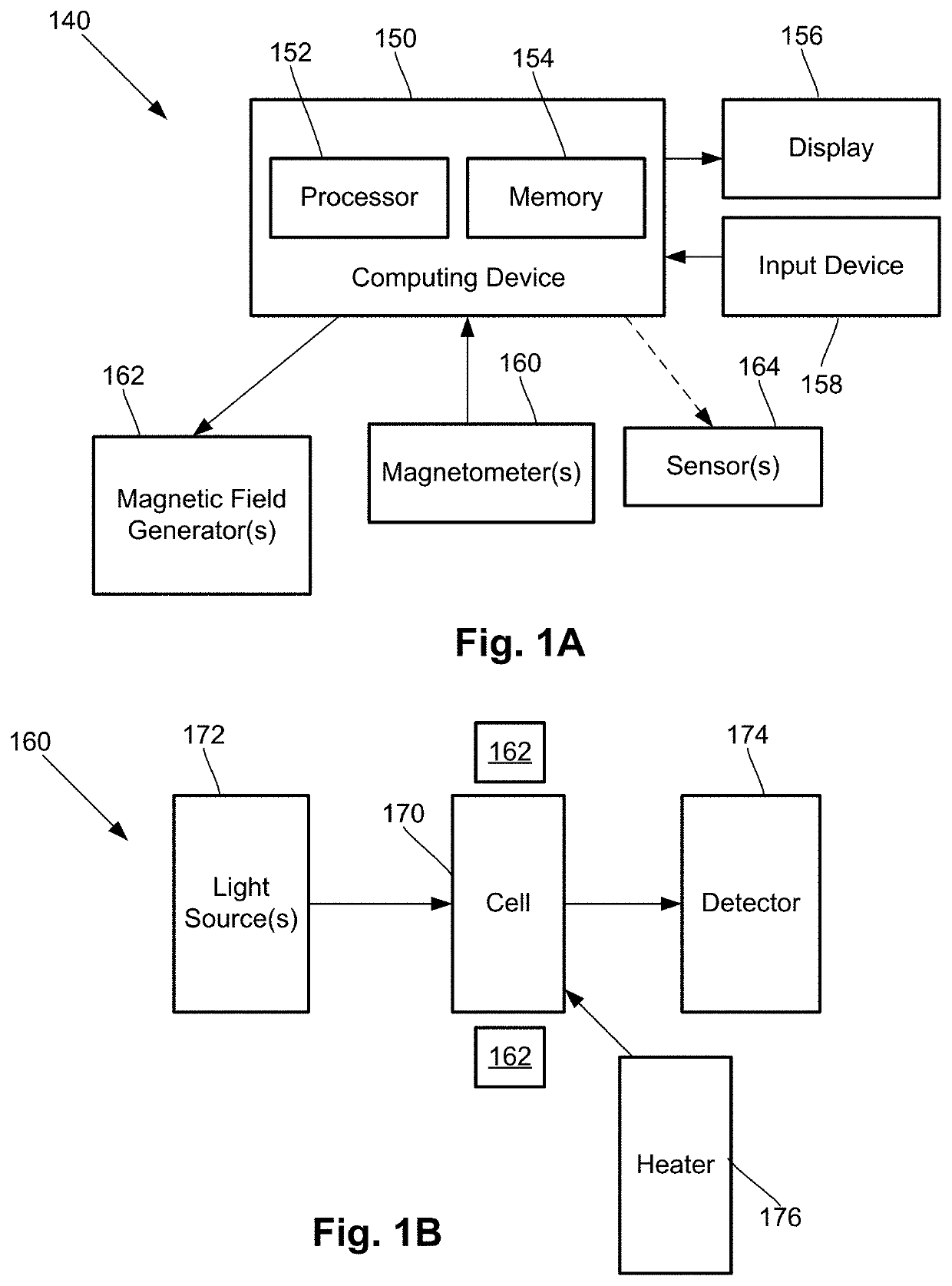

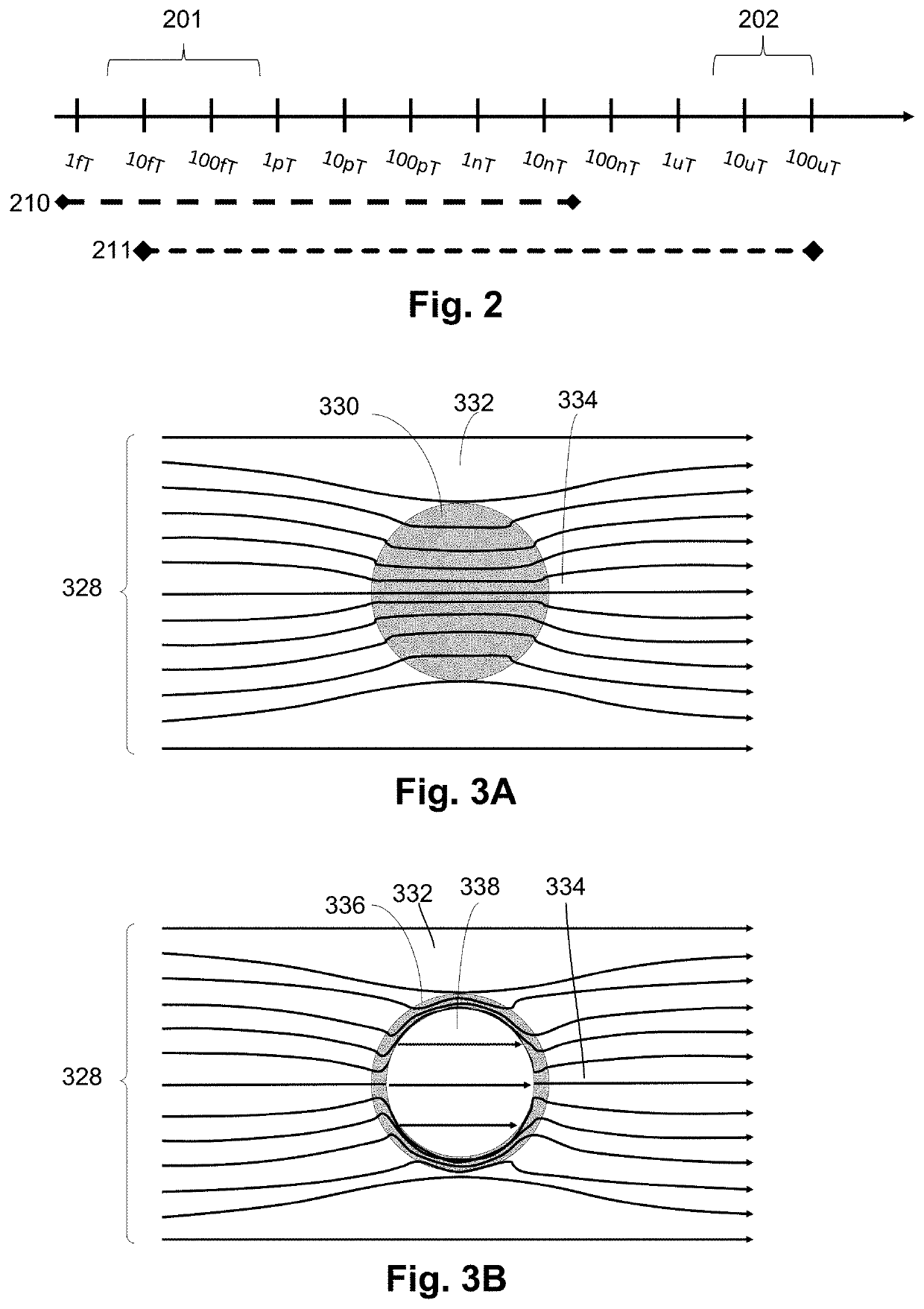

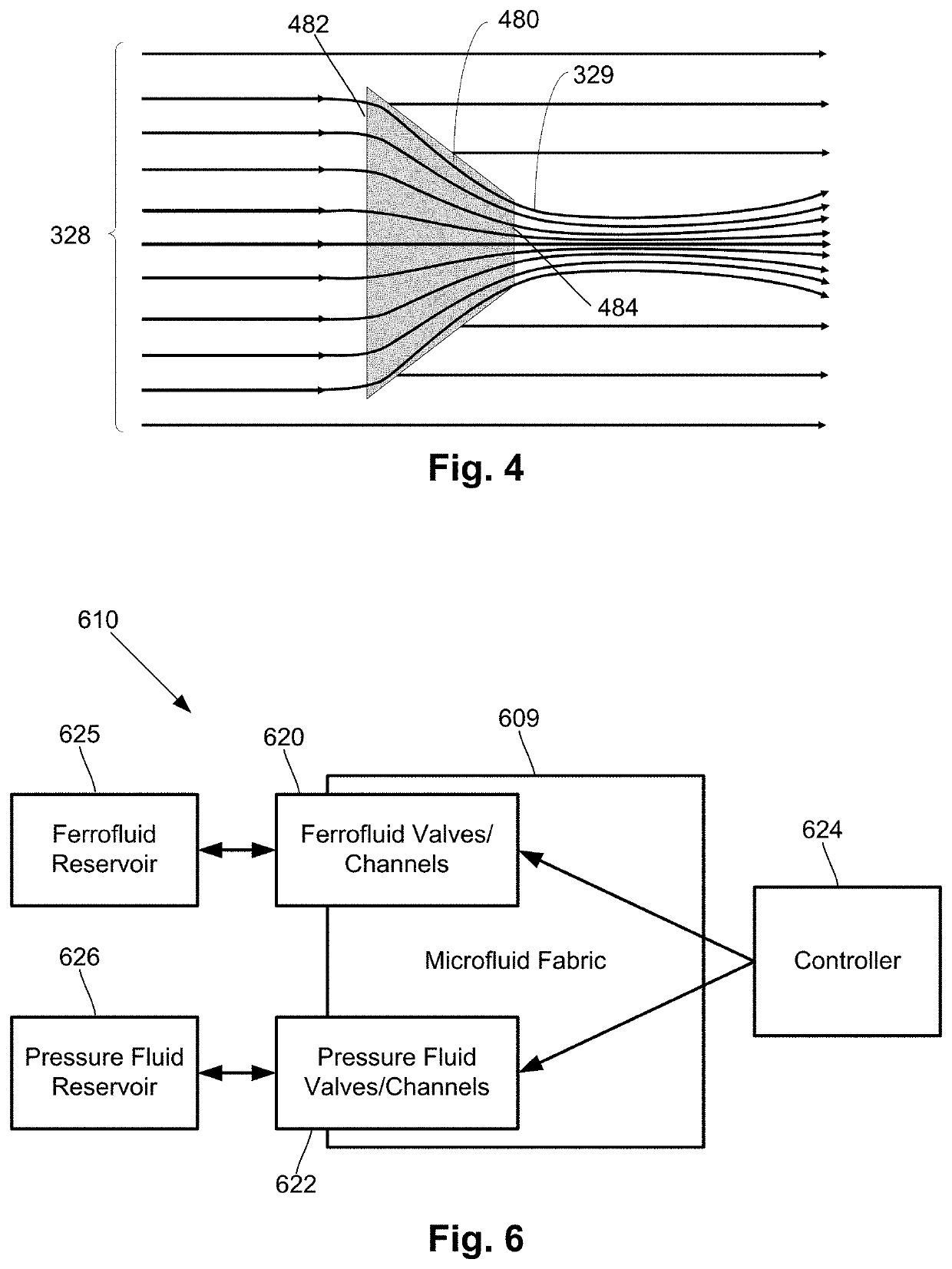

Dynamic magnetic shielding and beamforming using ferrofluid for compact magnetoencephalography (MEG)

PatentActiveUS20200088811A1

Innovation

- A magnetic field measurement system incorporating optically pumped magnetometers with a ferrofluid shield that uses a microfluid fabric and ferrofluid to create a flexible, conformal magnetic shield or flux concentrator, allowing for dynamic control of ferrofluid distribution to concentrate magnetic field lines and reduce ambient noise.

Three-Dimensional Molding Using Magnetically Activated Static and Dynamic Ferrofluid Configurations

PatentActiveUS20150050179A1

Innovation

- A method utilizing a combination of ferrofluid and non-magnetic substrates within a magnetic system, where the ferrofluid aligns with magnetic fields to form specific shapes, and the non-magnetic substrate acts as a guide or barrier, allowing for the creation of diverse and complex mold shapes by manipulating magnetic field lines and densities.

Environmental Impact of Ferrofluid Technologies

The environmental impact of ferrofluid technologies in magnetic field control systems is a crucial consideration as these systems become more prevalent in various industries. Ferrofluids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, offer unique properties that enable precise control of magnetic fields. However, their widespread use raises concerns about potential ecological consequences.

One primary environmental concern is the potential release of nanoparticles into ecosystems. If ferrofluids leak or are improperly disposed of, these particles could contaminate soil and water systems. The small size of nanoparticles allows them to penetrate biological barriers, potentially affecting organisms at cellular levels. Studies have shown that some nanoparticles can accumulate in aquatic organisms and move up the food chain, raising concerns about bioaccumulation and long-term ecological effects.

The production of ferrofluids also has environmental implications. The synthesis of nanoparticles often involves energy-intensive processes and the use of chemicals that may have their own environmental footprints. Additionally, the extraction of rare earth elements, which are sometimes used in high-performance ferrofluids, can lead to significant environmental degradation in mining areas.

On the positive side, ferrofluid-based magnetic field control systems can contribute to environmental protection in several ways. These systems often improve the efficiency of various processes, potentially reducing energy consumption and associated carbon emissions. For instance, in industrial separators, ferrofluids can enhance the removal of contaminants from wastewater, contributing to cleaner water systems.

The recyclability and longevity of ferrofluids are important factors in assessing their overall environmental impact. Well-designed systems can contain and reuse ferrofluids for extended periods, minimizing waste. However, end-of-life disposal remains a challenge, as the separation of nanoparticles from carrier fluids can be complex and energy-intensive.

As the technology advances, there is a growing focus on developing more environmentally friendly ferrofluids. Research is being conducted on biodegradable carrier fluids and less toxic nanoparticles. Some studies are exploring the use of naturally occurring magnetotactic bacteria as an alternative to synthetic magnetic nanoparticles, potentially offering a more sustainable approach.

The regulatory landscape surrounding nanoparticle technologies, including ferrofluids, is still evolving. As more data becomes available on the long-term environmental effects of these materials, it is likely that stricter guidelines will be implemented for their production, use, and disposal. This regulatory development will play a crucial role in shaping the environmental profile of ferrofluid technologies in the future.

One primary environmental concern is the potential release of nanoparticles into ecosystems. If ferrofluids leak or are improperly disposed of, these particles could contaminate soil and water systems. The small size of nanoparticles allows them to penetrate biological barriers, potentially affecting organisms at cellular levels. Studies have shown that some nanoparticles can accumulate in aquatic organisms and move up the food chain, raising concerns about bioaccumulation and long-term ecological effects.

The production of ferrofluids also has environmental implications. The synthesis of nanoparticles often involves energy-intensive processes and the use of chemicals that may have their own environmental footprints. Additionally, the extraction of rare earth elements, which are sometimes used in high-performance ferrofluids, can lead to significant environmental degradation in mining areas.

On the positive side, ferrofluid-based magnetic field control systems can contribute to environmental protection in several ways. These systems often improve the efficiency of various processes, potentially reducing energy consumption and associated carbon emissions. For instance, in industrial separators, ferrofluids can enhance the removal of contaminants from wastewater, contributing to cleaner water systems.

The recyclability and longevity of ferrofluids are important factors in assessing their overall environmental impact. Well-designed systems can contain and reuse ferrofluids for extended periods, minimizing waste. However, end-of-life disposal remains a challenge, as the separation of nanoparticles from carrier fluids can be complex and energy-intensive.

As the technology advances, there is a growing focus on developing more environmentally friendly ferrofluids. Research is being conducted on biodegradable carrier fluids and less toxic nanoparticles. Some studies are exploring the use of naturally occurring magnetotactic bacteria as an alternative to synthetic magnetic nanoparticles, potentially offering a more sustainable approach.

The regulatory landscape surrounding nanoparticle technologies, including ferrofluids, is still evolving. As more data becomes available on the long-term environmental effects of these materials, it is likely that stricter guidelines will be implemented for their production, use, and disposal. This regulatory development will play a crucial role in shaping the environmental profile of ferrofluid technologies in the future.

Scalability and Integration Considerations

The scalability and integration of ferrofluid-based magnetic field control systems present both challenges and opportunities for widespread adoption. As these systems evolve from laboratory-scale experiments to industrial applications, several key considerations must be addressed.

Firstly, the production and quality control of ferrofluids at larger scales require careful attention. Maintaining consistent magnetic properties and stability across larger volumes of ferrofluid is crucial for reliable system performance. This may involve developing new synthesis methods or refining existing processes to ensure uniformity and reproducibility.

Integration with existing infrastructure and equipment is another critical aspect. Ferrofluid-based systems must be designed to seamlessly interface with current magnetic field generation and control technologies. This includes compatibility with power supplies, sensors, and control software. Standardization of components and interfaces will be essential for facilitating broader adoption across different industries.

The scalability of magnetic field control precision and response time as system size increases is a significant technical challenge. Larger volumes of ferrofluid may exhibit different dynamic behaviors, potentially affecting the system's ability to rapidly and accurately manipulate magnetic fields. Advanced modeling and control algorithms may be necessary to maintain performance at larger scales.

Energy efficiency considerations become more prominent as systems scale up. Optimizing the power consumption of electromagnets and cooling systems while maintaining desired magnetic field characteristics is crucial for the economic viability of large-scale implementations. This may involve developing more efficient magnetic field generation techniques or improving the thermal management of ferrofluid-based systems.

Maintenance and longevity of scaled-up systems also require attention. Developing strategies for in-situ ferrofluid replenishment or replacement, as well as designing components for easy maintenance and repair, will be essential for long-term operational reliability. Additionally, ensuring the chemical stability of ferrofluids over extended periods in various environmental conditions is crucial for sustained performance.

As ferrofluid-based magnetic field control systems grow in size and complexity, safety considerations become increasingly important. Implementing robust containment measures, fail-safe mechanisms, and emergency shutdown procedures is critical, especially in applications where large volumes of ferrofluid are used.

Finally, the integration of these systems with emerging technologies such as IoT and AI presents opportunities for enhanced performance and new applications. Developing smart, self-optimizing ferrofluid-based systems that can adapt to changing conditions and requirements could significantly expand their utility across various industries.

Firstly, the production and quality control of ferrofluids at larger scales require careful attention. Maintaining consistent magnetic properties and stability across larger volumes of ferrofluid is crucial for reliable system performance. This may involve developing new synthesis methods or refining existing processes to ensure uniformity and reproducibility.

Integration with existing infrastructure and equipment is another critical aspect. Ferrofluid-based systems must be designed to seamlessly interface with current magnetic field generation and control technologies. This includes compatibility with power supplies, sensors, and control software. Standardization of components and interfaces will be essential for facilitating broader adoption across different industries.

The scalability of magnetic field control precision and response time as system size increases is a significant technical challenge. Larger volumes of ferrofluid may exhibit different dynamic behaviors, potentially affecting the system's ability to rapidly and accurately manipulate magnetic fields. Advanced modeling and control algorithms may be necessary to maintain performance at larger scales.

Energy efficiency considerations become more prominent as systems scale up. Optimizing the power consumption of electromagnets and cooling systems while maintaining desired magnetic field characteristics is crucial for the economic viability of large-scale implementations. This may involve developing more efficient magnetic field generation techniques or improving the thermal management of ferrofluid-based systems.

Maintenance and longevity of scaled-up systems also require attention. Developing strategies for in-situ ferrofluid replenishment or replacement, as well as designing components for easy maintenance and repair, will be essential for long-term operational reliability. Additionally, ensuring the chemical stability of ferrofluids over extended periods in various environmental conditions is crucial for sustained performance.

As ferrofluid-based magnetic field control systems grow in size and complexity, safety considerations become increasingly important. Implementing robust containment measures, fail-safe mechanisms, and emergency shutdown procedures is critical, especially in applications where large volumes of ferrofluid are used.

Finally, the integration of these systems with emerging technologies such as IoT and AI presents opportunities for enhanced performance and new applications. Developing smart, self-optimizing ferrofluid-based systems that can adapt to changing conditions and requirements could significantly expand their utility across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!