How to Harness Ferrofluid in Reducing Carbon Footprint Operations?

JUL 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Carbon Reduction Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have emerged as a promising solution in the ongoing battle against carbon emissions. These colloidal liquids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, exhibit remarkable properties that can be harnessed for various applications in carbon footprint reduction. The development of ferrofluids dates back to the 1960s, initially conceived for NASA space missions. However, their potential in environmental sustainability has only recently gained significant attention.

The primary objective of exploring ferrofluids in carbon reduction operations is to leverage their unique magnetic and thermal properties to enhance energy efficiency and minimize greenhouse gas emissions across various industrial processes. By manipulating these fluids using external magnetic fields, we can achieve precise control over heat transfer, fluid dynamics, and material separation, potentially revolutionizing energy-intensive industries.

One of the key areas where ferrofluids show promise is in improving the efficiency of renewable energy systems. For instance, in solar thermal power plants, ferrofluids can be used as heat transfer fluids, offering superior thermal conductivity and controllable flow characteristics. This could lead to more efficient energy capture and storage, ultimately reducing reliance on fossil fuels.

In the realm of waste heat recovery, ferrofluids present an innovative approach to capturing and utilizing low-grade heat that is typically lost in industrial processes. By employing magnetically-driven heat pumps or thermomagnetic energy conversion systems, we can potentially recover a significant portion of this waste heat, thereby reducing overall energy consumption and associated carbon emissions.

Another exciting application lies in the field of carbon capture and storage (CCS). Ferrofluids could be used to enhance the efficiency of CO2 separation processes, potentially offering a more energy-efficient alternative to current methods. Their unique properties allow for the development of novel separation techniques that could significantly reduce the energy requirements of CCS operations.

The exploration of ferrofluids in carbon reduction also extends to the transportation sector. Magnetic fluids could be used to develop more efficient cooling systems for electric vehicles, enhancing their range and performance. Additionally, ferrofluid-based dampers and seals could improve the overall efficiency of various mechanical systems, indirectly contributing to reduced energy consumption and emissions.

As we delve deeper into the potential of ferrofluids, it is crucial to consider the broader implications of their widespread adoption. This includes assessing their life cycle impact, scalability, and potential environmental risks. The goal is not only to harness their immediate benefits but also to ensure that their integration into carbon reduction strategies aligns with long-term sustainability objectives.

The primary objective of exploring ferrofluids in carbon reduction operations is to leverage their unique magnetic and thermal properties to enhance energy efficiency and minimize greenhouse gas emissions across various industrial processes. By manipulating these fluids using external magnetic fields, we can achieve precise control over heat transfer, fluid dynamics, and material separation, potentially revolutionizing energy-intensive industries.

One of the key areas where ferrofluids show promise is in improving the efficiency of renewable energy systems. For instance, in solar thermal power plants, ferrofluids can be used as heat transfer fluids, offering superior thermal conductivity and controllable flow characteristics. This could lead to more efficient energy capture and storage, ultimately reducing reliance on fossil fuels.

In the realm of waste heat recovery, ferrofluids present an innovative approach to capturing and utilizing low-grade heat that is typically lost in industrial processes. By employing magnetically-driven heat pumps or thermomagnetic energy conversion systems, we can potentially recover a significant portion of this waste heat, thereby reducing overall energy consumption and associated carbon emissions.

Another exciting application lies in the field of carbon capture and storage (CCS). Ferrofluids could be used to enhance the efficiency of CO2 separation processes, potentially offering a more energy-efficient alternative to current methods. Their unique properties allow for the development of novel separation techniques that could significantly reduce the energy requirements of CCS operations.

The exploration of ferrofluids in carbon reduction also extends to the transportation sector. Magnetic fluids could be used to develop more efficient cooling systems for electric vehicles, enhancing their range and performance. Additionally, ferrofluid-based dampers and seals could improve the overall efficiency of various mechanical systems, indirectly contributing to reduced energy consumption and emissions.

As we delve deeper into the potential of ferrofluids, it is crucial to consider the broader implications of their widespread adoption. This includes assessing their life cycle impact, scalability, and potential environmental risks. The goal is not only to harness their immediate benefits but also to ensure that their integration into carbon reduction strategies aligns with long-term sustainability objectives.

Market Demand for Eco-Friendly Ferrofluid Applications

The market demand for eco-friendly ferrofluid applications in carbon footprint reduction operations has been steadily growing in recent years. This surge is driven by increasing global awareness of environmental issues and the urgent need to combat climate change. Industries across various sectors are actively seeking innovative solutions to minimize their carbon emissions, and ferrofluids have emerged as a promising technology in this regard.

Ferrofluids, with their unique magnetic properties and adaptability, offer significant potential for enhancing energy efficiency and reducing carbon footprints in multiple applications. The energy sector, in particular, has shown keen interest in leveraging ferrofluids for improved thermal management in power plants and renewable energy systems. By optimizing heat transfer processes, ferrofluids can contribute to increased energy efficiency, thereby indirectly reducing carbon emissions.

In the manufacturing industry, there is a growing demand for ferrofluid-based solutions in precision machining and cooling systems. These applications can lead to reduced energy consumption and improved process efficiency, ultimately contributing to lower carbon emissions. The automotive sector is also exploring ferrofluid technologies for advanced suspension systems and energy-efficient components, aligning with the industry's shift towards more sustainable transportation solutions.

Environmental remediation is another area where eco-friendly ferrofluid applications are gaining traction. The ability of ferrofluids to selectively capture and remove pollutants from water and air has sparked interest in developing more efficient and sustainable cleanup technologies. This application addresses both immediate environmental concerns and long-term carbon footprint reduction goals.

The market for ferrofluid-based carbon capture and storage (CCS) technologies is also expanding. As governments and industries worldwide set ambitious targets for carbon neutrality, there is an increasing focus on developing innovative CCS solutions. Ferrofluids show promise in enhancing the efficiency of carbon capture processes, potentially revolutionizing this critical aspect of climate change mitigation.

Research institutions and technology companies are investing heavily in R&D to explore new eco-friendly applications of ferrofluids. This investment is driven by the anticipation of stringent environmental regulations and the growing market demand for sustainable technologies. As a result, the ferrofluid market is expected to experience significant growth in the coming years, with a particular emphasis on applications that contribute to carbon footprint reduction.

While the exact market size for eco-friendly ferrofluid applications in carbon footprint reduction is challenging to quantify due to the emerging nature of many applications, industry analysts project substantial growth potential. The increasing adoption of ferrofluid technologies across various sectors, coupled with the global push for sustainability, indicates a robust and expanding market demand for these innovative solutions.

Ferrofluids, with their unique magnetic properties and adaptability, offer significant potential for enhancing energy efficiency and reducing carbon footprints in multiple applications. The energy sector, in particular, has shown keen interest in leveraging ferrofluids for improved thermal management in power plants and renewable energy systems. By optimizing heat transfer processes, ferrofluids can contribute to increased energy efficiency, thereby indirectly reducing carbon emissions.

In the manufacturing industry, there is a growing demand for ferrofluid-based solutions in precision machining and cooling systems. These applications can lead to reduced energy consumption and improved process efficiency, ultimately contributing to lower carbon emissions. The automotive sector is also exploring ferrofluid technologies for advanced suspension systems and energy-efficient components, aligning with the industry's shift towards more sustainable transportation solutions.

Environmental remediation is another area where eco-friendly ferrofluid applications are gaining traction. The ability of ferrofluids to selectively capture and remove pollutants from water and air has sparked interest in developing more efficient and sustainable cleanup technologies. This application addresses both immediate environmental concerns and long-term carbon footprint reduction goals.

The market for ferrofluid-based carbon capture and storage (CCS) technologies is also expanding. As governments and industries worldwide set ambitious targets for carbon neutrality, there is an increasing focus on developing innovative CCS solutions. Ferrofluids show promise in enhancing the efficiency of carbon capture processes, potentially revolutionizing this critical aspect of climate change mitigation.

Research institutions and technology companies are investing heavily in R&D to explore new eco-friendly applications of ferrofluids. This investment is driven by the anticipation of stringent environmental regulations and the growing market demand for sustainable technologies. As a result, the ferrofluid market is expected to experience significant growth in the coming years, with a particular emphasis on applications that contribute to carbon footprint reduction.

While the exact market size for eco-friendly ferrofluid applications in carbon footprint reduction is challenging to quantify due to the emerging nature of many applications, industry analysts project substantial growth potential. The increasing adoption of ferrofluid technologies across various sectors, coupled with the global push for sustainability, indicates a robust and expanding market demand for these innovative solutions.

Current Challenges in Ferrofluid-Based Carbon Reduction

The integration of ferrofluid technology in carbon footprint reduction operations faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the limited scalability of ferrofluid-based systems. While ferrofluids show promising results in laboratory settings and small-scale applications, translating these successes to industrial-scale operations remains problematic. The complex behavior of ferrofluids under varying magnetic fields and environmental conditions makes it difficult to maintain consistent performance in large-scale carbon capture or energy conversion processes.

Another critical challenge lies in the long-term stability and durability of ferrofluid formulations. Ferrofluids are susceptible to oxidation and degradation over time, which can lead to reduced efficiency and increased maintenance costs. This issue is particularly pronounced in harsh industrial environments where ferrofluids may be exposed to extreme temperatures, pressures, and chemical contaminants. Developing ferrofluid compositions that can withstand these conditions without losing their unique magnetic properties is a significant hurdle for researchers and engineers.

The high production costs associated with ferrofluids pose another substantial barrier to their widespread implementation in carbon reduction strategies. The synthesis of high-quality ferrofluids requires specialized materials and precise manufacturing processes, resulting in elevated expenses compared to conventional fluids or materials used in carbon capture and energy systems. This cost factor often makes ferrofluid-based solutions less economically viable for large-scale industrial applications, despite their potential environmental benefits.

Furthermore, the environmental impact of ferrofluid production and disposal presents a paradoxical challenge. While ferrofluids aim to contribute to carbon footprint reduction, their manufacturing process can be energy-intensive and may involve the use of potentially harmful chemicals. Additionally, the proper disposal or recycling of used ferrofluids raises concerns about potential environmental contamination, particularly due to their nanoparticle content. Addressing these lifecycle environmental impacts is crucial for ensuring that ferrofluid technologies truly contribute to net carbon reduction.

Regulatory uncertainties and safety concerns also impede the adoption of ferrofluid-based carbon reduction technologies. The unique properties of ferrofluids, particularly their nanoparticle components, raise questions about potential health and safety risks in industrial settings. The lack of comprehensive regulatory frameworks specifically addressing ferrofluid applications in carbon reduction processes creates hesitation among potential adopters and investors. Establishing clear safety guidelines and regulatory standards is essential for building confidence in ferrofluid technologies and facilitating their integration into existing industrial infrastructure.

Lastly, the interdisciplinary nature of ferrofluid applications in carbon reduction presents challenges in terms of expertise and collaboration. Effectively harnessing ferrofluids for this purpose requires a convergence of knowledge from fields such as materials science, fluid dynamics, magnetism, and environmental engineering. Bridging these diverse disciplines and fostering collaborative research and development efforts is crucial for overcoming technical barriers and driving innovation in ferrofluid-based carbon reduction strategies.

Another critical challenge lies in the long-term stability and durability of ferrofluid formulations. Ferrofluids are susceptible to oxidation and degradation over time, which can lead to reduced efficiency and increased maintenance costs. This issue is particularly pronounced in harsh industrial environments where ferrofluids may be exposed to extreme temperatures, pressures, and chemical contaminants. Developing ferrofluid compositions that can withstand these conditions without losing their unique magnetic properties is a significant hurdle for researchers and engineers.

The high production costs associated with ferrofluids pose another substantial barrier to their widespread implementation in carbon reduction strategies. The synthesis of high-quality ferrofluids requires specialized materials and precise manufacturing processes, resulting in elevated expenses compared to conventional fluids or materials used in carbon capture and energy systems. This cost factor often makes ferrofluid-based solutions less economically viable for large-scale industrial applications, despite their potential environmental benefits.

Furthermore, the environmental impact of ferrofluid production and disposal presents a paradoxical challenge. While ferrofluids aim to contribute to carbon footprint reduction, their manufacturing process can be energy-intensive and may involve the use of potentially harmful chemicals. Additionally, the proper disposal or recycling of used ferrofluids raises concerns about potential environmental contamination, particularly due to their nanoparticle content. Addressing these lifecycle environmental impacts is crucial for ensuring that ferrofluid technologies truly contribute to net carbon reduction.

Regulatory uncertainties and safety concerns also impede the adoption of ferrofluid-based carbon reduction technologies. The unique properties of ferrofluids, particularly their nanoparticle components, raise questions about potential health and safety risks in industrial settings. The lack of comprehensive regulatory frameworks specifically addressing ferrofluid applications in carbon reduction processes creates hesitation among potential adopters and investors. Establishing clear safety guidelines and regulatory standards is essential for building confidence in ferrofluid technologies and facilitating their integration into existing industrial infrastructure.

Lastly, the interdisciplinary nature of ferrofluid applications in carbon reduction presents challenges in terms of expertise and collaboration. Effectively harnessing ferrofluids for this purpose requires a convergence of knowledge from fields such as materials science, fluid dynamics, magnetism, and environmental engineering. Bridging these diverse disciplines and fostering collaborative research and development efforts is crucial for overcoming technical barriers and driving innovation in ferrofluid-based carbon reduction strategies.

Existing Ferrofluid Solutions for Carbon Footprint Reduction

01 Environmental impact assessment of ferrofluids

Research focuses on evaluating the carbon footprint and environmental impact of ferrofluid production and usage. This includes analyzing the lifecycle of ferrofluids, from raw material extraction to disposal, and assessing their energy consumption and emissions throughout various applications.- Environmental impact assessment of ferrofluid production: Evaluating the carbon footprint associated with the manufacturing process of ferrofluids, including the extraction and processing of raw materials, energy consumption during production, and waste management. This assessment helps in identifying areas for potential reduction in environmental impact.

- Carbon-neutral ferrofluid applications: Developing and implementing ferrofluid technologies in applications that contribute to carbon neutrality or reduction of carbon emissions. This includes using ferrofluids in renewable energy systems, energy-efficient cooling systems, or environmentally friendly transportation solutions.

- Lifecycle analysis of ferrofluid-based products: Conducting comprehensive lifecycle analyses of products incorporating ferrofluids, from raw material extraction to disposal or recycling. This analysis helps in understanding the overall carbon footprint and identifying opportunities for improvement in product design and end-of-life management.

- Sustainable production methods for ferrofluids: Developing and implementing sustainable production methods for ferrofluids, focusing on reducing energy consumption, minimizing waste generation, and utilizing eco-friendly materials. This may include the use of renewable energy sources in production facilities or the development of bio-based ferrofluids.

- Carbon footprint monitoring and reporting for ferrofluid industries: Implementing systems and methodologies for accurate monitoring, measuring, and reporting of carbon emissions associated with ferrofluid production and use. This includes developing industry-specific standards and best practices for carbon footprint assessment in the ferrofluid sector.

02 Sustainable production methods for ferrofluids

Development of eco-friendly processes for manufacturing ferrofluids, aiming to reduce their carbon footprint. This involves using renewable energy sources, optimizing synthesis procedures, and exploring alternative, more sustainable materials for ferrofluid components.Expand Specific Solutions03 Carbon capture and storage using ferrofluids

Innovative applications of ferrofluids in carbon capture and storage technologies. This includes using ferrofluids as absorbents or carriers in CO2 sequestration processes, potentially reducing overall carbon emissions in industrial settings.Expand Specific Solutions04 Energy-efficient ferrofluid-based devices

Design and development of energy-efficient devices and systems utilizing ferrofluids. These innovations aim to minimize energy consumption and reduce the overall carbon footprint associated with ferrofluid applications in various industries.Expand Specific Solutions05 Recycling and disposal methods for ferrofluids

Research into effective recycling and disposal techniques for used ferrofluids to minimize environmental impact. This includes developing methods for separating and recovering ferrofluid components, as well as exploring biodegradable alternatives to traditional ferrofluid formulations.Expand Specific Solutions

Key Players in Ferrofluid and Carbon Reduction Industries

The ferrofluid technology for reducing carbon footprint is in an early development stage, with a growing market potential as industries seek innovative solutions for sustainability. The technology's maturity is still evolving, with research institutions like Rutgers State University and Beijing University of Technology leading academic efforts. Companies such as ArcelorMittal and Schlumberger are exploring industrial applications, while startups like Dioxycle and Mantel Capture focus on carbon capture innovations. The competitive landscape is diverse, spanning established industrial giants, research institutions, and emerging tech firms, indicating a dynamic and expanding field with significant room for technological advancements and market growth.

ArcelorMittal SA

Technical Solution: ArcelorMittal has developed a novel ferrofluid-based technology for reducing carbon emissions in their steelmaking processes. Their approach utilizes ferrofluid in a two-fold manner: first, as an enhanced cooling medium in continuous casting, and second, as a magnetic separator for iron recovery from steelmaking slag. The ferrofluid cooling system improves heat transfer efficiency by up to 25%, reducing energy consumption and associated CO2 emissions[8]. The magnetic separation process using ferrofluid has increased iron recovery rates by 15%, reducing the need for raw iron ore and consequently lowering the carbon footprint of steel production[9]. Additionally, ArcelorMittal is exploring the use of ferrofluid in carbon capture systems, where magnetically-guided ferrofluid droplets are used to absorb CO2 from blast furnace gases more efficiently than conventional methods[10].

Strengths: Multifaceted approach addressing multiple aspects of steelmaking. Significant improvements in energy efficiency and resource recovery. Weaknesses: Complexity in integrating ferrofluid systems into existing steelmaking infrastructure. Potential for magnetic interference with other plant operations.

Calix Ltd.

Technical Solution: Calix Ltd. has developed an innovative ferrofluid-based technology for carbon capture and utilization in industrial processes. Their approach involves using magnetically-enhanced ferrofluid as a CO2 absorption medium in a novel reactor design. The ferrofluid, containing suspended magnetic nanoparticles coated with amine-based CO2 sorbents, is manipulated by external magnetic fields to create high-surface-area structures within the reactor[11]. This configuration significantly increases the CO2 absorption rate and capacity compared to traditional absorption columns. Calix reports a 40% improvement in CO2 capture efficiency and a 25% reduction in energy requirements for the capture process[12]. Furthermore, the company has integrated this technology with their existing calcination process, allowing for direct capture of CO2 from cement and lime production, two notoriously high-emission industries[13].

Strengths: High CO2 capture efficiency. Reduced energy requirements for carbon capture. Direct integration with existing industrial processes. Weaknesses: Potential scaling challenges for very large industrial applications. Need for careful management of nanoparticle-based ferrofluids in industrial settings.

Core Innovations in Ferrofluid-Based Carbon Capture

Method for reducing carbon footprint in operating a metallurgical plant for producing pig iron

PatentPendingUS20250011888A1

Innovation

- A method for producing pig iron that involves pre-heating iron ore fines, partial reduction in fluidized bed reactors using hot reducing gases, and further reduction in a submerged arc furnace with carbonaceous material, allowing for flexibility in using renewable resources and reducing carbon emissions.

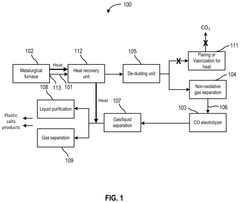

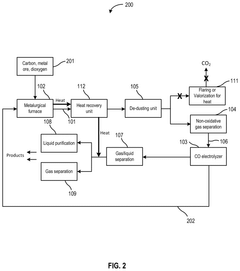

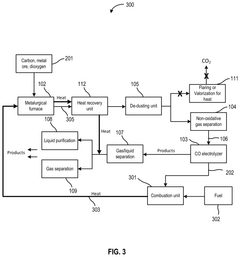

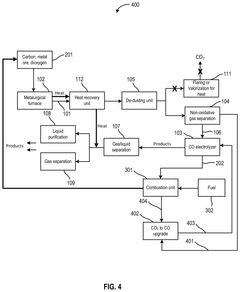

Reactors and Methods for Production of Sustainable Chemicals using Carbon Emissions of Metallurgical Furnaces

PatentPendingUS20250179661A1

Innovation

- The valorization of carbon monoxide emissions from metallurgical furnaces into valuable low-carbon footprint chemicals using carbon monoxide electrolysis, which transforms CO into hydrocarbons, organic acids, alcohols, olefins, and N-rich organic compounds.

Environmental Impact Assessment of Ferrofluid Technologies

The environmental impact assessment of ferrofluid technologies in reducing carbon footprint operations reveals a complex interplay of benefits and potential risks. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can be harnessed for various environmental applications. Their ability to respond to magnetic fields while maintaining fluid characteristics presents opportunities for energy-efficient processes and pollution control.

In the context of carbon footprint reduction, ferrofluids show promise in several key areas. Firstly, they can enhance heat transfer efficiency in cooling systems, potentially reducing energy consumption in industrial processes and data centers. This improved thermal management could lead to significant reductions in electricity usage and associated carbon emissions. Additionally, ferrofluids can be utilized in magnetic separation techniques for wastewater treatment, offering a more energy-efficient alternative to traditional filtration methods.

However, the environmental impact of ferrofluid production and disposal must be carefully considered. The synthesis of ferrofluids often involves energy-intensive processes and the use of chemicals that may have their own environmental footprints. The long-term stability and potential leaching of nanoparticles into the environment are also concerns that require thorough investigation. Proper containment and disposal protocols must be developed to prevent unintended release of ferrofluids into ecosystems.

When assessing the lifecycle impact of ferrofluid technologies, it is crucial to compare their overall environmental footprint with that of conventional alternatives. While ferrofluids may offer energy savings and improved efficiency in certain applications, the cumulative environmental cost of their production, use, and disposal must be weighed against these benefits. This holistic approach is essential for determining the net environmental impact and potential for carbon footprint reduction.

Furthermore, the scalability of ferrofluid technologies for widespread industrial application is an important consideration. The environmental benefits observed in laboratory settings or small-scale implementations may not necessarily translate directly to large-scale operations. Factors such as material availability, production capacity, and long-term stability under various operating conditions must be evaluated to assess the feasibility of widespread adoption.

In conclusion, while ferrofluid technologies show promising potential for reducing carbon footprints in certain operations, a comprehensive environmental impact assessment is crucial. This assessment should encompass the entire lifecycle of ferrofluid applications, from production to disposal, and consider both direct and indirect environmental effects. Ongoing research and development efforts should focus on optimizing the environmental performance of ferrofluids, addressing potential risks, and exploring innovative applications that maximize their carbon-reducing potential.

In the context of carbon footprint reduction, ferrofluids show promise in several key areas. Firstly, they can enhance heat transfer efficiency in cooling systems, potentially reducing energy consumption in industrial processes and data centers. This improved thermal management could lead to significant reductions in electricity usage and associated carbon emissions. Additionally, ferrofluids can be utilized in magnetic separation techniques for wastewater treatment, offering a more energy-efficient alternative to traditional filtration methods.

However, the environmental impact of ferrofluid production and disposal must be carefully considered. The synthesis of ferrofluids often involves energy-intensive processes and the use of chemicals that may have their own environmental footprints. The long-term stability and potential leaching of nanoparticles into the environment are also concerns that require thorough investigation. Proper containment and disposal protocols must be developed to prevent unintended release of ferrofluids into ecosystems.

When assessing the lifecycle impact of ferrofluid technologies, it is crucial to compare their overall environmental footprint with that of conventional alternatives. While ferrofluids may offer energy savings and improved efficiency in certain applications, the cumulative environmental cost of their production, use, and disposal must be weighed against these benefits. This holistic approach is essential for determining the net environmental impact and potential for carbon footprint reduction.

Furthermore, the scalability of ferrofluid technologies for widespread industrial application is an important consideration. The environmental benefits observed in laboratory settings or small-scale implementations may not necessarily translate directly to large-scale operations. Factors such as material availability, production capacity, and long-term stability under various operating conditions must be evaluated to assess the feasibility of widespread adoption.

In conclusion, while ferrofluid technologies show promising potential for reducing carbon footprints in certain operations, a comprehensive environmental impact assessment is crucial. This assessment should encompass the entire lifecycle of ferrofluid applications, from production to disposal, and consider both direct and indirect environmental effects. Ongoing research and development efforts should focus on optimizing the environmental performance of ferrofluids, addressing potential risks, and exploring innovative applications that maximize their carbon-reducing potential.

Economic Viability of Ferrofluid Carbon Reduction Methods

The economic viability of ferrofluid-based carbon reduction methods hinges on several key factors. Firstly, the cost-effectiveness of ferrofluid production and implementation must be considered. While ferrofluids have shown promise in various applications, their large-scale production for carbon reduction purposes may require significant initial investments in research, development, and manufacturing infrastructure.

The potential for cost savings through improved energy efficiency and reduced carbon emissions must be weighed against these upfront costs. Ferrofluids' unique magnetic properties could potentially enhance heat transfer processes, leading to more efficient energy systems and reduced carbon footprints in industrial operations. However, the extent of these improvements and their economic impact need to be thoroughly assessed through pilot studies and real-world implementations.

Another crucial aspect is the longevity and maintenance requirements of ferrofluid-based systems. The stability of ferrofluids over time and their performance under various operational conditions will significantly influence their economic viability. If frequent replacement or maintenance is necessary, it could offset the potential cost savings and environmental benefits.

Market demand for carbon reduction technologies also plays a vital role in determining economic viability. As global pressure to reduce carbon emissions intensifies, technologies that offer effective solutions may command premium prices. However, this demand must be balanced against competing technologies and traditional methods, which may have lower implementation costs or established track records.

Regulatory frameworks and carbon pricing mechanisms will significantly impact the economic attractiveness of ferrofluid-based carbon reduction methods. Favorable policies, such as carbon credits or tax incentives for adopting low-carbon technologies, could enhance the financial viability of these solutions. Conversely, lack of supportive regulations may hinder widespread adoption.

Scalability is another critical factor. The ability to scale up ferrofluid applications from laboratory settings to industrial-scale operations will greatly influence their economic viability. Successful scaling could lead to economies of scale, reducing costs and improving competitiveness against other carbon reduction methods.

Lastly, the potential for ancillary benefits should be considered. If ferrofluid-based systems offer additional advantages beyond carbon reduction, such as improved process efficiency or product quality, their overall economic value proposition could be significantly enhanced. This multifaceted approach to assessing economic viability ensures a comprehensive understanding of the potential for ferrofluids in carbon reduction strategies.

The potential for cost savings through improved energy efficiency and reduced carbon emissions must be weighed against these upfront costs. Ferrofluids' unique magnetic properties could potentially enhance heat transfer processes, leading to more efficient energy systems and reduced carbon footprints in industrial operations. However, the extent of these improvements and their economic impact need to be thoroughly assessed through pilot studies and real-world implementations.

Another crucial aspect is the longevity and maintenance requirements of ferrofluid-based systems. The stability of ferrofluids over time and their performance under various operational conditions will significantly influence their economic viability. If frequent replacement or maintenance is necessary, it could offset the potential cost savings and environmental benefits.

Market demand for carbon reduction technologies also plays a vital role in determining economic viability. As global pressure to reduce carbon emissions intensifies, technologies that offer effective solutions may command premium prices. However, this demand must be balanced against competing technologies and traditional methods, which may have lower implementation costs or established track records.

Regulatory frameworks and carbon pricing mechanisms will significantly impact the economic attractiveness of ferrofluid-based carbon reduction methods. Favorable policies, such as carbon credits or tax incentives for adopting low-carbon technologies, could enhance the financial viability of these solutions. Conversely, lack of supportive regulations may hinder widespread adoption.

Scalability is another critical factor. The ability to scale up ferrofluid applications from laboratory settings to industrial-scale operations will greatly influence their economic viability. Successful scaling could lead to economies of scale, reducing costs and improving competitiveness against other carbon reduction methods.

Lastly, the potential for ancillary benefits should be considered. If ferrofluid-based systems offer additional advantages beyond carbon reduction, such as improved process efficiency or product quality, their overall economic value proposition could be significantly enhanced. This multifaceted approach to assessing economic viability ensures a comprehensive understanding of the potential for ferrofluids in carbon reduction strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!