Exploring Flame Retardant Properties of Polypropylene

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flame Retardancy in PP: Background and Objectives

Polypropylene (PP) has been widely used in various industries due to its excellent mechanical properties, low cost, and versatility. However, its inherent flammability poses significant safety concerns, particularly in applications where fire resistance is crucial. The exploration of flame retardant properties in polypropylene has become a critical area of research and development in recent years, driven by the increasing demand for safer materials in construction, automotive, and consumer goods sectors.

The evolution of flame retardancy in polypropylene can be traced back to the 1960s when the first attempts to improve its fire resistance were made. Initially, halogenated compounds were widely used as flame retardants, but environmental and health concerns led to a shift towards more sustainable alternatives. This transition marked the beginning of a new era in flame retardant technology for polypropylene, focusing on developing eco-friendly and efficient solutions.

Over the past decades, the field has witnessed significant advancements in understanding the mechanisms of flame retardancy and developing novel flame retardant systems. The primary goal has been to enhance the fire resistance of polypropylene without compromising its desirable physical and mechanical properties. This challenge has driven researchers and industry professionals to explore various approaches, including the use of intumescent systems, nanocomposites, and synergistic combinations of different flame retardants.

The technological objectives in this field are multifaceted. Firstly, there is a continuous effort to improve the effectiveness of flame retardants in reducing the flammability and heat release rate of polypropylene. Secondly, researchers aim to develop flame retardant systems that can maintain the material's mechanical properties and processability. Thirdly, there is a growing emphasis on creating environmentally friendly and non-toxic flame retardant solutions to meet stringent regulatory requirements and consumer demands for safer products.

Recent trends in flame retardancy for polypropylene include the development of synergistic systems that combine multiple flame retardant mechanisms, the exploration of bio-based flame retardants, and the integration of nanotechnology to enhance flame retardant properties. These advancements are driven by the need for more efficient, sustainable, and cost-effective solutions to address the flammability issues of polypropylene across various applications.

As we look towards the future, the field of flame retardancy in polypropylene continues to evolve, with emerging technologies and innovative approaches promising to revolutionize fire safety in polymer materials. The ongoing research and development efforts in this area are expected to lead to new breakthroughs, further enhancing the fire resistance of polypropylene and expanding its applications in high-performance and safety-critical environments.

The evolution of flame retardancy in polypropylene can be traced back to the 1960s when the first attempts to improve its fire resistance were made. Initially, halogenated compounds were widely used as flame retardants, but environmental and health concerns led to a shift towards more sustainable alternatives. This transition marked the beginning of a new era in flame retardant technology for polypropylene, focusing on developing eco-friendly and efficient solutions.

Over the past decades, the field has witnessed significant advancements in understanding the mechanisms of flame retardancy and developing novel flame retardant systems. The primary goal has been to enhance the fire resistance of polypropylene without compromising its desirable physical and mechanical properties. This challenge has driven researchers and industry professionals to explore various approaches, including the use of intumescent systems, nanocomposites, and synergistic combinations of different flame retardants.

The technological objectives in this field are multifaceted. Firstly, there is a continuous effort to improve the effectiveness of flame retardants in reducing the flammability and heat release rate of polypropylene. Secondly, researchers aim to develop flame retardant systems that can maintain the material's mechanical properties and processability. Thirdly, there is a growing emphasis on creating environmentally friendly and non-toxic flame retardant solutions to meet stringent regulatory requirements and consumer demands for safer products.

Recent trends in flame retardancy for polypropylene include the development of synergistic systems that combine multiple flame retardant mechanisms, the exploration of bio-based flame retardants, and the integration of nanotechnology to enhance flame retardant properties. These advancements are driven by the need for more efficient, sustainable, and cost-effective solutions to address the flammability issues of polypropylene across various applications.

As we look towards the future, the field of flame retardancy in polypropylene continues to evolve, with emerging technologies and innovative approaches promising to revolutionize fire safety in polymer materials. The ongoing research and development efforts in this area are expected to lead to new breakthroughs, further enhancing the fire resistance of polypropylene and expanding its applications in high-performance and safety-critical environments.

Market Analysis for FR Polypropylene

The global market for flame retardant (FR) polypropylene has been experiencing significant growth in recent years, driven by increasing safety regulations and growing awareness of fire hazards across various industries. The demand for FR polypropylene is particularly strong in sectors such as automotive, electronics, construction, and textiles, where fire safety is a critical concern.

In the automotive industry, FR polypropylene is widely used in interior components, such as dashboards, door panels, and seat covers. The stringent fire safety standards in this sector, coupled with the trend towards lightweight materials, have been key drivers for market growth. The electronics industry also represents a substantial market for FR polypropylene, with applications in housings for consumer electronics, appliances, and electrical components.

The construction sector is another major consumer of FR polypropylene, particularly in insulation materials, roofing membranes, and pipes. The increasing focus on energy-efficient buildings and sustainable construction practices has further boosted the demand for FR polypropylene in this sector. In the textile industry, FR polypropylene finds applications in protective clothing, upholstery, and carpets, driven by workplace safety regulations and consumer awareness.

Geographically, North America and Europe have been the leading markets for FR polypropylene, owing to strict fire safety regulations and high adoption rates in key industries. However, the Asia-Pacific region is emerging as the fastest-growing market, fueled by rapid industrialization, urbanization, and increasing safety standards in countries like China and India.

The market for FR polypropylene is characterized by intense competition among key players, including major chemical companies and specialty polymer manufacturers. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of FR polypropylene formulations. Innovation in halogen-free flame retardants and the development of synergistic combinations of flame retardants are some of the key trends shaping the market landscape.

Despite the positive growth outlook, the FR polypropylene market faces challenges such as the higher cost compared to standard polypropylene and concerns about the environmental impact of certain flame retardant additives. However, ongoing research into more sustainable and eco-friendly flame retardant solutions is expected to address these concerns and further drive market growth in the coming years.

In the automotive industry, FR polypropylene is widely used in interior components, such as dashboards, door panels, and seat covers. The stringent fire safety standards in this sector, coupled with the trend towards lightweight materials, have been key drivers for market growth. The electronics industry also represents a substantial market for FR polypropylene, with applications in housings for consumer electronics, appliances, and electrical components.

The construction sector is another major consumer of FR polypropylene, particularly in insulation materials, roofing membranes, and pipes. The increasing focus on energy-efficient buildings and sustainable construction practices has further boosted the demand for FR polypropylene in this sector. In the textile industry, FR polypropylene finds applications in protective clothing, upholstery, and carpets, driven by workplace safety regulations and consumer awareness.

Geographically, North America and Europe have been the leading markets for FR polypropylene, owing to strict fire safety regulations and high adoption rates in key industries. However, the Asia-Pacific region is emerging as the fastest-growing market, fueled by rapid industrialization, urbanization, and increasing safety standards in countries like China and India.

The market for FR polypropylene is characterized by intense competition among key players, including major chemical companies and specialty polymer manufacturers. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of FR polypropylene formulations. Innovation in halogen-free flame retardants and the development of synergistic combinations of flame retardants are some of the key trends shaping the market landscape.

Despite the positive growth outlook, the FR polypropylene market faces challenges such as the higher cost compared to standard polypropylene and concerns about the environmental impact of certain flame retardant additives. However, ongoing research into more sustainable and eco-friendly flame retardant solutions is expected to address these concerns and further drive market growth in the coming years.

Current FR-PP Technologies and Challenges

Flame retardant polypropylene (FR-PP) has become increasingly important in various industries due to its enhanced safety properties. Current FR-PP technologies primarily focus on incorporating flame retardant additives into the polymer matrix. The most common additives include halogenated compounds, phosphorus-based additives, and inorganic fillers.

Halogenated flame retardants, such as brominated compounds, have been widely used due to their effectiveness. However, environmental and health concerns have led to a shift towards more sustainable alternatives. Phosphorus-based flame retardants, including ammonium polyphosphate and organophosphorus compounds, have gained popularity as they offer good flame retardancy with reduced environmental impact.

Inorganic fillers, such as aluminum hydroxide and magnesium hydroxide, are also extensively used in FR-PP formulations. These fillers work by releasing water vapor during combustion, which dilutes flammable gases and creates a protective char layer. However, high loading levels are often required, which can negatively impact the mechanical properties of the polymer.

One of the main challenges in FR-PP technology is achieving an optimal balance between flame retardancy and mechanical properties. High loadings of flame retardant additives can lead to decreased tensile strength, impact resistance, and processability. Researchers are exploring various approaches to address this issue, including the use of nanocomposites and synergistic combinations of different flame retardants.

Another significant challenge is the development of halogen-free flame retardant systems that meet stringent fire safety standards while maintaining cost-effectiveness. This has led to increased research into novel flame retardant additives and surface treatments that can enhance the fire performance of PP without compromising other properties.

The compatibility between flame retardant additives and the PP matrix remains a critical issue. Poor dispersion and weak interfacial adhesion can result in reduced flame retardant efficiency and deteriorated mechanical properties. Efforts are being made to develop compatibilizers and surface treatments to improve the interaction between additives and the polymer matrix.

Regulatory pressures and evolving fire safety standards pose ongoing challenges for FR-PP technologies. As regulations become more stringent, particularly regarding the use of certain halogenated flame retardants, manufacturers must continually adapt their formulations to comply with new requirements while maintaining performance and cost-effectiveness.

The development of sustainable and bio-based flame retardants for PP is an emerging area of research. This approach aims to address environmental concerns associated with traditional flame retardants while potentially offering new mechanisms for fire protection. However, challenges remain in terms of scalability, cost, and achieving comparable performance to conventional flame retardants.

Halogenated flame retardants, such as brominated compounds, have been widely used due to their effectiveness. However, environmental and health concerns have led to a shift towards more sustainable alternatives. Phosphorus-based flame retardants, including ammonium polyphosphate and organophosphorus compounds, have gained popularity as they offer good flame retardancy with reduced environmental impact.

Inorganic fillers, such as aluminum hydroxide and magnesium hydroxide, are also extensively used in FR-PP formulations. These fillers work by releasing water vapor during combustion, which dilutes flammable gases and creates a protective char layer. However, high loading levels are often required, which can negatively impact the mechanical properties of the polymer.

One of the main challenges in FR-PP technology is achieving an optimal balance between flame retardancy and mechanical properties. High loadings of flame retardant additives can lead to decreased tensile strength, impact resistance, and processability. Researchers are exploring various approaches to address this issue, including the use of nanocomposites and synergistic combinations of different flame retardants.

Another significant challenge is the development of halogen-free flame retardant systems that meet stringent fire safety standards while maintaining cost-effectiveness. This has led to increased research into novel flame retardant additives and surface treatments that can enhance the fire performance of PP without compromising other properties.

The compatibility between flame retardant additives and the PP matrix remains a critical issue. Poor dispersion and weak interfacial adhesion can result in reduced flame retardant efficiency and deteriorated mechanical properties. Efforts are being made to develop compatibilizers and surface treatments to improve the interaction between additives and the polymer matrix.

Regulatory pressures and evolving fire safety standards pose ongoing challenges for FR-PP technologies. As regulations become more stringent, particularly regarding the use of certain halogenated flame retardants, manufacturers must continually adapt their formulations to comply with new requirements while maintaining performance and cost-effectiveness.

The development of sustainable and bio-based flame retardants for PP is an emerging area of research. This approach aims to address environmental concerns associated with traditional flame retardants while potentially offering new mechanisms for fire protection. However, challenges remain in terms of scalability, cost, and achieving comparable performance to conventional flame retardants.

Existing FR Solutions for Polypropylene

01 Halogen-free flame retardant additives

Halogen-free flame retardant additives are increasingly used in polypropylene to improve fire resistance while addressing environmental concerns. These additives often include phosphorus-based compounds, nitrogen-containing substances, or mineral fillers that can effectively enhance the flame retardant properties of polypropylene without the use of halogenated materials.- Halogen-free flame retardant additives: Incorporation of halogen-free flame retardant additives into polypropylene to enhance its flame retardant properties. These additives can include phosphorus-based compounds, nitrogen-based compounds, or mineral-based additives that provide effective flame retardancy without the environmental concerns associated with halogenated flame retardants.

- Nanocomposite flame retardant systems: Development of nanocomposite flame retardant systems for polypropylene, utilizing nanomaterials such as nanoclay, carbon nanotubes, or graphene. These nanocomposites can significantly improve the flame retardant properties of polypropylene while maintaining or enhancing other mechanical and physical properties.

- Intumescent flame retardant formulations: Use of intumescent flame retardant formulations in polypropylene, which form a protective char layer when exposed to heat. These formulations typically consist of an acid source, a carbon source, and a blowing agent, working synergistically to provide effective flame retardancy and reduce heat release rate.

- Synergistic flame retardant combinations: Development of synergistic combinations of flame retardants for polypropylene, where two or more flame retardant additives work together to provide enhanced flame retardancy compared to their individual effects. These combinations can include organic and inorganic flame retardants, or different types of halogen-free flame retardants.

- Surface treatment and coating technologies: Application of surface treatments or coatings to polypropylene to improve its flame retardant properties. These technologies can include plasma treatment, chemical modification of the polymer surface, or the application of flame retardant coatings to create a protective barrier against fire.

02 Intumescent flame retardant systems

Intumescent flame retardant systems for polypropylene involve the use of materials that expand and form a protective char layer when exposed to heat. This approach typically combines acid sources, carbon sources, and blowing agents to create a barrier that insulates the underlying polymer and limits oxygen access, thereby improving the overall flame retardant properties of the material.Expand Specific Solutions03 Nanocomposite-based flame retardants

Incorporating nanoparticles or nanostructured materials into polypropylene can significantly enhance its flame retardant properties. These nanocomposites often include clay minerals, carbon nanotubes, or metal oxide nanoparticles that can improve the thermal stability and reduce the flammability of the polymer matrix, often at lower loading levels compared to conventional flame retardants.Expand Specific Solutions04 Synergistic flame retardant combinations

Combining different types of flame retardants can lead to synergistic effects, enhancing the overall flame retardant properties of polypropylene. These combinations may include mixtures of inorganic and organic flame retardants, or the use of compatibilizers to improve the dispersion and effectiveness of the additives within the polymer matrix.Expand Specific Solutions05 Surface treatment and coating technologies

Surface treatments and coatings can be applied to polypropylene to enhance its flame retardant properties. These methods may involve the application of flame retardant coatings, plasma treatments, or grafting of flame retardant molecules onto the polymer surface, providing an additional layer of protection against fire without significantly altering the bulk properties of the material.Expand Specific Solutions

Key Players in FR-PP Industry

The flame retardant polypropylene market is in a growth phase, driven by increasing safety regulations and demand across industries. The global market size is projected to reach several billion dollars by 2025, with a compound annual growth rate of around 5-7%. Technologically, the field is advancing rapidly, with companies like Borealis AG, SABIC, and ExxonMobil Chemical Patents leading innovation in halogen-free flame retardants and high-performance compounds. Chinese firms such as Kingfa Sci. & Tech. and Polyrocks Chemical are also making significant strides, particularly in eco-friendly solutions. Japanese players like Japan Polypropylene Corp. and Mitsui Chemicals contribute advanced formulations, while research institutions like Zhejiang University of Technology drive fundamental breakthroughs in flame retardant mechanisms and synergistic effects.

Borealis AG

Technical Solution: Borealis AG has developed a range of flame retardant polypropylene solutions under their Fibremod™ and Daploy™ product lines. Their approach focuses on tailoring PP compounds with specific flame retardant additives to meet diverse industry requirements. Borealis has introduced halogen-free flame retardant PP grades that achieve UL94 V-0 ratings at thicknesses as low as 0.8 mm[5]. The company utilizes a proprietary technology called Borstar® to create bimodal PP with enhanced processability and mechanical properties. This allows for better incorporation of flame retardant additives without significantly compromising the material's performance. Borealis has also developed flame retardant PP grades with improved electrical properties, such as a Comparative Tracking Index (CTI) of 600 volts, making them suitable for demanding electrical and electronic applications[6].

Strengths: Halogen-free solutions, thin-wall flame retardancy, and improved electrical properties. Weaknesses: Potential for higher costs associated with specialized PP grades and additives.

SABIC Global Technologies BV

Technical Solution: SABIC has developed innovative flame retardant polypropylene (PP) solutions, focusing on halogen-free formulations. Their approach involves incorporating intumescent flame retardant additives into PP, which form a protective char layer when exposed to fire. This technology, known as SABIC PP-UMS (Ultra Melt Strength), combines high melt strength with excellent flame retardancy[1]. The company has also introduced nano-sized flame retardant additives, which improve dispersion and enhance overall performance. SABIC's flame retardant PP grades meet stringent safety standards such as UL94 V-0 and achieve a limiting oxygen index (LOI) of over 30%[2], making them suitable for various applications including automotive, electronics, and construction.

Strengths: Halogen-free formulations, high melt strength, excellent flame retardancy, and compliance with safety standards. Weaknesses: Potential for increased cost due to specialized additives and possible impact on mechanical properties of PP.

Innovative FR Mechanisms for PP

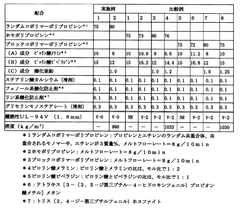

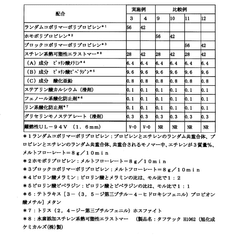

Flame retardant polypropylene composition

PatentInactiveUS6150442A

Innovation

- A flame retardant polypropylene composition comprising a homopolymer or copolymer of polypropylene, a styrene butadiene compatibilizer, a bromine-containing flame retardant additive, and a metallocene ethylene copolymer, specifically tris(tribromoneopentyl) phosphate, which exhibits no bloom and excellent moldability and color development properties.

Flame-retardant polypropylene composition

PatentWO2016125591A1

Innovation

- A lightweight flame-retardant polypropylene composition incorporating a random copolymer polypropylene, melamine and piperazine salts, and zinc oxide, along with a styrene-based thermoplastic elastomer, to achieve excellent flame retardancy without sacrificing physical properties, using a formulation that meets the UL-94V standard.

Environmental Impact of FR-PP

The environmental impact of flame retardant polypropylene (FR-PP) is a critical consideration in the development and application of these materials. As the use of FR-PP continues to grow in various industries, it is essential to assess its potential effects on ecosystems and human health throughout its lifecycle.

One of the primary environmental concerns associated with FR-PP is the release of flame retardant additives into the environment. Many flame retardants used in polypropylene, such as halogenated compounds, have been found to persist in the environment and bioaccumulate in living organisms. These chemicals can leach from products during use or disposal, potentially contaminating soil, water, and air.

The production process of FR-PP also contributes to its environmental footprint. The synthesis and incorporation of flame retardant additives often require additional energy and resources, leading to increased greenhouse gas emissions and resource depletion. Furthermore, the complexity of FR-PP formulations can make recycling more challenging, potentially increasing the amount of plastic waste in landfills or incineration facilities.

However, it is important to note that the use of FR-PP can also have positive environmental impacts. By improving fire safety in various applications, FR-PP can help prevent catastrophic fires, reducing the release of toxic combustion products and minimizing property damage. This indirect environmental benefit should be weighed against the potential negative impacts of the material itself.

Recent research has focused on developing more environmentally friendly flame retardant solutions for polypropylene. Bio-based flame retardants derived from renewable resources and nanocomposite technologies are emerging as promising alternatives to traditional halogenated compounds. These innovations aim to maintain the fire safety properties of FR-PP while reducing its environmental impact.

The end-of-life management of FR-PP products is another crucial aspect of their environmental impact. Improved recycling technologies and waste management strategies are being developed to address the challenges posed by flame retardant additives in the recycling process. Additionally, efforts are being made to design FR-PP products with easier disassembly and material recovery in mind.

As regulations and consumer awareness regarding environmental issues continue to evolve, manufacturers are increasingly focusing on life cycle assessments of FR-PP products. These assessments help identify areas for improvement in the production, use, and disposal phases, driving the development of more sustainable flame retardant solutions for polypropylene.

One of the primary environmental concerns associated with FR-PP is the release of flame retardant additives into the environment. Many flame retardants used in polypropylene, such as halogenated compounds, have been found to persist in the environment and bioaccumulate in living organisms. These chemicals can leach from products during use or disposal, potentially contaminating soil, water, and air.

The production process of FR-PP also contributes to its environmental footprint. The synthesis and incorporation of flame retardant additives often require additional energy and resources, leading to increased greenhouse gas emissions and resource depletion. Furthermore, the complexity of FR-PP formulations can make recycling more challenging, potentially increasing the amount of plastic waste in landfills or incineration facilities.

However, it is important to note that the use of FR-PP can also have positive environmental impacts. By improving fire safety in various applications, FR-PP can help prevent catastrophic fires, reducing the release of toxic combustion products and minimizing property damage. This indirect environmental benefit should be weighed against the potential negative impacts of the material itself.

Recent research has focused on developing more environmentally friendly flame retardant solutions for polypropylene. Bio-based flame retardants derived from renewable resources and nanocomposite technologies are emerging as promising alternatives to traditional halogenated compounds. These innovations aim to maintain the fire safety properties of FR-PP while reducing its environmental impact.

The end-of-life management of FR-PP products is another crucial aspect of their environmental impact. Improved recycling technologies and waste management strategies are being developed to address the challenges posed by flame retardant additives in the recycling process. Additionally, efforts are being made to design FR-PP products with easier disassembly and material recovery in mind.

As regulations and consumer awareness regarding environmental issues continue to evolve, manufacturers are increasingly focusing on life cycle assessments of FR-PP products. These assessments help identify areas for improvement in the production, use, and disposal phases, driving the development of more sustainable flame retardant solutions for polypropylene.

Regulatory Framework for FR Materials

The regulatory framework for flame retardant (FR) materials in polypropylene applications is complex and multifaceted, involving various international, national, and industry-specific standards. At the global level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a foundation for the safe use and handling of FR chemicals. This system is widely adopted and influences regulations across different regions.

In the United States, the Consumer Product Safety Commission (CPSC) plays a crucial role in regulating FR materials in consumer products. The Flammable Fabrics Act (FFA) and the Consumer Product Safety Act (CPSA) are key pieces of legislation that set standards for flame resistance in textiles and other materials. Additionally, the Environmental Protection Agency (EPA) regulates the use of certain FR chemicals under the Toxic Substances Control Act (TSCA).

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This comprehensive legislation aims to protect human health and the environment from the risks posed by chemicals, including FR additives used in polypropylene. The EU's RoHS (Restriction of Hazardous Substances) Directive also impacts the use of certain FR compounds in electrical and electronic equipment.

Industry-specific standards further shape the regulatory landscape. For instance, in the automotive sector, the Federal Motor Vehicle Safety Standard (FMVSS) 302 in the US and its international counterpart ISO 3795 set flammability requirements for materials used in vehicle interiors. In the construction industry, building codes such as the International Building Code (IBC) and standards like ASTM E84 dictate flame spread and smoke development limits for materials used in buildings.

The aviation industry has particularly stringent requirements, with regulations such as the Federal Aviation Administration's FAR 25.853 setting strict flammability standards for materials used in aircraft interiors. These regulations often drive innovation in FR technologies for polypropylene and other polymers used in high-risk environments.

Environmental concerns have led to increased scrutiny of certain FR chemicals, particularly halogenated compounds. This has resulted in a shift towards more environmentally friendly alternatives and stricter regulations on the use of persistent organic pollutants (POPs) in FR formulations. The Stockholm Convention on Persistent Organic Pollutants has been instrumental in phasing out certain brominated flame retardants globally.

As research continues to reveal potential health and environmental impacts of FR chemicals, regulatory frameworks are evolving. There is a growing trend towards more comprehensive life-cycle assessments of FR materials and a push for safer, sustainable alternatives. This dynamic regulatory environment necessitates ongoing vigilance and adaptation from manufacturers and researchers working with flame retardant polypropylene materials.

In the United States, the Consumer Product Safety Commission (CPSC) plays a crucial role in regulating FR materials in consumer products. The Flammable Fabrics Act (FFA) and the Consumer Product Safety Act (CPSA) are key pieces of legislation that set standards for flame resistance in textiles and other materials. Additionally, the Environmental Protection Agency (EPA) regulates the use of certain FR chemicals under the Toxic Substances Control Act (TSCA).

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This comprehensive legislation aims to protect human health and the environment from the risks posed by chemicals, including FR additives used in polypropylene. The EU's RoHS (Restriction of Hazardous Substances) Directive also impacts the use of certain FR compounds in electrical and electronic equipment.

Industry-specific standards further shape the regulatory landscape. For instance, in the automotive sector, the Federal Motor Vehicle Safety Standard (FMVSS) 302 in the US and its international counterpart ISO 3795 set flammability requirements for materials used in vehicle interiors. In the construction industry, building codes such as the International Building Code (IBC) and standards like ASTM E84 dictate flame spread and smoke development limits for materials used in buildings.

The aviation industry has particularly stringent requirements, with regulations such as the Federal Aviation Administration's FAR 25.853 setting strict flammability standards for materials used in aircraft interiors. These regulations often drive innovation in FR technologies for polypropylene and other polymers used in high-risk environments.

Environmental concerns have led to increased scrutiny of certain FR chemicals, particularly halogenated compounds. This has resulted in a shift towards more environmentally friendly alternatives and stricter regulations on the use of persistent organic pollutants (POPs) in FR formulations. The Stockholm Convention on Persistent Organic Pollutants has been instrumental in phasing out certain brominated flame retardants globally.

As research continues to reveal potential health and environmental impacts of FR chemicals, regulatory frameworks are evolving. There is a growing trend towards more comprehensive life-cycle assessments of FR materials and a push for safer, sustainable alternatives. This dynamic regulatory environment necessitates ongoing vigilance and adaptation from manufacturers and researchers working with flame retardant polypropylene materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!