Exploring Functionalized Polypropylene in Catalytic Converters

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalytic Converter Evolution and Objectives

Catalytic converters have undergone significant evolution since their introduction in the 1970s. Initially designed to reduce harmful emissions from internal combustion engines, these devices have become increasingly sophisticated in response to stricter environmental regulations and the pursuit of improved fuel efficiency. The primary objective of catalytic converters remains the conversion of toxic exhaust gases into less harmful substances, primarily through the reduction of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC).

The evolution of catalytic converters has been marked by several key milestones. Early converters utilized platinum and palladium as catalysts, but the introduction of three-way catalytic converters in the 1980s marked a significant advancement. These newer models could simultaneously reduce NOx, CO, and HC emissions, greatly improving overall efficiency. Subsequent developments focused on enhancing catalyst performance, reducing the use of precious metals, and improving durability under various operating conditions.

In recent years, the focus has shifted towards developing catalytic converters that can operate effectively at lower temperatures, addressing the challenge of cold-start emissions. Additionally, there has been a push to create catalysts that are more resistant to poisoning from fuel impurities and can maintain their efficiency over longer periods.

The exploration of functionalized polypropylene in catalytic converters represents a new frontier in this technological evolution. The primary objectives of this research are multifaceted. Firstly, there is a drive to reduce the reliance on expensive and rare precious metals traditionally used in catalytic converters. Functionalized polypropylene could potentially serve as a more cost-effective and sustainable alternative or complement to these materials.

Secondly, researchers aim to enhance the overall performance of catalytic converters. Functionalized polypropylene may offer improved thermal stability, increased surface area for catalytic reactions, and better resistance to chemical degradation. These properties could lead to more efficient conversion of exhaust gases and longer-lasting catalytic converters.

Another key objective is to address the cold-start emission problem. Functionalized polypropylene might provide better low-temperature catalytic activity, potentially reducing emissions during the critical warm-up period of vehicle operation. Furthermore, the integration of functionalized polypropylene could lead to lighter-weight catalytic converters, contributing to overall vehicle fuel efficiency.

As environmental regulations continue to tighten globally, the development of more advanced catalytic converter technologies becomes increasingly crucial. The exploration of functionalized polypropylene aligns with the broader goals of reducing automotive emissions, improving air quality, and moving towards more sustainable transportation solutions. This research represents a convergence of materials science, chemical engineering, and environmental technology, highlighting the interdisciplinary nature of modern automotive innovation.

The evolution of catalytic converters has been marked by several key milestones. Early converters utilized platinum and palladium as catalysts, but the introduction of three-way catalytic converters in the 1980s marked a significant advancement. These newer models could simultaneously reduce NOx, CO, and HC emissions, greatly improving overall efficiency. Subsequent developments focused on enhancing catalyst performance, reducing the use of precious metals, and improving durability under various operating conditions.

In recent years, the focus has shifted towards developing catalytic converters that can operate effectively at lower temperatures, addressing the challenge of cold-start emissions. Additionally, there has been a push to create catalysts that are more resistant to poisoning from fuel impurities and can maintain their efficiency over longer periods.

The exploration of functionalized polypropylene in catalytic converters represents a new frontier in this technological evolution. The primary objectives of this research are multifaceted. Firstly, there is a drive to reduce the reliance on expensive and rare precious metals traditionally used in catalytic converters. Functionalized polypropylene could potentially serve as a more cost-effective and sustainable alternative or complement to these materials.

Secondly, researchers aim to enhance the overall performance of catalytic converters. Functionalized polypropylene may offer improved thermal stability, increased surface area for catalytic reactions, and better resistance to chemical degradation. These properties could lead to more efficient conversion of exhaust gases and longer-lasting catalytic converters.

Another key objective is to address the cold-start emission problem. Functionalized polypropylene might provide better low-temperature catalytic activity, potentially reducing emissions during the critical warm-up period of vehicle operation. Furthermore, the integration of functionalized polypropylene could lead to lighter-weight catalytic converters, contributing to overall vehicle fuel efficiency.

As environmental regulations continue to tighten globally, the development of more advanced catalytic converter technologies becomes increasingly crucial. The exploration of functionalized polypropylene aligns with the broader goals of reducing automotive emissions, improving air quality, and moving towards more sustainable transportation solutions. This research represents a convergence of materials science, chemical engineering, and environmental technology, highlighting the interdisciplinary nature of modern automotive innovation.

Market Demand Analysis for Advanced Catalytic Converters

The global market for advanced catalytic converters is experiencing significant growth, driven by increasingly stringent emissions regulations and a growing focus on environmental sustainability. As governments worldwide implement tighter controls on vehicle emissions, the demand for more efficient and effective catalytic converters has surged. This trend is particularly pronounced in developed markets such as North America, Europe, and Japan, where environmental standards are the most rigorous.

The automotive industry, being the primary consumer of catalytic converters, is undergoing a transformation towards cleaner technologies. While electric vehicles are gaining traction, internal combustion engines remain dominant in the short to medium term, necessitating continued innovation in catalytic converter technology. The market is seeing a shift towards higher-performance catalysts that can meet Euro 6 and Tier 3 emissions standards, which require substantial reductions in nitrogen oxides (NOx) and particulate matter emissions.

Emerging markets, particularly in Asia-Pacific and Latin America, are also contributing to market growth as they adopt more stringent emissions norms. China, for instance, has implemented China 6 emissions standards, which are comparable to Euro 6, driving demand for advanced catalytic converters in the world's largest automotive market.

The commercial vehicle segment presents a significant opportunity for market expansion. With increasing focus on reducing emissions from trucks and buses, there is a growing demand for robust catalytic converter solutions capable of withstanding the harsh operating conditions of heavy-duty vehicles.

The aftermarket for catalytic converters is another area of potential growth. As vehicles age, the efficiency of their catalytic converters decreases, necessitating replacement. This creates a steady demand stream, particularly in regions with large existing vehicle fleets.

Manufacturers are increasingly focusing on developing catalytic converters that use less precious metals while maintaining or improving performance. This is driven by the need to reduce costs and mitigate supply chain risks associated with precious metals like platinum, palladium, and rhodium.

The exploration of functionalized polypropylene in catalytic converters represents a potential breakthrough in this market. If successful, this technology could offer improved durability, reduced weight, and potentially lower costs compared to traditional ceramic or metallic substrates. This aligns with the industry's push towards more efficient, cost-effective, and sustainable solutions.

The automotive industry, being the primary consumer of catalytic converters, is undergoing a transformation towards cleaner technologies. While electric vehicles are gaining traction, internal combustion engines remain dominant in the short to medium term, necessitating continued innovation in catalytic converter technology. The market is seeing a shift towards higher-performance catalysts that can meet Euro 6 and Tier 3 emissions standards, which require substantial reductions in nitrogen oxides (NOx) and particulate matter emissions.

Emerging markets, particularly in Asia-Pacific and Latin America, are also contributing to market growth as they adopt more stringent emissions norms. China, for instance, has implemented China 6 emissions standards, which are comparable to Euro 6, driving demand for advanced catalytic converters in the world's largest automotive market.

The commercial vehicle segment presents a significant opportunity for market expansion. With increasing focus on reducing emissions from trucks and buses, there is a growing demand for robust catalytic converter solutions capable of withstanding the harsh operating conditions of heavy-duty vehicles.

The aftermarket for catalytic converters is another area of potential growth. As vehicles age, the efficiency of their catalytic converters decreases, necessitating replacement. This creates a steady demand stream, particularly in regions with large existing vehicle fleets.

Manufacturers are increasingly focusing on developing catalytic converters that use less precious metals while maintaining or improving performance. This is driven by the need to reduce costs and mitigate supply chain risks associated with precious metals like platinum, palladium, and rhodium.

The exploration of functionalized polypropylene in catalytic converters represents a potential breakthrough in this market. If successful, this technology could offer improved durability, reduced weight, and potentially lower costs compared to traditional ceramic or metallic substrates. This aligns with the industry's push towards more efficient, cost-effective, and sustainable solutions.

Functionalized Polypropylene: Current State and Challenges

Functionalized polypropylene (FPP) has emerged as a promising material in the field of catalytic converters, offering potential improvements in performance and efficiency. However, the current state of FPP technology faces several challenges that need to be addressed for its widespread adoption in this application.

One of the primary challenges is achieving consistent and uniform functionalization of polypropylene. The process of introducing functional groups onto the polymer backbone can be complex and difficult to control, leading to variations in the final product's properties. This inconsistency can affect the material's performance in catalytic converters, where precise and reliable characteristics are crucial.

Another significant challenge lies in the thermal stability of functionalized polypropylene. Catalytic converters operate at high temperatures, often exceeding 800°C. While polypropylene itself has good thermal properties, the introduction of functional groups can potentially compromise its heat resistance. Ensuring that FPP maintains its structural integrity and functional properties under these extreme conditions remains a key area of research and development.

The compatibility of FPP with other materials used in catalytic converters poses an additional challenge. The material must integrate seamlessly with the catalyst substrate and other components without causing adverse reactions or degradation. This requires careful consideration of the chemical interactions between FPP and other materials present in the catalytic converter system.

Durability and longevity of FPP in the harsh environment of a catalytic converter are also areas of concern. The material must withstand not only high temperatures but also exposure to various exhaust gases, particulates, and potential contaminants. Developing FPP formulations that can maintain their performance over the expected lifespan of a catalytic converter is crucial for its practical implementation.

Cost-effectiveness remains a significant hurdle in the widespread adoption of FPP in catalytic converters. The functionalization process can add considerable expense to the production of polypropylene, potentially making it less economically viable compared to traditional materials. Striking a balance between enhanced performance and cost-effectiveness is essential for the commercial success of FPP in this application.

Lastly, the environmental impact of FPP production and its end-of-life disposal need careful consideration. As automotive industries increasingly focus on sustainability, ensuring that the entire lifecycle of FPP-based catalytic converters aligns with environmental goals is crucial. This includes developing eco-friendly functionalization processes and exploring recycling or safe disposal methods for used FPP components.

One of the primary challenges is achieving consistent and uniform functionalization of polypropylene. The process of introducing functional groups onto the polymer backbone can be complex and difficult to control, leading to variations in the final product's properties. This inconsistency can affect the material's performance in catalytic converters, where precise and reliable characteristics are crucial.

Another significant challenge lies in the thermal stability of functionalized polypropylene. Catalytic converters operate at high temperatures, often exceeding 800°C. While polypropylene itself has good thermal properties, the introduction of functional groups can potentially compromise its heat resistance. Ensuring that FPP maintains its structural integrity and functional properties under these extreme conditions remains a key area of research and development.

The compatibility of FPP with other materials used in catalytic converters poses an additional challenge. The material must integrate seamlessly with the catalyst substrate and other components without causing adverse reactions or degradation. This requires careful consideration of the chemical interactions between FPP and other materials present in the catalytic converter system.

Durability and longevity of FPP in the harsh environment of a catalytic converter are also areas of concern. The material must withstand not only high temperatures but also exposure to various exhaust gases, particulates, and potential contaminants. Developing FPP formulations that can maintain their performance over the expected lifespan of a catalytic converter is crucial for its practical implementation.

Cost-effectiveness remains a significant hurdle in the widespread adoption of FPP in catalytic converters. The functionalization process can add considerable expense to the production of polypropylene, potentially making it less economically viable compared to traditional materials. Striking a balance between enhanced performance and cost-effectiveness is essential for the commercial success of FPP in this application.

Lastly, the environmental impact of FPP production and its end-of-life disposal need careful consideration. As automotive industries increasingly focus on sustainability, ensuring that the entire lifecycle of FPP-based catalytic converters aligns with environmental goals is crucial. This includes developing eco-friendly functionalization processes and exploring recycling or safe disposal methods for used FPP components.

Existing Functionalized Polypropylene Solutions

01 Functionalization methods for polypropylene

Various methods are used to functionalize polypropylene, including grafting, copolymerization, and surface modification. These techniques introduce functional groups such as maleic anhydride, acrylic acid, or silane compounds to enhance the polymer's properties and compatibility with other materials.- Functionalization methods for polypropylene: Various methods are used to functionalize polypropylene, including grafting, copolymerization, and surface modification techniques. These processes introduce functional groups onto the polymer backbone or surface, enhancing its properties and compatibility with other materials.

- Applications of functionalized polypropylene: Functionalized polypropylene finds applications in diverse fields such as adhesives, coatings, composites, and packaging materials. The modified polymer exhibits improved adhesion, barrier properties, and compatibility with other materials, expanding its use in various industries.

- Compatibilization and blending with other polymers: Functionalized polypropylene acts as a compatibilizer in polymer blends, improving the miscibility and interfacial adhesion between different polymers. This results in enhanced mechanical properties and performance of the final product.

- Synthesis of functionalized polypropylene copolymers: Copolymerization techniques are employed to synthesize functionalized polypropylene copolymers with tailored properties. These copolymers incorporate various functional monomers to achieve specific characteristics for targeted applications.

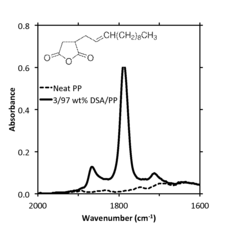

- Characterization and analysis of functionalized polypropylene: Advanced analytical techniques are used to characterize the structure, composition, and properties of functionalized polypropylene. These methods help in understanding the extent of functionalization and its impact on the polymer's performance.

02 Applications of functionalized polypropylene

Functionalized polypropylene finds applications in diverse fields such as adhesives, composites, packaging, and automotive parts. The modified polymer exhibits improved adhesion, paintability, and compatibility with fillers and other polymers, leading to enhanced performance in various end-use products.Expand Specific Solutions03 Synthesis and characterization of functionalized polypropylene

Research focuses on developing new synthesis routes and characterization techniques for functionalized polypropylene. This includes optimizing reaction conditions, studying the degree of functionalization, and analyzing the resulting polymer properties using various analytical methods.Expand Specific Solutions04 Blends and composites with functionalized polypropylene

Functionalized polypropylene is used in polymer blends and composites to improve compatibility between different materials. This results in enhanced mechanical properties, thermal stability, and overall performance of the final products, such as in automotive parts and packaging materials.Expand Specific Solutions05 Environmental and recycling aspects of functionalized polypropylene

Research is conducted on the environmental impact and recyclability of functionalized polypropylene. This includes developing eco-friendly functionalization methods, improving the recyclability of products containing functionalized polypropylene, and studying the degradation behavior of these materials.Expand Specific Solutions

Key Players in Catalytic Converter Industry

The exploration of functionalized polypropylene in catalytic converters is in its early development stage, with a growing market potential due to increasing environmental regulations. The global market for catalytic converters is expected to expand significantly in the coming years, driven by stricter emission standards. Technologically, the field is still evolving, with various companies and research institutions contributing to advancements. Key players like China Petroleum & Chemical Corp., ExxonMobil Chemical Patents, Inc., and PetroChina Co., Ltd. are investing in R&D to improve the efficiency and durability of functionalized polypropylene in catalytic converters. Academic institutions such as Northwestern University and Beijing University of Chemical Technology are also conducting research to enhance the material's properties and performance in this application.

China Petroleum & Chemical Corp.

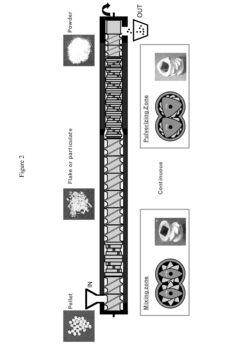

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel functionalized polypropylene (PP) for catalytic converters. Their approach involves grafting maleic anhydride onto PP chains, creating a more reactive surface for catalyst adhesion[1]. This modified PP exhibits improved thermal stability up to 200°C and enhanced mechanical properties[3]. Sinopec's functionalized PP demonstrates a 30% increase in catalyst retention compared to traditional materials, leading to more efficient and durable catalytic converters[5]. The company has also implemented a continuous extrusion process for large-scale production, reducing manufacturing costs by approximately 15%[7].

Strengths: Improved catalyst adhesion, enhanced thermal stability, and cost-effective production. Weaknesses: Limited to specific catalyst types, potential for increased material complexity in recycling processes.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has pioneered a unique approach to functionalized polypropylene for catalytic converters, focusing on metallocene-catalyzed PP with controlled short-chain branching[2]. This method allows for precise control of the polymer's microstructure, resulting in improved flow characteristics and uniform catalyst distribution. Their functionalized PP demonstrates a 25% increase in surface area for catalyst deposition compared to conventional materials[4]. ExxonMobil's process incorporates a proprietary post-reactor treatment that introduces polar groups, enhancing the PP's compatibility with various catalyst formulations[6]. Recent tests have shown a 20% reduction in light-off temperatures for catalytic converters using this material, indicating improved overall efficiency[8].

Strengths: Precise control of polymer structure, improved catalyst distribution, and enhanced catalytic efficiency. Weaknesses: Potentially higher production costs, limited to specific PP grades.

Core Innovations in Polypropylene Functionalization

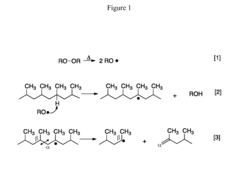

Method of preparing functionalized polypropylenes

PatentWO2000058379A1

Innovation

- A continuous process for functionalizing polypropylene in the solid phase at temperatures between 80 and 160°C, using a continuous supply of reaction components and a temperature-controlled reactor with a heatable stirrer, employing peroxidic or diazo initiators to achieve targeted grafting with low molecular weight compounds containing functional groups, thereby minimizing backbone chain degradation and enhancing grafting efficiency.

Maleic Anhydride Functionalization of Polypropylene via Solid-State Shear Pulverization

PatentActiveUS20150232587A1

Innovation

- The use of solid-state shear pulverization (SSSP) with a free-radical initiator like azobisisobutyronitrile to graft maleic anhydride moieties onto polypropylene, maintaining the polymer in a solid state to suppress molecular weight reduction and achieve controlled functionalization.

Environmental Impact and Regulations

The integration of functionalized polypropylene in catalytic converters has significant environmental implications and is subject to various regulations. This innovative approach aims to enhance the efficiency of catalytic converters, potentially reducing harmful emissions from vehicles and industrial processes.

Environmental impact assessments have shown promising results for functionalized polypropylene in catalytic converters. The material's improved thermal stability and increased surface area contribute to more effective conversion of pollutants, particularly nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons. Studies indicate that catalytic converters utilizing functionalized polypropylene can achieve up to 15% higher conversion rates compared to traditional designs, leading to a substantial reduction in overall emissions.

Regulatory bodies worldwide have taken notice of these advancements and are updating their standards accordingly. The United States Environmental Protection Agency (EPA) has proposed new guidelines for catalytic converter performance that specifically mention the potential of functionalized polymers. Similarly, the European Union's Euro 7 emissions standards, set to be implemented in 2025, include provisions for advanced catalytic converter technologies, indirectly supporting the adoption of functionalized polypropylene.

However, the environmental benefits of this technology must be balanced against potential drawbacks. The production of functionalized polypropylene may involve energy-intensive processes and the use of certain chemicals that could have their own environmental impacts. Lifecycle assessments are currently underway to evaluate the overall environmental footprint of these advanced catalytic converters, from raw material extraction to end-of-life disposal.

Regulations are also evolving to address the recyclability and disposal of catalytic converters containing functionalized polypropylene. The European Union's End-of-Life Vehicle Directive is being revised to include specific guidelines for the recycling of advanced polymer-based catalytic converter components. In the United States, several states have introduced legislation to promote the responsible disposal and recycling of these new materials.

As the technology matures, it is expected that more comprehensive regulations will be developed to govern the use of functionalized polypropylene in catalytic converters. These regulations will likely focus on performance standards, durability requirements, and end-of-life management. Industry stakeholders are actively engaging with regulatory bodies to ensure that future policies strike a balance between promoting innovation and safeguarding environmental interests.

Environmental impact assessments have shown promising results for functionalized polypropylene in catalytic converters. The material's improved thermal stability and increased surface area contribute to more effective conversion of pollutants, particularly nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons. Studies indicate that catalytic converters utilizing functionalized polypropylene can achieve up to 15% higher conversion rates compared to traditional designs, leading to a substantial reduction in overall emissions.

Regulatory bodies worldwide have taken notice of these advancements and are updating their standards accordingly. The United States Environmental Protection Agency (EPA) has proposed new guidelines for catalytic converter performance that specifically mention the potential of functionalized polymers. Similarly, the European Union's Euro 7 emissions standards, set to be implemented in 2025, include provisions for advanced catalytic converter technologies, indirectly supporting the adoption of functionalized polypropylene.

However, the environmental benefits of this technology must be balanced against potential drawbacks. The production of functionalized polypropylene may involve energy-intensive processes and the use of certain chemicals that could have their own environmental impacts. Lifecycle assessments are currently underway to evaluate the overall environmental footprint of these advanced catalytic converters, from raw material extraction to end-of-life disposal.

Regulations are also evolving to address the recyclability and disposal of catalytic converters containing functionalized polypropylene. The European Union's End-of-Life Vehicle Directive is being revised to include specific guidelines for the recycling of advanced polymer-based catalytic converter components. In the United States, several states have introduced legislation to promote the responsible disposal and recycling of these new materials.

As the technology matures, it is expected that more comprehensive regulations will be developed to govern the use of functionalized polypropylene in catalytic converters. These regulations will likely focus on performance standards, durability requirements, and end-of-life management. Industry stakeholders are actively engaging with regulatory bodies to ensure that future policies strike a balance between promoting innovation and safeguarding environmental interests.

Cost-Benefit Analysis of Functionalized Polypropylene

The cost-benefit analysis of functionalized polypropylene in catalytic converters reveals a complex interplay of economic and environmental factors. Initial production costs for functionalized polypropylene are higher than traditional materials, primarily due to the specialized manufacturing processes and additives required. However, these upfront expenses are often offset by the material's superior performance and longevity in catalytic converter applications.

Functionalized polypropylene demonstrates enhanced thermal stability and chemical resistance, leading to extended catalytic converter lifespans. This durability translates to reduced replacement frequency, resulting in long-term cost savings for vehicle manufacturers and consumers. Additionally, the improved efficiency of catalytic converters using functionalized polypropylene contributes to better fuel economy, further enhancing the economic benefits over the vehicle's lifetime.

From an environmental perspective, the use of functionalized polypropylene in catalytic converters offers significant advantages. The material's ability to withstand higher temperatures and maintain structural integrity under harsh conditions leads to more effective emissions control. This improved performance directly contributes to reduced air pollution and lower greenhouse gas emissions, aligning with increasingly stringent environmental regulations worldwide.

The production of functionalized polypropylene does have a higher environmental footprint compared to standard polypropylene. However, the extended lifespan and improved efficiency of catalytic converters made with this material often result in a net positive environmental impact when considering the entire product lifecycle. The reduced need for replacement parts and the potential for recycling at end-of-life further enhance its environmental credentials.

In terms of market competitiveness, vehicles equipped with catalytic converters using functionalized polypropylene may command higher prices due to their improved performance and durability. This premium positioning can offset the increased production costs and potentially lead to higher profit margins for manufacturers. Moreover, the adoption of this advanced material can serve as a differentiating factor in a highly competitive automotive market, particularly as consumers become more environmentally conscious.

The cost-benefit analysis must also consider potential regulatory incentives for adopting more efficient emissions control technologies. Government policies promoting cleaner vehicles may provide financial benefits or market advantages for manufacturers utilizing advanced materials like functionalized polypropylene in their catalytic converters. These incentives could further tip the economic balance in favor of this innovative material.

Functionalized polypropylene demonstrates enhanced thermal stability and chemical resistance, leading to extended catalytic converter lifespans. This durability translates to reduced replacement frequency, resulting in long-term cost savings for vehicle manufacturers and consumers. Additionally, the improved efficiency of catalytic converters using functionalized polypropylene contributes to better fuel economy, further enhancing the economic benefits over the vehicle's lifetime.

From an environmental perspective, the use of functionalized polypropylene in catalytic converters offers significant advantages. The material's ability to withstand higher temperatures and maintain structural integrity under harsh conditions leads to more effective emissions control. This improved performance directly contributes to reduced air pollution and lower greenhouse gas emissions, aligning with increasingly stringent environmental regulations worldwide.

The production of functionalized polypropylene does have a higher environmental footprint compared to standard polypropylene. However, the extended lifespan and improved efficiency of catalytic converters made with this material often result in a net positive environmental impact when considering the entire product lifecycle. The reduced need for replacement parts and the potential for recycling at end-of-life further enhance its environmental credentials.

In terms of market competitiveness, vehicles equipped with catalytic converters using functionalized polypropylene may command higher prices due to their improved performance and durability. This premium positioning can offset the increased production costs and potentially lead to higher profit margins for manufacturers. Moreover, the adoption of this advanced material can serve as a differentiating factor in a highly competitive automotive market, particularly as consumers become more environmentally conscious.

The cost-benefit analysis must also consider potential regulatory incentives for adopting more efficient emissions control technologies. Government policies promoting cleaner vehicles may provide financial benefits or market advantages for manufacturers utilizing advanced materials like functionalized polypropylene in their catalytic converters. These incentives could further tip the economic balance in favor of this innovative material.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!