Frequency Variation Effects on Transverse Waves in Magnetorheological Applications

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MR Frequency Effects Background and Objectives

Magnetorheological (MR) fluids have been a subject of intense research and development since their discovery in the 1940s. These smart materials, which can rapidly change their rheological properties under the influence of magnetic fields, have found applications in various fields, including automotive, aerospace, and civil engineering. The study of frequency variation effects on transverse waves in MR applications represents a critical area of investigation, as it directly impacts the performance and efficiency of MR-based systems.

The evolution of MR technology has been marked by significant milestones, from the initial discovery of the MR effect to the development of sophisticated control algorithms and advanced MR fluid compositions. As the technology has matured, researchers have increasingly focused on understanding the dynamic behavior of MR fluids under varying conditions, including frequency variations in applied magnetic fields and mechanical excitations.

The primary objective of this technical research is to comprehensively examine the effects of frequency variation on transverse waves in MR applications. This investigation aims to bridge the gap between theoretical models and practical implementations, providing insights that can lead to more efficient and responsive MR-based systems. By exploring how different frequencies influence the propagation and characteristics of transverse waves in MR fluids, we seek to optimize the performance of MR devices across a wide range of operating conditions.

Key areas of focus include the analysis of wave propagation mechanisms in MR fluids, the relationship between applied magnetic field strength and frequency, and the impact of these factors on the fluid's viscoelastic properties. Additionally, this research aims to identify potential limitations and challenges in current MR applications related to frequency-dependent behavior, and to propose innovative solutions to overcome these obstacles.

The technological trend in this field is moving towards more precise control of MR fluid properties, with an emphasis on rapid response times and enhanced stability across broader frequency ranges. This trend is driven by the increasing demands of high-performance applications, such as advanced vibration control systems and adaptive damping mechanisms in next-generation vehicles and structures.

By delving into the frequency variation effects on transverse waves, this research seeks to contribute to the development of more sophisticated MR fluid formulations and improved device designs. The ultimate goal is to expand the applicability of MR technology, enabling its integration into more complex and demanding systems that require precise and dynamic control of mechanical properties.

The evolution of MR technology has been marked by significant milestones, from the initial discovery of the MR effect to the development of sophisticated control algorithms and advanced MR fluid compositions. As the technology has matured, researchers have increasingly focused on understanding the dynamic behavior of MR fluids under varying conditions, including frequency variations in applied magnetic fields and mechanical excitations.

The primary objective of this technical research is to comprehensively examine the effects of frequency variation on transverse waves in MR applications. This investigation aims to bridge the gap between theoretical models and practical implementations, providing insights that can lead to more efficient and responsive MR-based systems. By exploring how different frequencies influence the propagation and characteristics of transverse waves in MR fluids, we seek to optimize the performance of MR devices across a wide range of operating conditions.

Key areas of focus include the analysis of wave propagation mechanisms in MR fluids, the relationship between applied magnetic field strength and frequency, and the impact of these factors on the fluid's viscoelastic properties. Additionally, this research aims to identify potential limitations and challenges in current MR applications related to frequency-dependent behavior, and to propose innovative solutions to overcome these obstacles.

The technological trend in this field is moving towards more precise control of MR fluid properties, with an emphasis on rapid response times and enhanced stability across broader frequency ranges. This trend is driven by the increasing demands of high-performance applications, such as advanced vibration control systems and adaptive damping mechanisms in next-generation vehicles and structures.

By delving into the frequency variation effects on transverse waves, this research seeks to contribute to the development of more sophisticated MR fluid formulations and improved device designs. The ultimate goal is to expand the applicability of MR technology, enabling its integration into more complex and demanding systems that require precise and dynamic control of mechanical properties.

Market Demand for MR Wave Control

The market demand for magnetorheological (MR) wave control technologies has been steadily growing across various industries, driven by the increasing need for advanced vibration and motion control solutions. This demand is particularly pronounced in sectors such as automotive, civil engineering, aerospace, and medical devices, where precise control of mechanical waves is crucial for performance and safety.

In the automotive industry, MR-based suspension systems have gained significant traction. These systems offer real-time adjustable damping, enhancing vehicle stability, comfort, and handling. The global market for MR suspension systems is expected to expand as automakers seek to differentiate their products and meet stringent ride quality standards. Additionally, the growing interest in autonomous vehicles has further boosted the demand for advanced suspension technologies that can adapt to changing road conditions and driving scenarios.

Civil engineering applications, particularly in seismic protection of buildings and bridges, represent another substantial market for MR wave control technologies. As urbanization continues and infrastructure projects increase in complexity, the need for adaptive vibration control systems becomes more critical. MR dampers are being increasingly incorporated into structures to mitigate the effects of earthquakes and wind-induced vibrations, offering a more efficient and responsive alternative to traditional passive damping systems.

The aerospace sector has also shown growing interest in MR technologies for vibration control in aircraft and spacecraft. These applications range from improving passenger comfort in commercial aviation to enhancing the stability of sensitive equipment in satellites. The ability of MR systems to provide variable stiffness and damping characteristics makes them particularly valuable in the dynamic and challenging environments encountered in aerospace applications.

In the medical field, MR technology is finding applications in prosthetics and rehabilitation devices. The demand for more advanced, responsive prosthetic limbs that can adapt to different walking speeds and terrains is driving research and development in this area. MR-based devices offer the potential for smoother, more natural movements, significantly improving the quality of life for users.

The industrial machinery sector is another area where MR wave control is gaining traction. Manufacturers are increasingly looking for ways to reduce vibrations in heavy machinery, improve precision in manufacturing processes, and enhance worker safety. MR-based solutions offer the flexibility and responsiveness needed to address these diverse requirements across various industrial applications.

As research continues to advance our understanding of frequency variation effects on transverse waves in MR applications, the potential for new and innovative products expands. This ongoing research is likely to open up new market opportunities and drive further demand for MR wave control technologies across a wide range of industries.

In the automotive industry, MR-based suspension systems have gained significant traction. These systems offer real-time adjustable damping, enhancing vehicle stability, comfort, and handling. The global market for MR suspension systems is expected to expand as automakers seek to differentiate their products and meet stringent ride quality standards. Additionally, the growing interest in autonomous vehicles has further boosted the demand for advanced suspension technologies that can adapt to changing road conditions and driving scenarios.

Civil engineering applications, particularly in seismic protection of buildings and bridges, represent another substantial market for MR wave control technologies. As urbanization continues and infrastructure projects increase in complexity, the need for adaptive vibration control systems becomes more critical. MR dampers are being increasingly incorporated into structures to mitigate the effects of earthquakes and wind-induced vibrations, offering a more efficient and responsive alternative to traditional passive damping systems.

The aerospace sector has also shown growing interest in MR technologies for vibration control in aircraft and spacecraft. These applications range from improving passenger comfort in commercial aviation to enhancing the stability of sensitive equipment in satellites. The ability of MR systems to provide variable stiffness and damping characteristics makes them particularly valuable in the dynamic and challenging environments encountered in aerospace applications.

In the medical field, MR technology is finding applications in prosthetics and rehabilitation devices. The demand for more advanced, responsive prosthetic limbs that can adapt to different walking speeds and terrains is driving research and development in this area. MR-based devices offer the potential for smoother, more natural movements, significantly improving the quality of life for users.

The industrial machinery sector is another area where MR wave control is gaining traction. Manufacturers are increasingly looking for ways to reduce vibrations in heavy machinery, improve precision in manufacturing processes, and enhance worker safety. MR-based solutions offer the flexibility and responsiveness needed to address these diverse requirements across various industrial applications.

As research continues to advance our understanding of frequency variation effects on transverse waves in MR applications, the potential for new and innovative products expands. This ongoing research is likely to open up new market opportunities and drive further demand for MR wave control technologies across a wide range of industries.

Current Challenges in MR Transverse Wave Manipulation

The manipulation of transverse waves in magnetorheological (MR) applications faces several significant challenges, particularly when considering the effects of frequency variation. One of the primary obstacles is the complex relationship between the applied magnetic field, the rheological properties of the MR fluid, and the propagation characteristics of transverse waves. As the frequency of the waves changes, the dynamic response of the MR fluid can vary dramatically, leading to unpredictable behavior and reduced control over wave propagation.

Another major challenge lies in the inherent non-linear nature of MR fluids. The yield stress and viscosity of these smart materials change non-linearly with the applied magnetic field strength, making it difficult to develop accurate models for predicting wave behavior across a wide range of frequencies. This non-linearity becomes even more pronounced at higher frequencies, where the response time of the MR fluid may not be sufficient to fully adapt to rapid changes in the magnetic field.

The issue of frequency-dependent attenuation presents yet another hurdle in MR transverse wave manipulation. As the frequency increases, the energy dissipation within the MR fluid tends to rise, potentially leading to significant wave attenuation. This phenomenon can limit the effective range and intensity of transverse waves in MR applications, particularly in scenarios requiring high-frequency operation or long-distance wave propagation.

Furthermore, the challenge of maintaining consistent wave characteristics across different frequencies is compounded by the presence of multiple interfaces within MR devices. The interaction between transverse waves and the boundaries of MR fluid chambers, as well as any solid structures within the system, can lead to complex reflection and refraction patterns. These interactions may vary significantly with frequency, making it difficult to achieve uniform wave manipulation across a broad spectrum.

The development of robust control algorithms for MR transverse wave manipulation is also hindered by the frequency-dependent behavior of the system. Traditional control strategies may struggle to adapt to the rapidly changing dynamics of the MR fluid as the wave frequency varies. This necessitates the development of advanced, adaptive control techniques that can account for the complex interplay between frequency, magnetic field strength, and fluid properties in real-time.

Lastly, the challenge of miniaturization and integration of MR wave manipulation systems becomes more pronounced when dealing with a wide range of frequencies. Designing compact devices that can effectively generate and control transverse waves across various frequencies while maintaining the necessary magnetic field strength and fluid volume presents significant engineering challenges. This is particularly relevant in applications such as microfluidics or portable sensing devices, where size and power constraints are critical considerations.

Another major challenge lies in the inherent non-linear nature of MR fluids. The yield stress and viscosity of these smart materials change non-linearly with the applied magnetic field strength, making it difficult to develop accurate models for predicting wave behavior across a wide range of frequencies. This non-linearity becomes even more pronounced at higher frequencies, where the response time of the MR fluid may not be sufficient to fully adapt to rapid changes in the magnetic field.

The issue of frequency-dependent attenuation presents yet another hurdle in MR transverse wave manipulation. As the frequency increases, the energy dissipation within the MR fluid tends to rise, potentially leading to significant wave attenuation. This phenomenon can limit the effective range and intensity of transverse waves in MR applications, particularly in scenarios requiring high-frequency operation or long-distance wave propagation.

Furthermore, the challenge of maintaining consistent wave characteristics across different frequencies is compounded by the presence of multiple interfaces within MR devices. The interaction between transverse waves and the boundaries of MR fluid chambers, as well as any solid structures within the system, can lead to complex reflection and refraction patterns. These interactions may vary significantly with frequency, making it difficult to achieve uniform wave manipulation across a broad spectrum.

The development of robust control algorithms for MR transverse wave manipulation is also hindered by the frequency-dependent behavior of the system. Traditional control strategies may struggle to adapt to the rapidly changing dynamics of the MR fluid as the wave frequency varies. This necessitates the development of advanced, adaptive control techniques that can account for the complex interplay between frequency, magnetic field strength, and fluid properties in real-time.

Lastly, the challenge of miniaturization and integration of MR wave manipulation systems becomes more pronounced when dealing with a wide range of frequencies. Designing compact devices that can effectively generate and control transverse waves across various frequencies while maintaining the necessary magnetic field strength and fluid volume presents significant engineering challenges. This is particularly relevant in applications such as microfluidics or portable sensing devices, where size and power constraints are critical considerations.

Existing Frequency-based MR Wave Control Solutions

01 Frequency variation effects on wave propagation

Changes in frequency of transverse waves can significantly impact their propagation characteristics. This includes alterations in wavelength, energy distribution, and interaction with various media. Understanding these effects is crucial for applications in telecommunications, optics, and material science.- Frequency variation effects on wave propagation: Changes in frequency of transverse waves can significantly affect their propagation characteristics. This includes alterations in wavelength, energy distribution, and interaction with various media. Understanding these effects is crucial for applications in telecommunications, optics, and material science.

- Frequency-dependent wave detection and measurement: Specialized techniques and devices are employed to detect and measure transverse waves with varying frequencies. These methods often involve advanced sensors, signal processing algorithms, and calibration techniques to accurately capture and analyze frequency-dependent wave phenomena.

- Applications in imaging and sensing technologies: Frequency variation in transverse waves is utilized in various imaging and sensing technologies. This includes applications in medical imaging, non-destructive testing, and environmental monitoring. The ability to manipulate and interpret frequency variations enhances the resolution and sensitivity of these systems.

- Frequency modulation and signal processing: Frequency variation is a key aspect of signal modulation and processing techniques. This involves manipulating the frequency of transverse waves to encode information, improve signal quality, or optimize transmission efficiency. These techniques are fundamental in modern communication systems and data processing.

- Material interaction and characterization: The effects of frequency variation in transverse waves are used to study and characterize materials. Different frequencies interact uniquely with various materials, allowing for analysis of material properties, structural integrity, and composition. This principle is applied in fields such as materials science, geophysics, and quality control in manufacturing.

02 Frequency-dependent sensing and measurement techniques

Utilizing frequency variations in transverse waves enables the development of advanced sensing and measurement technologies. These techniques can be applied in diverse fields such as medical imaging, non-destructive testing, and environmental monitoring, offering improved accuracy and resolution.Expand Specific Solutions03 Frequency modulation in communication systems

Frequency variation of transverse waves plays a crucial role in communication systems, particularly in frequency modulation (FM) techniques. This allows for efficient data transmission, improved signal-to-noise ratios, and enhanced bandwidth utilization in wireless and optical communication networks.Expand Specific Solutions04 Frequency-based material characterization

The response of materials to transverse waves of varying frequencies can be used to characterize their properties. This principle is applied in spectroscopy, materials testing, and quality control processes across industries, enabling non-invasive analysis of composition and structure.Expand Specific Solutions05 Frequency effects in acoustic and ultrasonic applications

Variation in the frequency of transverse waves has significant implications in acoustic and ultrasonic applications. This includes effects on sound propagation, attenuation, and interaction with different media, which are crucial in fields such as sonar technology, medical ultrasound, and non-destructive testing.Expand Specific Solutions

Key Players in MR Fluid and Wave Control Industry

The field of frequency variation effects on transverse waves in magnetorheological applications is in a developing stage, with growing market potential and increasing technological maturity. The competitive landscape is characterized by a mix of established energy companies, research institutions, and specialized technology firms. Major players like Baker Hughes, ExxonMobil, and Schlumberger are investing in this area, leveraging their expertise in oilfield services and energy technologies. Research organizations such as CNRS and Fraunhofer-Gesellschaft are contributing to fundamental advancements, while companies like VACUUMSCHMELZE and TDK Corp. are focusing on material innovations. The market is expected to expand as applications in vibration control, smart structures, and energy harvesting gain traction across industries.

Exxonmobil Upstream Research Co.

Technical Solution: ExxonMobil has invested in research on magnetorheological fluids for enhanced oil recovery (EOR) applications. Their approach involves using MR fluids in conjunction with electromagnetic fields to create controllable barriers in oil reservoirs. By manipulating the frequency of the applied magnetic field, they can alter the rheological properties of the fluid to optimize flow control in porous media[3]. The company has developed proprietary models to predict and manage the effects of frequency variation on transverse waves within the MR fluid, allowing for precise control of fluid viscosity and yield stress in reservoir conditions[4].

Strengths: Potential for significant improvements in oil recovery rates; Highly customizable for different reservoir characteristics. Weaknesses: Technology still in developmental stages; May require significant modifications to existing infrastructure.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has conducted extensive research on the behavior of magnetorheological fluids under varying frequency conditions. Their work focuses on developing MR-based damping systems for nuclear power plant components subjected to seismic activity. The CEA has created advanced models that account for the complex interactions between transverse waves and MR fluid particles at different excitation frequencies[5]. These models have led to the design of adaptive seismic isolation systems that can rapidly adjust their damping characteristics in response to a wide spectrum of vibrational frequencies, significantly enhancing the safety of nuclear facilities[6].

Strengths: Cutting-edge modeling capabilities for complex MR fluid behavior; Potential for significant improvements in nuclear safety. Weaknesses: Highly specialized application may limit broader market appeal; Stringent regulatory requirements for nuclear industry implementation.

Core Innovations in MR Transverse Wave Frequency Modulation

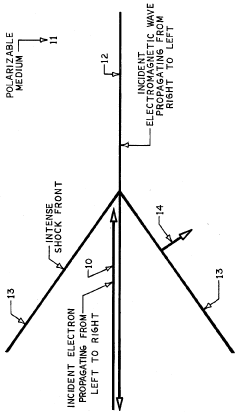

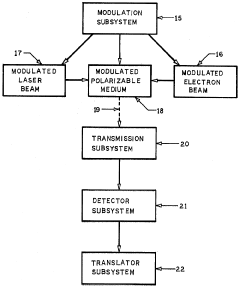

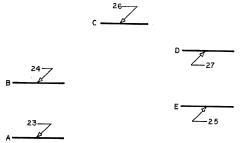

Method for the generation of frequency-transferred electromagnetic waves

PatentInactiveUS4109218A

Innovation

- The method involves scattering coherent electromagnetic waves from moving charged particles in a polarizable medium, utilizing lasers or similar sources, to produce frequency-shifted, highly directional radiation with controlled frequency and wavenumber selection, and modulation, achieving stimulated electromagnetic shock radiation with narrow-band and high spatial directionality.

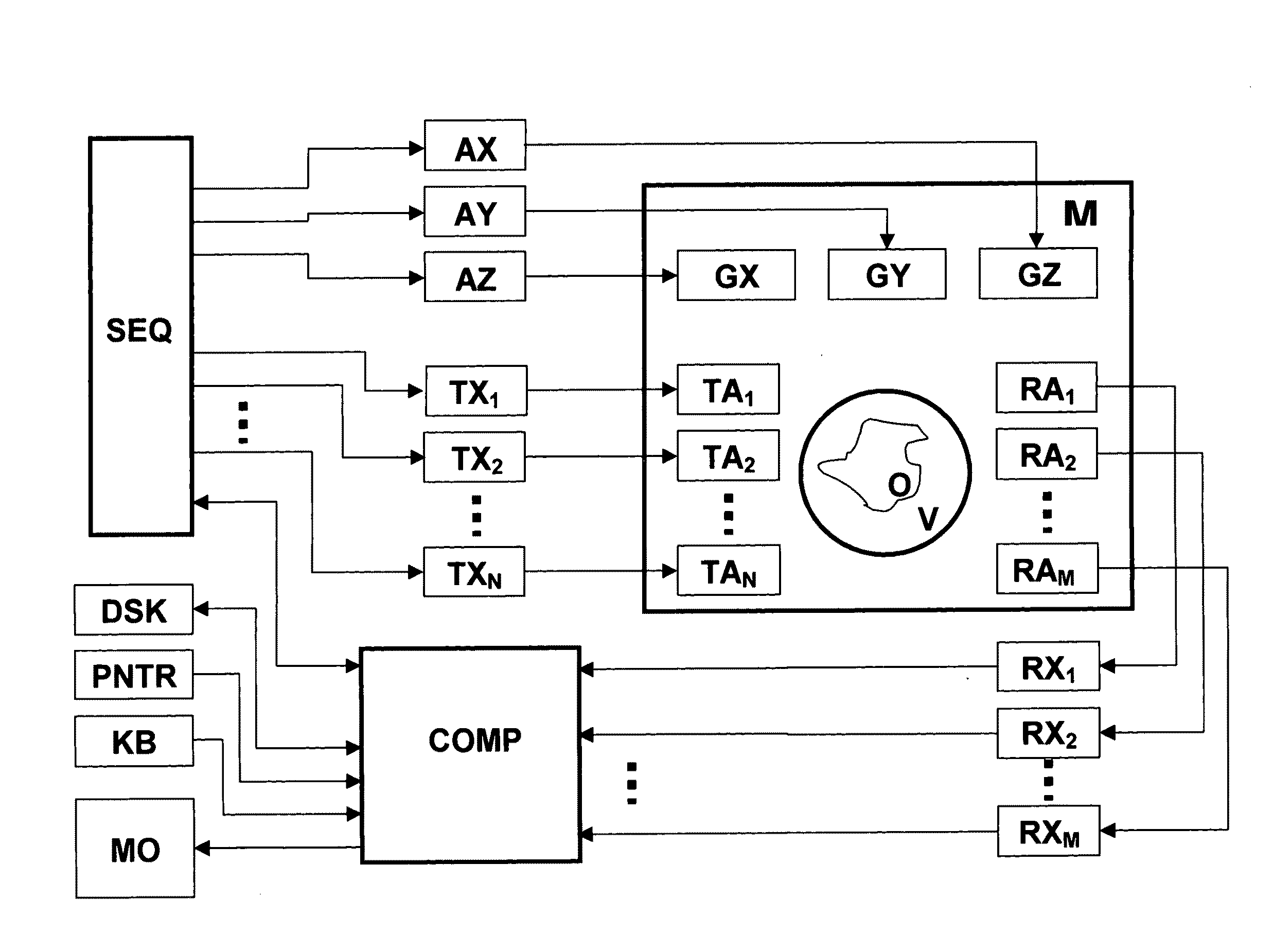

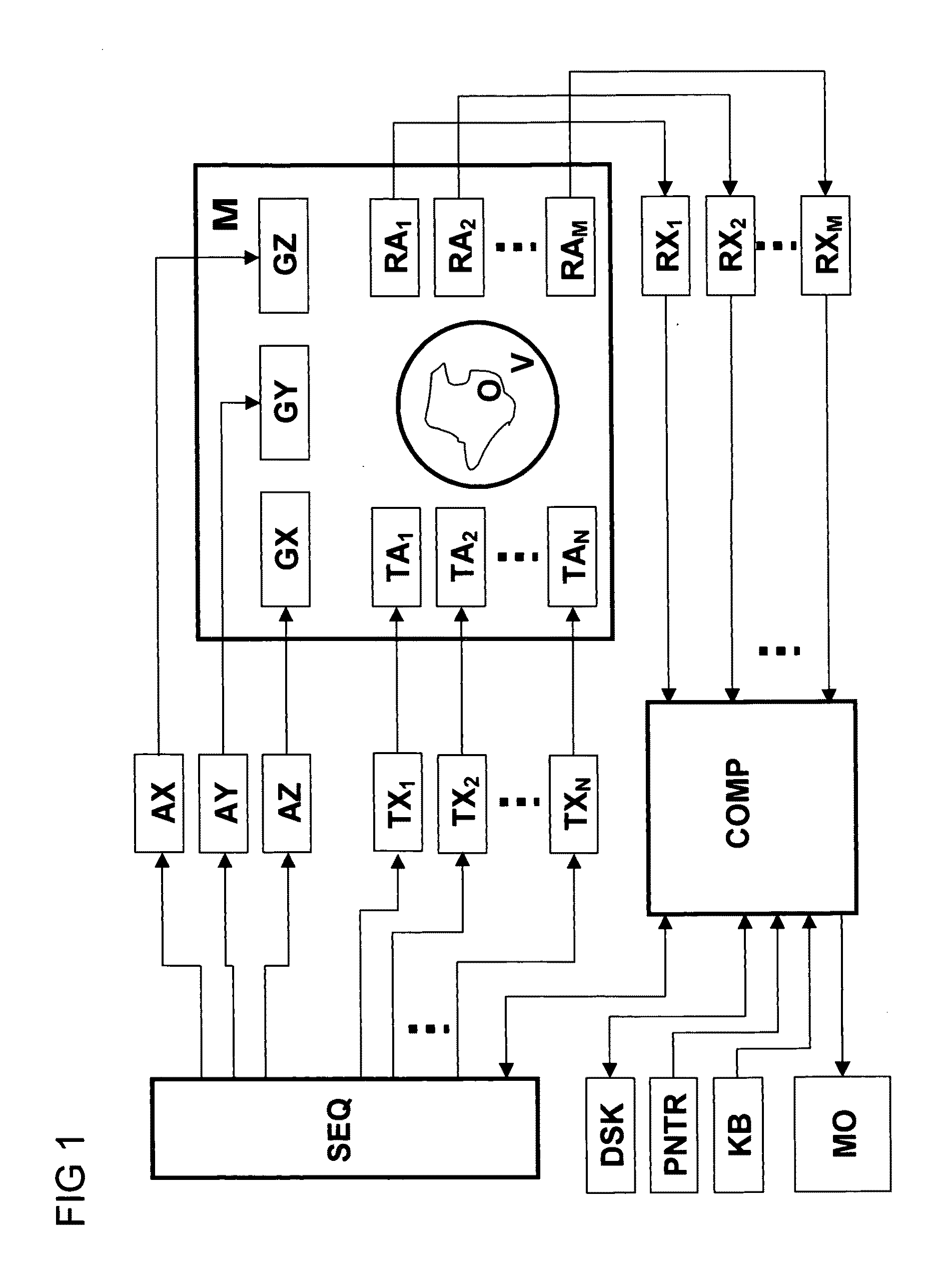

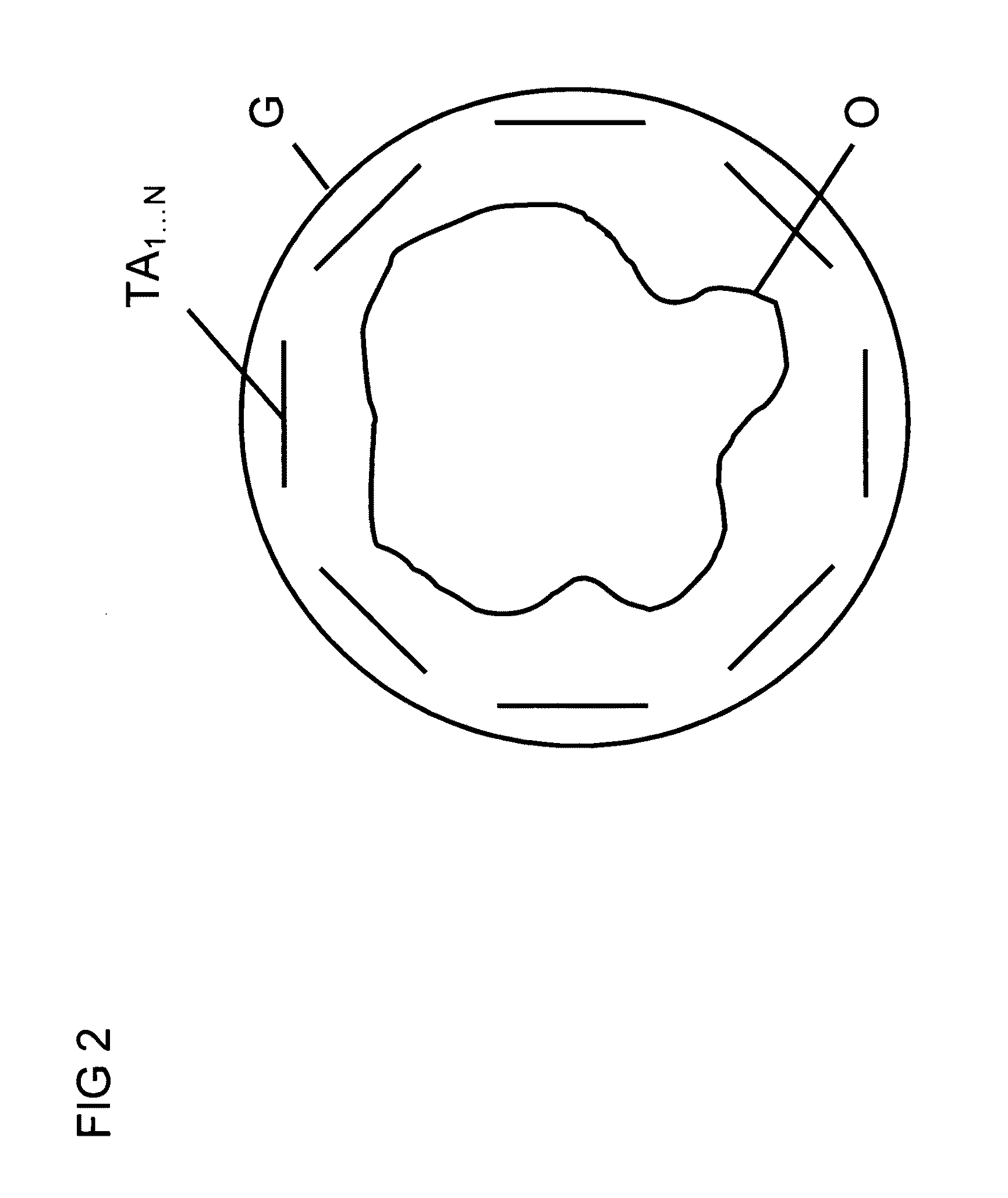

Method for obtaining amplitude and phase dependencies of RF pulses for spatially selective excitation

PatentActiveUS20100253336A1

Innovation

- A method involving a preparational measurement to resolve the phase and amplitude dependencies of RF pulses, accounting for both intentional and unintentional additional magnetic fields, allowing for compensation of experimental imperfections and enabling the use of non-linear magnetic fields for improved encoding and accuracy.

Safety Considerations in MR Fluid Applications

Safety considerations in magnetorheological (MR) fluid applications are paramount due to the unique properties and potential risks associated with these smart materials. The use of MR fluids in various applications, including automotive suspension systems, seismic protection devices, and prosthetic limbs, necessitates a comprehensive understanding of safety protocols and potential hazards.

One primary safety concern in MR fluid applications is the potential for leakage or spillage. MR fluids typically contain fine magnetic particles suspended in a carrier fluid, which can pose environmental and health risks if not properly contained. Proper sealing and containment systems must be implemented to prevent unintended release of the fluid. Regular maintenance and inspection of MR fluid-based devices are crucial to identify and address any potential leaks or degradation of containment components.

The magnetic properties of MR fluids also present unique safety challenges. Strong magnetic fields are often used to activate and control the rheological properties of these fluids. Proper shielding and isolation of magnetic components are essential to prevent interference with nearby electronic devices or medical implants. Additionally, appropriate warning signs and restricted access measures should be implemented in areas where strong magnetic fields are present.

Thermal management is another critical safety aspect in MR fluid applications. The continuous operation of MR devices can lead to heat generation, potentially altering the fluid's properties or causing thermal expansion of components. Adequate cooling systems and temperature monitoring mechanisms should be incorporated into the design to prevent overheating and maintain optimal performance.

The potential for particle settling or agglomeration in MR fluids over time can impact both performance and safety. Regular agitation or circulation of the fluid may be necessary to maintain its intended properties and prevent the formation of solid deposits that could interfere with the device's operation or cause mechanical failures.

Chemical compatibility between MR fluids and the materials used in the application must be carefully considered. Incompatible materials may lead to degradation of seals, corrosion of components, or alteration of the fluid's properties. Proper material selection and testing are essential to ensure long-term safety and reliability of MR fluid-based systems.

In applications where MR fluids come into contact with human skin or are used in medical devices, biocompatibility and toxicity assessments are crucial. The potential for allergic reactions or long-term health effects must be thoroughly evaluated, and appropriate protective measures implemented to minimize exposure risks.

Proper disposal and recycling procedures for MR fluids and related components must be established to address environmental concerns. The magnetic particles and carrier fluids may require special handling and treatment to prevent contamination of soil or water sources.

One primary safety concern in MR fluid applications is the potential for leakage or spillage. MR fluids typically contain fine magnetic particles suspended in a carrier fluid, which can pose environmental and health risks if not properly contained. Proper sealing and containment systems must be implemented to prevent unintended release of the fluid. Regular maintenance and inspection of MR fluid-based devices are crucial to identify and address any potential leaks or degradation of containment components.

The magnetic properties of MR fluids also present unique safety challenges. Strong magnetic fields are often used to activate and control the rheological properties of these fluids. Proper shielding and isolation of magnetic components are essential to prevent interference with nearby electronic devices or medical implants. Additionally, appropriate warning signs and restricted access measures should be implemented in areas where strong magnetic fields are present.

Thermal management is another critical safety aspect in MR fluid applications. The continuous operation of MR devices can lead to heat generation, potentially altering the fluid's properties or causing thermal expansion of components. Adequate cooling systems and temperature monitoring mechanisms should be incorporated into the design to prevent overheating and maintain optimal performance.

The potential for particle settling or agglomeration in MR fluids over time can impact both performance and safety. Regular agitation or circulation of the fluid may be necessary to maintain its intended properties and prevent the formation of solid deposits that could interfere with the device's operation or cause mechanical failures.

Chemical compatibility between MR fluids and the materials used in the application must be carefully considered. Incompatible materials may lead to degradation of seals, corrosion of components, or alteration of the fluid's properties. Proper material selection and testing are essential to ensure long-term safety and reliability of MR fluid-based systems.

In applications where MR fluids come into contact with human skin or are used in medical devices, biocompatibility and toxicity assessments are crucial. The potential for allergic reactions or long-term health effects must be thoroughly evaluated, and appropriate protective measures implemented to minimize exposure risks.

Proper disposal and recycling procedures for MR fluids and related components must be established to address environmental concerns. The magnetic particles and carrier fluids may require special handling and treatment to prevent contamination of soil or water sources.

Environmental Impact of MR Fluid Technologies

The environmental impact of magnetorheological (MR) fluid technologies is an increasingly important consideration as these smart materials find wider applications in various industries. MR fluids, composed of micron-sized magnetic particles suspended in a carrier fluid, offer unique properties that can be controlled by external magnetic fields. However, their production, use, and disposal present several environmental challenges that must be addressed.

The manufacturing process of MR fluids involves the synthesis of magnetic particles, typically iron-based, which can have significant energy requirements and associated carbon emissions. The production of carrier fluids, often petroleum-based, also contributes to the environmental footprint. As the demand for MR fluids grows, there is a pressing need to develop more sustainable manufacturing processes and explore eco-friendly alternatives for both magnetic particles and carrier fluids.

During their operational lifetime, MR fluids generally have a low direct environmental impact. They are contained within closed systems and do not typically release pollutants into the environment. However, the energy consumption of MR fluid-based devices, particularly in large-scale applications like civil engineering structures, should be considered in overall environmental assessments.

The end-of-life management of MR fluids poses significant environmental challenges. The disposal of used MR fluids, which may contain heavy metals and other potentially harmful substances, requires careful handling to prevent soil and water contamination. Recycling MR fluids is complex due to the difficulty in separating the magnetic particles from the carrier fluid, often resulting in the need for specialized waste treatment processes.

To mitigate these environmental concerns, research is being conducted on biodegradable carrier fluids and more easily recyclable magnetic particles. Some studies have explored the use of plant-based oils as carrier fluids, which could reduce the reliance on petroleum products. Additionally, efforts are being made to develop more efficient recycling techniques for MR fluids, including methods to recover and reuse the magnetic particles.

The long-term environmental impact of MR fluid technologies also depends on their potential to improve energy efficiency in various applications. For instance, MR fluid-based dampers in vehicles and buildings can enhance performance and potentially reduce overall energy consumption. Similarly, MR fluid clutches and brakes may lead to more efficient power transmission systems, indirectly contributing to reduced environmental impact through improved energy utilization.

As MR fluid technologies continue to evolve, it is crucial to adopt a lifecycle approach to assess and minimize their environmental impact. This includes considering the sourcing of raw materials, optimizing manufacturing processes, improving the longevity and efficiency of MR fluid-based devices, and developing effective end-of-life management strategies. By addressing these aspects, the environmental sustainability of MR fluid technologies can be significantly enhanced, ensuring their continued development and application aligns with global environmental goals.

The manufacturing process of MR fluids involves the synthesis of magnetic particles, typically iron-based, which can have significant energy requirements and associated carbon emissions. The production of carrier fluids, often petroleum-based, also contributes to the environmental footprint. As the demand for MR fluids grows, there is a pressing need to develop more sustainable manufacturing processes and explore eco-friendly alternatives for both magnetic particles and carrier fluids.

During their operational lifetime, MR fluids generally have a low direct environmental impact. They are contained within closed systems and do not typically release pollutants into the environment. However, the energy consumption of MR fluid-based devices, particularly in large-scale applications like civil engineering structures, should be considered in overall environmental assessments.

The end-of-life management of MR fluids poses significant environmental challenges. The disposal of used MR fluids, which may contain heavy metals and other potentially harmful substances, requires careful handling to prevent soil and water contamination. Recycling MR fluids is complex due to the difficulty in separating the magnetic particles from the carrier fluid, often resulting in the need for specialized waste treatment processes.

To mitigate these environmental concerns, research is being conducted on biodegradable carrier fluids and more easily recyclable magnetic particles. Some studies have explored the use of plant-based oils as carrier fluids, which could reduce the reliance on petroleum products. Additionally, efforts are being made to develop more efficient recycling techniques for MR fluids, including methods to recover and reuse the magnetic particles.

The long-term environmental impact of MR fluid technologies also depends on their potential to improve energy efficiency in various applications. For instance, MR fluid-based dampers in vehicles and buildings can enhance performance and potentially reduce overall energy consumption. Similarly, MR fluid clutches and brakes may lead to more efficient power transmission systems, indirectly contributing to reduced environmental impact through improved energy utilization.

As MR fluid technologies continue to evolve, it is crucial to adopt a lifecycle approach to assess and minimize their environmental impact. This includes considering the sourcing of raw materials, optimizing manufacturing processes, improving the longevity and efficiency of MR fluid-based devices, and developing effective end-of-life management strategies. By addressing these aspects, the environmental sustainability of MR fluid technologies can be significantly enhanced, ensuring their continued development and application aligns with global environmental goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!