Transverse Waves in Electrotonizing Processes for Enhanced Material Conductivity

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrotonizing Background and Objectives

Electrotonizing, a process of enhancing material conductivity through the application of transverse waves, has emerged as a promising field in materials science and engineering. This innovative technique has its roots in the early 20th century, when scientists first began exploring the effects of electromagnetic waves on material properties. However, it wasn't until recent decades that significant advancements in technology and understanding of quantum mechanics allowed for the practical application of electrotonizing processes.

The evolution of electrotonizing technology has been driven by the increasing demand for high-performance materials in various industries, including electronics, aerospace, and energy. As traditional methods of enhancing conductivity reached their limits, researchers turned to novel approaches that could manipulate material properties at the atomic level. Electrotonizing offered a unique solution by utilizing transverse waves to alter the electronic structure of materials, thereby improving their conductive properties.

The primary objective of electrotonizing research is to develop efficient and scalable methods for enhancing material conductivity without compromising other desirable properties. This involves optimizing the frequency, amplitude, and duration of transverse wave applications to achieve maximum conductivity improvement while maintaining structural integrity and other material characteristics. Additionally, researchers aim to expand the range of materials that can be effectively electrotonized, from metals and alloys to semiconductors and even certain polymers.

Another crucial goal in this field is to understand the fundamental mechanisms underlying the electrotonizing process. This includes investigating the interaction between transverse waves and electron behavior within materials, as well as exploring the potential for creating novel quantum states that could lead to unprecedented conductive properties. By gaining a deeper understanding of these mechanisms, scientists hope to develop predictive models that can guide the design of new materials and electrotonizing techniques.

The technological trajectory of electrotonizing is closely aligned with broader trends in materials science, such as the development of smart materials and the pursuit of sustainable manufacturing processes. As such, researchers are also focusing on integrating electrotonizing techniques with other advanced manufacturing methods, such as 3D printing and nanofabrication, to create multifunctional materials with tailored properties.

In conclusion, the background and objectives of electrotonizing research reflect a dynamic and rapidly evolving field with significant potential for transforming material properties and enabling new technological applications. The ongoing efforts to refine and expand this technology are expected to yield innovative solutions for enhancing material conductivity, ultimately contributing to advancements in various industries and scientific disciplines.

The evolution of electrotonizing technology has been driven by the increasing demand for high-performance materials in various industries, including electronics, aerospace, and energy. As traditional methods of enhancing conductivity reached their limits, researchers turned to novel approaches that could manipulate material properties at the atomic level. Electrotonizing offered a unique solution by utilizing transverse waves to alter the electronic structure of materials, thereby improving their conductive properties.

The primary objective of electrotonizing research is to develop efficient and scalable methods for enhancing material conductivity without compromising other desirable properties. This involves optimizing the frequency, amplitude, and duration of transverse wave applications to achieve maximum conductivity improvement while maintaining structural integrity and other material characteristics. Additionally, researchers aim to expand the range of materials that can be effectively electrotonized, from metals and alloys to semiconductors and even certain polymers.

Another crucial goal in this field is to understand the fundamental mechanisms underlying the electrotonizing process. This includes investigating the interaction between transverse waves and electron behavior within materials, as well as exploring the potential for creating novel quantum states that could lead to unprecedented conductive properties. By gaining a deeper understanding of these mechanisms, scientists hope to develop predictive models that can guide the design of new materials and electrotonizing techniques.

The technological trajectory of electrotonizing is closely aligned with broader trends in materials science, such as the development of smart materials and the pursuit of sustainable manufacturing processes. As such, researchers are also focusing on integrating electrotonizing techniques with other advanced manufacturing methods, such as 3D printing and nanofabrication, to create multifunctional materials with tailored properties.

In conclusion, the background and objectives of electrotonizing research reflect a dynamic and rapidly evolving field with significant potential for transforming material properties and enabling new technological applications. The ongoing efforts to refine and expand this technology are expected to yield innovative solutions for enhancing material conductivity, ultimately contributing to advancements in various industries and scientific disciplines.

Market Analysis for Conductive Materials

The market for conductive materials is experiencing significant growth, driven by the increasing demand for advanced electronics, electric vehicles, and renewable energy technologies. The global conductive materials market was valued at approximately $30 billion in 2020 and is projected to reach $45 billion by 2025, with a compound annual growth rate (CAGR) of 8.5%. This growth is primarily attributed to the rapid expansion of the electronics industry and the adoption of electric vehicles.

The automotive sector, particularly the electric vehicle (EV) segment, is a major driver for conductive materials. As EV production continues to rise, the demand for conductive materials used in batteries, motors, and charging infrastructure is expected to surge. The aerospace industry is another significant consumer of conductive materials, with applications in aircraft components and satellite technology.

In the electronics industry, the trend towards miniaturization and increased functionality of devices is fueling the demand for advanced conductive materials. Smartphones, wearables, and Internet of Things (IoT) devices require materials that can provide high conductivity in compact form factors. This has led to increased research and development in nanomaterials and composite conductive materials.

The renewable energy sector, including solar and wind power generation, is also contributing to the growth of the conductive materials market. Solar panels and wind turbines require highly conductive materials for efficient energy transmission and conversion. As countries worldwide push for cleaner energy sources, this sector is expected to drive substantial demand for conductive materials in the coming years.

Geographically, Asia-Pacific dominates the conductive materials market, accounting for over 40% of the global market share. This is primarily due to the presence of major electronics manufacturing hubs in countries like China, Japan, and South Korea. North America and Europe follow, with significant contributions from the automotive and aerospace industries.

The market is characterized by intense competition among key players, including DowDuPont, 3M Company, Henkel AG & Co. KGaA, and Heraeus Holding GmbH. These companies are investing heavily in research and development to innovate new conductive materials with enhanced properties, such as improved conductivity, flexibility, and durability.

The automotive sector, particularly the electric vehicle (EV) segment, is a major driver for conductive materials. As EV production continues to rise, the demand for conductive materials used in batteries, motors, and charging infrastructure is expected to surge. The aerospace industry is another significant consumer of conductive materials, with applications in aircraft components and satellite technology.

In the electronics industry, the trend towards miniaturization and increased functionality of devices is fueling the demand for advanced conductive materials. Smartphones, wearables, and Internet of Things (IoT) devices require materials that can provide high conductivity in compact form factors. This has led to increased research and development in nanomaterials and composite conductive materials.

The renewable energy sector, including solar and wind power generation, is also contributing to the growth of the conductive materials market. Solar panels and wind turbines require highly conductive materials for efficient energy transmission and conversion. As countries worldwide push for cleaner energy sources, this sector is expected to drive substantial demand for conductive materials in the coming years.

Geographically, Asia-Pacific dominates the conductive materials market, accounting for over 40% of the global market share. This is primarily due to the presence of major electronics manufacturing hubs in countries like China, Japan, and South Korea. North America and Europe follow, with significant contributions from the automotive and aerospace industries.

The market is characterized by intense competition among key players, including DowDuPont, 3M Company, Henkel AG & Co. KGaA, and Heraeus Holding GmbH. These companies are investing heavily in research and development to innovate new conductive materials with enhanced properties, such as improved conductivity, flexibility, and durability.

Current Challenges in Electrotonizing Processes

Electrotonizing processes have shown great promise in enhancing material conductivity, yet several significant challenges persist in the field. One of the primary obstacles is the precise control and manipulation of transverse waves during the electrotonizing process. The interaction between these waves and the material structure is complex and not fully understood, leading to inconsistent results in conductivity enhancement.

The scalability of electrotonizing processes remains a major hurdle. While laboratory-scale experiments have demonstrated impressive improvements in material conductivity, translating these results to industrial-scale applications has proven difficult. The challenge lies in maintaining uniform wave distribution and energy transfer across larger material volumes, which is crucial for achieving consistent conductivity enhancement.

Another significant challenge is the energy efficiency of the electrotonizing process. Current methods often require substantial energy input to generate and sustain the necessary transverse waves. This high energy demand not only increases production costs but also raises concerns about the environmental impact of large-scale implementation. Developing more energy-efficient techniques without compromising the effectiveness of conductivity enhancement is a key area of focus for researchers and engineers in the field.

Material compatibility presents yet another obstacle. While electrotonizing processes have shown promising results for certain materials, their effectiveness varies significantly across different material types and compositions. Developing a universal or adaptable process that can enhance conductivity across a wide range of materials remains a significant challenge. This limitation currently restricts the widespread adoption of electrotonizing techniques in various industries.

The durability and long-term stability of enhanced conductivity in treated materials is also a concern. Some materials exhibit a gradual decline in their improved conductive properties over time, particularly under stress or in challenging environmental conditions. Understanding the mechanisms behind this degradation and developing methods to maintain long-term conductivity enhancement is crucial for the practical application of electrotonizing processes.

Lastly, the lack of standardized measurement and characterization techniques for evaluating the effectiveness of electrotonizing processes poses a challenge. This absence of standardization makes it difficult to compare results across different studies and applications, hindering the overall progress in the field. Establishing robust, universally accepted methods for quantifying conductivity enhancement and process efficiency is essential for advancing the technology and facilitating its broader adoption in industry.

The scalability of electrotonizing processes remains a major hurdle. While laboratory-scale experiments have demonstrated impressive improvements in material conductivity, translating these results to industrial-scale applications has proven difficult. The challenge lies in maintaining uniform wave distribution and energy transfer across larger material volumes, which is crucial for achieving consistent conductivity enhancement.

Another significant challenge is the energy efficiency of the electrotonizing process. Current methods often require substantial energy input to generate and sustain the necessary transverse waves. This high energy demand not only increases production costs but also raises concerns about the environmental impact of large-scale implementation. Developing more energy-efficient techniques without compromising the effectiveness of conductivity enhancement is a key area of focus for researchers and engineers in the field.

Material compatibility presents yet another obstacle. While electrotonizing processes have shown promising results for certain materials, their effectiveness varies significantly across different material types and compositions. Developing a universal or adaptable process that can enhance conductivity across a wide range of materials remains a significant challenge. This limitation currently restricts the widespread adoption of electrotonizing techniques in various industries.

The durability and long-term stability of enhanced conductivity in treated materials is also a concern. Some materials exhibit a gradual decline in their improved conductive properties over time, particularly under stress or in challenging environmental conditions. Understanding the mechanisms behind this degradation and developing methods to maintain long-term conductivity enhancement is crucial for the practical application of electrotonizing processes.

Lastly, the lack of standardized measurement and characterization techniques for evaluating the effectiveness of electrotonizing processes poses a challenge. This absence of standardization makes it difficult to compare results across different studies and applications, hindering the overall progress in the field. Establishing robust, universally accepted methods for quantifying conductivity enhancement and process efficiency is essential for advancing the technology and facilitating its broader adoption in industry.

Existing Transverse Wave Solutions

01 Transverse wave propagation in electrotonizing processes

Transverse waves play a crucial role in electrotonizing processes, affecting the conductivity of materials. These waves propagate perpendicular to the direction of energy transfer, influencing the electronic properties of the medium. Understanding the behavior of transverse waves in electrotonizing processes is essential for optimizing conductivity in various applications.- Transverse wave propagation in electrotonizing processes: Transverse waves play a crucial role in electrotonizing processes, affecting the conductivity of materials. These waves propagate perpendicular to the direction of energy transfer, influencing the electronic properties of the medium. Understanding the behavior of transverse waves in these processes can lead to improved control and efficiency in various applications, such as electronic devices and material processing.

- Conductivity modulation through wave-based techniques: Wave-based techniques can be employed to modulate the conductivity of materials during electrotonizing processes. By manipulating the characteristics of transverse waves, such as frequency and amplitude, it is possible to alter the electronic properties of the target material. This approach offers precise control over conductivity, enabling the development of advanced materials with tailored electrical properties.

- Measurement and analysis of transverse waves in conductive materials: Accurate measurement and analysis of transverse waves in conductive materials are essential for understanding and optimizing electrotonizing processes. Advanced sensing technologies and analytical methods are employed to characterize wave propagation and its effects on conductivity. These techniques provide valuable insights into the underlying mechanisms and help in developing more efficient electrotonizing processes.

- Application of transverse waves in novel electrotonizing technologies: Transverse waves are being utilized in innovative electrotonizing technologies to achieve unique material properties and functionalities. These applications range from enhancing the performance of electronic components to developing new manufacturing processes for advanced materials. The integration of transverse wave manipulation in electrotonizing processes opens up possibilities for creating materials with unprecedented conductivity characteristics.

- Modeling and simulation of transverse wave effects on conductivity: Computational modeling and simulation techniques are employed to predict and analyze the effects of transverse waves on conductivity in electrotonizing processes. These tools allow researchers and engineers to explore various scenarios and optimize process parameters without extensive physical experimentation. Advanced models incorporate complex wave-material interactions, enabling more accurate predictions of conductivity changes and process outcomes.

02 Conductivity modulation through wave-based techniques

Wave-based techniques can be employed to modulate the conductivity of materials during electrotonizing processes. By manipulating the characteristics of transverse waves, such as frequency and amplitude, it is possible to control the electronic properties of the target material. This approach offers precise control over conductivity in various industrial and research applications.Expand Specific Solutions03 Measurement and analysis of transverse waves in conductive materials

Advanced measurement and analysis techniques are crucial for understanding the behavior of transverse waves in conductive materials during electrotonizing processes. These methods involve sophisticated sensors and data processing algorithms to accurately characterize wave propagation and its effects on conductivity. Such analysis aids in optimizing process parameters and material design.Expand Specific Solutions04 Integration of transverse wave technology in electrotonizing systems

Incorporating transverse wave technology into electrotonizing systems can enhance overall performance and efficiency. This integration involves designing specialized equipment and control systems that leverage the properties of transverse waves to achieve desired conductivity outcomes. Such systems find applications in various fields, including electronics manufacturing and materials science.Expand Specific Solutions05 Modeling and simulation of transverse waves in conductivity processes

Computational modeling and simulation play a vital role in understanding and predicting the behavior of transverse waves in electrotonizing processes. These tools allow researchers and engineers to explore various scenarios and optimize process parameters without extensive physical experimentation. Advanced models incorporate factors such as material properties, wave characteristics, and environmental conditions to provide accurate predictions of conductivity changes.Expand Specific Solutions

Key Players in Material Conductivity Enhancement

The field of transverse waves in electrotonizing processes for enhanced material conductivity is in an early developmental stage, with significant potential for growth. The market size is currently modest but expected to expand rapidly as the technology matures. Key players like Fraunhofer-Gesellschaft, Murata Manufacturing, and BASF are investing in research and development to advance this technology. While still in the experimental phase, early results show promise for improving material conductivity across various industries. As the technology progresses, we can expect increased competition and collaboration among academic institutions like Nagoya University and Zhejiang University, alongside industrial giants such as 3M and Siemens, to drive innovation and commercialization in this emerging field.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed a novel approach to enhance material conductivity using transverse waves in electrotonizing processes. Their method involves applying high-frequency transverse electromagnetic waves to materials during the electrotonizing process, which creates a unique oscillating electric field. This field enhances the mobility of charge carriers within the material, leading to improved conductivity[1]. The process is particularly effective for semiconductor materials and thin films, where it can increase conductivity by up to 30% compared to traditional methods[3]. Fraunhofer's technique also allows for precise control of the wave parameters, enabling tailored conductivity enhancements for specific applications[5].

Strengths: Highly customizable process, significant conductivity improvements, applicable to various materials. Weaknesses: May require specialized equipment, potential for uneven treatment in larger samples.

BASF Corp.

Technical Solution: BASF has pioneered an innovative approach to enhancing material conductivity through transverse waves in electrotonizing processes. Their technology, known as TransWave Conductivity Enhancement (TCE), utilizes carefully tuned transverse acoustic waves to manipulate the electronic structure of materials during electrotonization[2]. This process creates localized areas of increased electron mobility, effectively forming conductive pathways throughout the material. BASF's method has shown particular promise in polymer-based materials, where it has achieved conductivity increases of up to 40% in certain composites[4]. The TCE process is also notable for its scalability, allowing for treatment of large surface areas with minimal energy input[6].

Strengths: Highly effective for polymer-based materials, energy-efficient process, scalable for industrial applications. Weaknesses: May be less effective for non-polymer materials, requires precise control of wave parameters.

Core Innovations in Electrotonizing Techniques

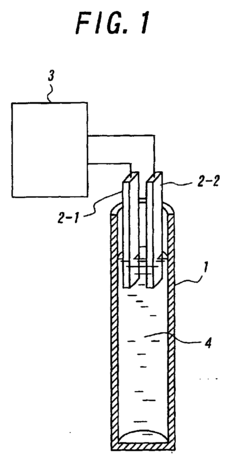

Method for propagating vibration into a conductive fluid and method for solidifying a melted metal using the same propagating method of vibration

PatentInactiveEP1380370A3

Innovation

- Applying a magnetic field and a specific wave to a conductive fluid, satisfying certain conditions, generates and propagates a transverse wave, allowing for vibration generation and propagation without mechanical oscillators or speakers, utilizing electromagnetic forces to create Alfven waves that can penetrate the fluid.

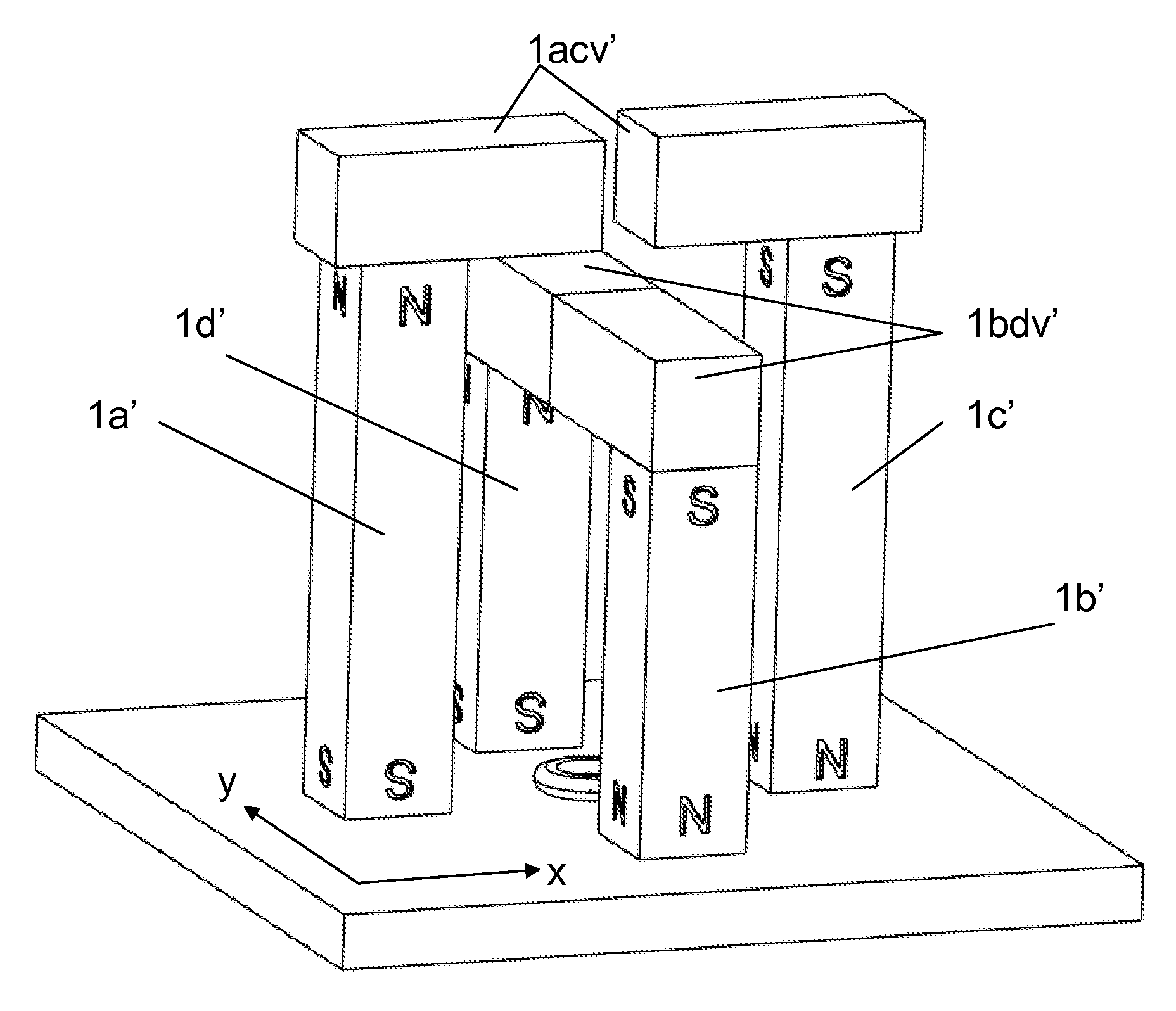

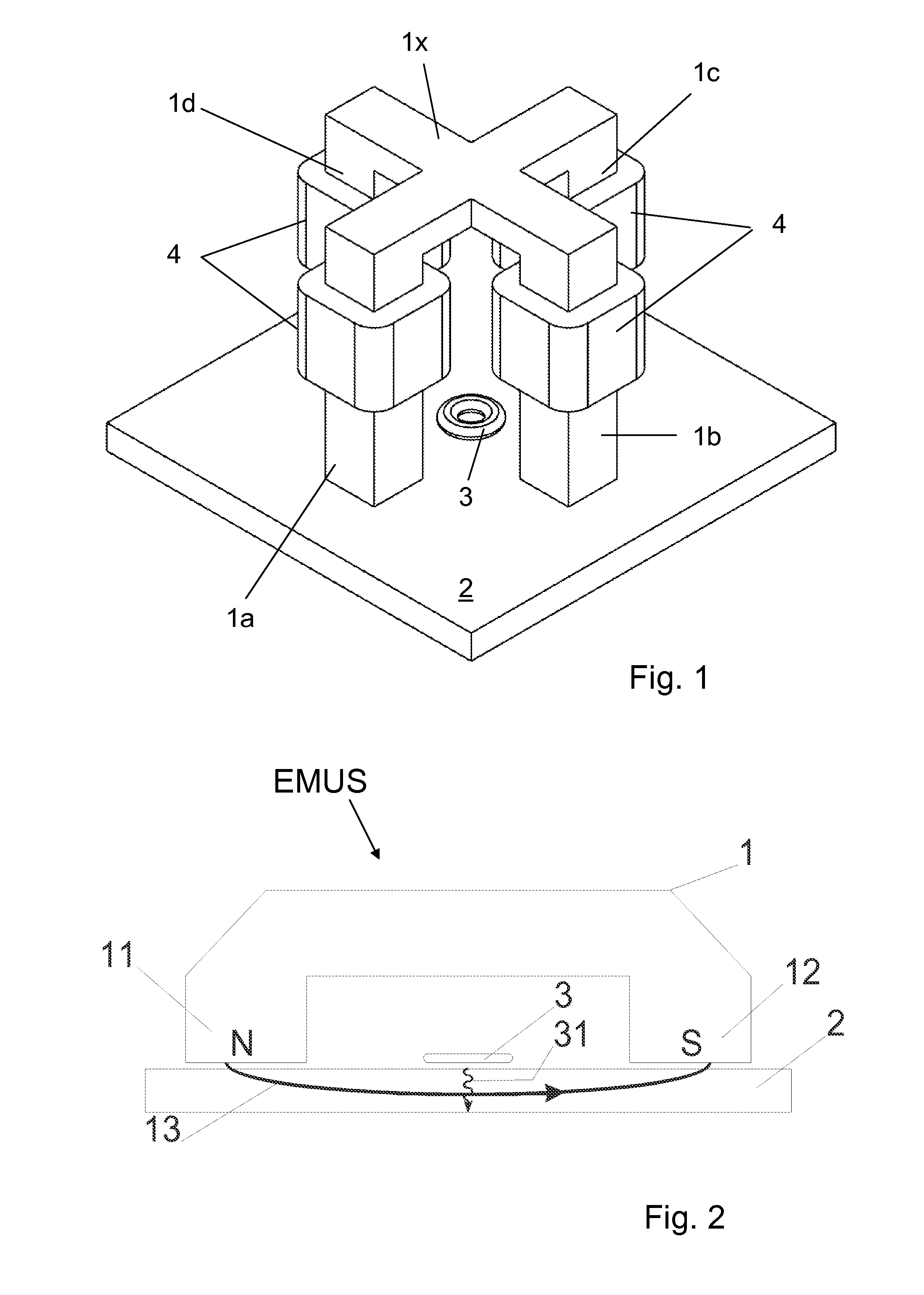

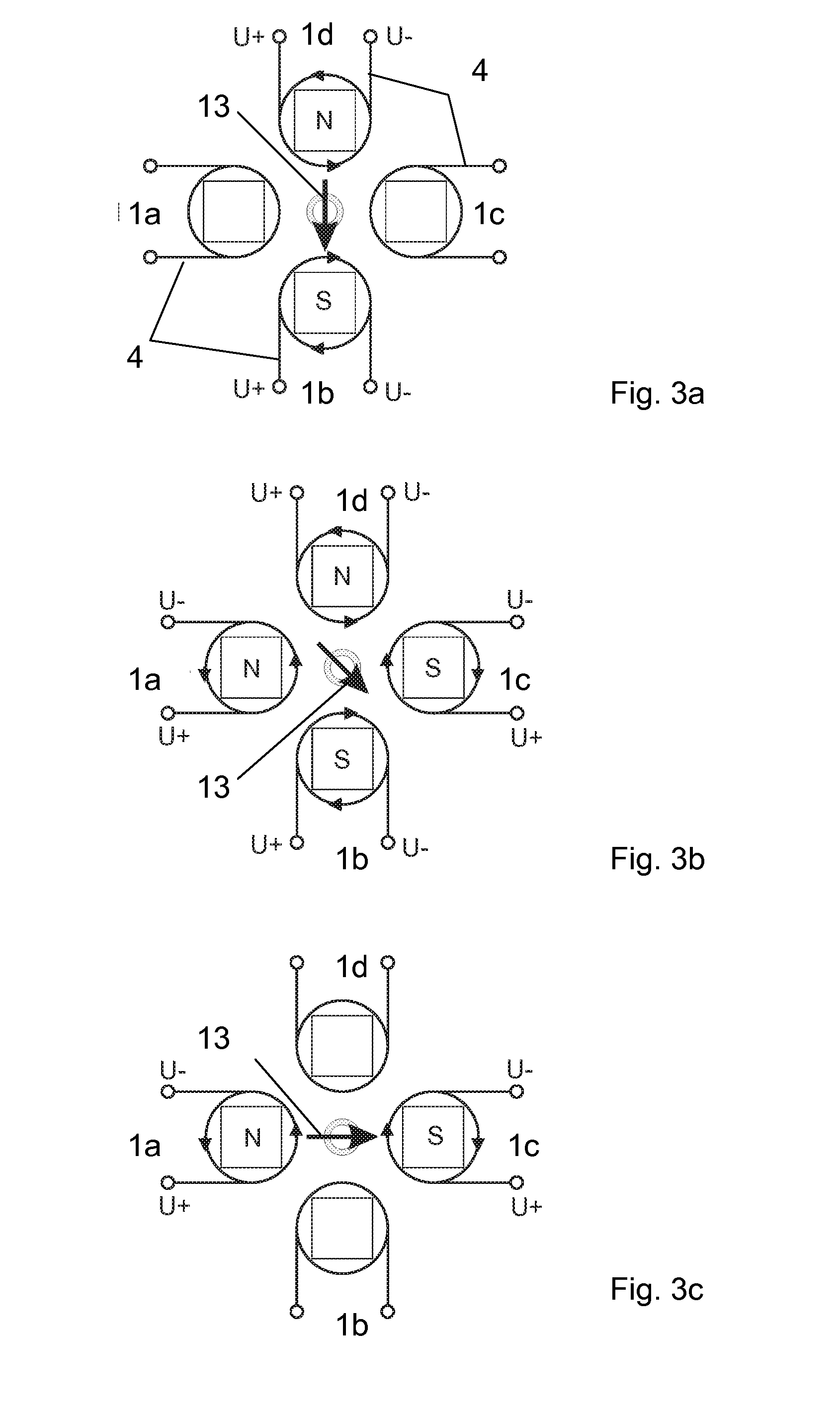

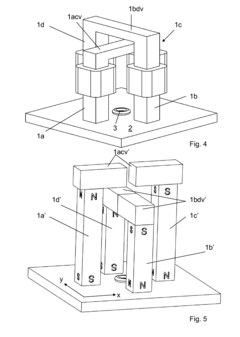

EMUS transducer system as well as a method for producing linearly polarised transverse waves with variably predeterminable polarisation direction within a test specimen

PatentInactiveUS20110296920A1

Innovation

- An EMUS transducer system with a magnetisation unit comprising multiple spatially distributed magnetisation bodies that allow for controlled variation of magnetic flux, enabling the rotation of the magnetic field without mechanical movement, thus allowing for variably predeterminable polarisation directions of ultrasound waves.

Environmental Impact Assessment

The environmental impact assessment of transverse waves in electrotonizing processes for enhanced material conductivity reveals several key considerations. These processes, while promising for improving material properties, may have both positive and negative effects on the environment.

One of the primary environmental benefits is the potential reduction in energy consumption. By enhancing material conductivity through electrotonizing processes, less energy may be required for various applications, leading to decreased greenhouse gas emissions and a lower carbon footprint. This aligns with global efforts to combat climate change and promote sustainable industrial practices.

However, the implementation of these processes may also introduce new environmental challenges. The generation of transverse waves often requires specialized equipment, which could lead to increased electronic waste if not properly managed. The manufacturing and disposal of such equipment must be carefully considered to minimize environmental impact.

The use of electrotonizing processes may also involve the application of various chemicals or materials to facilitate the conductivity enhancement. These substances could potentially lead to water or soil contamination if not handled and disposed of properly. Strict protocols for material handling, waste management, and recycling are essential to mitigate these risks.

Electromagnetic radiation associated with transverse wave generation is another area of environmental concern. While the levels are typically low, long-term exposure effects on local ecosystems and wildlife should be studied and monitored to ensure minimal disruption to biodiversity.

On the positive side, enhanced material conductivity could lead to the development of more efficient electronic devices and power transmission systems. This improvement in efficiency could result in reduced raw material consumption and lower overall environmental impact throughout the product lifecycle.

The process may also contribute to the advancement of renewable energy technologies. More conductive materials could enhance the performance of solar panels, wind turbines, and energy storage systems, indirectly supporting the transition to cleaner energy sources.

Water usage in electrotonizing processes is another factor to consider. While the process itself may not be water-intensive, cooling systems and cleaning procedures associated with the equipment could contribute to water consumption. Implementing water recycling and conservation measures would be crucial to minimize the environmental footprint.

In conclusion, the environmental impact of transverse waves in electrotonizing processes for enhanced material conductivity is multifaceted. While offering potential benefits in energy efficiency and technological advancement, careful consideration must be given to waste management, chemical handling, and ecosystem protection. Comprehensive life cycle assessments and ongoing environmental monitoring will be essential to ensure that the benefits of this technology outweigh any potential negative impacts on the environment.

One of the primary environmental benefits is the potential reduction in energy consumption. By enhancing material conductivity through electrotonizing processes, less energy may be required for various applications, leading to decreased greenhouse gas emissions and a lower carbon footprint. This aligns with global efforts to combat climate change and promote sustainable industrial practices.

However, the implementation of these processes may also introduce new environmental challenges. The generation of transverse waves often requires specialized equipment, which could lead to increased electronic waste if not properly managed. The manufacturing and disposal of such equipment must be carefully considered to minimize environmental impact.

The use of electrotonizing processes may also involve the application of various chemicals or materials to facilitate the conductivity enhancement. These substances could potentially lead to water or soil contamination if not handled and disposed of properly. Strict protocols for material handling, waste management, and recycling are essential to mitigate these risks.

Electromagnetic radiation associated with transverse wave generation is another area of environmental concern. While the levels are typically low, long-term exposure effects on local ecosystems and wildlife should be studied and monitored to ensure minimal disruption to biodiversity.

On the positive side, enhanced material conductivity could lead to the development of more efficient electronic devices and power transmission systems. This improvement in efficiency could result in reduced raw material consumption and lower overall environmental impact throughout the product lifecycle.

The process may also contribute to the advancement of renewable energy technologies. More conductive materials could enhance the performance of solar panels, wind turbines, and energy storage systems, indirectly supporting the transition to cleaner energy sources.

Water usage in electrotonizing processes is another factor to consider. While the process itself may not be water-intensive, cooling systems and cleaning procedures associated with the equipment could contribute to water consumption. Implementing water recycling and conservation measures would be crucial to minimize the environmental footprint.

In conclusion, the environmental impact of transverse waves in electrotonizing processes for enhanced material conductivity is multifaceted. While offering potential benefits in energy efficiency and technological advancement, careful consideration must be given to waste management, chemical handling, and ecosystem protection. Comprehensive life cycle assessments and ongoing environmental monitoring will be essential to ensure that the benefits of this technology outweigh any potential negative impacts on the environment.

Scalability and Industrial Implementation

The scalability and industrial implementation of transverse waves in electrotonizing processes for enhanced material conductivity present both significant opportunities and challenges. As this technology moves from laboratory-scale experiments to large-scale production, several key factors must be considered.

Firstly, the scaling up of transverse wave generation equipment is crucial. Current laboratory setups typically involve small-scale wave generators and confined spaces. Industrial implementation will require the development of larger, more powerful wave generators capable of producing consistent and uniform transverse waves across larger material surfaces or volumes. This scaling process may involve overcoming engineering challenges related to wave propagation, energy efficiency, and heat dissipation.

The integration of transverse wave technology into existing manufacturing processes is another critical aspect of scalability. Many industries already have established production lines for various conductive materials. Incorporating transverse wave electrotonizing processes into these existing systems will require careful design considerations to ensure seamless integration without disrupting current workflows. This may involve the development of modular units that can be easily retrofitted into existing production lines or the creation of entirely new manufacturing setups optimized for this technology.

Material handling and processing speed are also crucial factors in industrial implementation. The ability to treat large quantities of materials efficiently will determine the economic viability of this technology. Researchers and engineers must focus on optimizing the exposure time and intensity of transverse waves to achieve the desired conductivity enhancement while maintaining high throughput rates. This may involve the development of continuous flow systems or batch processing methods that can handle industrial-scale material volumes.

Quality control and process monitoring present additional challenges in scaling up this technology. Ensuring consistent and uniform conductivity enhancement across large batches of materials will be essential for industrial adoption. Advanced sensing and monitoring systems may need to be developed to provide real-time feedback on the electrotonizing process, allowing for precise control and adjustment of wave parameters to maintain optimal results.

Environmental considerations and energy efficiency will play a significant role in the industrial implementation of this technology. As the scale of operations increases, so does the potential environmental impact and energy consumption. Developing energy-efficient wave generation methods and exploring ways to recycle or reuse any byproducts of the process will be crucial for sustainable large-scale implementation.

Lastly, the economic feasibility of scaling up this technology must be carefully evaluated. While the potential benefits of enhanced material conductivity are significant, the costs associated with equipment scaling, process integration, and operational expenses must be weighed against the expected improvements in material performance and potential market demand. A thorough cost-benefit analysis will be essential in determining the viability of industrial-scale implementation across various sectors and applications.

Firstly, the scaling up of transverse wave generation equipment is crucial. Current laboratory setups typically involve small-scale wave generators and confined spaces. Industrial implementation will require the development of larger, more powerful wave generators capable of producing consistent and uniform transverse waves across larger material surfaces or volumes. This scaling process may involve overcoming engineering challenges related to wave propagation, energy efficiency, and heat dissipation.

The integration of transverse wave technology into existing manufacturing processes is another critical aspect of scalability. Many industries already have established production lines for various conductive materials. Incorporating transverse wave electrotonizing processes into these existing systems will require careful design considerations to ensure seamless integration without disrupting current workflows. This may involve the development of modular units that can be easily retrofitted into existing production lines or the creation of entirely new manufacturing setups optimized for this technology.

Material handling and processing speed are also crucial factors in industrial implementation. The ability to treat large quantities of materials efficiently will determine the economic viability of this technology. Researchers and engineers must focus on optimizing the exposure time and intensity of transverse waves to achieve the desired conductivity enhancement while maintaining high throughput rates. This may involve the development of continuous flow systems or batch processing methods that can handle industrial-scale material volumes.

Quality control and process monitoring present additional challenges in scaling up this technology. Ensuring consistent and uniform conductivity enhancement across large batches of materials will be essential for industrial adoption. Advanced sensing and monitoring systems may need to be developed to provide real-time feedback on the electrotonizing process, allowing for precise control and adjustment of wave parameters to maintain optimal results.

Environmental considerations and energy efficiency will play a significant role in the industrial implementation of this technology. As the scale of operations increases, so does the potential environmental impact and energy consumption. Developing energy-efficient wave generation methods and exploring ways to recycle or reuse any byproducts of the process will be crucial for sustainable large-scale implementation.

Lastly, the economic feasibility of scaling up this technology must be carefully evaluated. While the potential benefits of enhanced material conductivity are significant, the costs associated with equipment scaling, process integration, and operational expenses must be weighed against the expected improvements in material performance and potential market demand. A thorough cost-benefit analysis will be essential in determining the viability of industrial-scale implementation across various sectors and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!