Understanding Transverse Wave Formations in Microstructured Hydrophobic Surfaces

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microstructured Hydrophobic Surface Wave Dynamics

The study of transverse wave formations in microstructured hydrophobic surfaces has gained significant attention in recent years due to its potential applications in various fields, including microfluidics, heat transfer, and self-cleaning surfaces. These wave dynamics are characterized by the interaction between liquid droplets and the underlying microstructured surface, resulting in unique patterns and behaviors.

Microstructured hydrophobic surfaces typically consist of engineered patterns or textures at the microscale, which enhance the natural hydrophobicity of the material. These structures can include arrays of pillars, grooves, or more complex geometries. When a liquid droplet is placed on such a surface, it tends to maintain a high contact angle, minimizing its contact area with the solid substrate.

The formation of transverse waves on these surfaces is primarily driven by the interplay between surface tension, gravity, and the specific geometry of the microstructures. As a droplet moves across the surface, it encounters periodic variations in surface energy due to the microstructures. This interaction can lead to the development of standing waves or traveling waves along the liquid-air interface.

One of the key factors influencing wave dynamics is the spacing and dimensions of the microstructures. Researchers have observed that the wavelength of the transverse waves is often closely related to the periodicity of the underlying surface features. Additionally, the amplitude of these waves can be affected by the height and shape of the microstructures, as well as the properties of the liquid itself.

The behavior of these waves can be further complicated by external factors such as vibration, temperature gradients, or electric fields. For instance, applying an oscillating electric field to the system can induce resonant modes in the liquid, leading to more complex wave patterns and potentially enhancing droplet mobility.

Understanding the mechanisms behind these wave formations is crucial for optimizing surface designs for specific applications. For example, in heat transfer applications, the presence of these waves can significantly enhance the heat dissipation rate by increasing the effective surface area and promoting mixing within the liquid layer.

Recent advancements in high-speed imaging and computational modeling have greatly improved our ability to study these phenomena. Researchers are now able to capture the rapid dynamics of wave formation and propagation with unprecedented detail, allowing for more accurate comparisons between experimental observations and theoretical predictions.

As the field progresses, there is growing interest in developing active control mechanisms for these wave dynamics. This could potentially lead to smart surfaces capable of adapting their wetting properties in real-time, opening up new possibilities for advanced liquid handling and manipulation at the microscale.

Microstructured hydrophobic surfaces typically consist of engineered patterns or textures at the microscale, which enhance the natural hydrophobicity of the material. These structures can include arrays of pillars, grooves, or more complex geometries. When a liquid droplet is placed on such a surface, it tends to maintain a high contact angle, minimizing its contact area with the solid substrate.

The formation of transverse waves on these surfaces is primarily driven by the interplay between surface tension, gravity, and the specific geometry of the microstructures. As a droplet moves across the surface, it encounters periodic variations in surface energy due to the microstructures. This interaction can lead to the development of standing waves or traveling waves along the liquid-air interface.

One of the key factors influencing wave dynamics is the spacing and dimensions of the microstructures. Researchers have observed that the wavelength of the transverse waves is often closely related to the periodicity of the underlying surface features. Additionally, the amplitude of these waves can be affected by the height and shape of the microstructures, as well as the properties of the liquid itself.

The behavior of these waves can be further complicated by external factors such as vibration, temperature gradients, or electric fields. For instance, applying an oscillating electric field to the system can induce resonant modes in the liquid, leading to more complex wave patterns and potentially enhancing droplet mobility.

Understanding the mechanisms behind these wave formations is crucial for optimizing surface designs for specific applications. For example, in heat transfer applications, the presence of these waves can significantly enhance the heat dissipation rate by increasing the effective surface area and promoting mixing within the liquid layer.

Recent advancements in high-speed imaging and computational modeling have greatly improved our ability to study these phenomena. Researchers are now able to capture the rapid dynamics of wave formation and propagation with unprecedented detail, allowing for more accurate comparisons between experimental observations and theoretical predictions.

As the field progresses, there is growing interest in developing active control mechanisms for these wave dynamics. This could potentially lead to smart surfaces capable of adapting their wetting properties in real-time, opening up new possibilities for advanced liquid handling and manipulation at the microscale.

Industrial Applications of Transverse Waves

Transverse waves in microstructured hydrophobic surfaces have found numerous industrial applications across various sectors, leveraging their unique properties to enhance processes and product performance. In the manufacturing industry, these waves have been utilized to improve surface coatings and treatments, particularly in the production of self-cleaning materials. By creating microscale patterns that mimic the lotus leaf effect, manufacturers can produce surfaces with exceptional water-repellent and anti-fouling properties. This technology has been applied to automotive windshields, reducing the need for wipers and improving visibility in adverse weather conditions.

The aerospace industry has also benefited from the application of transverse waves in hydrophobic surfaces. Aircraft manufacturers have incorporated these microstructures into the design of wing surfaces and fuselages to reduce drag and improve fuel efficiency. The ability of these surfaces to repel water and prevent ice formation has led to significant advancements in de-icing systems, enhancing flight safety and reducing maintenance costs.

In the energy sector, transverse wave formations have been employed in the development of more efficient solar panels. By applying microstructured hydrophobic coatings to photovoltaic cells, researchers have achieved improved light absorption and reduced dust accumulation, resulting in higher energy conversion rates and lower maintenance requirements. This technology has also been adapted for use in wind turbine blades, where it helps to prevent ice buildup and maintain optimal aerodynamic performance in cold climates.

The textile industry has embraced transverse wave technology to create high-performance fabrics with enhanced water-repellent properties. Outdoor clothing and equipment manufacturers have incorporated these microstructures into their products, offering consumers garments and gear with superior water resistance and breathability. This has led to the development of more comfortable and durable outdoor wear, suitable for extreme weather conditions.

In the field of marine engineering, transverse waves in hydrophobic surfaces have been applied to ship hulls and offshore structures. The resulting reduction in drag and biofouling has contributed to improved fuel efficiency and reduced maintenance costs for shipping companies. Additionally, this technology has been used in the design of underwater sensors and equipment, enhancing their performance and longevity in harsh marine environments.

The medical industry has also found applications for transverse wave formations in hydrophobic surfaces. These microstructures have been used to develop more effective drug delivery systems, create anti-bacterial surfaces for medical devices, and improve the performance of diagnostic tools. In particular, the ability to control fluid behavior at the microscale has led to advancements in microfluidic devices used in point-of-care diagnostics and lab-on-a-chip technologies.

The aerospace industry has also benefited from the application of transverse waves in hydrophobic surfaces. Aircraft manufacturers have incorporated these microstructures into the design of wing surfaces and fuselages to reduce drag and improve fuel efficiency. The ability of these surfaces to repel water and prevent ice formation has led to significant advancements in de-icing systems, enhancing flight safety and reducing maintenance costs.

In the energy sector, transverse wave formations have been employed in the development of more efficient solar panels. By applying microstructured hydrophobic coatings to photovoltaic cells, researchers have achieved improved light absorption and reduced dust accumulation, resulting in higher energy conversion rates and lower maintenance requirements. This technology has also been adapted for use in wind turbine blades, where it helps to prevent ice buildup and maintain optimal aerodynamic performance in cold climates.

The textile industry has embraced transverse wave technology to create high-performance fabrics with enhanced water-repellent properties. Outdoor clothing and equipment manufacturers have incorporated these microstructures into their products, offering consumers garments and gear with superior water resistance and breathability. This has led to the development of more comfortable and durable outdoor wear, suitable for extreme weather conditions.

In the field of marine engineering, transverse waves in hydrophobic surfaces have been applied to ship hulls and offshore structures. The resulting reduction in drag and biofouling has contributed to improved fuel efficiency and reduced maintenance costs for shipping companies. Additionally, this technology has been used in the design of underwater sensors and equipment, enhancing their performance and longevity in harsh marine environments.

The medical industry has also found applications for transverse wave formations in hydrophobic surfaces. These microstructures have been used to develop more effective drug delivery systems, create anti-bacterial surfaces for medical devices, and improve the performance of diagnostic tools. In particular, the ability to control fluid behavior at the microscale has led to advancements in microfluidic devices used in point-of-care diagnostics and lab-on-a-chip technologies.

Current Challenges in Wave Formation Analysis

The analysis of transverse wave formations in microstructured hydrophobic surfaces presents several significant challenges that researchers and engineers are currently grappling with. One of the primary difficulties lies in accurately modeling the complex interactions between the liquid-solid interface and the surrounding fluid dynamics. The intricate nature of microstructured surfaces, with their varied geometries and surface properties, makes it challenging to develop comprehensive mathematical models that can predict wave behavior across different scales and conditions.

Another major hurdle is the limitation of current experimental techniques in capturing high-resolution, real-time data of wave formation and propagation at the microscale. Traditional imaging methods often lack the spatial and temporal resolution necessary to observe the rapid and subtle changes in wave patterns on these surfaces. This gap in observational capabilities hinders the validation of theoretical models and impedes the development of more accurate predictive tools.

The multiscale nature of the phenomenon also poses a significant challenge. Researchers must consider interactions at the molecular level, where surface chemistry and nanoscale roughness play crucial roles, while simultaneously accounting for macroscopic fluid behavior. Bridging these disparate scales in a unified theoretical framework remains an ongoing challenge in the field.

Furthermore, the influence of external factors such as temperature, pressure, and environmental contaminants on wave formation and stability is not fully understood. These variables can significantly alter surface properties and fluid dynamics, making it difficult to develop robust and universally applicable models for wave formation analysis.

The non-linear nature of wave formation and propagation on microstructured hydrophobic surfaces adds another layer of complexity to the analysis. Traditional linear approximations often fail to capture the full range of behaviors observed in these systems, necessitating the development of more sophisticated non-linear analytical and computational methods.

Lastly, the interdisciplinary nature of this research area presents its own set of challenges. Effective analysis requires expertise from various fields, including fluid dynamics, materials science, surface chemistry, and advanced computational methods. Integrating these diverse perspectives and methodologies into a cohesive analytical framework remains an ongoing challenge in advancing our understanding of transverse wave formations in microstructured hydrophobic surfaces.

Another major hurdle is the limitation of current experimental techniques in capturing high-resolution, real-time data of wave formation and propagation at the microscale. Traditional imaging methods often lack the spatial and temporal resolution necessary to observe the rapid and subtle changes in wave patterns on these surfaces. This gap in observational capabilities hinders the validation of theoretical models and impedes the development of more accurate predictive tools.

The multiscale nature of the phenomenon also poses a significant challenge. Researchers must consider interactions at the molecular level, where surface chemistry and nanoscale roughness play crucial roles, while simultaneously accounting for macroscopic fluid behavior. Bridging these disparate scales in a unified theoretical framework remains an ongoing challenge in the field.

Furthermore, the influence of external factors such as temperature, pressure, and environmental contaminants on wave formation and stability is not fully understood. These variables can significantly alter surface properties and fluid dynamics, making it difficult to develop robust and universally applicable models for wave formation analysis.

The non-linear nature of wave formation and propagation on microstructured hydrophobic surfaces adds another layer of complexity to the analysis. Traditional linear approximations often fail to capture the full range of behaviors observed in these systems, necessitating the development of more sophisticated non-linear analytical and computational methods.

Lastly, the interdisciplinary nature of this research area presents its own set of challenges. Effective analysis requires expertise from various fields, including fluid dynamics, materials science, surface chemistry, and advanced computational methods. Integrating these diverse perspectives and methodologies into a cohesive analytical framework remains an ongoing challenge in advancing our understanding of transverse wave formations in microstructured hydrophobic surfaces.

Existing Models for Transverse Wave Prediction

01 Microstructured hydrophobic surface design

Surfaces with microscale structures can be engineered to enhance hydrophobicity. These designs often incorporate patterns or textures that trap air pockets, reducing water contact with the surface. Such microstructures can be inspired by natural surfaces like lotus leaves, and may involve techniques like lithography or etching to create precise patterns.- Fabrication of microstructured hydrophobic surfaces: Various techniques are employed to create microstructured hydrophobic surfaces, including lithography, etching, and deposition methods. These processes allow for precise control over surface topography, creating patterns that enhance hydrophobicity and potentially incorporate transverse wave formations.

- Transverse wave formations on hydrophobic surfaces: Transverse wave formations on hydrophobic surfaces can be engineered to manipulate fluid behavior, enhance self-cleaning properties, and control wettability. These structures may be designed to create specific patterns of air pockets or to guide liquid flow in desired directions.

- Applications of microstructured hydrophobic surfaces: Microstructured hydrophobic surfaces with transverse wave formations find applications in various fields, including self-cleaning coatings, anti-icing surfaces, drag reduction in fluid dynamics, and enhanced heat transfer in thermal management systems.

- Characterization and analysis of surface structures: Advanced characterization techniques are used to analyze and measure the properties of microstructured hydrophobic surfaces and transverse wave formations. These may include atomic force microscopy, scanning electron microscopy, and optical profilometry to assess surface topography and wetting behavior.

- Biomimetic approaches to hydrophobic surface design: Inspiration from nature, such as lotus leaves or shark skin, guides the design of microstructured hydrophobic surfaces with transverse wave formations. These bio-inspired approaches aim to replicate the exceptional water-repellent and drag-reducing properties found in natural systems.

02 Transverse wave formations on surfaces

Transverse wave patterns can be created on surfaces to manipulate fluid behavior. These wave-like structures can influence flow dynamics, potentially enhancing hydrophobicity or other surface properties. The specific geometry and scale of these waves can be tailored for different applications, from microfluidics to larger-scale fluid management.Expand Specific Solutions03 Advanced manufacturing techniques for surface texturing

Various manufacturing methods are employed to create microstructured hydrophobic surfaces. These may include laser ablation, 3D printing, chemical etching, or plasma treatments. Each technique offers different capabilities in terms of feature size, material compatibility, and scalability for producing complex surface patterns.Expand Specific Solutions04 Applications of microstructured hydrophobic surfaces

Microstructured hydrophobic surfaces find applications in diverse fields. They can be used in self-cleaning materials, anti-icing surfaces, drag reduction in fluid systems, and enhanced heat transfer devices. The specific surface design is often tailored to the intended application, balancing factors like durability, cost, and performance.Expand Specific Solutions05 Characterization and analysis of surface structures

Advanced techniques are used to characterize and analyze microstructured surfaces. These may include atomic force microscopy, scanning electron microscopy, and optical profilometry. Computational modeling and simulation tools are also employed to predict and optimize surface behavior, particularly for complex wave formations and their interactions with fluids.Expand Specific Solutions

Key Players in Hydrophobic Surface Research

The field of transverse wave formations in microstructured hydrophobic surfaces is in an early development stage, with growing interest from both academia and industry. The market size is relatively small but expanding as applications in microfluidics and surface engineering emerge. Technologically, it's still in the research phase, with key players like Centre National de la Recherche Scientifique, Jiangsu University, and The University of Liverpool leading academic efforts. Companies such as FUJIFILM Corp. and TDK Corp. are exploring potential industrial applications, though commercial products are limited. The technology's maturity is low to moderate, with ongoing research focusing on understanding fundamental mechanisms and developing practical applications.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed advanced techniques for studying transverse wave formations in microstructured hydrophobic surfaces. Their approach combines high-resolution imaging techniques with computational fluid dynamics to analyze the complex interactions between liquid and microstructured surfaces. They have successfully mapped the formation and propagation of transverse waves at the micro-scale, providing insights into the mechanisms of droplet movement and surface wettability[1]. CNRS researchers have also developed novel surface patterning methods to control and manipulate transverse wave formations, potentially leading to applications in microfluidics and self-cleaning surfaces[3].

Strengths: Cutting-edge imaging and computational techniques, interdisciplinary approach combining physics and materials science. Weaknesses: Potential challenges in scaling up laboratory findings to practical applications.

The University of Liverpool

Technical Solution: The University of Liverpool has made significant contributions to understanding transverse wave formations in microstructured hydrophobic surfaces through their innovative research in soft matter physics and nanomaterials. Their team has developed a unique experimental setup that allows real-time observation of transverse wave dynamics on specially designed hydrophobic surfaces[2]. Using advanced spectroscopic techniques, they have characterized the molecular interactions at the liquid-solid interface, providing new insights into the mechanisms of wave formation and propagation. The university's research has also explored the potential applications of these phenomena in areas such as drag reduction and enhanced heat transfer in microfluidic devices[5].

Strengths: Strong expertise in soft matter physics and nanomaterials, state-of-the-art experimental facilities. Weaknesses: May face challenges in translating fundamental research into practical industrial applications.

Innovative Approaches in Wave Formation Study

Hydrophobic and/or oleophobic coating on microstructured glass surfaces providing an anti-fingerprint effect

PatentInactiveEP1555249A1

Innovation

- A composition comprising 0.1% to 10% alkylsilane, 0.01% to 10% reactive silicone, and a solvent, which forms a long-term stable hydrophobic and oleophobic coating by reacting with the glass surface, utilizing polymer chains with low surface energy and reactive silane residues for adhesion and repellency, respectively.

Hydrophobic Surface Structure Having Micro-Nano Dual Roughness and Method for Preparing the Same

PatentInactiveKR1020150070719A

Innovation

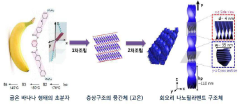

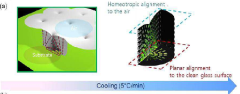

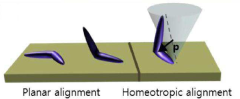

- A method involving the spontaneous self-assembly of banana-shaped liquid crystal supramolecules, utilizing a hydrophilic substrate and air interface to form a conical defect structure, followed by secondary assembly to create a micro-nano double roughened structure, achieving a stable and uniform super-water-repellent surface.

Environmental Impact of Hydrophobic Surfaces

The environmental impact of hydrophobic surfaces, particularly those with microstructured features capable of generating transverse wave formations, is a topic of growing interest in both scientific and industrial circles. These surfaces, often inspired by natural phenomena such as the lotus leaf effect, have far-reaching implications for various ecosystems and environmental processes.

One of the primary environmental benefits of hydrophobic surfaces is their potential for water conservation. By repelling water and preventing its adherence, these surfaces can significantly reduce water consumption in various applications. For instance, in agriculture, hydrophobic coatings on irrigation systems can minimize water loss through evaporation and improve the efficiency of water delivery to crops. This is particularly crucial in water-scarce regions, where every drop counts.

However, the widespread use of hydrophobic surfaces also raises concerns about their long-term environmental effects. The chemicals used to create these surfaces, such as fluoropolymers or silicones, may have persistence in the environment. There is ongoing research to assess the potential for these compounds to bioaccumulate in food chains or leach into water systems, which could have unforeseen consequences on aquatic ecosystems.

The impact on local microclimates is another area of study. Hydrophobic surfaces can alter the way water interacts with the environment, potentially affecting local humidity levels and small-scale water cycles. This could have implications for plant growth, soil moisture retention, and even local weather patterns in urban areas where these surfaces might be extensively used.

On a positive note, the self-cleaning properties of hydrophobic surfaces can lead to reduced use of chemical cleaning agents, thereby decreasing the release of harmful substances into the environment. This is particularly beneficial in urban settings, where the accumulation of pollutants on buildings and infrastructure is a significant issue.

The interaction between hydrophobic surfaces and microorganisms is also a critical area of environmental concern. While these surfaces can inhibit the growth of certain bacteria and fungi, potentially reducing the spread of pathogens, they may also disrupt beneficial microbial communities that play essential roles in ecosystem functions.

As research into transverse wave formations on microstructured hydrophobic surfaces advances, it is crucial to consider the environmental implications of scaling up these technologies. The potential for these surfaces to influence fluid dynamics at larger scales could have both positive and negative environmental impacts, from enhancing the efficiency of water treatment processes to potentially altering natural water flow patterns in ecosystems.

One of the primary environmental benefits of hydrophobic surfaces is their potential for water conservation. By repelling water and preventing its adherence, these surfaces can significantly reduce water consumption in various applications. For instance, in agriculture, hydrophobic coatings on irrigation systems can minimize water loss through evaporation and improve the efficiency of water delivery to crops. This is particularly crucial in water-scarce regions, where every drop counts.

However, the widespread use of hydrophobic surfaces also raises concerns about their long-term environmental effects. The chemicals used to create these surfaces, such as fluoropolymers or silicones, may have persistence in the environment. There is ongoing research to assess the potential for these compounds to bioaccumulate in food chains or leach into water systems, which could have unforeseen consequences on aquatic ecosystems.

The impact on local microclimates is another area of study. Hydrophobic surfaces can alter the way water interacts with the environment, potentially affecting local humidity levels and small-scale water cycles. This could have implications for plant growth, soil moisture retention, and even local weather patterns in urban areas where these surfaces might be extensively used.

On a positive note, the self-cleaning properties of hydrophobic surfaces can lead to reduced use of chemical cleaning agents, thereby decreasing the release of harmful substances into the environment. This is particularly beneficial in urban settings, where the accumulation of pollutants on buildings and infrastructure is a significant issue.

The interaction between hydrophobic surfaces and microorganisms is also a critical area of environmental concern. While these surfaces can inhibit the growth of certain bacteria and fungi, potentially reducing the spread of pathogens, they may also disrupt beneficial microbial communities that play essential roles in ecosystem functions.

As research into transverse wave formations on microstructured hydrophobic surfaces advances, it is crucial to consider the environmental implications of scaling up these technologies. The potential for these surfaces to influence fluid dynamics at larger scales could have both positive and negative environmental impacts, from enhancing the efficiency of water treatment processes to potentially altering natural water flow patterns in ecosystems.

Scalability of Microstructured Surface Production

The scalability of microstructured surface production is a critical factor in the widespread adoption and commercialization of hydrophobic surfaces with transverse wave formations. As research progresses in understanding these unique surface structures, the ability to manufacture them at scale becomes increasingly important.

Current production methods for microstructured hydrophobic surfaces often involve complex and time-consuming processes, such as photolithography or laser ablation. While these techniques offer high precision, they are typically limited to small-scale production and can be cost-prohibitive for large-scale applications. To address this challenge, researchers and engineers are exploring various approaches to enhance scalability.

One promising avenue is the development of roll-to-roll manufacturing techniques. This continuous production method allows for the creation of microstructured surfaces on flexible substrates at high speeds. By adapting existing roll-to-roll processes used in industries like printing and packaging, researchers aim to achieve efficient and cost-effective production of hydrophobic surfaces with transverse wave formations.

Another approach focuses on improving the efficiency of existing microfabrication techniques. For instance, advancements in nanoimprint lithography have shown potential for faster and more cost-effective production of microstructured surfaces. By optimizing the imprinting process and developing more durable molds, researchers are working towards increasing throughput while maintaining the necessary precision for creating transverse wave formations.

The use of self-assembly techniques is also being explored as a scalable production method. By leveraging the natural tendency of certain materials to form organized structures at the microscale, researchers aim to create hydrophobic surfaces with desired properties without the need for complex fabrication equipment. This approach could potentially lead to more economical and easily scalable production processes.

As the demand for microstructured hydrophobic surfaces grows across various industries, including automotive, aerospace, and consumer electronics, the need for scalable production methods becomes increasingly urgent. Addressing this challenge will require collaborative efforts between materials scientists, process engineers, and manufacturing experts to develop innovative solutions that balance precision, cost-effectiveness, and production speed.

The successful scaling of microstructured surface production will not only facilitate broader adoption of these advanced materials but also open up new possibilities for their application in diverse fields. As research continues to progress, it is likely that a combination of improved existing techniques and novel manufacturing approaches will pave the way for large-scale production of surfaces with controlled transverse wave formations, ultimately bringing the benefits of these innovative materials to a wider range of applications and industries.

Current production methods for microstructured hydrophobic surfaces often involve complex and time-consuming processes, such as photolithography or laser ablation. While these techniques offer high precision, they are typically limited to small-scale production and can be cost-prohibitive for large-scale applications. To address this challenge, researchers and engineers are exploring various approaches to enhance scalability.

One promising avenue is the development of roll-to-roll manufacturing techniques. This continuous production method allows for the creation of microstructured surfaces on flexible substrates at high speeds. By adapting existing roll-to-roll processes used in industries like printing and packaging, researchers aim to achieve efficient and cost-effective production of hydrophobic surfaces with transverse wave formations.

Another approach focuses on improving the efficiency of existing microfabrication techniques. For instance, advancements in nanoimprint lithography have shown potential for faster and more cost-effective production of microstructured surfaces. By optimizing the imprinting process and developing more durable molds, researchers are working towards increasing throughput while maintaining the necessary precision for creating transverse wave formations.

The use of self-assembly techniques is also being explored as a scalable production method. By leveraging the natural tendency of certain materials to form organized structures at the microscale, researchers aim to create hydrophobic surfaces with desired properties without the need for complex fabrication equipment. This approach could potentially lead to more economical and easily scalable production processes.

As the demand for microstructured hydrophobic surfaces grows across various industries, including automotive, aerospace, and consumer electronics, the need for scalable production methods becomes increasingly urgent. Addressing this challenge will require collaborative efforts between materials scientists, process engineers, and manufacturing experts to develop innovative solutions that balance precision, cost-effectiveness, and production speed.

The successful scaling of microstructured surface production will not only facilitate broader adoption of these advanced materials but also open up new possibilities for their application in diverse fields. As research continues to progress, it is likely that a combination of improved existing techniques and novel manufacturing approaches will pave the way for large-scale production of surfaces with controlled transverse wave formations, ultimately bringing the benefits of these innovative materials to a wider range of applications and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!