The Application of Transverse Waves in Isolation of Vibrations in Machinery

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transverse Wave Fundamentals and Objectives

Transverse waves have been a subject of scientific interest for centuries, with their unique properties making them particularly suitable for various applications in vibration isolation. These waves, characterized by oscillations perpendicular to the direction of wave propagation, have become increasingly relevant in the field of machinery vibration control.

The fundamental principles of transverse waves are rooted in classical physics, with their behavior governed by the wave equation. In the context of machinery, these waves can be generated and manipulated to counteract unwanted vibrations, thereby improving equipment performance and longevity. The study of transverse waves in this application draws from diverse fields such as acoustics, materials science, and mechanical engineering.

The primary objective of applying transverse waves in machinery vibration isolation is to develop more effective and efficient methods for reducing mechanical vibrations. This goal is driven by the need to enhance the precision and reliability of industrial equipment, minimize wear and tear, and ultimately extend the operational lifespan of machinery. By harnessing the properties of transverse waves, engineers aim to create innovative solutions that can adapt to various operational conditions and vibration frequencies.

Recent advancements in materials science and control systems have opened new avenues for the application of transverse waves in vibration isolation. Smart materials capable of generating or modifying transverse waves in response to external stimuli have emerged as promising candidates for next-generation vibration control systems. Additionally, the integration of advanced sensors and real-time processing capabilities allows for more sophisticated and responsive wave-based isolation techniques.

The evolution of transverse wave applications in machinery has been marked by a shift from passive to active and adaptive systems. Early implementations relied on static wave-guiding structures, while modern approaches incorporate dynamic wave generation and manipulation. This progression reflects the broader trend towards more intelligent and responsive mechanical systems in the era of Industry 4.0.

As research in this field continues to advance, the objectives extend beyond mere vibration reduction. There is growing interest in developing multifunctional systems that not only isolate vibrations but also harvest energy from them, contributing to the overall efficiency of industrial processes. Furthermore, the potential for transverse wave-based systems to provide real-time diagnostics and predictive maintenance capabilities is an area of active exploration.

The fundamental principles of transverse waves are rooted in classical physics, with their behavior governed by the wave equation. In the context of machinery, these waves can be generated and manipulated to counteract unwanted vibrations, thereby improving equipment performance and longevity. The study of transverse waves in this application draws from diverse fields such as acoustics, materials science, and mechanical engineering.

The primary objective of applying transverse waves in machinery vibration isolation is to develop more effective and efficient methods for reducing mechanical vibrations. This goal is driven by the need to enhance the precision and reliability of industrial equipment, minimize wear and tear, and ultimately extend the operational lifespan of machinery. By harnessing the properties of transverse waves, engineers aim to create innovative solutions that can adapt to various operational conditions and vibration frequencies.

Recent advancements in materials science and control systems have opened new avenues for the application of transverse waves in vibration isolation. Smart materials capable of generating or modifying transverse waves in response to external stimuli have emerged as promising candidates for next-generation vibration control systems. Additionally, the integration of advanced sensors and real-time processing capabilities allows for more sophisticated and responsive wave-based isolation techniques.

The evolution of transverse wave applications in machinery has been marked by a shift from passive to active and adaptive systems. Early implementations relied on static wave-guiding structures, while modern approaches incorporate dynamic wave generation and manipulation. This progression reflects the broader trend towards more intelligent and responsive mechanical systems in the era of Industry 4.0.

As research in this field continues to advance, the objectives extend beyond mere vibration reduction. There is growing interest in developing multifunctional systems that not only isolate vibrations but also harvest energy from them, contributing to the overall efficiency of industrial processes. Furthermore, the potential for transverse wave-based systems to provide real-time diagnostics and predictive maintenance capabilities is an area of active exploration.

Market Demand for Vibration Isolation

The market demand for vibration isolation in machinery has been steadily increasing due to the growing awareness of the detrimental effects of vibrations on equipment performance, longevity, and workplace safety. Industries such as manufacturing, automotive, aerospace, and construction are particularly driving this demand as they seek to improve the efficiency and reliability of their machinery.

In the manufacturing sector, precision equipment and sensitive instruments require effective vibration isolation to maintain accuracy and prevent damage. The automotive industry is focusing on enhancing passenger comfort and reducing noise, vibration, and harshness (NVH) in vehicles, leading to increased demand for advanced vibration isolation solutions. Aerospace applications require high-performance vibration isolation systems to protect delicate avionics and ensure structural integrity in aircraft and spacecraft.

The construction industry is another significant market for vibration isolation, particularly in urban areas where construction activities must minimize disturbances to nearby structures and residents. This has led to the development of specialized isolation systems for heavy machinery and foundation designs that incorporate vibration damping technologies.

The global market for vibration isolation systems is projected to experience substantial growth in the coming years. This growth is driven by factors such as increasing industrialization, stringent workplace safety regulations, and the need for higher precision in manufacturing processes. Additionally, the rising adoption of automation and robotics in various industries is creating new opportunities for vibration isolation technologies.

Emerging trends in the market include the development of smart vibration isolation systems that can adapt to changing conditions and provide real-time monitoring. These systems often incorporate sensors and advanced materials to offer superior performance and durability. There is also a growing demand for compact and lightweight isolation solutions, particularly in portable equipment and mobile applications.

The healthcare and life sciences sectors are emerging as new markets for vibration isolation, with applications in medical imaging equipment, laboratory instruments, and pharmaceutical manufacturing. These fields require ultra-stable environments to ensure accurate results and maintain product quality.

As environmental concerns gain prominence, there is an increasing focus on developing eco-friendly vibration isolation materials and systems. This trend is likely to shape future market demands and drive innovation in sustainable vibration control solutions.

The application of transverse waves in vibration isolation represents a promising area of development within this market. As research progresses and new technologies emerge, the demand for more effective and efficient vibration isolation solutions utilizing transverse wave principles is expected to grow, potentially opening up new market segments and applications across various industries.

In the manufacturing sector, precision equipment and sensitive instruments require effective vibration isolation to maintain accuracy and prevent damage. The automotive industry is focusing on enhancing passenger comfort and reducing noise, vibration, and harshness (NVH) in vehicles, leading to increased demand for advanced vibration isolation solutions. Aerospace applications require high-performance vibration isolation systems to protect delicate avionics and ensure structural integrity in aircraft and spacecraft.

The construction industry is another significant market for vibration isolation, particularly in urban areas where construction activities must minimize disturbances to nearby structures and residents. This has led to the development of specialized isolation systems for heavy machinery and foundation designs that incorporate vibration damping technologies.

The global market for vibration isolation systems is projected to experience substantial growth in the coming years. This growth is driven by factors such as increasing industrialization, stringent workplace safety regulations, and the need for higher precision in manufacturing processes. Additionally, the rising adoption of automation and robotics in various industries is creating new opportunities for vibration isolation technologies.

Emerging trends in the market include the development of smart vibration isolation systems that can adapt to changing conditions and provide real-time monitoring. These systems often incorporate sensors and advanced materials to offer superior performance and durability. There is also a growing demand for compact and lightweight isolation solutions, particularly in portable equipment and mobile applications.

The healthcare and life sciences sectors are emerging as new markets for vibration isolation, with applications in medical imaging equipment, laboratory instruments, and pharmaceutical manufacturing. These fields require ultra-stable environments to ensure accurate results and maintain product quality.

As environmental concerns gain prominence, there is an increasing focus on developing eco-friendly vibration isolation materials and systems. This trend is likely to shape future market demands and drive innovation in sustainable vibration control solutions.

The application of transverse waves in vibration isolation represents a promising area of development within this market. As research progresses and new technologies emerge, the demand for more effective and efficient vibration isolation solutions utilizing transverse wave principles is expected to grow, potentially opening up new market segments and applications across various industries.

Current Challenges in Machinery Vibration Control

Machinery vibration control remains a critical challenge in various industrial sectors, with significant implications for equipment performance, longevity, and operational safety. Despite advancements in vibration isolation techniques, several persistent challenges continue to hinder optimal control and mitigation of machinery vibrations.

One of the primary challenges is the complexity of vibration sources in modern machinery. Industrial equipment often operates under diverse conditions, experiencing multiple vibration frequencies simultaneously. This multi-modal nature of vibrations makes it difficult to design isolation systems that effectively address all frequency ranges. Particularly problematic are low-frequency vibrations, which can propagate through traditional isolation materials and structures with minimal attenuation.

The nonlinear behavior of many vibration sources further complicates control efforts. Machinery components may exhibit different vibrational characteristics under varying loads, speeds, or environmental conditions. This nonlinearity challenges the effectiveness of linear control systems and necessitates more sophisticated, adaptive approaches to vibration isolation.

Another significant hurdle is the trade-off between isolation effectiveness and system stability. Highly effective vibration isolators often introduce instability into the overall system, potentially leading to unintended resonances or reduced operational performance. Striking the right balance between isolation and stability remains a delicate engineering task, especially in high-precision machinery or sensitive equipment.

The integration of vibration control systems with existing machinery poses its own set of challenges. Retrofitting older equipment with modern isolation technologies can be complex and costly, often requiring significant modifications to the machine structure or surrounding environment. This integration challenge is particularly acute in industries with legacy equipment or space constraints.

Energy dissipation in vibration isolation systems presents another ongoing challenge. While many isolation techniques effectively reduce transmitted vibrations, they often struggle with efficiently dissipating the absorbed energy. This can lead to heat buildup, material fatigue, or reduced long-term effectiveness of the isolation system.

The increasing demand for lightweight and compact machinery further complicates vibration control efforts. Traditional isolation methods often rely on mass and volume to achieve effective damping, which conflicts with the trend towards more streamlined and efficient machine designs. Developing effective vibration control solutions that are both compact and lightweight remains an active area of research and development.

Lastly, the cost-effectiveness of advanced vibration control systems continues to be a significant challenge, particularly for small to medium-sized enterprises. High-performance isolation technologies often come with substantial implementation and maintenance costs, limiting their widespread adoption across all industrial sectors.

One of the primary challenges is the complexity of vibration sources in modern machinery. Industrial equipment often operates under diverse conditions, experiencing multiple vibration frequencies simultaneously. This multi-modal nature of vibrations makes it difficult to design isolation systems that effectively address all frequency ranges. Particularly problematic are low-frequency vibrations, which can propagate through traditional isolation materials and structures with minimal attenuation.

The nonlinear behavior of many vibration sources further complicates control efforts. Machinery components may exhibit different vibrational characteristics under varying loads, speeds, or environmental conditions. This nonlinearity challenges the effectiveness of linear control systems and necessitates more sophisticated, adaptive approaches to vibration isolation.

Another significant hurdle is the trade-off between isolation effectiveness and system stability. Highly effective vibration isolators often introduce instability into the overall system, potentially leading to unintended resonances or reduced operational performance. Striking the right balance between isolation and stability remains a delicate engineering task, especially in high-precision machinery or sensitive equipment.

The integration of vibration control systems with existing machinery poses its own set of challenges. Retrofitting older equipment with modern isolation technologies can be complex and costly, often requiring significant modifications to the machine structure or surrounding environment. This integration challenge is particularly acute in industries with legacy equipment or space constraints.

Energy dissipation in vibration isolation systems presents another ongoing challenge. While many isolation techniques effectively reduce transmitted vibrations, they often struggle with efficiently dissipating the absorbed energy. This can lead to heat buildup, material fatigue, or reduced long-term effectiveness of the isolation system.

The increasing demand for lightweight and compact machinery further complicates vibration control efforts. Traditional isolation methods often rely on mass and volume to achieve effective damping, which conflicts with the trend towards more streamlined and efficient machine designs. Developing effective vibration control solutions that are both compact and lightweight remains an active area of research and development.

Lastly, the cost-effectiveness of advanced vibration control systems continues to be a significant challenge, particularly for small to medium-sized enterprises. High-performance isolation technologies often come with substantial implementation and maintenance costs, limiting their widespread adoption across all industrial sectors.

Existing Transverse Wave Applications

01 Piezoelectric transducers for generating transverse waves

Piezoelectric materials are used to create transducers that can generate transverse waves. These transducers convert electrical energy into mechanical vibrations, producing transverse waves that can be used in various applications such as ultrasonic imaging, sensors, and actuators.- Piezoelectric transducers for generating transverse waves: Piezoelectric materials are used to create transducers that can generate transverse waves. These transducers convert electrical energy into mechanical vibrations, producing transverse waves that can be used in various applications such as ultrasonic imaging, sensors, and actuators.

- Vibration damping systems for transverse waves: Vibration damping systems are designed to reduce or eliminate unwanted transverse wave vibrations in mechanical structures. These systems employ various techniques such as mass dampers, viscoelastic materials, or active control mechanisms to absorb or counteract the energy of transverse waves.

- Transverse wave sensors and measurement devices: Sensors and measurement devices are developed to detect and analyze transverse wave vibrations. These instruments utilize various principles such as optical interferometry, capacitive sensing, or accelerometers to accurately measure the characteristics of transverse waves in different mediums.

- Transverse wave generators for material testing: Specialized transverse wave generators are designed for material testing applications. These devices produce controlled transverse wave vibrations to evaluate the mechanical properties, structural integrity, and fatigue resistance of materials and components in industries such as aerospace, automotive, and construction.

- Acoustic transverse wave applications in communication: Transverse waves are utilized in acoustic communication systems, particularly in underwater or solid medium environments. These applications leverage the properties of transverse waves to transmit information over long distances or through challenging mediums where traditional electromagnetic waves may be ineffective.

02 Vibration control systems using transverse waves

Vibration control systems utilize transverse waves to dampen or suppress unwanted vibrations in structures, machinery, or vehicles. These systems often employ sensors to detect vibrations and actuators to generate counter-vibrations, effectively reducing the overall vibration amplitude.Expand Specific Solutions03 Acoustic wave devices employing transverse waves

Acoustic wave devices, such as surface acoustic wave (SAW) and bulk acoustic wave (BAW) devices, utilize transverse waves for signal processing, filtering, and sensing applications. These devices exploit the properties of transverse waves propagating through piezoelectric materials to achieve desired frequency responses or sensing capabilities.Expand Specific Solutions04 Transverse wave generators for material testing and characterization

Transverse wave generators are used in non-destructive testing and material characterization techniques. By propagating transverse waves through materials, properties such as elasticity, density, and structural integrity can be analyzed. This approach is particularly useful in fields like materials science and structural engineering.Expand Specific Solutions05 Energy harvesting from transverse wave vibrations

Energy harvesting systems are designed to capture and convert energy from transverse wave vibrations in the environment into usable electrical power. These systems often employ piezoelectric materials or electromagnetic induction to transform mechanical vibrations into electrical energy, which can be used to power small electronic devices or sensors.Expand Specific Solutions

Key Players in Vibration Control Industry

The application of transverse waves in machinery vibration isolation is in a mature development stage, with a well-established market and proven technologies. The global market size for vibration control systems is estimated to be in the billions of dollars, driven by increasing demand for precision machinery and equipment across various industries. Leading players in this field include GERB Schwingungsisolierungen, Minus K Technology, and Schaeffler Technologies, who offer advanced solutions utilizing transverse wave principles. These companies, along with research institutions like Huazhong University of Science & Technology and Brown University, continue to innovate and refine existing technologies, focusing on improving efficiency, reducing costs, and expanding applications across different sectors.

Hitachi Ltd.

Technical Solution: Hitachi has developed advanced vibration isolation technologies incorporating transverse wave principles for various applications. Their active vibration control system uses piezoelectric actuators and adaptive control algorithms to counteract vibrations in real-time. This technology has been applied in high-precision manufacturing equipment, reducing vibration amplitudes by up to 98% in critical frequency ranges [5]. Hitachi has also developed hybrid active-passive isolation systems that combine the benefits of both approaches, offering enhanced performance and energy efficiency. For large-scale applications, such as buildings and infrastructure, Hitachi's seismic isolation systems utilize innovative damper designs that convert vertical seismic waves into horizontal movements, significantly reducing structural damage during earthquakes.

Strengths: Diverse range of solutions from precision equipment to large-scale structures, advanced active control technologies. Weaknesses: Active systems may have higher complexity and cost, potential dependence on power supply for active components.

Minus K Technology, Inc.

Technical Solution: Minus K Technology has developed a unique negative-stiffness vibration isolation system that utilizes transverse wave principles. Their patented technology employs a combination of vertical and horizontal springs with a negative-stiffness mechanism to achieve exceptional low-frequency vibration isolation. This system can provide isolation performance down to 0.5 Hz [2], making it particularly effective for ultra-sensitive equipment. Minus K's isolators use a passive mechanical design, eliminating the need for electricity or air, which enhances reliability and reduces maintenance requirements. The company's technology has found applications in various fields, including nanotechnology research, electron microscopy, and laser-based precision manufacturing.

Strengths: Exceptional low-frequency isolation, passive design for high reliability, suitable for ultra-sensitive equipment. Weaknesses: May be less cost-effective for large-scale industrial applications, limited to specific high-precision markets.

Core Innovations in Transverse Wave Technology

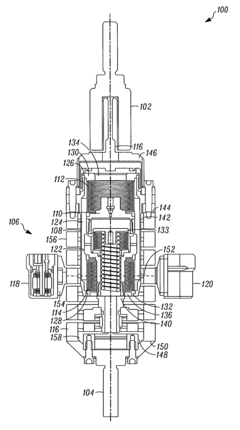

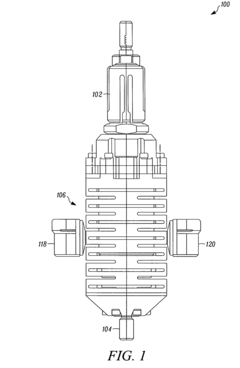

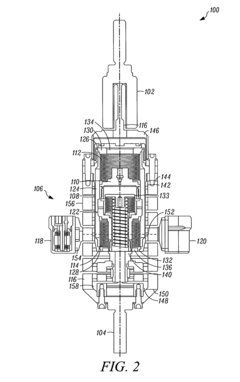

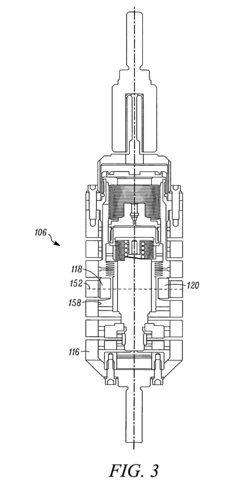

Vibration isolation apparatus and methods of manufacture

PatentActiveUS8002094B2

Innovation

- A vibration isolation apparatus featuring a main spring with tuned mass dampers coupled equidistantly between its ends to reduce axial surge mode resonance by at least 50% within a predetermined frequency range, using fluid-filled bellows and a temperature compensator to maintain damping and prevent overheating.

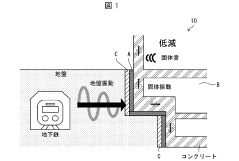

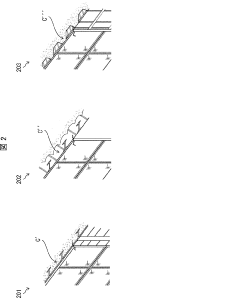

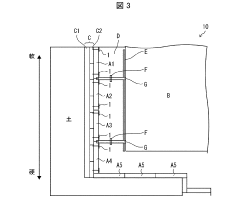

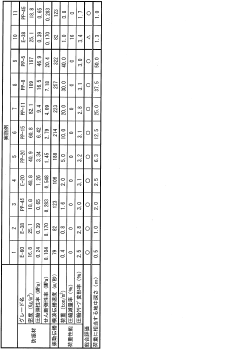

Vibration-isolating structure of building

PatentActiveJP2022146635A

Innovation

- A vibration-isolating structure for buildings that uses synthetic resin foam with specific compressive creep deformation rates and shear modulus settings, combined with a retaining wall, to isolate ground vibrations while ensuring ease of construction. The structure includes a foundation portion covered by a vibration isolator made of synthetic resin foam, with a retaining wall outside, and sets shear elastic modulus within certain ranges to maintain shape and resist soil pressure.

Standards and Regulations for Vibration Control

The field of vibration control in machinery is governed by a comprehensive set of standards and regulations designed to ensure safety, efficiency, and environmental compliance. These guidelines are established by various international, national, and industry-specific organizations to address the potential risks associated with mechanical vibrations and to promote best practices in vibration isolation techniques.

At the international level, the International Organization for Standardization (ISO) has developed several key standards related to vibration control. ISO 2631 series focuses on human exposure to whole-body vibration, providing guidelines for measurement and evaluation of vibrations in various environments, including machinery. ISO 10816 series establishes standards for evaluating machine vibration by measurements on non-rotating parts, which is crucial for implementing effective vibration isolation strategies.

In the United States, the Occupational Safety and Health Administration (OSHA) has set forth regulations under 29 CFR 1910.95 to protect workers from the harmful effects of occupational noise, which often correlates with vibration exposure. The American National Standards Institute (ANSI) also plays a significant role in developing standards for vibration measurement and control, such as ANSI S2.70, which provides guidelines for the measurement and evaluation of human exposure to vibration transmitted to the hand.

The European Union has established the Machinery Directive 2006/42/EC, which includes essential health and safety requirements related to vibration risks. This directive mandates that machinery must be designed and constructed to reduce risks arising from vibrations to the lowest level possible, taking into account technical progress and the availability of means to reduce vibration.

Specific to the application of transverse waves in vibration isolation, standards often address the design, testing, and performance criteria for vibration isolators. For instance, the Society of Automotive Engineers (SAE) has developed standards like SAE J1133, which provides a uniform method for testing and reporting the dynamic characteristics of elastomeric vibration isolators used in vehicles and machinery.

In the context of industrial machinery, standards such as API 686 from the American Petroleum Institute provide guidelines for the design and installation of machinery vibration isolation systems in petroleum, chemical, and gas industry services. These standards often include specifications for the selection and application of vibration isolators, including those utilizing transverse wave principles.

Compliance with these standards and regulations is not only a legal requirement in many jurisdictions but also a crucial factor in ensuring the effectiveness and reliability of vibration isolation systems. As technology advances, particularly in the application of transverse waves for vibration control, these standards are regularly reviewed and updated to incorporate new findings and best practices, ensuring that they remain relevant and effective in addressing the challenges of modern machinery vibration isolation.

At the international level, the International Organization for Standardization (ISO) has developed several key standards related to vibration control. ISO 2631 series focuses on human exposure to whole-body vibration, providing guidelines for measurement and evaluation of vibrations in various environments, including machinery. ISO 10816 series establishes standards for evaluating machine vibration by measurements on non-rotating parts, which is crucial for implementing effective vibration isolation strategies.

In the United States, the Occupational Safety and Health Administration (OSHA) has set forth regulations under 29 CFR 1910.95 to protect workers from the harmful effects of occupational noise, which often correlates with vibration exposure. The American National Standards Institute (ANSI) also plays a significant role in developing standards for vibration measurement and control, such as ANSI S2.70, which provides guidelines for the measurement and evaluation of human exposure to vibration transmitted to the hand.

The European Union has established the Machinery Directive 2006/42/EC, which includes essential health and safety requirements related to vibration risks. This directive mandates that machinery must be designed and constructed to reduce risks arising from vibrations to the lowest level possible, taking into account technical progress and the availability of means to reduce vibration.

Specific to the application of transverse waves in vibration isolation, standards often address the design, testing, and performance criteria for vibration isolators. For instance, the Society of Automotive Engineers (SAE) has developed standards like SAE J1133, which provides a uniform method for testing and reporting the dynamic characteristics of elastomeric vibration isolators used in vehicles and machinery.

In the context of industrial machinery, standards such as API 686 from the American Petroleum Institute provide guidelines for the design and installation of machinery vibration isolation systems in petroleum, chemical, and gas industry services. These standards often include specifications for the selection and application of vibration isolators, including those utilizing transverse wave principles.

Compliance with these standards and regulations is not only a legal requirement in many jurisdictions but also a crucial factor in ensuring the effectiveness and reliability of vibration isolation systems. As technology advances, particularly in the application of transverse waves for vibration control, these standards are regularly reviewed and updated to incorporate new findings and best practices, ensuring that they remain relevant and effective in addressing the challenges of modern machinery vibration isolation.

Economic Impact of Improved Machinery Stability

The application of transverse waves in vibration isolation for machinery has significant economic implications, extending far beyond the immediate benefits of improved equipment stability. By effectively reducing vibrations, this technology enhances the overall performance and longevity of industrial machinery, leading to substantial cost savings and increased productivity across various sectors.

One of the primary economic advantages is the reduction in maintenance and repair costs. Machinery subjected to less vibration experiences reduced wear and tear, resulting in fewer breakdowns and extended operational lifespans. This translates to lower replacement costs and decreased downtime, allowing businesses to optimize their capital expenditure and maintain consistent production schedules.

Furthermore, improved machinery stability contributes to enhanced product quality. In manufacturing processes where precision is crucial, minimized vibrations lead to more accurate and consistent output. This reduction in defects and waste not only improves the bottom line but also strengthens brand reputation, potentially increasing market share and customer satisfaction.

Energy efficiency is another area where economic benefits are realized. Machines operating with reduced vibrations typically consume less energy, as they encounter less resistance and friction. This leads to lower operational costs and aligns with sustainability goals, which are increasingly important in today's business environment.

The implementation of transverse wave technology in vibration isolation also opens up new market opportunities. Industries that previously faced limitations due to vibration issues can now explore new applications and product lines. This expansion potential drives innovation and creates additional revenue streams for businesses adopting the technology.

From a workforce perspective, improved machinery stability contributes to a safer working environment. Reduced vibrations mean less operator fatigue and lower risk of accidents, potentially leading to decreased workers' compensation claims and insurance premiums. Additionally, a more comfortable work environment can boost employee morale and productivity.

On a broader scale, the adoption of this technology can enhance a nation's industrial competitiveness. Countries and companies at the forefront of implementing advanced vibration isolation techniques may gain a significant edge in global markets, attracting investment and fostering economic growth.

In conclusion, the economic impact of improved machinery stability through transverse wave application is multifaceted and far-reaching. It encompasses direct cost savings, quality improvements, energy efficiency, market expansion, workplace safety, and national competitiveness. As industries continue to evolve and seek optimization, the role of such innovative technologies in driving economic growth and sustainability becomes increasingly pivotal.

One of the primary economic advantages is the reduction in maintenance and repair costs. Machinery subjected to less vibration experiences reduced wear and tear, resulting in fewer breakdowns and extended operational lifespans. This translates to lower replacement costs and decreased downtime, allowing businesses to optimize their capital expenditure and maintain consistent production schedules.

Furthermore, improved machinery stability contributes to enhanced product quality. In manufacturing processes where precision is crucial, minimized vibrations lead to more accurate and consistent output. This reduction in defects and waste not only improves the bottom line but also strengthens brand reputation, potentially increasing market share and customer satisfaction.

Energy efficiency is another area where economic benefits are realized. Machines operating with reduced vibrations typically consume less energy, as they encounter less resistance and friction. This leads to lower operational costs and aligns with sustainability goals, which are increasingly important in today's business environment.

The implementation of transverse wave technology in vibration isolation also opens up new market opportunities. Industries that previously faced limitations due to vibration issues can now explore new applications and product lines. This expansion potential drives innovation and creates additional revenue streams for businesses adopting the technology.

From a workforce perspective, improved machinery stability contributes to a safer working environment. Reduced vibrations mean less operator fatigue and lower risk of accidents, potentially leading to decreased workers' compensation claims and insurance premiums. Additionally, a more comfortable work environment can boost employee morale and productivity.

On a broader scale, the adoption of this technology can enhance a nation's industrial competitiveness. Countries and companies at the forefront of implementing advanced vibration isolation techniques may gain a significant edge in global markets, attracting investment and fostering economic growth.

In conclusion, the economic impact of improved machinery stability through transverse wave application is multifaceted and far-reaching. It encompasses direct cost savings, quality improvements, energy efficiency, market expansion, workplace safety, and national competitiveness. As industries continue to evolve and seek optimization, the role of such innovative technologies in driving economic growth and sustainability becomes increasingly pivotal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!