How Antimicrobial Agents Add Value to Polypropylene Applications

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antimicrobial PP Overview

Antimicrobial polypropylene (PP) represents a significant advancement in polymer technology, combining the versatile properties of PP with enhanced resistance to microbial growth. This innovative material addresses the growing demand for hygienic and long-lasting plastic products across various industries. Antimicrobial PP is created by incorporating specialized additives into the polymer matrix during the manufacturing process, enabling the material to inhibit or kill microorganisms such as bacteria, fungi, and algae.

The primary mechanism of action for antimicrobial PP involves the controlled release of active agents or the presence of surface-bound antimicrobial compounds. These additives can include silver ions, zinc pyrithione, triclosan, or other proprietary formulations. The choice of antimicrobial agent depends on factors such as the intended application, regulatory requirements, and desired efficacy spectrum.

Antimicrobial PP offers numerous benefits over standard polypropylene. It provides an additional layer of protection against harmful microorganisms, reducing the risk of contamination and the spread of infections. This property is particularly valuable in healthcare settings, food processing facilities, and public spaces where hygiene is paramount. Moreover, antimicrobial PP can extend the lifespan of products by preventing microbial degradation, odors, and staining.

The applications of antimicrobial PP are diverse and expanding. In the medical field, it is used for manufacturing disposable medical devices, hospital furniture, and packaging for sterile products. The food industry utilizes antimicrobial PP for food storage containers, cutting boards, and conveyor belts. Consumer goods such as household appliances, personal care products, and sports equipment also benefit from the incorporation of antimicrobial PP.

While antimicrobial PP offers significant advantages, it is essential to consider potential limitations and challenges. These include the need for careful selection of antimicrobial agents to ensure compatibility with PP and the intended use, as well as addressing concerns about the development of antimicrobial resistance. Additionally, the effectiveness of antimicrobial PP can vary depending on factors such as environmental conditions, cleaning practices, and the specific microorganisms targeted.

As research and development in this field continue, new formulations and technologies are emerging to enhance the performance and sustainability of antimicrobial PP. These advancements aim to improve the longevity of antimicrobial effects, expand the spectrum of microbial inhibition, and address environmental concerns associated with certain antimicrobial agents.

The primary mechanism of action for antimicrobial PP involves the controlled release of active agents or the presence of surface-bound antimicrobial compounds. These additives can include silver ions, zinc pyrithione, triclosan, or other proprietary formulations. The choice of antimicrobial agent depends on factors such as the intended application, regulatory requirements, and desired efficacy spectrum.

Antimicrobial PP offers numerous benefits over standard polypropylene. It provides an additional layer of protection against harmful microorganisms, reducing the risk of contamination and the spread of infections. This property is particularly valuable in healthcare settings, food processing facilities, and public spaces where hygiene is paramount. Moreover, antimicrobial PP can extend the lifespan of products by preventing microbial degradation, odors, and staining.

The applications of antimicrobial PP are diverse and expanding. In the medical field, it is used for manufacturing disposable medical devices, hospital furniture, and packaging for sterile products. The food industry utilizes antimicrobial PP for food storage containers, cutting boards, and conveyor belts. Consumer goods such as household appliances, personal care products, and sports equipment also benefit from the incorporation of antimicrobial PP.

While antimicrobial PP offers significant advantages, it is essential to consider potential limitations and challenges. These include the need for careful selection of antimicrobial agents to ensure compatibility with PP and the intended use, as well as addressing concerns about the development of antimicrobial resistance. Additionally, the effectiveness of antimicrobial PP can vary depending on factors such as environmental conditions, cleaning practices, and the specific microorganisms targeted.

As research and development in this field continue, new formulations and technologies are emerging to enhance the performance and sustainability of antimicrobial PP. These advancements aim to improve the longevity of antimicrobial effects, expand the spectrum of microbial inhibition, and address environmental concerns associated with certain antimicrobial agents.

Market Demand Analysis

The market demand for antimicrobial agents in polypropylene applications has been steadily growing, driven by increasing awareness of hygiene and health concerns across various industries. The global antimicrobial plastics market, which includes polypropylene as a significant component, is experiencing robust growth. This expansion is primarily fueled by the rising need for hygienic and safe materials in healthcare, packaging, consumer goods, and automotive sectors.

In the healthcare industry, there is a strong demand for antimicrobial polypropylene in medical devices, equipment, and hospital furnishings. The ongoing global health challenges have further accelerated this trend, with healthcare facilities seeking materials that can help reduce the spread of infections. The packaging industry, particularly in food and beverage sectors, is another major driver for antimicrobial polypropylene. Consumers are increasingly concerned about food safety and shelf life, leading to a higher demand for packaging materials that can inhibit microbial growth.

The consumer goods sector is also contributing significantly to the market demand. Products such as household appliances, personal care items, and kitchenware are incorporating antimicrobial polypropylene to offer enhanced hygiene and durability. This trend is particularly evident in regions with growing middle-class populations and increasing disposable incomes.

In the automotive industry, the use of antimicrobial polypropylene is gaining traction for interior components. As vehicles become more advanced and shared mobility concepts evolve, there is a growing emphasis on maintaining clean and hygienic interiors, driving the demand for antimicrobial materials.

Geographically, North America and Europe are leading markets for antimicrobial polypropylene applications, owing to stringent regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing health consciousness.

The market demand is also influenced by technological advancements in antimicrobial agents. There is a growing preference for sustainable and non-toxic antimicrobial solutions, aligning with the broader trend towards environmentally friendly materials. This shift is creating opportunities for innovative antimicrobial agents that can effectively add value to polypropylene without compromising its recyclability or environmental impact.

As industries continue to prioritize hygiene and safety, the demand for antimicrobial polypropylene is expected to maintain its upward trajectory. The market is likely to see further diversification in applications and continuous improvements in antimicrobial technologies, ensuring sustained growth in the coming years.

In the healthcare industry, there is a strong demand for antimicrobial polypropylene in medical devices, equipment, and hospital furnishings. The ongoing global health challenges have further accelerated this trend, with healthcare facilities seeking materials that can help reduce the spread of infections. The packaging industry, particularly in food and beverage sectors, is another major driver for antimicrobial polypropylene. Consumers are increasingly concerned about food safety and shelf life, leading to a higher demand for packaging materials that can inhibit microbial growth.

The consumer goods sector is also contributing significantly to the market demand. Products such as household appliances, personal care items, and kitchenware are incorporating antimicrobial polypropylene to offer enhanced hygiene and durability. This trend is particularly evident in regions with growing middle-class populations and increasing disposable incomes.

In the automotive industry, the use of antimicrobial polypropylene is gaining traction for interior components. As vehicles become more advanced and shared mobility concepts evolve, there is a growing emphasis on maintaining clean and hygienic interiors, driving the demand for antimicrobial materials.

Geographically, North America and Europe are leading markets for antimicrobial polypropylene applications, owing to stringent regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing health consciousness.

The market demand is also influenced by technological advancements in antimicrobial agents. There is a growing preference for sustainable and non-toxic antimicrobial solutions, aligning with the broader trend towards environmentally friendly materials. This shift is creating opportunities for innovative antimicrobial agents that can effectively add value to polypropylene without compromising its recyclability or environmental impact.

As industries continue to prioritize hygiene and safety, the demand for antimicrobial polypropylene is expected to maintain its upward trajectory. The market is likely to see further diversification in applications and continuous improvements in antimicrobial technologies, ensuring sustained growth in the coming years.

Technical Challenges

The integration of antimicrobial agents into polypropylene applications presents several technical challenges that need to be addressed for successful implementation. One of the primary obstacles is achieving uniform dispersion of the antimicrobial agents within the polymer matrix. Inadequate dispersion can lead to inconsistent antimicrobial performance and potential degradation of the material's mechanical properties.

Another significant challenge is maintaining the long-term efficacy of the antimicrobial agents. Polypropylene products are often exposed to various environmental conditions, including UV radiation, moisture, and temperature fluctuations. These factors can potentially degrade the antimicrobial agents over time, reducing their effectiveness and compromising the product's intended functionality.

The compatibility between the antimicrobial agents and the polypropylene matrix is also a critical concern. Some antimicrobial additives may interact negatively with the polymer, affecting its processability, appearance, or mechanical properties. This necessitates careful selection of antimicrobial agents that are chemically compatible with polypropylene and can withstand the high temperatures involved in polymer processing.

Regulatory compliance poses another challenge in the development of antimicrobial polypropylene applications. Different regions have varying regulations regarding the use of antimicrobial agents in consumer products. Ensuring that the chosen antimicrobial additives meet global regulatory standards while maintaining their effectiveness is a complex task that requires extensive testing and documentation.

The potential for microbial resistance development is an ongoing concern in the field of antimicrobial materials. As antimicrobial polypropylene products become more widespread, there is a risk of microorganisms developing resistance to the incorporated agents. This necessitates continuous research and development of new antimicrobial technologies to stay ahead of potential resistance issues.

Cost considerations also present a significant challenge. Incorporating effective antimicrobial agents into polypropylene can substantially increase the overall production costs. Balancing the added value of antimicrobial properties with the economic viability of the final product is crucial for market success.

Lastly, the environmental impact of antimicrobial polypropylene products is an emerging concern. As sustainability becomes increasingly important, there is a need to develop antimicrobial agents that are not only effective but also environmentally friendly. This includes considerations for biodegradability, toxicity to aquatic life, and the overall lifecycle impact of the antimicrobial additives.

Another significant challenge is maintaining the long-term efficacy of the antimicrobial agents. Polypropylene products are often exposed to various environmental conditions, including UV radiation, moisture, and temperature fluctuations. These factors can potentially degrade the antimicrobial agents over time, reducing their effectiveness and compromising the product's intended functionality.

The compatibility between the antimicrobial agents and the polypropylene matrix is also a critical concern. Some antimicrobial additives may interact negatively with the polymer, affecting its processability, appearance, or mechanical properties. This necessitates careful selection of antimicrobial agents that are chemically compatible with polypropylene and can withstand the high temperatures involved in polymer processing.

Regulatory compliance poses another challenge in the development of antimicrobial polypropylene applications. Different regions have varying regulations regarding the use of antimicrobial agents in consumer products. Ensuring that the chosen antimicrobial additives meet global regulatory standards while maintaining their effectiveness is a complex task that requires extensive testing and documentation.

The potential for microbial resistance development is an ongoing concern in the field of antimicrobial materials. As antimicrobial polypropylene products become more widespread, there is a risk of microorganisms developing resistance to the incorporated agents. This necessitates continuous research and development of new antimicrobial technologies to stay ahead of potential resistance issues.

Cost considerations also present a significant challenge. Incorporating effective antimicrobial agents into polypropylene can substantially increase the overall production costs. Balancing the added value of antimicrobial properties with the economic viability of the final product is crucial for market success.

Lastly, the environmental impact of antimicrobial polypropylene products is an emerging concern. As sustainability becomes increasingly important, there is a need to develop antimicrobial agents that are not only effective but also environmentally friendly. This includes considerations for biodegradability, toxicity to aquatic life, and the overall lifecycle impact of the antimicrobial additives.

Current Solutions

01 Incorporation of antimicrobial agents in materials

Antimicrobial agents can be incorporated into various materials to provide protection against microorganisms. This technique is widely used in textiles, plastics, and coatings to create products with inherent antimicrobial properties. The agents can be added during the manufacturing process or applied as a surface treatment.- Incorporation of antimicrobial agents in materials: Antimicrobial agents can be incorporated into various materials to provide protection against microorganisms. This technique is widely used in textiles, plastics, and other surfaces to create products with inherent antimicrobial properties. The agents can be added during the manufacturing process or applied as a coating, offering long-lasting protection against bacteria, fungi, and other microbes.

- Novel antimicrobial compounds and formulations: Research and development efforts focus on discovering and synthesizing new antimicrobial compounds with improved efficacy and safety profiles. These novel formulations may include combinations of existing antimicrobials or entirely new chemical entities. The goal is to create more potent and broad-spectrum antimicrobial agents that can combat resistant microorganisms while minimizing side effects and environmental impact.

- Antimicrobial coatings and surface treatments: Antimicrobial coatings and surface treatments are applied to various substrates to create hygienic and self-cleaning surfaces. These coatings can be used on medical devices, household items, and industrial equipment to prevent microbial growth and reduce the spread of infections. The technology often involves the use of nanoparticles or specialized polymers that release antimicrobial agents over time.

- Natural and plant-derived antimicrobial agents: There is growing interest in natural and plant-derived antimicrobial agents as alternatives to synthetic chemicals. These compounds, often extracted from herbs, spices, and other plant sources, offer antimicrobial properties with potentially fewer side effects and environmental concerns. Research in this area focuses on identifying, extracting, and formulating these natural agents for use in various applications, including food preservation and personal care products.

- Controlled release systems for antimicrobial agents: Controlled release systems are designed to deliver antimicrobial agents in a sustained and targeted manner. These systems can prolong the effectiveness of the antimicrobial agents, reduce the frequency of application, and minimize the risk of developing resistance. The technology involves encapsulation techniques, polymer matrices, and other delivery mechanisms that allow for the gradual release of the active compounds over extended periods.

02 Novel antimicrobial compounds and formulations

Research and development of new antimicrobial compounds and formulations aim to enhance efficacy against a broader spectrum of microorganisms. These innovations often focus on overcoming resistance issues and improving the stability and longevity of antimicrobial effects in various applications.Expand Specific Solutions03 Antimicrobial agents in medical devices

The use of antimicrobial agents in medical devices is crucial for preventing healthcare-associated infections. These agents are incorporated into catheters, implants, and wound dressings to reduce the risk of bacterial colonization and biofilm formation, thereby improving patient outcomes and reducing healthcare costs.Expand Specific Solutions04 Eco-friendly and natural antimicrobial agents

There is a growing trend towards developing and using eco-friendly and natural antimicrobial agents. These include plant extracts, essential oils, and biodegradable compounds that offer antimicrobial properties without the environmental concerns associated with some synthetic agents. This approach aligns with the increasing demand for sustainable and green technologies.Expand Specific Solutions05 Antimicrobial agents in food packaging and preservation

Antimicrobial agents play a vital role in food packaging and preservation technologies. These agents are incorporated into packaging materials or applied as coatings to extend shelf life, maintain food quality, and ensure food safety by preventing the growth of spoilage and pathogenic microorganisms.Expand Specific Solutions

Key Industry Players

The antimicrobial agents market for polypropylene applications is in a growth phase, driven by increasing demand for hygienic and safe materials across various industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like 3M Innovative Properties, Microban Products, and BASF Corp. leading innovation in antimicrobial additives. These firms are developing more effective and sustainable solutions, focusing on long-lasting protection and compatibility with polypropylene. Other key players, including Henkel AG & Co. KGaA and LG Chem Ltd., are also contributing to the market's technological maturity through research and development of novel antimicrobial compounds and application methods.

3M Innovative Properties Co.

Technical Solution: 3M has developed a range of antimicrobial additives for polypropylene applications, focusing on their proprietary Scotchgard™ Protector technology. This technology incorporates silver ions as the active antimicrobial agent, which is dispersed throughout the polypropylene matrix[4]. The silver ions work by disrupting the cell membranes of microorganisms, preventing their growth and reproduction. 3M's approach ensures that the antimicrobial effect is not just surface-deep but persists throughout the material's lifetime. Their additives are designed to be compatible with various polypropylene grades and processing methods, including injection molding and extrusion[5]. The company has reported significant reductions in microbial populations on treated surfaces, with some studies showing up to 99.9% reduction in bacterial counts within 24 hours of exposure[6].

Strengths: Well-established brand, proven efficacy, and compatibility with various manufacturing processes. Weaknesses: Higher cost compared to non-antimicrobial alternatives and potential for environmental concerns related to silver ion release.

Microban Products Co.

Technical Solution: Microban Products Co. has developed advanced antimicrobial technologies specifically for polypropylene applications. Their approach involves integrating silver-based antimicrobial agents directly into the polymer matrix during the manufacturing process. This results in a homogeneous distribution of the antimicrobial throughout the material, providing long-lasting protection against bacteria, mold, and mildew[1]. The company's proprietary formulations are designed to be thermally stable, allowing them to withstand the high temperatures involved in polypropylene processing without losing efficacy[2]. Microban's technologies have been shown to reduce bacterial growth by up to 99.99% on treated surfaces, significantly extending the useful life of polypropylene products in various industries, including healthcare, consumer goods, and industrial applications[3].

Strengths: Long-lasting antimicrobial protection, thermal stability, and broad-spectrum efficacy. Weaknesses: Potential for increased production costs and regulatory challenges in certain markets.

Core Innovations

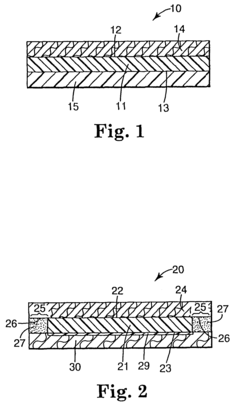

Hydrophilic polypropylene fibers having antimicrobial activity

PatentInactiveUS7879746B2

Innovation

- Incorporating C8 to C16 fatty acid monoglycerides and antimicrobial enhancer materials like lactic acid into polypropylene fibers as melt additives to create hydrophilic and antimicrobial fibers, suitable for use in absorbent devices such as wound dressings and medical drapes.

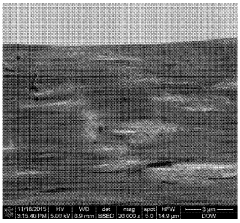

Polypropylene composition, preparation method therefor and use thereof

PatentActiveAU2020409646B2

Innovation

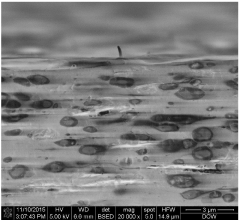

- A polypropylene composition incorporating 40-99 parts of polypropylene resin, 15-30 parts of ethylene-a olefin copolymer, 0.2-1 part of an antimicrobial agent, and 1-3 parts of polypropylene grafted polydimethylsiloxane, which forms a highly oriented filamentous network structure during injection molding, enhancing antimicrobial and stain-resistant properties without compromising the material's hydrophobicity.

Environmental Impact

The incorporation of antimicrobial agents into polypropylene applications has significant environmental implications that warrant careful consideration. These additives, while providing valuable protection against microbial growth, can impact the environment throughout the product lifecycle.

During the production phase, the addition of antimicrobial agents may require additional processing steps or energy inputs, potentially increasing the carbon footprint of manufacturing. However, this initial environmental cost may be offset by the extended lifespan of products, reducing the need for frequent replacements and thereby conserving resources in the long term.

In the use phase, antimicrobial polypropylene products can contribute to improved hygiene and reduced spread of pathogens, potentially decreasing the need for harsh cleaning chemicals and frequent washing. This can lead to water and energy savings, as well as reduced chemical pollution in wastewater systems.

End-of-life considerations are particularly crucial. Some antimicrobial agents may persist in the environment long after the product's useful life, raising concerns about bioaccumulation and potential ecological impacts. The presence of these additives can also complicate recycling processes, as they may interfere with standard recycling methods or contaminate recycled materials.

However, advancements in antimicrobial technology are addressing these concerns. New generations of antimicrobial agents are being developed with improved biodegradability and reduced environmental persistence. Some innovative solutions even incorporate naturally derived antimicrobial compounds, aligning with principles of green chemistry and sustainability.

The environmental impact also extends to waste reduction. By preventing microbial degradation, antimicrobial polypropylene products can maintain their integrity for longer periods, potentially reducing plastic waste in landfills and oceans. This is particularly relevant for single-use plastics and packaging materials, where extended shelf life can significantly impact waste volumes.

Regulatory bodies are increasingly focusing on the environmental aspects of antimicrobial additives. Stricter regulations and standards are being implemented to ensure that these agents meet environmental safety criteria. This regulatory pressure is driving innovation towards more environmentally friendly antimicrobial solutions for polypropylene applications.

In conclusion, while the environmental impact of antimicrobial agents in polypropylene applications is complex, ongoing research and development are striving to balance the benefits of microbial protection with environmental sustainability. The future of these additives lies in solutions that not only enhance product performance but also minimize ecological footprints throughout the product lifecycle.

During the production phase, the addition of antimicrobial agents may require additional processing steps or energy inputs, potentially increasing the carbon footprint of manufacturing. However, this initial environmental cost may be offset by the extended lifespan of products, reducing the need for frequent replacements and thereby conserving resources in the long term.

In the use phase, antimicrobial polypropylene products can contribute to improved hygiene and reduced spread of pathogens, potentially decreasing the need for harsh cleaning chemicals and frequent washing. This can lead to water and energy savings, as well as reduced chemical pollution in wastewater systems.

End-of-life considerations are particularly crucial. Some antimicrobial agents may persist in the environment long after the product's useful life, raising concerns about bioaccumulation and potential ecological impacts. The presence of these additives can also complicate recycling processes, as they may interfere with standard recycling methods or contaminate recycled materials.

However, advancements in antimicrobial technology are addressing these concerns. New generations of antimicrobial agents are being developed with improved biodegradability and reduced environmental persistence. Some innovative solutions even incorporate naturally derived antimicrobial compounds, aligning with principles of green chemistry and sustainability.

The environmental impact also extends to waste reduction. By preventing microbial degradation, antimicrobial polypropylene products can maintain their integrity for longer periods, potentially reducing plastic waste in landfills and oceans. This is particularly relevant for single-use plastics and packaging materials, where extended shelf life can significantly impact waste volumes.

Regulatory bodies are increasingly focusing on the environmental aspects of antimicrobial additives. Stricter regulations and standards are being implemented to ensure that these agents meet environmental safety criteria. This regulatory pressure is driving innovation towards more environmentally friendly antimicrobial solutions for polypropylene applications.

In conclusion, while the environmental impact of antimicrobial agents in polypropylene applications is complex, ongoing research and development are striving to balance the benefits of microbial protection with environmental sustainability. The future of these additives lies in solutions that not only enhance product performance but also minimize ecological footprints throughout the product lifecycle.

Regulatory Compliance

The regulatory landscape for antimicrobial agents in polypropylene applications is complex and constantly evolving. Manufacturers must navigate a web of regulations across different regions to ensure compliance and market access. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial agents under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Products containing these agents must be registered with the EPA and meet stringent safety and efficacy standards.

The European Union has its own set of regulations, primarily governed by the Biocidal Products Regulation (BPR). This regulation aims to harmonize the market for biocidal products while ensuring a high level of protection for human health and the environment. Manufacturers must obtain product authorization before placing antimicrobial-treated polypropylene products on the EU market.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare oversees the regulation of antimicrobial agents, while China's National Medical Products Administration (NMPA) is responsible for similar oversight in their jurisdiction.

Compliance with these regulations often requires extensive testing and documentation. This includes demonstrating the safety and efficacy of the antimicrobial agents, as well as providing detailed information on their chemical composition and intended use. Manufacturers must also consider regulations related to food contact materials if the polypropylene applications are intended for use in food packaging or processing equipment.

Environmental considerations are increasingly important in regulatory compliance. Many jurisdictions are implementing stricter controls on potentially harmful substances, including certain types of antimicrobial agents. This has led to a shift towards more environmentally friendly and sustainable antimicrobial solutions for polypropylene applications.

Labeling and marketing claims for antimicrobial polypropylene products are also subject to regulatory scrutiny. Manufacturers must ensure that any claims about the antimicrobial properties of their products are substantiated and comply with relevant advertising standards and regulations.

As regulations continue to evolve, staying compliant requires ongoing vigilance and adaptability. Manufacturers must regularly review and update their compliance strategies to address new requirements and changing regulatory landscapes. This may involve reformulating products, conducting additional testing, or revising marketing materials to meet new standards.

The European Union has its own set of regulations, primarily governed by the Biocidal Products Regulation (BPR). This regulation aims to harmonize the market for biocidal products while ensuring a high level of protection for human health and the environment. Manufacturers must obtain product authorization before placing antimicrobial-treated polypropylene products on the EU market.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare oversees the regulation of antimicrobial agents, while China's National Medical Products Administration (NMPA) is responsible for similar oversight in their jurisdiction.

Compliance with these regulations often requires extensive testing and documentation. This includes demonstrating the safety and efficacy of the antimicrobial agents, as well as providing detailed information on their chemical composition and intended use. Manufacturers must also consider regulations related to food contact materials if the polypropylene applications are intended for use in food packaging or processing equipment.

Environmental considerations are increasingly important in regulatory compliance. Many jurisdictions are implementing stricter controls on potentially harmful substances, including certain types of antimicrobial agents. This has led to a shift towards more environmentally friendly and sustainable antimicrobial solutions for polypropylene applications.

Labeling and marketing claims for antimicrobial polypropylene products are also subject to regulatory scrutiny. Manufacturers must ensure that any claims about the antimicrobial properties of their products are substantiated and comply with relevant advertising standards and regulations.

As regulations continue to evolve, staying compliant requires ongoing vigilance and adaptability. Manufacturers must regularly review and update their compliance strategies to address new requirements and changing regulatory landscapes. This may involve reformulating products, conducting additional testing, or revising marketing materials to meet new standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!