How Butane Affects Gasoline Formation in Refinery Operations

JUL 25, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Gasoline: Background and Objectives

Butane plays a crucial role in gasoline formation within refinery operations, significantly impacting the final product's quality and performance. The evolution of butane usage in gasoline production can be traced back to the early 20th century when refineries began to recognize its potential as a blending component. As automotive technology advanced, the demand for higher-octane fuels increased, leading to greater utilization of butane in gasoline blends.

The primary objective of incorporating butane into gasoline is to enhance the fuel's volatility and octane rating. Butane's low boiling point and high vapor pressure make it an ideal additive for improving cold-start performance in vehicles, especially in colder climates. Additionally, its high octane rating contributes to the overall anti-knock properties of the fuel, allowing for better engine efficiency and performance.

In recent years, the role of butane in gasoline formation has become increasingly complex due to evolving environmental regulations and fuel efficiency standards. Refineries must carefully balance the amount of butane added to gasoline to meet stringent vapor pressure limits while still maintaining the desired fuel properties. This balancing act has led to the development of sophisticated blending techniques and advanced process control systems in modern refineries.

The technical goals associated with butane in gasoline formation include optimizing the blending process to achieve the desired Reid Vapor Pressure (RVP) while maximizing octane rating and minimizing production costs. Refineries aim to develop precise control mechanisms for butane addition, taking into account seasonal variations in temperature and regulatory requirements. Furthermore, there is a growing focus on developing alternative blending components that can provide similar benefits to butane while reducing environmental impact.

As the automotive industry transitions towards more sustainable technologies, the future of butane in gasoline formation faces new challenges and opportunities. Research efforts are underway to explore the potential of renewable butane sources and to investigate novel blending strategies that can meet the evolving needs of modern engines and environmental standards. The ongoing technological advancements in this field continue to shape the landscape of gasoline production, driving innovation in refinery operations and fuel formulation techniques.

The primary objective of incorporating butane into gasoline is to enhance the fuel's volatility and octane rating. Butane's low boiling point and high vapor pressure make it an ideal additive for improving cold-start performance in vehicles, especially in colder climates. Additionally, its high octane rating contributes to the overall anti-knock properties of the fuel, allowing for better engine efficiency and performance.

In recent years, the role of butane in gasoline formation has become increasingly complex due to evolving environmental regulations and fuel efficiency standards. Refineries must carefully balance the amount of butane added to gasoline to meet stringent vapor pressure limits while still maintaining the desired fuel properties. This balancing act has led to the development of sophisticated blending techniques and advanced process control systems in modern refineries.

The technical goals associated with butane in gasoline formation include optimizing the blending process to achieve the desired Reid Vapor Pressure (RVP) while maximizing octane rating and minimizing production costs. Refineries aim to develop precise control mechanisms for butane addition, taking into account seasonal variations in temperature and regulatory requirements. Furthermore, there is a growing focus on developing alternative blending components that can provide similar benefits to butane while reducing environmental impact.

As the automotive industry transitions towards more sustainable technologies, the future of butane in gasoline formation faces new challenges and opportunities. Research efforts are underway to explore the potential of renewable butane sources and to investigate novel blending strategies that can meet the evolving needs of modern engines and environmental standards. The ongoing technological advancements in this field continue to shape the landscape of gasoline production, driving innovation in refinery operations and fuel formulation techniques.

Market Demand Analysis for Butane-Blended Gasoline

The market demand for butane-blended gasoline has been steadily increasing due to its cost-effectiveness and performance benefits. Refineries are increasingly incorporating butane into their gasoline blending processes to meet consumer demand and regulatory requirements. The global market for butane-blended gasoline is projected to grow significantly in the coming years, driven by factors such as rising vehicle ownership, urbanization, and the need for cleaner-burning fuels.

In developed markets like North America and Europe, the demand for butane-blended gasoline is primarily driven by its ability to improve octane ratings and reduce production costs. Refineries in these regions are under pressure to produce higher-quality fuels while maintaining competitive pricing. The addition of butane allows them to achieve these goals more efficiently.

Emerging markets, particularly in Asia-Pacific and Latin America, are experiencing rapid growth in demand for butane-blended gasoline. This is largely due to the expansion of the automotive industry and increasing disposable incomes. Countries like China and India are witnessing a surge in vehicle ownership, leading to higher consumption of gasoline and, consequently, butane-blended variants.

Environmental regulations are also playing a crucial role in shaping market demand. Many countries are implementing stricter emissions standards, which require cleaner-burning fuels. Butane-blended gasoline can help meet these requirements by reducing certain harmful emissions when compared to traditional gasoline formulations.

The seasonal nature of butane blending adds complexity to market demand analysis. During winter months, refineries can blend higher percentages of butane into gasoline due to lower vapor pressure requirements. This seasonal flexibility allows refineries to optimize their production and cost structures throughout the year.

From an economic perspective, the volatility of crude oil prices has made butane an attractive blending component. When crude oil prices are high, butane can be a more cost-effective alternative for increasing gasoline volume and octane rating. This economic advantage has led to increased demand for butane in gasoline blending operations.

The market for butane-blended gasoline is also influenced by advancements in refinery technology. Modern blending systems allow for more precise control of butane content, enabling refineries to maximize the benefits of butane addition while staying within regulatory limits. This technological progress is expected to further drive demand for butane in gasoline production.

In developed markets like North America and Europe, the demand for butane-blended gasoline is primarily driven by its ability to improve octane ratings and reduce production costs. Refineries in these regions are under pressure to produce higher-quality fuels while maintaining competitive pricing. The addition of butane allows them to achieve these goals more efficiently.

Emerging markets, particularly in Asia-Pacific and Latin America, are experiencing rapid growth in demand for butane-blended gasoline. This is largely due to the expansion of the automotive industry and increasing disposable incomes. Countries like China and India are witnessing a surge in vehicle ownership, leading to higher consumption of gasoline and, consequently, butane-blended variants.

Environmental regulations are also playing a crucial role in shaping market demand. Many countries are implementing stricter emissions standards, which require cleaner-burning fuels. Butane-blended gasoline can help meet these requirements by reducing certain harmful emissions when compared to traditional gasoline formulations.

The seasonal nature of butane blending adds complexity to market demand analysis. During winter months, refineries can blend higher percentages of butane into gasoline due to lower vapor pressure requirements. This seasonal flexibility allows refineries to optimize their production and cost structures throughout the year.

From an economic perspective, the volatility of crude oil prices has made butane an attractive blending component. When crude oil prices are high, butane can be a more cost-effective alternative for increasing gasoline volume and octane rating. This economic advantage has led to increased demand for butane in gasoline blending operations.

The market for butane-blended gasoline is also influenced by advancements in refinery technology. Modern blending systems allow for more precise control of butane content, enabling refineries to maximize the benefits of butane addition while staying within regulatory limits. This technological progress is expected to further drive demand for butane in gasoline production.

Current Challenges in Butane Integration

The integration of butane into gasoline production presents several significant challenges for refinery operations. One of the primary issues is the volatility of butane, which can lead to vapor pressure problems in the final gasoline product. Refineries must carefully balance the amount of butane added to meet regulatory requirements for Reid Vapor Pressure (RVP) while maximizing gasoline volume and octane rating.

Seasonal variations in temperature further complicate butane integration. During warmer months, refineries must reduce butane content to prevent excessive evaporation and maintain compliance with environmental regulations. This seasonal adjustment necessitates complex logistical planning and storage management to handle fluctuating butane inventories throughout the year.

Another challenge lies in the precise blending of butane with other gasoline components. Achieving consistent quality across batches requires sophisticated control systems and real-time monitoring of blend properties. Even small variations in butane concentration can significantly impact the overall gasoline specifications, potentially leading to off-spec products and costly reprocessing.

The economic aspects of butane integration also pose challenges. Butane prices can be volatile, affecting refinery margins and decision-making regarding its use in gasoline production. Refineries must constantly evaluate the cost-benefit ratio of butane addition against other octane-boosting alternatives, considering market conditions and regulatory constraints.

Furthermore, the increasing push for cleaner fuels and lower emissions has put pressure on refineries to reduce the use of high-vapor pressure components like butane. This trend necessitates investment in alternative technologies and processes to maintain gasoline quality and volume while meeting stricter environmental standards.

Safety concerns associated with butane handling and storage represent another significant challenge. As a highly flammable substance, butane requires specialized equipment and rigorous safety protocols throughout the refinery. Ensuring proper containment, leak detection, and emergency response procedures adds complexity to refinery operations and increases operational costs.

Lastly, the optimization of butane recovery from various refinery streams presents technical challenges. Efficient extraction and purification of butane from mixed hydrocarbon streams require advanced separation technologies and energy-intensive processes. Balancing the energy consumption of these recovery operations against the value of the recovered butane is an ongoing challenge for refineries striving for both economic and environmental sustainability.

Seasonal variations in temperature further complicate butane integration. During warmer months, refineries must reduce butane content to prevent excessive evaporation and maintain compliance with environmental regulations. This seasonal adjustment necessitates complex logistical planning and storage management to handle fluctuating butane inventories throughout the year.

Another challenge lies in the precise blending of butane with other gasoline components. Achieving consistent quality across batches requires sophisticated control systems and real-time monitoring of blend properties. Even small variations in butane concentration can significantly impact the overall gasoline specifications, potentially leading to off-spec products and costly reprocessing.

The economic aspects of butane integration also pose challenges. Butane prices can be volatile, affecting refinery margins and decision-making regarding its use in gasoline production. Refineries must constantly evaluate the cost-benefit ratio of butane addition against other octane-boosting alternatives, considering market conditions and regulatory constraints.

Furthermore, the increasing push for cleaner fuels and lower emissions has put pressure on refineries to reduce the use of high-vapor pressure components like butane. This trend necessitates investment in alternative technologies and processes to maintain gasoline quality and volume while meeting stricter environmental standards.

Safety concerns associated with butane handling and storage represent another significant challenge. As a highly flammable substance, butane requires specialized equipment and rigorous safety protocols throughout the refinery. Ensuring proper containment, leak detection, and emergency response procedures adds complexity to refinery operations and increases operational costs.

Lastly, the optimization of butane recovery from various refinery streams presents technical challenges. Efficient extraction and purification of butane from mixed hydrocarbon streams require advanced separation technologies and energy-intensive processes. Balancing the energy consumption of these recovery operations against the value of the recovered butane is an ongoing challenge for refineries striving for both economic and environmental sustainability.

Existing Butane Blending Methods in Refineries

01 Butane production from petroleum refining

Butane is produced as a byproduct of petroleum refining processes. It can be extracted from natural gas or obtained during the cracking of crude oil. The process involves distillation, separation, and purification steps to isolate butane from other hydrocarbons.- Butane production from petroleum refining: Butane is produced as a byproduct of petroleum refining processes. It can be extracted from natural gas or obtained during the cracking of crude oil. The process involves distillation, separation, and purification steps to isolate butane from other hydrocarbons.

- Blending butane with gasoline: Butane is commonly blended with gasoline to improve its volatility and octane rating. The blending process involves carefully mixing butane with gasoline in specific proportions to meet fuel specifications and environmental regulations. This process often requires specialized equipment and control systems.

- Catalytic conversion of butane to gasoline: Catalytic processes can be used to convert butane into gasoline-range hydrocarbons. This typically involves isomerization, alkylation, or reforming reactions using specific catalysts and reaction conditions. The process aims to increase the octane number and improve the fuel quality of the resulting gasoline.

- Butane storage and handling for gasoline blending: Proper storage and handling of butane are crucial for its use in gasoline formation. This includes specialized storage tanks, pressure control systems, and safety measures to prevent leaks and explosions. The infrastructure also includes transfer systems for blending butane with gasoline at refineries or terminals.

- Environmental and regulatory considerations: The use of butane in gasoline formation is subject to various environmental regulations and quality standards. This includes controlling vapor pressure, emissions, and overall fuel composition to meet air quality requirements. Advanced monitoring and control systems are often employed to ensure compliance with these regulations.

02 Blending butane with gasoline

Butane is commonly blended with gasoline to improve its volatility and octane rating. The blending process involves carefully mixing butane with gasoline in specific ratios, considering factors such as seasonal requirements and regulatory limits. This process can be performed at refineries or distribution terminals.Expand Specific Solutions03 Catalytic conversion of butane to gasoline

Catalytic processes can be used to convert butane into gasoline-range hydrocarbons. These processes typically involve the use of specific catalysts and reaction conditions to promote the transformation of butane molecules into longer-chain hydrocarbons suitable for use in gasoline.Expand Specific Solutions04 Butane storage and handling for gasoline blending

Specialized equipment and facilities are required for the storage and handling of butane used in gasoline blending. This includes pressurized storage tanks, safety systems, and precise metering devices to ensure accurate blending ratios and maintain product quality.Expand Specific Solutions05 Quality control and testing of butane-gasoline blends

Quality control measures and testing procedures are essential in the production of butane-gasoline blends. This involves analyzing the composition, vapor pressure, octane rating, and other properties of the blended fuel to ensure compliance with regulatory standards and performance specifications.Expand Specific Solutions

Key Players in Refinery and Butane Blending Industry

The competition landscape for butane's impact on gasoline formation in refinery operations is characterized by a mature market with established players and ongoing technological advancements. Major oil companies like Saudi Aramco, ExxonMobil, and Sinopec dominate the field, leveraging their extensive refinery networks and research capabilities. The market size is substantial, given the global demand for gasoline and the critical role of butane in its production. Technological maturity is high, with companies like UOP LLC, DuPont, and Air Liquide offering specialized solutions. However, there's continuous innovation, particularly in areas of efficiency and environmental impact, driven by research institutions and emerging players like LanzaTech and Genomatica focusing on sustainable alternatives.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced catalytic reforming processes to optimize butane utilization in gasoline production. Their technology involves a multi-stage reforming process that selectively converts butane into high-octane aromatics and iso-paraffins[1]. This process employs a proprietary catalyst system that enhances butane conversion efficiency while minimizing coke formation. Sinopec's approach also integrates an intelligent control system that dynamically adjusts operating parameters based on feed composition and market demand, allowing for flexible production of various gasoline grades[3]. The company has implemented this technology in several of its refineries, reporting a 5-8% increase in gasoline yield and a 2-3 octane number improvement in the final product[5].

Strengths: High conversion efficiency, flexible production capabilities, and improved gasoline quality. Weaknesses: Potentially higher initial investment costs and the need for specialized catalyst management.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed an innovative approach to managing butane in gasoline production through their patented Gasoline Desulfurization and Blending (GDB) process. This technology integrates butane management with sulfur reduction, allowing for optimal butane incorporation while meeting stringent sulfur specifications[2]. The process utilizes a novel catalyst formulation that selectively removes sulfur compounds while preserving octane-enhancing components, including those derived from butane. Saudi Aramco's system also incorporates advanced process control algorithms that optimize butane blending based on real-time analysis of feedstock properties and product specifications[4]. This approach has enabled the company to increase butane utilization in gasoline by up to 15% compared to conventional methods, while maintaining compliance with international fuel standards[6].

Strengths: Simultaneous sulfur reduction and butane optimization, increased butane utilization, and compliance with strict fuel standards. Weaknesses: Potential complexity in implementation and higher operational costs due to advanced control systems.

Core Innovations in Butane-Gasoline Formulation

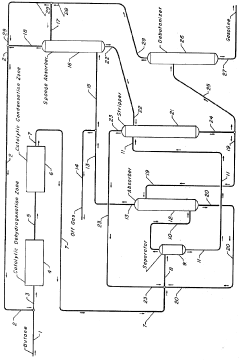

Process for conversion of butane to gasoline

PatentInactiveUS4304948A

Innovation

- A novel integrated hydrocarbon conversion process involving dehydrogenation of butane to form butylenes, followed by catalytic condensation to produce C8 and C12 hydrocarbons, using a dehydrogenation zone with a platinum group component catalyst and a catalytic condensation zone with solid phosphoric acid catalyst, and subsequent separation and recovery using absorption and stripping columns to isolate and recycle butane, resulting in high octane gasoline blending components.

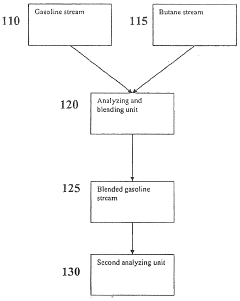

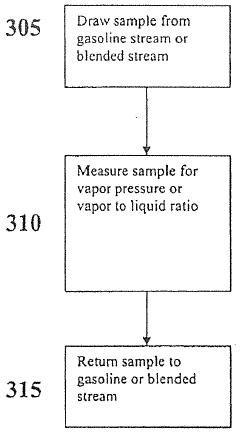

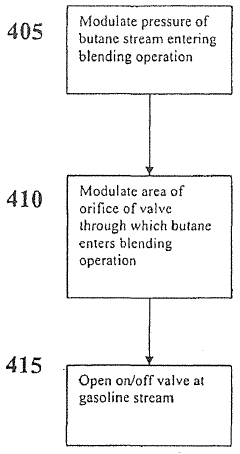

Method for continuous in-line blending of butane and petroleum

PatentActiveHK1252410A

Innovation

- Continuous in-line blending of butane into gasoline streams, allowing for real-time adjustments based on vapor pressure measurements.

- Automated recording of butane quantity blended with each batch of gasoline, enhancing traceability and quality control.

- Remote access and monitoring capabilities for off-site operation management and control.

Environmental Impact of Butane in Gasoline

The addition of butane to gasoline during refinery operations has significant environmental implications that warrant careful consideration. Butane, a highly volatile hydrocarbon, contributes to the formation of ground-level ozone when released into the atmosphere. This pollutant can have detrimental effects on human health, particularly respiratory issues, and can damage vegetation. The increased volatility of gasoline containing butane also leads to higher evaporative emissions, especially during storage and transportation.

Furthermore, the combustion of butane-enhanced gasoline in vehicles results in increased emissions of volatile organic compounds (VOCs) and nitrogen oxides (NOx), both of which are precursors to smog formation. This can exacerbate air quality issues in urban areas, particularly during periods of high temperature and sunlight. The environmental impact extends beyond air quality, as the production and transportation of butane itself contribute to greenhouse gas emissions, albeit to a lesser extent than other fossil fuel processes.

The use of butane in gasoline also affects water resources. Accidental spills or leaks of butane-containing gasoline can contaminate groundwater and surface water, posing risks to aquatic ecosystems and potentially entering the food chain. The remediation of such contamination is often costly and time-consuming, placing additional burdens on environmental management systems.

From a lifecycle perspective, the environmental footprint of butane in gasoline includes the energy and resources required for its extraction, processing, and transportation. While butane is often a byproduct of natural gas processing and petroleum refining, its intentional production for gasoline blending can lead to additional environmental impacts associated with these industrial processes.

Regulatory bodies have recognized these environmental concerns and have implemented measures to mitigate the impact of butane in gasoline. For instance, many regions have seasonal restrictions on the amount of butane that can be blended into gasoline, with lower limits during warmer months to reduce evaporative emissions. Additionally, advancements in vehicle technology, such as improved fuel systems and evaporative emission controls, have helped to minimize the environmental impact of butane-containing gasoline during vehicle operation.

As the automotive industry shifts towards electrification and alternative fuels, the environmental impact of butane in gasoline may decrease in the long term. However, in the interim, ongoing research and development efforts are focused on optimizing gasoline formulations to balance performance requirements with environmental considerations, including the judicious use of butane and other light hydrocarbons.

Furthermore, the combustion of butane-enhanced gasoline in vehicles results in increased emissions of volatile organic compounds (VOCs) and nitrogen oxides (NOx), both of which are precursors to smog formation. This can exacerbate air quality issues in urban areas, particularly during periods of high temperature and sunlight. The environmental impact extends beyond air quality, as the production and transportation of butane itself contribute to greenhouse gas emissions, albeit to a lesser extent than other fossil fuel processes.

The use of butane in gasoline also affects water resources. Accidental spills or leaks of butane-containing gasoline can contaminate groundwater and surface water, posing risks to aquatic ecosystems and potentially entering the food chain. The remediation of such contamination is often costly and time-consuming, placing additional burdens on environmental management systems.

From a lifecycle perspective, the environmental footprint of butane in gasoline includes the energy and resources required for its extraction, processing, and transportation. While butane is often a byproduct of natural gas processing and petroleum refining, its intentional production for gasoline blending can lead to additional environmental impacts associated with these industrial processes.

Regulatory bodies have recognized these environmental concerns and have implemented measures to mitigate the impact of butane in gasoline. For instance, many regions have seasonal restrictions on the amount of butane that can be blended into gasoline, with lower limits during warmer months to reduce evaporative emissions. Additionally, advancements in vehicle technology, such as improved fuel systems and evaporative emission controls, have helped to minimize the environmental impact of butane-containing gasoline during vehicle operation.

As the automotive industry shifts towards electrification and alternative fuels, the environmental impact of butane in gasoline may decrease in the long term. However, in the interim, ongoing research and development efforts are focused on optimizing gasoline formulations to balance performance requirements with environmental considerations, including the judicious use of butane and other light hydrocarbons.

Regulatory Framework for Butane in Fuel Blending

The regulatory framework for butane in fuel blending is a complex and evolving landscape that significantly impacts refinery operations and gasoline formation. Environmental Protection Agency (EPA) regulations play a crucial role in defining the permissible limits of butane content in gasoline blends. These regulations are primarily aimed at controlling volatile organic compound (VOC) emissions and maintaining fuel quality standards.

Under the Clean Air Act, the EPA has established Reid Vapor Pressure (RVP) limits for gasoline, which directly affects the amount of butane that can be blended into gasoline. During summer months, when temperatures are higher, stricter RVP limits are enforced to reduce evaporative emissions. This seasonal variation in regulations requires refineries to adjust their butane blending practices throughout the year.

The EPA's Reformulated Gasoline (RFG) program, implemented in certain areas with air quality issues, imposes additional restrictions on fuel composition, including butane content. RFG requirements are designed to reduce ozone-forming and toxic emissions from gasoline-powered vehicles. Refineries operating in RFG areas must carefully manage their butane usage to meet these stringent specifications.

State-level regulations further complicate the regulatory landscape. Some states, particularly those with air quality concerns, have implemented their own fuel standards that may be more stringent than federal requirements. California, for instance, has its own California Air Resources Board (CARB) gasoline specifications, which include strict limits on butane content and other fuel properties.

International regulations also impact butane blending practices for refineries involved in global fuel markets. The European Union, for example, has its own set of fuel quality directives that regulate the composition of gasoline, including limitations on vapor pressure that indirectly affect butane content.

Compliance with these diverse regulatory requirements necessitates sophisticated blending strategies and advanced process control systems in refineries. Continuous monitoring and adjustment of butane levels are essential to ensure that gasoline blends meet all applicable standards while optimizing production efficiency and product quality.

The regulatory framework also influences the economics of butane blending. Refineries must balance the cost-effectiveness of using butane as a high-octane, low-cost blending component against the expenses associated with compliance and potential penalties for violations. This economic consideration drives ongoing research and development efforts to improve blending technologies and strategies that maximize butane utilization within regulatory constraints.

Under the Clean Air Act, the EPA has established Reid Vapor Pressure (RVP) limits for gasoline, which directly affects the amount of butane that can be blended into gasoline. During summer months, when temperatures are higher, stricter RVP limits are enforced to reduce evaporative emissions. This seasonal variation in regulations requires refineries to adjust their butane blending practices throughout the year.

The EPA's Reformulated Gasoline (RFG) program, implemented in certain areas with air quality issues, imposes additional restrictions on fuel composition, including butane content. RFG requirements are designed to reduce ozone-forming and toxic emissions from gasoline-powered vehicles. Refineries operating in RFG areas must carefully manage their butane usage to meet these stringent specifications.

State-level regulations further complicate the regulatory landscape. Some states, particularly those with air quality concerns, have implemented their own fuel standards that may be more stringent than federal requirements. California, for instance, has its own California Air Resources Board (CARB) gasoline specifications, which include strict limits on butane content and other fuel properties.

International regulations also impact butane blending practices for refineries involved in global fuel markets. The European Union, for example, has its own set of fuel quality directives that regulate the composition of gasoline, including limitations on vapor pressure that indirectly affect butane content.

Compliance with these diverse regulatory requirements necessitates sophisticated blending strategies and advanced process control systems in refineries. Continuous monitoring and adjustment of butane levels are essential to ensure that gasoline blends meet all applicable standards while optimizing production efficiency and product quality.

The regulatory framework also influences the economics of butane blending. Refineries must balance the cost-effectiveness of using butane as a high-octane, low-cost blending component against the expenses associated with compliance and potential penalties for violations. This economic consideration drives ongoing research and development efforts to improve blending technologies and strategies that maximize butane utilization within regulatory constraints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!