How Butane Catalysts Enhance Reaction Efficiency

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane Catalysis Background and Objectives

Butane catalysis has emerged as a crucial field in the chemical industry, playing a pivotal role in enhancing reaction efficiency and promoting sustainable practices. The development of butane catalysts has been driven by the increasing demand for cleaner and more efficient energy sources, as well as the need to optimize industrial processes.

The evolution of butane catalysis can be traced back to the early 20th century when researchers began exploring ways to improve the conversion of hydrocarbons. Over the decades, significant advancements have been made in catalyst design, synthesis methods, and characterization techniques, leading to more effective and selective catalytic systems for butane-related reactions.

One of the primary objectives in butane catalysis research is to develop catalysts that can efficiently convert butane into more valuable products, such as olefins and aromatics. This goal aligns with the broader aim of maximizing resource utilization and reducing waste in industrial processes. Additionally, researchers are focused on creating catalysts that can operate at lower temperatures and pressures, thereby reducing energy consumption and improving overall process economics.

Another critical aspect of butane catalysis is the development of catalysts that exhibit high stability and long lifetimes under reaction conditions. This objective is particularly important for industrial applications, where catalyst longevity directly impacts operational costs and process efficiency. Researchers are exploring various strategies to enhance catalyst stability, including the use of novel support materials and the incorporation of promoters to mitigate deactivation mechanisms.

The field of butane catalysis is also driven by environmental considerations. There is a growing emphasis on developing catalysts that can minimize the formation of undesired by-products and reduce emissions of harmful pollutants. This objective is closely tied to the broader goal of creating more sustainable chemical processes and reducing the environmental footprint of industrial operations.

As the field progresses, researchers are increasingly focusing on understanding the fundamental mechanisms underlying butane catalysis at the molecular level. This knowledge is crucial for designing next-generation catalysts with improved performance and selectivity. Advanced characterization techniques, such as in-situ spectroscopy and high-resolution microscopy, are being employed to gain deeper insights into catalyst structure and behavior under reaction conditions.

The future of butane catalysis research is expected to be shaped by emerging technologies and interdisciplinary approaches. The integration of computational modeling, machine learning, and high-throughput experimentation is likely to accelerate catalyst discovery and optimization. Furthermore, the development of novel reactor designs and process intensification strategies will complement advancements in catalyst technology, leading to more efficient and sustainable butane conversion processes.

The evolution of butane catalysis can be traced back to the early 20th century when researchers began exploring ways to improve the conversion of hydrocarbons. Over the decades, significant advancements have been made in catalyst design, synthesis methods, and characterization techniques, leading to more effective and selective catalytic systems for butane-related reactions.

One of the primary objectives in butane catalysis research is to develop catalysts that can efficiently convert butane into more valuable products, such as olefins and aromatics. This goal aligns with the broader aim of maximizing resource utilization and reducing waste in industrial processes. Additionally, researchers are focused on creating catalysts that can operate at lower temperatures and pressures, thereby reducing energy consumption and improving overall process economics.

Another critical aspect of butane catalysis is the development of catalysts that exhibit high stability and long lifetimes under reaction conditions. This objective is particularly important for industrial applications, where catalyst longevity directly impacts operational costs and process efficiency. Researchers are exploring various strategies to enhance catalyst stability, including the use of novel support materials and the incorporation of promoters to mitigate deactivation mechanisms.

The field of butane catalysis is also driven by environmental considerations. There is a growing emphasis on developing catalysts that can minimize the formation of undesired by-products and reduce emissions of harmful pollutants. This objective is closely tied to the broader goal of creating more sustainable chemical processes and reducing the environmental footprint of industrial operations.

As the field progresses, researchers are increasingly focusing on understanding the fundamental mechanisms underlying butane catalysis at the molecular level. This knowledge is crucial for designing next-generation catalysts with improved performance and selectivity. Advanced characterization techniques, such as in-situ spectroscopy and high-resolution microscopy, are being employed to gain deeper insights into catalyst structure and behavior under reaction conditions.

The future of butane catalysis research is expected to be shaped by emerging technologies and interdisciplinary approaches. The integration of computational modeling, machine learning, and high-throughput experimentation is likely to accelerate catalyst discovery and optimization. Furthermore, the development of novel reactor designs and process intensification strategies will complement advancements in catalyst technology, leading to more efficient and sustainable butane conversion processes.

Market Demand for Efficient Butane Reactions

The demand for efficient butane reactions has been steadily increasing across various industries, driven by the need for cleaner energy sources and more sustainable chemical processes. Butane, a versatile hydrocarbon, plays a crucial role in numerous applications, including fuel production, petrochemical manufacturing, and industrial processes. The market for butane-based products and technologies is experiencing significant growth, with a particular focus on enhancing reaction efficiency through advanced catalysts.

In the energy sector, the demand for efficient butane reactions is primarily fueled by the growing emphasis on cleaner-burning fuels and the transition towards more sustainable energy sources. Butane's role in liquefied petroleum gas (LPG) production has led to increased interest in optimizing its conversion processes. The automotive industry, in particular, has shown a keen interest in improving butane-based fuel efficiency to meet stringent emission standards and reduce overall fuel consumption.

The petrochemical industry represents another major driver for efficient butane reactions. As a key feedstock for the production of various chemicals and polymers, butane's efficient conversion is critical for improving overall process economics and reducing environmental impact. The demand for butadiene, a valuable chemical intermediate derived from butane, has been growing steadily, further emphasizing the need for more efficient catalytic processes.

In the industrial sector, butane's use as a refrigerant and aerosol propellant has created a niche market for efficient reaction technologies. With increasing regulations on environmental protection and energy efficiency, industries are seeking ways to optimize butane-based processes to minimize waste and maximize product yield.

The global push for sustainability and circular economy principles has also influenced the market demand for efficient butane reactions. Industries are increasingly looking for ways to valorize butane from waste streams and convert it into high-value products, driving research and development in catalytic technologies.

Geographically, the demand for efficient butane reactions is particularly strong in regions with significant petrochemical and energy industries, such as North America, Europe, and Asia-Pacific. Emerging economies in these regions are experiencing rapid industrialization and urbanization, further fueling the need for advanced butane processing technologies.

As environmental regulations become more stringent worldwide, the market for catalysts that can enhance butane reaction efficiency while reducing emissions and energy consumption is expected to grow substantially. This trend is likely to drive innovation in catalyst design and process optimization, creating new opportunities for technology providers and chemical companies alike.

In the energy sector, the demand for efficient butane reactions is primarily fueled by the growing emphasis on cleaner-burning fuels and the transition towards more sustainable energy sources. Butane's role in liquefied petroleum gas (LPG) production has led to increased interest in optimizing its conversion processes. The automotive industry, in particular, has shown a keen interest in improving butane-based fuel efficiency to meet stringent emission standards and reduce overall fuel consumption.

The petrochemical industry represents another major driver for efficient butane reactions. As a key feedstock for the production of various chemicals and polymers, butane's efficient conversion is critical for improving overall process economics and reducing environmental impact. The demand for butadiene, a valuable chemical intermediate derived from butane, has been growing steadily, further emphasizing the need for more efficient catalytic processes.

In the industrial sector, butane's use as a refrigerant and aerosol propellant has created a niche market for efficient reaction technologies. With increasing regulations on environmental protection and energy efficiency, industries are seeking ways to optimize butane-based processes to minimize waste and maximize product yield.

The global push for sustainability and circular economy principles has also influenced the market demand for efficient butane reactions. Industries are increasingly looking for ways to valorize butane from waste streams and convert it into high-value products, driving research and development in catalytic technologies.

Geographically, the demand for efficient butane reactions is particularly strong in regions with significant petrochemical and energy industries, such as North America, Europe, and Asia-Pacific. Emerging economies in these regions are experiencing rapid industrialization and urbanization, further fueling the need for advanced butane processing technologies.

As environmental regulations become more stringent worldwide, the market for catalysts that can enhance butane reaction efficiency while reducing emissions and energy consumption is expected to grow substantially. This trend is likely to drive innovation in catalyst design and process optimization, creating new opportunities for technology providers and chemical companies alike.

Current Challenges in Butane Catalysis

Despite significant advancements in butane catalysis, several challenges persist in enhancing reaction efficiency. One of the primary obstacles is catalyst deactivation, which occurs due to various factors such as coking, sintering, and poisoning. Coking, the deposition of carbonaceous materials on the catalyst surface, is particularly problematic in butane reactions, leading to reduced active sites and diminished catalytic performance over time.

Another challenge lies in achieving optimal selectivity towards desired products. Butane catalysis often involves complex reaction networks, with multiple potential pathways and intermediates. Controlling the reaction to favor specific products while minimizing unwanted side reactions remains a significant hurdle. This is especially crucial in processes like butane dehydrogenation, where maximizing olefin yield is essential for economic viability.

Temperature management presents another critical challenge. Many butane catalytic reactions are highly endothermic, requiring substantial energy input. Maintaining uniform temperature distribution across the catalyst bed is crucial for consistent performance and product quality. However, achieving this uniformity in large-scale industrial reactors can be technically demanding and energy-intensive.

Catalyst stability under varying reaction conditions is an ongoing concern. Fluctuations in feed composition, temperature, and pressure can significantly impact catalyst performance and lifespan. Developing catalysts that maintain high activity and selectivity across a broad range of operating conditions remains a key research focus.

The trade-off between catalyst activity and longevity poses another challenge. Highly active catalysts often suffer from rapid deactivation, necessitating frequent regeneration or replacement. Conversely, more stable catalysts may exhibit lower initial activity. Striking the right balance between these factors is crucial for optimizing overall process efficiency and economics.

Scalability of laboratory-developed catalysts to industrial applications presents additional hurdles. Promising catalysts at the bench scale may face issues related to mass transfer limitations, pressure drop, and heat management when scaled up to commercial reactors. Bridging this gap requires extensive pilot-scale testing and optimization.

Lastly, the environmental impact of butane catalysis processes remains a concern. Reducing greenhouse gas emissions, minimizing waste generation, and improving energy efficiency are critical challenges that need to be addressed to ensure the sustainability of these processes in the face of increasingly stringent environmental regulations.

Another challenge lies in achieving optimal selectivity towards desired products. Butane catalysis often involves complex reaction networks, with multiple potential pathways and intermediates. Controlling the reaction to favor specific products while minimizing unwanted side reactions remains a significant hurdle. This is especially crucial in processes like butane dehydrogenation, where maximizing olefin yield is essential for economic viability.

Temperature management presents another critical challenge. Many butane catalytic reactions are highly endothermic, requiring substantial energy input. Maintaining uniform temperature distribution across the catalyst bed is crucial for consistent performance and product quality. However, achieving this uniformity in large-scale industrial reactors can be technically demanding and energy-intensive.

Catalyst stability under varying reaction conditions is an ongoing concern. Fluctuations in feed composition, temperature, and pressure can significantly impact catalyst performance and lifespan. Developing catalysts that maintain high activity and selectivity across a broad range of operating conditions remains a key research focus.

The trade-off between catalyst activity and longevity poses another challenge. Highly active catalysts often suffer from rapid deactivation, necessitating frequent regeneration or replacement. Conversely, more stable catalysts may exhibit lower initial activity. Striking the right balance between these factors is crucial for optimizing overall process efficiency and economics.

Scalability of laboratory-developed catalysts to industrial applications presents additional hurdles. Promising catalysts at the bench scale may face issues related to mass transfer limitations, pressure drop, and heat management when scaled up to commercial reactors. Bridging this gap requires extensive pilot-scale testing and optimization.

Lastly, the environmental impact of butane catalysis processes remains a concern. Reducing greenhouse gas emissions, minimizing waste generation, and improving energy efficiency are critical challenges that need to be addressed to ensure the sustainability of these processes in the face of increasingly stringent environmental regulations.

Existing Butane Catalyst Solutions

01 Catalyst composition for butane reactions

Various catalyst compositions are developed to improve the efficiency of butane reactions. These catalysts often include metal oxides, supported metals, or zeolites. The specific composition is tailored to enhance selectivity, conversion rates, and overall reaction efficiency for processes involving butane.- Catalyst composition for butane reactions: Various catalyst compositions are developed to improve the efficiency of butane reactions. These catalysts often include metal oxides, supported metals, or zeolites. The specific composition is tailored to enhance selectivity, conversion rates, and overall reaction efficiency for processes involving butane.

- Reaction conditions optimization: Optimizing reaction conditions such as temperature, pressure, and flow rates is crucial for improving butane catalyst efficiency. Researchers investigate the effects of these parameters on reaction kinetics and product distribution to determine optimal operating conditions for specific catalytic processes involving butane.

- Catalyst support and preparation methods: The choice of catalyst support and preparation methods significantly influences the efficiency of butane reactions. Various techniques are employed to enhance catalyst surface area, porosity, and dispersion of active sites. These methods aim to improve catalyst stability, activity, and selectivity in butane-related processes.

- Catalyst regeneration and deactivation prevention: Strategies for catalyst regeneration and prevention of deactivation are essential for maintaining long-term efficiency in butane reactions. Researchers develop methods to remove coke deposits, restore catalyst activity, and enhance resistance to poisoning, thereby extending catalyst lifetime and improving overall process economics.

- Novel reactor designs for butane catalysis: Innovative reactor designs are explored to enhance the efficiency of catalytic processes involving butane. These designs aim to improve heat and mass transfer, minimize pressure drop, and optimize catalyst-reactant contact. Advanced reactor configurations can lead to increased conversion rates and improved selectivity in butane reactions.

02 Reaction conditions optimization

Optimizing reaction conditions such as temperature, pressure, and flow rates is crucial for improving butane catalyst efficiency. Researchers investigate the effects of these parameters on reaction kinetics and product distribution to determine optimal operating conditions for specific catalytic processes involving butane.Expand Specific Solutions03 Catalyst support and preparation methods

The choice of catalyst support and preparation methods significantly impacts the efficiency of butane reactions. Various techniques are employed to enhance catalyst surface area, porosity, and dispersion of active sites. These methods aim to improve catalyst stability, activity, and selectivity in butane-related processes.Expand Specific Solutions04 Catalyst regeneration and deactivation prevention

Strategies for catalyst regeneration and prevention of deactivation are essential for maintaining long-term efficiency in butane reactions. Researchers develop methods to remove coke deposits, restore catalyst activity, and enhance resistance to poisoning, thereby extending catalyst lifespan and improving overall process economics.Expand Specific Solutions05 Novel reactor designs for butane catalysis

Innovative reactor designs are explored to enhance the efficiency of catalytic processes involving butane. These designs aim to improve heat and mass transfer, minimize pressure drop, and optimize catalyst-reactant contact. Advanced reactor configurations contribute to increased conversion rates and improved selectivity in butane reactions.Expand Specific Solutions

Key Players in Butane Catalyst Industry

The competitive landscape for butane catalyst technology is characterized by a mature market with established players and ongoing innovation. The industry is in a growth phase, driven by increasing demand for efficient chemical processes. Major companies like ExxonMobil Chemical, China Petroleum & Chemical Corp. (Sinopec), and LG Chem are at the forefront, investing heavily in R&D to enhance catalyst performance. The market size is substantial, with petrochemical giants and specialized chemical firms competing globally. Technological maturity varies, with some companies focusing on incremental improvements while others pursue breakthrough innovations in areas such as nano-catalysts and process intensification. Collaborations between industry leaders and research institutions are accelerating advancements in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced butane catalysts to enhance reaction efficiency in various petrochemical processes. Their technology focuses on zeolite-based catalysts with optimized pore structures and acidity, allowing for improved selectivity and conversion rates in butane-related reactions. Sinopec's catalysts incorporate rare earth elements and transition metals to enhance stability and activity[1]. The company has also implemented novel preparation methods, such as hydrothermal synthesis and post-treatment techniques, to tailor catalyst properties for specific reactions[3]. These catalysts have been successfully applied in processes like butane dehydrogenation, isomerization, and alkylation, significantly improving product yields and reducing energy consumption[5].

Strengths: Extensive research capabilities, access to large-scale industrial testing, and integration with existing petrochemical infrastructure. Weaknesses: Potential reliance on specific raw materials and higher production costs compared to conventional catalysts.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents, Inc. has developed innovative butane catalyst technologies to enhance reaction efficiency across various petrochemical processes. Their approach focuses on multi-functional catalysts that combine acidic and metallic sites to promote simultaneous dehydrogenation and isomerization reactions[2]. ExxonMobil's catalysts often utilize noble metals such as platinum or palladium supported on high-surface-area materials like alumina or silica-alumina[4]. The company has also pioneered the use of zeolite-based catalysts with tailored pore structures to improve selectivity in butane conversion processes[6]. Additionally, ExxonMobil has developed proprietary catalyst regeneration techniques that extend catalyst lifetime and maintain high activity levels over prolonged periods of operation[8].

Strengths: Strong research and development capabilities, extensive patent portfolio, and global industrial implementation experience. Weaknesses: Higher initial catalyst costs and potential sensitivity to feedstock impurities.

Core Innovations in Butane Catalysis

Catalysts for the production of maleic anhydride by the oxidation of butane

PatentInactiveUS4515904A

Innovation

- A process involving the preparation of phosphorus-vanadium and phosphorus-vanadium-co-metal oxide catalysts using phosphoryl halides as a source of phosphorus and activating agents, with specific conditions in organic solvents and co-metals like molybdenum oxide, to enhance catalyst performance and yield.

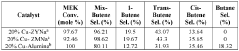

Catalysts and methods for converting methyl ethyl ketone to butene

PatentWO2018136218A1

Innovation

- A bifunctional copper-containing catalyst supported on sodium aluminosilicate zeolite is used to convert methyl ethyl ketone and hydrogen into butene, offering high selectivity and yield through its hydrogenation and dehydration functionalities.

Environmental Impact of Butane Catalysis

The environmental impact of butane catalysis is a critical consideration in the broader context of how butane catalysts enhance reaction efficiency. The use of butane catalysts in industrial processes has both positive and negative implications for the environment, which must be carefully evaluated.

One of the primary environmental benefits of butane catalysis is the potential for increased energy efficiency. By enhancing reaction rates and selectivity, butane catalysts can significantly reduce the energy requirements of various chemical processes. This reduction in energy consumption translates to lower greenhouse gas emissions associated with power generation, contributing to overall climate change mitigation efforts.

However, the production and use of butane catalysts also present environmental challenges. The manufacturing process of these catalysts often involves the use of rare earth elements and precious metals, which can have significant environmental impacts during extraction and processing. Mining activities for these materials can lead to habitat destruction, soil erosion, and water pollution if not properly managed.

Additionally, the disposal of spent catalysts poses environmental risks. Many butane catalysts contain heavy metals and other potentially toxic substances that can leach into soil and water systems if not properly handled. This necessitates the development of effective recycling and disposal methods to minimize environmental contamination.

The use of butane as a feedstock in catalytic processes also has environmental implications. While butane is a relatively clean-burning hydrocarbon, its production and transportation still contribute to carbon emissions. However, when compared to alternative feedstocks, butane often presents a lower environmental footprint, particularly in terms of greenhouse gas emissions.

It is important to note that the environmental impact of butane catalysis can vary significantly depending on the specific application and process design. In some cases, the use of butane catalysts can lead to the production of more environmentally friendly products or enable the replacement of more harmful chemical processes.

Efforts to improve the environmental performance of butane catalysis are ongoing. Research into green chemistry principles is driving the development of more sustainable catalyst materials and production methods. This includes exploring bio-based catalysts, utilizing renewable feedstocks, and designing catalysts that can operate under milder conditions, further reducing energy requirements and environmental impact.

In conclusion, while butane catalysis offers significant potential for enhancing reaction efficiency and reducing overall environmental impact in many industrial processes, it is crucial to consider the entire lifecycle of catalyst production, use, and disposal. Balancing the benefits of improved reaction efficiency against potential environmental risks remains a key challenge in the ongoing development and application of butane catalysts.

One of the primary environmental benefits of butane catalysis is the potential for increased energy efficiency. By enhancing reaction rates and selectivity, butane catalysts can significantly reduce the energy requirements of various chemical processes. This reduction in energy consumption translates to lower greenhouse gas emissions associated with power generation, contributing to overall climate change mitigation efforts.

However, the production and use of butane catalysts also present environmental challenges. The manufacturing process of these catalysts often involves the use of rare earth elements and precious metals, which can have significant environmental impacts during extraction and processing. Mining activities for these materials can lead to habitat destruction, soil erosion, and water pollution if not properly managed.

Additionally, the disposal of spent catalysts poses environmental risks. Many butane catalysts contain heavy metals and other potentially toxic substances that can leach into soil and water systems if not properly handled. This necessitates the development of effective recycling and disposal methods to minimize environmental contamination.

The use of butane as a feedstock in catalytic processes also has environmental implications. While butane is a relatively clean-burning hydrocarbon, its production and transportation still contribute to carbon emissions. However, when compared to alternative feedstocks, butane often presents a lower environmental footprint, particularly in terms of greenhouse gas emissions.

It is important to note that the environmental impact of butane catalysis can vary significantly depending on the specific application and process design. In some cases, the use of butane catalysts can lead to the production of more environmentally friendly products or enable the replacement of more harmful chemical processes.

Efforts to improve the environmental performance of butane catalysis are ongoing. Research into green chemistry principles is driving the development of more sustainable catalyst materials and production methods. This includes exploring bio-based catalysts, utilizing renewable feedstocks, and designing catalysts that can operate under milder conditions, further reducing energy requirements and environmental impact.

In conclusion, while butane catalysis offers significant potential for enhancing reaction efficiency and reducing overall environmental impact in many industrial processes, it is crucial to consider the entire lifecycle of catalyst production, use, and disposal. Balancing the benefits of improved reaction efficiency against potential environmental risks remains a key challenge in the ongoing development and application of butane catalysts.

Economic Implications of Enhanced Butane Reactions

The enhanced efficiency of butane reactions through catalysis has significant economic implications across various industries. The petrochemical sector, in particular, stands to benefit greatly from improved butane conversion processes. By increasing reaction rates and yields, catalysts reduce energy consumption and raw material waste, leading to substantial cost savings in production.

In the energy industry, more efficient butane reactions can contribute to the development of cleaner-burning fuels and improved energy storage solutions. This has the potential to reduce environmental impact while simultaneously lowering operational costs for energy providers. The automotive sector may also see economic advantages through the use of more efficient butane-based fuels, potentially reducing fuel consumption and emissions.

The manufacturing sector, especially in the production of plastics and synthetic materials, can experience increased productivity and reduced costs through enhanced butane reactions. This can lead to more competitive pricing of end products and potentially open up new market opportunities. Additionally, the agricultural industry may benefit from more cost-effective production of butane-derived fertilizers and pesticides.

From a macroeconomic perspective, advancements in butane catalysis can contribute to overall industrial growth and competitiveness. Countries with strong petrochemical industries may see improvements in their trade balances and economic output. The potential for job creation in research and development, as well as in the production and implementation of new catalytic technologies, should not be overlooked.

However, it is important to consider potential economic challenges as well. The initial investment required for implementing new catalytic technologies can be substantial, potentially creating barriers for smaller companies. There may also be shifts in the labor market, with increased demand for skilled workers in catalyst development and application, while potentially reducing demand in traditional processing roles.

In conclusion, the economic implications of enhanced butane reactions through catalysis are far-reaching and multifaceted. While the potential for cost savings, increased productivity, and new market opportunities is significant, careful consideration must be given to implementation costs and potential market disruptions. As the technology continues to evolve, its economic impact is likely to grow, shaping industries and markets in the coming years.

In the energy industry, more efficient butane reactions can contribute to the development of cleaner-burning fuels and improved energy storage solutions. This has the potential to reduce environmental impact while simultaneously lowering operational costs for energy providers. The automotive sector may also see economic advantages through the use of more efficient butane-based fuels, potentially reducing fuel consumption and emissions.

The manufacturing sector, especially in the production of plastics and synthetic materials, can experience increased productivity and reduced costs through enhanced butane reactions. This can lead to more competitive pricing of end products and potentially open up new market opportunities. Additionally, the agricultural industry may benefit from more cost-effective production of butane-derived fertilizers and pesticides.

From a macroeconomic perspective, advancements in butane catalysis can contribute to overall industrial growth and competitiveness. Countries with strong petrochemical industries may see improvements in their trade balances and economic output. The potential for job creation in research and development, as well as in the production and implementation of new catalytic technologies, should not be overlooked.

However, it is important to consider potential economic challenges as well. The initial investment required for implementing new catalytic technologies can be substantial, potentially creating barriers for smaller companies. There may also be shifts in the labor market, with increased demand for skilled workers in catalyst development and application, while potentially reducing demand in traditional processing roles.

In conclusion, the economic implications of enhanced butane reactions through catalysis are far-reaching and multifaceted. While the potential for cost savings, increased productivity, and new market opportunities is significant, careful consideration must be given to implementation costs and potential market disruptions. As the technology continues to evolve, its economic impact is likely to grow, shaping industries and markets in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!