How Electrode Geometry Affects Sodium Ion Battery Output

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Electrode Design Evolution

The evolution of sodium ion battery electrode design has been a critical factor in advancing the performance and viability of this emerging energy storage technology. Initially, researchers focused on adapting lithium-ion battery electrode designs for sodium-ion systems, but quickly realized the need for sodium-specific approaches due to the larger ionic radius of sodium.

In the early stages of development, simple layered oxide cathodes and hard carbon anodes were predominant. These materials offered reasonable sodium storage capacity but suffered from poor cycling stability and rate capability. As understanding of sodium ion insertion mechanisms improved, researchers began exploring more complex structures to enhance electrode performance.

A significant breakthrough came with the development of Prussian blue analogs as cathode materials. These open framework structures provided excellent sodium ion mobility and structural stability during cycling. This led to a shift towards exploring other open framework materials, including NASICON-type compounds and polyanionic structures.

On the anode side, the focus moved beyond hard carbons to engineered carbon structures like graphene and carbon nanotubes. These materials offered higher surface area and improved sodium ion diffusion pathways. Simultaneously, alloying and conversion-type anodes gained attention for their potential to achieve higher capacities.

The realization that electrode geometry plays a crucial role in battery performance sparked a new wave of innovation. Researchers began exploring nanostructured electrodes, including nanowires, nanoflakes, and 3D porous structures. These designs aimed to shorten ion diffusion distances, increase active material utilization, and improve electrode kinetics.

More recently, the field has seen a surge in composite electrode designs that combine multiple active materials or incorporate conductive additives. These hybrid approaches seek to synergistically enhance capacity, rate capability, and cycling stability. Advanced manufacturing techniques like 3D printing and laser patterning have also emerged as tools for precise control over electrode architecture.

The latest frontier in sodium ion battery electrode design focuses on rational nanoengineering and interface optimization. This includes strategies like surface coatings, dopant incorporation, and defect engineering to fine-tune the electrochemical properties of electrode materials. Additionally, there is growing interest in developing flexible and stretchable electrodes to enable new form factors and applications for sodium ion batteries.

In the early stages of development, simple layered oxide cathodes and hard carbon anodes were predominant. These materials offered reasonable sodium storage capacity but suffered from poor cycling stability and rate capability. As understanding of sodium ion insertion mechanisms improved, researchers began exploring more complex structures to enhance electrode performance.

A significant breakthrough came with the development of Prussian blue analogs as cathode materials. These open framework structures provided excellent sodium ion mobility and structural stability during cycling. This led to a shift towards exploring other open framework materials, including NASICON-type compounds and polyanionic structures.

On the anode side, the focus moved beyond hard carbons to engineered carbon structures like graphene and carbon nanotubes. These materials offered higher surface area and improved sodium ion diffusion pathways. Simultaneously, alloying and conversion-type anodes gained attention for their potential to achieve higher capacities.

The realization that electrode geometry plays a crucial role in battery performance sparked a new wave of innovation. Researchers began exploring nanostructured electrodes, including nanowires, nanoflakes, and 3D porous structures. These designs aimed to shorten ion diffusion distances, increase active material utilization, and improve electrode kinetics.

More recently, the field has seen a surge in composite electrode designs that combine multiple active materials or incorporate conductive additives. These hybrid approaches seek to synergistically enhance capacity, rate capability, and cycling stability. Advanced manufacturing techniques like 3D printing and laser patterning have also emerged as tools for precise control over electrode architecture.

The latest frontier in sodium ion battery electrode design focuses on rational nanoengineering and interface optimization. This includes strategies like surface coatings, dopant incorporation, and defect engineering to fine-tune the electrochemical properties of electrode materials. Additionally, there is growing interest in developing flexible and stretchable electrodes to enable new form factors and applications for sodium ion batteries.

Market Demand for Sodium Ion Batteries

The market demand for sodium-ion batteries has been steadily growing in recent years, driven by the increasing need for sustainable and cost-effective energy storage solutions. As the world transitions towards renewable energy sources and electrification of transportation, the demand for high-performance batteries continues to rise. Sodium-ion batteries have emerged as a promising alternative to lithium-ion batteries, particularly in applications where cost and resource availability are critical factors.

The global energy storage market is experiencing rapid expansion, with projections indicating significant growth in the coming decades. This growth is fueled by the increasing adoption of renewable energy sources, such as solar and wind power, which require efficient energy storage systems to manage intermittency. Sodium-ion batteries are well-positioned to capture a portion of this market, especially in grid-scale energy storage applications where cost-effectiveness is paramount.

In the automotive sector, the shift towards electric vehicles (EVs) is creating a substantial demand for battery technologies. While lithium-ion batteries currently dominate the EV market, concerns over the long-term availability and cost of lithium have led to increased interest in sodium-ion alternatives. The potential for sodium-ion batteries to offer comparable performance at a lower cost makes them an attractive option for budget-friendly EVs and other electric mobility solutions.

The consumer electronics industry also presents opportunities for sodium-ion batteries. As portable devices become more power-hungry and consumers demand longer battery life, there is a growing need for advanced energy storage solutions. Sodium-ion batteries could potentially fill this gap, offering a balance between performance and cost that appeals to manufacturers and consumers alike.

Developing countries are expected to be significant drivers of demand for sodium-ion batteries. These regions often face challenges in accessing lithium resources and may find sodium-ion technology more economically viable. Additionally, the potential for local production of sodium-ion batteries using abundant and widely available materials could stimulate economic growth and energy independence in these markets.

The industrial sector is another area where sodium-ion batteries are gaining traction. Applications such as backup power systems, material handling equipment, and off-grid power solutions are increasingly looking for cost-effective and reliable energy storage options. Sodium-ion batteries' potential for long cycle life and improved safety characteristics make them well-suited for these demanding industrial environments.

As research and development in sodium-ion technology continue to advance, addressing key challenges such as energy density and cycle life, the market demand is expected to grow further. Improvements in electrode geometry and other technical aspects will play a crucial role in enhancing the performance and competitiveness of sodium-ion batteries, potentially accelerating their adoption across various sectors.

The global energy storage market is experiencing rapid expansion, with projections indicating significant growth in the coming decades. This growth is fueled by the increasing adoption of renewable energy sources, such as solar and wind power, which require efficient energy storage systems to manage intermittency. Sodium-ion batteries are well-positioned to capture a portion of this market, especially in grid-scale energy storage applications where cost-effectiveness is paramount.

In the automotive sector, the shift towards electric vehicles (EVs) is creating a substantial demand for battery technologies. While lithium-ion batteries currently dominate the EV market, concerns over the long-term availability and cost of lithium have led to increased interest in sodium-ion alternatives. The potential for sodium-ion batteries to offer comparable performance at a lower cost makes them an attractive option for budget-friendly EVs and other electric mobility solutions.

The consumer electronics industry also presents opportunities for sodium-ion batteries. As portable devices become more power-hungry and consumers demand longer battery life, there is a growing need for advanced energy storage solutions. Sodium-ion batteries could potentially fill this gap, offering a balance between performance and cost that appeals to manufacturers and consumers alike.

Developing countries are expected to be significant drivers of demand for sodium-ion batteries. These regions often face challenges in accessing lithium resources and may find sodium-ion technology more economically viable. Additionally, the potential for local production of sodium-ion batteries using abundant and widely available materials could stimulate economic growth and energy independence in these markets.

The industrial sector is another area where sodium-ion batteries are gaining traction. Applications such as backup power systems, material handling equipment, and off-grid power solutions are increasingly looking for cost-effective and reliable energy storage options. Sodium-ion batteries' potential for long cycle life and improved safety characteristics make them well-suited for these demanding industrial environments.

As research and development in sodium-ion technology continue to advance, addressing key challenges such as energy density and cycle life, the market demand is expected to grow further. Improvements in electrode geometry and other technical aspects will play a crucial role in enhancing the performance and competitiveness of sodium-ion batteries, potentially accelerating their adoption across various sectors.

Current Challenges in Electrode Geometry

Despite significant advancements in sodium-ion battery technology, electrode geometry remains a critical challenge in optimizing battery output. The current electrode designs face several limitations that hinder the full potential of sodium-ion batteries.

One of the primary challenges is the volume expansion and contraction of electrode materials during charge-discharge cycles. This phenomenon leads to mechanical stress and structural degradation, ultimately reducing the battery's lifespan and performance. The current electrode geometries struggle to accommodate these volume changes effectively, resulting in capacity fading and decreased cycling stability.

Another significant challenge is the limited surface area of conventional electrode designs. The interaction between electrode materials and electrolytes occurs at the electrode-electrolyte interface, and the available surface area directly impacts the battery's charge-discharge rates and overall capacity. Current electrode geometries often fail to maximize this crucial interface, limiting the battery's power output and energy density.

The ionic conductivity within the electrode structure also poses a challenge. Existing electrode geometries may not provide optimal pathways for sodium ion transport, leading to increased internal resistance and reduced battery efficiency. This issue becomes particularly pronounced in thick electrodes, where ion diffusion limitations can significantly impact the battery's rate capability.

Furthermore, the current electrode designs face difficulties in maintaining uniform current distribution across the electrode surface. This non-uniformity can lead to localized hotspots, accelerated degradation, and potential safety issues. Addressing this challenge requires innovative electrode geometries that promote even current distribution and heat dissipation.

The scalability of electrode manufacturing processes for complex geometries presents another hurdle. While certain advanced electrode designs show promise in laboratory settings, translating these intricate structures to large-scale production remains challenging. The industry needs to develop cost-effective and scalable manufacturing techniques that can produce high-performance electrode geometries consistently.

Lastly, the trade-off between energy density and power density continues to be a significant challenge in electrode design. Current geometries often struggle to balance these two crucial parameters effectively. Achieving high energy density typically requires thicker electrodes, which can compromise power density due to increased ion diffusion distances.

Addressing these challenges in electrode geometry is crucial for unlocking the full potential of sodium-ion batteries. Future research and development efforts must focus on innovative electrode designs that can simultaneously tackle multiple issues, such as volume expansion, surface area optimization, ionic conductivity, and uniform current distribution. Only by overcoming these hurdles can sodium-ion batteries become a viable and competitive alternative to lithium-ion technology in various applications.

One of the primary challenges is the volume expansion and contraction of electrode materials during charge-discharge cycles. This phenomenon leads to mechanical stress and structural degradation, ultimately reducing the battery's lifespan and performance. The current electrode geometries struggle to accommodate these volume changes effectively, resulting in capacity fading and decreased cycling stability.

Another significant challenge is the limited surface area of conventional electrode designs. The interaction between electrode materials and electrolytes occurs at the electrode-electrolyte interface, and the available surface area directly impacts the battery's charge-discharge rates and overall capacity. Current electrode geometries often fail to maximize this crucial interface, limiting the battery's power output and energy density.

The ionic conductivity within the electrode structure also poses a challenge. Existing electrode geometries may not provide optimal pathways for sodium ion transport, leading to increased internal resistance and reduced battery efficiency. This issue becomes particularly pronounced in thick electrodes, where ion diffusion limitations can significantly impact the battery's rate capability.

Furthermore, the current electrode designs face difficulties in maintaining uniform current distribution across the electrode surface. This non-uniformity can lead to localized hotspots, accelerated degradation, and potential safety issues. Addressing this challenge requires innovative electrode geometries that promote even current distribution and heat dissipation.

The scalability of electrode manufacturing processes for complex geometries presents another hurdle. While certain advanced electrode designs show promise in laboratory settings, translating these intricate structures to large-scale production remains challenging. The industry needs to develop cost-effective and scalable manufacturing techniques that can produce high-performance electrode geometries consistently.

Lastly, the trade-off between energy density and power density continues to be a significant challenge in electrode design. Current geometries often struggle to balance these two crucial parameters effectively. Achieving high energy density typically requires thicker electrodes, which can compromise power density due to increased ion diffusion distances.

Addressing these challenges in electrode geometry is crucial for unlocking the full potential of sodium-ion batteries. Future research and development efforts must focus on innovative electrode designs that can simultaneously tackle multiple issues, such as volume expansion, surface area optimization, ionic conductivity, and uniform current distribution. Only by overcoming these hurdles can sodium-ion batteries become a viable and competitive alternative to lithium-ion technology in various applications.

Existing Electrode Geometry Solutions

01 Electrode materials for sodium-ion batteries

Development of novel electrode materials to enhance the performance of sodium-ion batteries. This includes research on cathode and anode materials that offer improved capacity, cycling stability, and energy density. These materials are crucial for increasing the overall output and efficiency of sodium-ion batteries.- Electrode materials for sodium-ion batteries: Development of novel electrode materials to enhance the performance of sodium-ion batteries. This includes research on cathode and anode materials that offer improved capacity, cycling stability, and energy density. These materials are crucial for increasing the overall output and efficiency of sodium-ion batteries.

- Electrolyte compositions for sodium-ion batteries: Formulation of advanced electrolyte compositions tailored for sodium-ion batteries. These electrolytes are designed to improve ionic conductivity, enhance the stability of the electrode-electrolyte interface, and extend the battery's operational temperature range, ultimately contributing to increased battery output and longevity.

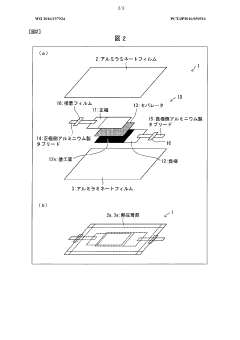

- Battery cell design and architecture: Innovative approaches to sodium-ion battery cell design and architecture. This includes optimizing cell components, improving packaging techniques, and developing new cell configurations to maximize energy density, power output, and overall performance of the battery system.

- Battery management systems for sodium-ion batteries: Development of specialized battery management systems (BMS) for sodium-ion batteries. These systems are designed to optimize charging and discharging processes, monitor battery health, and ensure safe operation, thereby maximizing the output and lifespan of sodium-ion battery packs.

- Manufacturing processes for sodium-ion batteries: Advancements in manufacturing techniques and processes specific to sodium-ion batteries. This includes innovations in electrode fabrication, cell assembly, and quality control measures to improve production efficiency, reduce costs, and enhance the overall output and performance of mass-produced sodium-ion batteries.

02 Electrolyte compositions for sodium-ion batteries

Formulation of advanced electrolyte compositions tailored for sodium-ion batteries. These electrolytes are designed to improve ionic conductivity, enhance the stability of the solid-electrolyte interphase (SEI), and increase the overall battery performance. Optimized electrolyte compositions contribute to higher output and longer cycle life of sodium-ion batteries.Expand Specific Solutions03 Battery cell design and architecture

Innovative designs and architectures for sodium-ion battery cells to maximize output and efficiency. This includes optimizing cell components, improving packaging, and developing new cell configurations that enhance energy density and power output while maintaining safety and reliability.Expand Specific Solutions04 Manufacturing processes for sodium-ion batteries

Advanced manufacturing techniques and processes specifically developed for sodium-ion batteries. These methods aim to improve production efficiency, reduce costs, and enhance the quality and consistency of battery components. Optimized manufacturing processes contribute to higher output and better performance of sodium-ion batteries at scale.Expand Specific Solutions05 Battery management systems for sodium-ion batteries

Development of specialized battery management systems (BMS) tailored for sodium-ion batteries. These systems are designed to optimize charging and discharging processes, monitor battery health, and maximize overall output and lifespan. Advanced BMS solutions contribute to improved performance and reliability of sodium-ion battery systems.Expand Specific Solutions

Key Players in Sodium Ion Battery Industry

The sodium-ion battery market is in an early growth stage, characterized by increasing research and development efforts across academia and industry. The market size is expanding, driven by the demand for sustainable energy storage solutions. While the technology is not yet fully mature, significant progress has been made in electrode geometry optimization. Key players like Contemporary Amperex Technology, LG Energy Solution, and Faradion are leading the charge in commercialization efforts. Universities such as Central South University and Chung Yuan Christian University are contributing valuable research. The involvement of established companies like Toshiba and Panasonic indicates growing industry interest, suggesting a competitive landscape poised for rapid development in the coming years.

Contemporary Amperex Technology Co., Ltd.

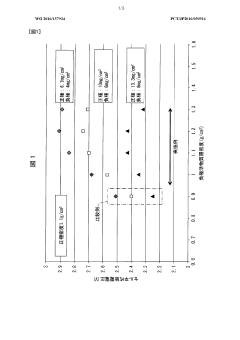

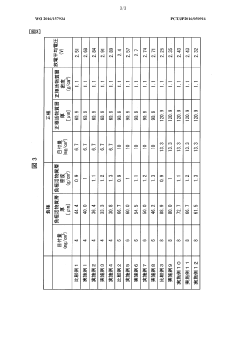

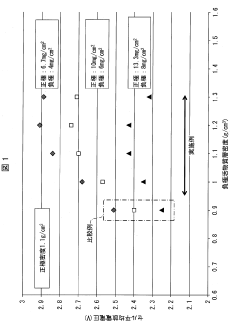

Technical Solution: CATL has developed innovative electrode geometries for sodium-ion batteries, focusing on layered oxide cathodes and hard carbon anodes. Their approach involves optimizing the particle size and morphology of electrode materials to enhance sodium ion diffusion and storage capacity. CATL's sodium-ion cells have achieved energy densities up to 160Wh/kg [1], with the potential to reach 200Wh/kg in the near future. They have also implemented advanced coating technologies to improve the electrode-electrolyte interface stability, resulting in enhanced cycle life and rate performance [2].

Strengths: High energy density, improved cycle life, and scalable production. Weaknesses: Still lower energy density compared to lithium-ion batteries, potential challenges in long-term stability.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a unique "sandwich" electrode structure for sodium-ion batteries, alternating layers of active material with conductive additives. This geometry enhances electron transport and sodium ion diffusion, leading to improved rate capability and cycle life. Their research has shown that controlling the thickness and composition of these layers can significantly impact battery performance. LG has also explored the use of 3D-structured current collectors to increase the effective surface area and reduce internal resistance [3]. Their sodium-ion cells have demonstrated impressive power densities, making them suitable for high-rate applications [4].

Strengths: High power density, improved rate capability, and innovative electrode design. Weaknesses: Potentially higher manufacturing complexity and cost compared to conventional electrode structures.

Innovative Electrode Designs Analysis

Sodium-ion cell

PatentWO2016157934A1

Innovation

- A sodium ion battery design featuring a positive electrode with a transition metal-based active material capable of intercalating and deintercalating sodium ions, combined with a non-graphitizable carbon negative electrode active material layer of specific density (0.95 to 1.35 g/cm³) to enhance sodium ion conductivity and reduce polarization, along with an electrolyte providing sodium ion conductivity.

Sodium ion battery positive electrode material, and preparation method therefor and use thereof

PatentWO2025087018A1

Innovation

- By doping elements M and element A, the structural stability of the positive electrode material is improved. The M-O bond energy of element M is greater than 500kJ/mol, doped at the position of the gap atoms, bound oxygen and restrict its release; the ionic radius of element A is greater than or equal to 0.06nm and the valence state is ≥+3 valence, so it is preferred to replace the transition metal at the transition metal position to play a supporting role and improve the internal structure of the layered material.

Material Science Advancements for Electrodes

Recent advancements in materials science have significantly impacted the development of electrodes for sodium-ion batteries, addressing key challenges in electrode geometry and performance. Researchers have focused on optimizing the structure and composition of electrode materials to enhance sodium ion diffusion and storage capacity.

One major breakthrough has been the development of nanostructured electrode materials. By engineering electrodes at the nanoscale, scientists have created materials with increased surface area and shortened diffusion paths for sodium ions. This has led to improved charge/discharge rates and overall battery performance. For example, carbon-based nanostructures, such as graphene and carbon nanotubes, have shown promise as electrode materials due to their high conductivity and ability to accommodate sodium ions.

Another area of advancement is the exploration of novel electrode materials with unique crystal structures. Layered transition metal oxides, such as NaxMO2 (where M represents various transition metals), have been extensively studied for their ability to reversibly intercalate sodium ions. These materials offer high theoretical capacities and good structural stability during cycling. Additionally, researchers have investigated polyanionic compounds, like sodium iron phosphates, which demonstrate excellent thermal stability and safety characteristics.

The development of composite electrode materials has also gained traction in recent years. By combining different materials with complementary properties, scientists have created electrodes that exhibit enhanced performance compared to their individual components. For instance, carbon-coated metal oxides have shown improved electronic conductivity and structural stability during cycling.

Surface modification techniques have emerged as a powerful tool for enhancing electrode performance. By tailoring the surface chemistry of electrode materials, researchers have successfully mitigated issues such as unwanted side reactions and electrode degradation. Techniques like atomic layer deposition and surface functionalization have been employed to create protective coatings and modify the electrode-electrolyte interface.

Advances in computational materials science have accelerated the discovery and optimization of electrode materials. High-throughput screening methods, combined with machine learning algorithms, have enabled researchers to rapidly identify promising candidate materials and predict their properties. This approach has significantly reduced the time and resources required for experimental testing and has led to the discovery of novel electrode materials with superior performance.

In conclusion, materials science advancements have played a crucial role in improving electrode geometry and performance for sodium-ion batteries. The development of nanostructured materials, novel crystal structures, composite electrodes, surface modification techniques, and computational screening methods have all contributed to addressing the challenges associated with sodium-ion battery electrodes. These advancements pave the way for the development of high-performance, cost-effective, and sustainable energy storage solutions.

One major breakthrough has been the development of nanostructured electrode materials. By engineering electrodes at the nanoscale, scientists have created materials with increased surface area and shortened diffusion paths for sodium ions. This has led to improved charge/discharge rates and overall battery performance. For example, carbon-based nanostructures, such as graphene and carbon nanotubes, have shown promise as electrode materials due to their high conductivity and ability to accommodate sodium ions.

Another area of advancement is the exploration of novel electrode materials with unique crystal structures. Layered transition metal oxides, such as NaxMO2 (where M represents various transition metals), have been extensively studied for their ability to reversibly intercalate sodium ions. These materials offer high theoretical capacities and good structural stability during cycling. Additionally, researchers have investigated polyanionic compounds, like sodium iron phosphates, which demonstrate excellent thermal stability and safety characteristics.

The development of composite electrode materials has also gained traction in recent years. By combining different materials with complementary properties, scientists have created electrodes that exhibit enhanced performance compared to their individual components. For instance, carbon-coated metal oxides have shown improved electronic conductivity and structural stability during cycling.

Surface modification techniques have emerged as a powerful tool for enhancing electrode performance. By tailoring the surface chemistry of electrode materials, researchers have successfully mitigated issues such as unwanted side reactions and electrode degradation. Techniques like atomic layer deposition and surface functionalization have been employed to create protective coatings and modify the electrode-electrolyte interface.

Advances in computational materials science have accelerated the discovery and optimization of electrode materials. High-throughput screening methods, combined with machine learning algorithms, have enabled researchers to rapidly identify promising candidate materials and predict their properties. This approach has significantly reduced the time and resources required for experimental testing and has led to the discovery of novel electrode materials with superior performance.

In conclusion, materials science advancements have played a crucial role in improving electrode geometry and performance for sodium-ion batteries. The development of nanostructured materials, novel crystal structures, composite electrodes, surface modification techniques, and computational screening methods have all contributed to addressing the challenges associated with sodium-ion battery electrodes. These advancements pave the way for the development of high-performance, cost-effective, and sustainable energy storage solutions.

Environmental Impact of Electrode Materials

The environmental impact of electrode materials in sodium-ion batteries is a critical consideration as these batteries gain prominence in the energy storage landscape. The choice of electrode materials significantly influences the overall sustainability and ecological footprint of battery production and disposal.

Sodium-ion batteries typically employ carbon-based anodes and metal oxide cathodes. The extraction and processing of these materials can have substantial environmental consequences. Mining operations for metal oxides often involve large-scale land disturbance, habitat destruction, and water pollution. The carbon-based anodes, while generally less environmentally harmful to produce, still contribute to the overall carbon footprint of battery manufacturing.

The production of electrode materials also requires significant energy input, contributing to greenhouse gas emissions. However, compared to lithium-ion batteries, sodium-ion batteries offer potential environmental advantages due to the greater abundance and more even global distribution of sodium resources. This reduces the need for long-distance transportation and the associated emissions.

End-of-life considerations for electrode materials are crucial. The recyclability of sodium-ion battery components is an area of ongoing research and development. Current recycling processes for these materials are less established than those for lithium-ion batteries, presenting both a challenge and an opportunity for improvement in the circular economy of battery production.

The geometry of electrodes can indirectly affect environmental impact by influencing battery performance and lifespan. Optimized electrode geometries that enhance battery efficiency and longevity can reduce the frequency of battery replacement, thereby decreasing the overall material demand and associated environmental costs over time.

Innovations in electrode materials, such as the development of organic or bio-derived alternatives, show promise in reducing the environmental impact. These materials could potentially offer more sustainable sourcing options and improved biodegradability at the end of the battery's life cycle.

As the demand for sodium-ion batteries grows, it is imperative to consider the full life cycle environmental impact of electrode materials. This includes assessing not only the immediate effects of production but also the long-term implications of material disposal and recycling. Balancing performance requirements with environmental considerations will be key to the sustainable development of sodium-ion battery technology.

Sodium-ion batteries typically employ carbon-based anodes and metal oxide cathodes. The extraction and processing of these materials can have substantial environmental consequences. Mining operations for metal oxides often involve large-scale land disturbance, habitat destruction, and water pollution. The carbon-based anodes, while generally less environmentally harmful to produce, still contribute to the overall carbon footprint of battery manufacturing.

The production of electrode materials also requires significant energy input, contributing to greenhouse gas emissions. However, compared to lithium-ion batteries, sodium-ion batteries offer potential environmental advantages due to the greater abundance and more even global distribution of sodium resources. This reduces the need for long-distance transportation and the associated emissions.

End-of-life considerations for electrode materials are crucial. The recyclability of sodium-ion battery components is an area of ongoing research and development. Current recycling processes for these materials are less established than those for lithium-ion batteries, presenting both a challenge and an opportunity for improvement in the circular economy of battery production.

The geometry of electrodes can indirectly affect environmental impact by influencing battery performance and lifespan. Optimized electrode geometries that enhance battery efficiency and longevity can reduce the frequency of battery replacement, thereby decreasing the overall material demand and associated environmental costs over time.

Innovations in electrode materials, such as the development of organic or bio-derived alternatives, show promise in reducing the environmental impact. These materials could potentially offer more sustainable sourcing options and improved biodegradability at the end of the battery's life cycle.

As the demand for sodium-ion batteries grows, it is imperative to consider the full life cycle environmental impact of electrode materials. This includes assessing not only the immediate effects of production but also the long-term implications of material disposal and recycling. Balancing performance requirements with environmental considerations will be key to the sustainable development of sodium-ion battery technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!