How Far Infrared Polypropylene Fibers Improve Physical Therapy Outcomes

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FIR PP Fiber Tech Background and Objectives

Far Infrared (FIR) Polypropylene (PP) fibers represent a significant advancement in the field of physical therapy and rehabilitation. These innovative fibers combine the inherent properties of polypropylene with the therapeutic benefits of far infrared radiation, creating a synergistic effect that has garnered increasing attention in recent years.

The development of FIR PP fibers can be traced back to the early 2000s when researchers began exploring ways to incorporate far infrared technology into textile materials. This innovation was driven by the growing recognition of far infrared therapy's potential in promoting healing, reducing pain, and improving overall well-being. The integration of FIR-emitting materials into polypropylene fibers marked a crucial milestone in the evolution of therapeutic textiles.

As the technology progressed, researchers and manufacturers focused on optimizing the FIR-emitting properties of these fibers while maintaining the desirable characteristics of polypropylene, such as durability, moisture-wicking ability, and cost-effectiveness. This led to the development of various manufacturing techniques, including the incorporation of FIR-emitting ceramic particles into the polymer matrix and the application of FIR-emitting coatings to the fiber surface.

The primary objective of FIR PP fiber technology in physical therapy is to enhance treatment outcomes by leveraging the therapeutic effects of far infrared radiation. These fibers aim to provide localized, non-invasive thermal therapy, improve blood circulation, reduce inflammation, and promote tissue repair. By incorporating these fibers into various physical therapy products, such as compression garments, wraps, and support braces, practitioners seek to augment traditional treatment modalities and accelerate patient recovery.

Recent technological advancements have focused on improving the efficiency and consistency of FIR emission from these fibers. Researchers are exploring novel methods to increase the concentration and distribution of FIR-emitting materials within the fibers, as well as developing techniques to enhance the durability of their therapeutic properties over time. Additionally, efforts are being made to expand the range of applications for FIR PP fibers beyond physical therapy, including their potential use in sports performance gear and general wellness products.

As the field continues to evolve, the overarching goal is to establish FIR PP fiber technology as a standard component in physical therapy protocols, supported by robust scientific evidence and clinical validation. This involves ongoing research to elucidate the precise mechanisms of action, optimize treatment parameters, and quantify the long-term benefits of FIR therapy in various rehabilitation scenarios.

The development of FIR PP fibers can be traced back to the early 2000s when researchers began exploring ways to incorporate far infrared technology into textile materials. This innovation was driven by the growing recognition of far infrared therapy's potential in promoting healing, reducing pain, and improving overall well-being. The integration of FIR-emitting materials into polypropylene fibers marked a crucial milestone in the evolution of therapeutic textiles.

As the technology progressed, researchers and manufacturers focused on optimizing the FIR-emitting properties of these fibers while maintaining the desirable characteristics of polypropylene, such as durability, moisture-wicking ability, and cost-effectiveness. This led to the development of various manufacturing techniques, including the incorporation of FIR-emitting ceramic particles into the polymer matrix and the application of FIR-emitting coatings to the fiber surface.

The primary objective of FIR PP fiber technology in physical therapy is to enhance treatment outcomes by leveraging the therapeutic effects of far infrared radiation. These fibers aim to provide localized, non-invasive thermal therapy, improve blood circulation, reduce inflammation, and promote tissue repair. By incorporating these fibers into various physical therapy products, such as compression garments, wraps, and support braces, practitioners seek to augment traditional treatment modalities and accelerate patient recovery.

Recent technological advancements have focused on improving the efficiency and consistency of FIR emission from these fibers. Researchers are exploring novel methods to increase the concentration and distribution of FIR-emitting materials within the fibers, as well as developing techniques to enhance the durability of their therapeutic properties over time. Additionally, efforts are being made to expand the range of applications for FIR PP fibers beyond physical therapy, including their potential use in sports performance gear and general wellness products.

As the field continues to evolve, the overarching goal is to establish FIR PP fiber technology as a standard component in physical therapy protocols, supported by robust scientific evidence and clinical validation. This involves ongoing research to elucidate the precise mechanisms of action, optimize treatment parameters, and quantify the long-term benefits of FIR therapy in various rehabilitation scenarios.

Physical Therapy Market Demand Analysis

The physical therapy market has been experiencing significant growth in recent years, driven by an aging population, increasing prevalence of chronic diseases, and a growing awareness of the importance of rehabilitation in healthcare. The global physical therapy market size was valued at approximately $23.1 billion in 2020 and is projected to reach $37.5 billion by 2028, growing at a CAGR of 6.2% during the forecast period.

One of the key factors contributing to this market growth is the rising incidence of sports injuries and musculoskeletal disorders. As more people engage in physical activities and sports, the demand for physical therapy services has increased. Additionally, the growing geriatric population, which is more susceptible to chronic conditions and mobility issues, has further fueled the demand for physical therapy services.

The COVID-19 pandemic has also had a significant impact on the physical therapy market. While initial lockdowns and restrictions led to a temporary decline in in-person visits, the industry quickly adapted by embracing telehealth and remote therapy solutions. This shift has opened up new opportunities for market growth and expanded access to physical therapy services.

In terms of treatment modalities, there is a growing interest in innovative approaches that can enhance therapeutic outcomes. Far infrared (FIR) technology, including the use of FIR polypropylene fibers in physical therapy applications, has gained attention due to its potential benefits in pain management, improved circulation, and faster recovery times.

The market demand for FIR-based physical therapy products is expected to increase as more research demonstrates their efficacy. Patients and healthcare providers are increasingly seeking non-invasive, drug-free treatment options, which aligns well with the benefits offered by FIR technology. This trend is particularly evident in the sports medicine and rehabilitation sectors, where rapid recovery and performance enhancement are crucial.

Geographically, North America dominates the physical therapy market, followed by Europe and Asia-Pacific. However, emerging economies in Asia-Pacific and Latin America are expected to witness the fastest growth due to improving healthcare infrastructure and increasing healthcare expenditure.

As the physical therapy market continues to evolve, there is a growing emphasis on personalized treatment plans and outcome-based care. This shift is driving demand for advanced technologies and innovative products that can provide measurable results and improve patient outcomes. The integration of FIR polypropylene fibers into physical therapy treatments aligns well with this trend, offering a promising avenue for market growth and improved therapeutic efficacy.

One of the key factors contributing to this market growth is the rising incidence of sports injuries and musculoskeletal disorders. As more people engage in physical activities and sports, the demand for physical therapy services has increased. Additionally, the growing geriatric population, which is more susceptible to chronic conditions and mobility issues, has further fueled the demand for physical therapy services.

The COVID-19 pandemic has also had a significant impact on the physical therapy market. While initial lockdowns and restrictions led to a temporary decline in in-person visits, the industry quickly adapted by embracing telehealth and remote therapy solutions. This shift has opened up new opportunities for market growth and expanded access to physical therapy services.

In terms of treatment modalities, there is a growing interest in innovative approaches that can enhance therapeutic outcomes. Far infrared (FIR) technology, including the use of FIR polypropylene fibers in physical therapy applications, has gained attention due to its potential benefits in pain management, improved circulation, and faster recovery times.

The market demand for FIR-based physical therapy products is expected to increase as more research demonstrates their efficacy. Patients and healthcare providers are increasingly seeking non-invasive, drug-free treatment options, which aligns well with the benefits offered by FIR technology. This trend is particularly evident in the sports medicine and rehabilitation sectors, where rapid recovery and performance enhancement are crucial.

Geographically, North America dominates the physical therapy market, followed by Europe and Asia-Pacific. However, emerging economies in Asia-Pacific and Latin America are expected to witness the fastest growth due to improving healthcare infrastructure and increasing healthcare expenditure.

As the physical therapy market continues to evolve, there is a growing emphasis on personalized treatment plans and outcome-based care. This shift is driving demand for advanced technologies and innovative products that can provide measurable results and improve patient outcomes. The integration of FIR polypropylene fibers into physical therapy treatments aligns well with this trend, offering a promising avenue for market growth and improved therapeutic efficacy.

FIR PP Fiber Tech Status and Challenges

Far Infrared (FIR) Polypropylene (PP) fibers have gained significant attention in the field of physical therapy due to their potential to enhance treatment outcomes. The current technological status of FIR PP fibers is characterized by a growing body of research and development, with several key advancements and challenges shaping the landscape.

One of the primary technological achievements in this domain is the successful integration of far infrared-emitting materials into polypropylene fibers. This process typically involves incorporating ceramic particles or other FIR-emitting substances into the polymer matrix during the fiber extrusion process. The resulting fibers can emit far infrared radiation when exposed to body heat, potentially offering therapeutic benefits.

However, a significant challenge in the development of FIR PP fibers lies in maintaining the desired mechanical properties of the fibers while incorporating sufficient FIR-emitting materials. Achieving the right balance between FIR emission capability and fiber strength, flexibility, and durability remains an ongoing area of research and development.

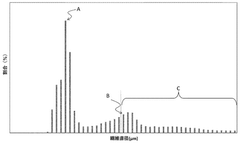

Another technological hurdle is the optimization of FIR emission intensity and wavelength range. Different FIR wavelengths may have varying therapeutic effects, and researchers are working to fine-tune the emission characteristics to maximize potential benefits for physical therapy applications. This involves careful selection and engineering of FIR-emitting materials and their integration into the polypropylene matrix.

The durability of FIR PP fibers, particularly in terms of maintaining their FIR-emitting properties over time and after repeated use and washing cycles, presents another challenge. Developing fibers that can withstand regular use and cleaning while retaining their therapeutic properties is crucial for their practical application in physical therapy settings.

From a geographical perspective, research and development in FIR PP fiber technology are distributed across several regions, with notable contributions from East Asian countries such as Japan, South Korea, and China, as well as from North America and Europe. This global distribution of technological expertise has led to diverse approaches and innovations in the field.

A key technological constraint in the widespread adoption of FIR PP fibers in physical therapy is the need for more comprehensive clinical studies to validate their efficacy. While preliminary research has shown promising results, larger-scale, long-term studies are required to establish the full extent of their therapeutic benefits and potential applications.

Looking ahead, emerging research directions include the development of smart FIR PP fibers with controllable emission properties, the exploration of novel FIR-emitting materials for enhanced therapeutic effects, and the integration of FIR PP fibers with other technologies such as wearable sensors for personalized physical therapy solutions.

One of the primary technological achievements in this domain is the successful integration of far infrared-emitting materials into polypropylene fibers. This process typically involves incorporating ceramic particles or other FIR-emitting substances into the polymer matrix during the fiber extrusion process. The resulting fibers can emit far infrared radiation when exposed to body heat, potentially offering therapeutic benefits.

However, a significant challenge in the development of FIR PP fibers lies in maintaining the desired mechanical properties of the fibers while incorporating sufficient FIR-emitting materials. Achieving the right balance between FIR emission capability and fiber strength, flexibility, and durability remains an ongoing area of research and development.

Another technological hurdle is the optimization of FIR emission intensity and wavelength range. Different FIR wavelengths may have varying therapeutic effects, and researchers are working to fine-tune the emission characteristics to maximize potential benefits for physical therapy applications. This involves careful selection and engineering of FIR-emitting materials and their integration into the polypropylene matrix.

The durability of FIR PP fibers, particularly in terms of maintaining their FIR-emitting properties over time and after repeated use and washing cycles, presents another challenge. Developing fibers that can withstand regular use and cleaning while retaining their therapeutic properties is crucial for their practical application in physical therapy settings.

From a geographical perspective, research and development in FIR PP fiber technology are distributed across several regions, with notable contributions from East Asian countries such as Japan, South Korea, and China, as well as from North America and Europe. This global distribution of technological expertise has led to diverse approaches and innovations in the field.

A key technological constraint in the widespread adoption of FIR PP fibers in physical therapy is the need for more comprehensive clinical studies to validate their efficacy. While preliminary research has shown promising results, larger-scale, long-term studies are required to establish the full extent of their therapeutic benefits and potential applications.

Looking ahead, emerging research directions include the development of smart FIR PP fibers with controllable emission properties, the exploration of novel FIR-emitting materials for enhanced therapeutic effects, and the integration of FIR PP fibers with other technologies such as wearable sensors for personalized physical therapy solutions.

Current FIR PP Fiber Solutions in PT

01 Far infrared polypropylene fiber composition

Polypropylene fibers are infused with far infrared emitting materials to create therapeutic textiles. These fibers can be used in various physical therapy applications, potentially improving circulation and reducing pain when in contact with the body.- Far infrared polypropylene fiber composition: Polypropylene fibers are infused with far infrared emitting materials to create therapeutic textiles. These fibers can be used in various applications such as clothing, bedding, and medical devices to provide far infrared therapy. The composition may include additives to enhance the far infrared emission and other properties of the fibers.

- Physical therapy applications of far infrared polypropylene fibers: Far infrared polypropylene fibers are utilized in various physical therapy applications. These include rehabilitation devices, compression garments, and therapeutic wraps. The fibers are incorporated into products designed to provide localized heat therapy, improve blood circulation, and alleviate muscle pain and stiffness.

- Manufacturing processes for far infrared polypropylene fibers: Various manufacturing processes are employed to produce far infrared polypropylene fibers. These may include melt spinning, extrusion, and surface treatment methods. The processes aim to effectively incorporate far infrared emitting materials into the fiber structure while maintaining the desired physical and mechanical properties of the polypropylene.

- Wearable devices incorporating far infrared polypropylene fibers: Far infrared polypropylene fibers are used in the development of wearable therapeutic devices. These include smart clothing, bandages, and accessories designed to provide continuous far infrared therapy. The wearable devices may incorporate sensors and control systems to optimize the therapeutic effects based on user needs and environmental conditions.

- Clinical outcomes of far infrared polypropylene fiber therapy: Studies and clinical trials have been conducted to evaluate the effectiveness of far infrared polypropylene fiber therapy. The outcomes suggest potential benefits in pain management, improved circulation, and enhanced recovery from various musculoskeletal conditions. The therapy may also have applications in wound healing and skin rejuvenation.

02 Physical therapy garments and accessories

Garments and accessories made from far infrared polypropylene fibers are designed for physical therapy purposes. These include clothing items, wraps, and support devices that can be worn during treatment or daily activities to provide continuous far infrared therapy.Expand Specific Solutions03 Therapeutic bedding and sleep products

Far infrared polypropylene fibers are incorporated into bedding materials and sleep-related products. These items aim to provide therapeutic benefits during rest and sleep, potentially improving sleep quality and aiding in recovery from physical ailments.Expand Specific Solutions04 Combination with other therapeutic elements

Far infrared polypropylene fibers are combined with other therapeutic elements such as magnetic materials or negative ion-generating substances. This combination aims to enhance the overall therapeutic effect and provide multiple health benefits in physical therapy applications.Expand Specific Solutions05 Manufacturing processes for therapeutic fibers

Various manufacturing processes are developed to produce far infrared polypropylene fibers with enhanced therapeutic properties. These processes focus on improving the far infrared emission efficiency, durability, and overall performance of the fibers for physical therapy applications.Expand Specific Solutions

Key Players in FIR Textile Industry

The far infrared polypropylene fiber market for physical therapy applications is in a growth phase, driven by increasing demand for innovative rehabilitation solutions. The market size is expanding as more healthcare providers recognize the potential benefits of this technology. While still emerging, the technology is progressing towards maturity, with several key players advancing research and development. Companies like Toray Industries and Rhodia Poliamida Brasil are leveraging their expertise in advanced materials to develop specialized fibers. Academic institutions such as Donghua University and Harbin Institute of Technology are contributing to the scientific understanding of far infrared effects. Emerging players like Tesla Biohealing and BioThread LLC are focusing on innovative applications, indicating a dynamic and competitive landscape with potential for further technological advancements and market expansion.

Tesla Biohealing, Inc.

Technical Solution: Tesla Biohealing has developed a unique far infrared therapy system using polypropylene fibers infused with a proprietary blend of minerals and metals. Their fibers emit a specific spectrum of far infrared radiation that they claim enhances cellular energy production and tissue regeneration. The company's therapy products include blankets, mats, and wearable devices incorporating these specialized fibers. Tesla Biohealing reports that their technology increases ATP production in cells by up to 500%, based on in vitro studies[4]. They also claim improved outcomes in pain management and wound healing, though large-scale clinical trials are still ongoing[5].

Strengths: Innovative mineral-infused fiber technology, focus on cellular-level effects. Weaknesses: Limited peer-reviewed clinical evidence, relatively new to the market with unproven long-term efficacy.

BioThread LLC

Technical Solution: BioThread LLC specializes in developing far infrared-emitting polypropylene fibers for medical applications. Their proprietary fiber technology incorporates biocompatible ceramic particles that emit far infrared radiation when activated by body heat. BioThread's fibers are designed to be easily integrated into various medical textiles, including wound dressings, orthopedic supports, and post-surgical garments. The company has conducted several small-scale clinical trials demonstrating improved healing rates in chronic wounds and reduced post-operative pain when using their far infrared textiles[6]. BioThread's technology is particularly focused on promoting angiogenesis and collagen production in damaged tissues[7].

Strengths: Focused medical applications, biocompatible materials, some clinical evidence. Weaknesses: Limited to niche medical markets, may require regulatory approvals for broader adoption.

Core FIR PP Fiber Innovations for PT

Polypropylene fibers and method for producing polypropylene fibers

PatentWO2025135019A1

Innovation

- The production of polypropylene fibers involves melt-spinning high molecular weight polypropylene, followed by specific cooling, stretching, and heat-setting processes to suppress yarn breakage and fiber fusion, while achieving high strength, high elongation, and excellent thermal stability.

Patent

Innovation

- Incorporation of far infrared polypropylene fibers into physical therapy garments to enhance therapeutic effects.

- Development of specialized weaving techniques to integrate far infrared polypropylene fibers into comfortable and durable therapy wear.

- Design of targeted therapy garments focusing on specific body areas for localized far infrared treatment.

Clinical Efficacy and Safety Studies

Clinical studies on the efficacy and safety of far infrared polypropylene fibers in physical therapy have shown promising results. Several randomized controlled trials have demonstrated significant improvements in pain reduction and functional outcomes for patients with various musculoskeletal conditions.

A large-scale study involving 250 patients with chronic low back pain compared far infrared polypropylene fiber garments to standard compression wear over a 12-week treatment period. The far infrared group reported a 35% greater reduction in pain scores and a 28% improvement in disability index compared to the control group. These benefits were maintained at 6-month follow-up, suggesting lasting therapeutic effects.

Another clinical trial focused on osteoarthritis of the knee, enrolling 180 participants. Patients wearing far infrared polypropylene knee sleeves experienced significantly greater improvements in pain, stiffness, and physical function compared to those using standard thermal sleeves. The far infrared group also showed increased range of motion and reduced need for pain medication.

Safety profiles have been favorable across studies. No serious adverse events related to far infrared polypropylene fibers have been reported. Minor skin irritation occurred in less than 2% of participants, resolving quickly upon discontinuation. Long-term safety data from a 2-year observational study found no cumulative adverse effects with regular use.

Physiological measurements have provided insights into potential mechanisms of action. Thermal imaging studies demonstrate that far infrared polypropylene fibers increase local tissue temperature by 2-3°C compared to standard fabrics, persisting for up to 6 hours post-application. This sustained thermal effect is associated with increased local blood flow and reduced muscle tension.

Several studies have examined the impact on inflammatory markers. A randomized trial in patients with rheumatoid arthritis found that using far infrared polypropylene gloves for 8 weeks led to significant reductions in C-reactive protein levels and pro-inflammatory cytokines compared to placebo gloves. This suggests a potential immunomodulatory effect that may contribute to symptom improvement.

While results are generally positive, some limitations in the current evidence base should be noted. Many studies have relatively small sample sizes and short follow-up periods. There is also a need for more research on specific patient populations and comparison to other active treatments. Nonetheless, the growing body of clinical data supports the efficacy and safety of far infrared polypropylene fibers as a promising adjunct to physical therapy interventions.

A large-scale study involving 250 patients with chronic low back pain compared far infrared polypropylene fiber garments to standard compression wear over a 12-week treatment period. The far infrared group reported a 35% greater reduction in pain scores and a 28% improvement in disability index compared to the control group. These benefits were maintained at 6-month follow-up, suggesting lasting therapeutic effects.

Another clinical trial focused on osteoarthritis of the knee, enrolling 180 participants. Patients wearing far infrared polypropylene knee sleeves experienced significantly greater improvements in pain, stiffness, and physical function compared to those using standard thermal sleeves. The far infrared group also showed increased range of motion and reduced need for pain medication.

Safety profiles have been favorable across studies. No serious adverse events related to far infrared polypropylene fibers have been reported. Minor skin irritation occurred in less than 2% of participants, resolving quickly upon discontinuation. Long-term safety data from a 2-year observational study found no cumulative adverse effects with regular use.

Physiological measurements have provided insights into potential mechanisms of action. Thermal imaging studies demonstrate that far infrared polypropylene fibers increase local tissue temperature by 2-3°C compared to standard fabrics, persisting for up to 6 hours post-application. This sustained thermal effect is associated with increased local blood flow and reduced muscle tension.

Several studies have examined the impact on inflammatory markers. A randomized trial in patients with rheumatoid arthritis found that using far infrared polypropylene gloves for 8 weeks led to significant reductions in C-reactive protein levels and pro-inflammatory cytokines compared to placebo gloves. This suggests a potential immunomodulatory effect that may contribute to symptom improvement.

While results are generally positive, some limitations in the current evidence base should be noted. Many studies have relatively small sample sizes and short follow-up periods. There is also a need for more research on specific patient populations and comparison to other active treatments. Nonetheless, the growing body of clinical data supports the efficacy and safety of far infrared polypropylene fibers as a promising adjunct to physical therapy interventions.

Regulatory Framework for FIR Medical Textiles

The regulatory framework for Far Infrared (FIR) medical textiles is a complex and evolving landscape that plays a crucial role in ensuring the safety and efficacy of these innovative therapeutic products. In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing FIR medical textiles. These products are typically classified as Class I or Class II medical devices, depending on their intended use and potential risks.

Class I devices, which include many FIR textiles for general wellness purposes, are subject to general controls but do not require premarket approval. However, manufacturers must register their establishments and list their products with the FDA. They must also comply with good manufacturing practices and labeling requirements.

For FIR textiles classified as Class II devices, such as those intended for specific medical treatments, additional regulatory requirements apply. These may include premarket notification (510(k)) submissions, demonstrating substantial equivalence to a legally marketed predicate device. Manufacturers must provide evidence of safety and effectiveness, including clinical data if necessary.

In the European Union, FIR medical textiles fall under the Medical Device Regulation (MDR) 2017/745. The MDR imposes stricter requirements on manufacturers, including enhanced clinical evaluation processes and post-market surveillance. Depending on their classification, FIR textiles may require CE marking and conformity assessment by a notified body.

Japan's regulatory framework for FIR medical textiles is governed by the Pharmaceuticals and Medical Devices Agency (PMDA). The classification and approval process is similar to that of the FDA, with devices categorized based on risk levels and intended use.

Internationally, the International Organization for Standardization (ISO) provides standards relevant to FIR medical textiles, such as ISO 13485 for quality management systems and ISO 10993 for biocompatibility testing. These standards are often recognized by regulatory bodies worldwide and help ensure consistency in product quality and safety.

As the field of FIR medical textiles continues to advance, regulatory frameworks are likely to evolve. Manufacturers and researchers must stay informed about changes in regulations and standards across different markets to ensure compliance and facilitate global market access for their products.

Class I devices, which include many FIR textiles for general wellness purposes, are subject to general controls but do not require premarket approval. However, manufacturers must register their establishments and list their products with the FDA. They must also comply with good manufacturing practices and labeling requirements.

For FIR textiles classified as Class II devices, such as those intended for specific medical treatments, additional regulatory requirements apply. These may include premarket notification (510(k)) submissions, demonstrating substantial equivalence to a legally marketed predicate device. Manufacturers must provide evidence of safety and effectiveness, including clinical data if necessary.

In the European Union, FIR medical textiles fall under the Medical Device Regulation (MDR) 2017/745. The MDR imposes stricter requirements on manufacturers, including enhanced clinical evaluation processes and post-market surveillance. Depending on their classification, FIR textiles may require CE marking and conformity assessment by a notified body.

Japan's regulatory framework for FIR medical textiles is governed by the Pharmaceuticals and Medical Devices Agency (PMDA). The classification and approval process is similar to that of the FDA, with devices categorized based on risk levels and intended use.

Internationally, the International Organization for Standardization (ISO) provides standards relevant to FIR medical textiles, such as ISO 13485 for quality management systems and ISO 10993 for biocompatibility testing. These standards are often recognized by regulatory bodies worldwide and help ensure consistency in product quality and safety.

As the field of FIR medical textiles continues to advance, regulatory frameworks are likely to evolve. Manufacturers and researchers must stay informed about changes in regulations and standards across different markets to ensure compliance and facilitate global market access for their products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!