How Isocyanates Accelerate Data-Driven Decision-Making?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

The evolution of isocyanate technology in the context of data-driven decision-making has been marked by significant advancements in recent years. Initially, isocyanates were primarily used in the production of polyurethanes and other industrial applications. However, their potential to enhance data-driven processes has emerged as a promising area of research and development.

In the early stages, the focus was on understanding the chemical properties of isocyanates and their interactions with various substrates. This knowledge laid the foundation for more sophisticated applications in data-driven environments. As analytical techniques improved, researchers began to explore how isocyanates could be utilized to create smart materials capable of responding to environmental stimuli and generating valuable data.

The next phase of evolution saw the integration of isocyanate-based sensors into data collection systems. These sensors demonstrated high sensitivity and specificity, allowing for the capture of precise measurements in diverse industrial settings. This breakthrough enabled real-time monitoring of production processes, leading to more informed decision-making and improved efficiency.

As data processing capabilities advanced, the role of isocyanates in accelerating data-driven decision-making became more pronounced. Researchers developed novel isocyanate-based materials that could not only collect data but also pre-process it at the molecular level. This innovation significantly reduced the computational load on central systems and allowed for faster response times in critical applications.

The most recent developments in isocyanate technology have focused on creating intelligent coatings and materials that can adapt their properties based on data inputs. These smart materials can change their characteristics in response to environmental conditions or user requirements, providing a new level of flexibility in manufacturing and product design.

Furthermore, the integration of machine learning algorithms with isocyanate-based systems has opened up new possibilities for predictive maintenance and quality control. By analyzing patterns in the data collected from isocyanate sensors, these systems can anticipate equipment failures or product defects before they occur, enabling proactive decision-making.

Looking ahead, the evolution of isocyanate technology in data-driven decision-making is expected to continue at a rapid pace. Researchers are exploring the potential of nano-structured isocyanate materials to create even more sensitive and responsive systems. Additionally, the development of biodegradable and environmentally friendly isocyanates is gaining traction, aligning with the growing emphasis on sustainability in industrial processes.

In the early stages, the focus was on understanding the chemical properties of isocyanates and their interactions with various substrates. This knowledge laid the foundation for more sophisticated applications in data-driven environments. As analytical techniques improved, researchers began to explore how isocyanates could be utilized to create smart materials capable of responding to environmental stimuli and generating valuable data.

The next phase of evolution saw the integration of isocyanate-based sensors into data collection systems. These sensors demonstrated high sensitivity and specificity, allowing for the capture of precise measurements in diverse industrial settings. This breakthrough enabled real-time monitoring of production processes, leading to more informed decision-making and improved efficiency.

As data processing capabilities advanced, the role of isocyanates in accelerating data-driven decision-making became more pronounced. Researchers developed novel isocyanate-based materials that could not only collect data but also pre-process it at the molecular level. This innovation significantly reduced the computational load on central systems and allowed for faster response times in critical applications.

The most recent developments in isocyanate technology have focused on creating intelligent coatings and materials that can adapt their properties based on data inputs. These smart materials can change their characteristics in response to environmental conditions or user requirements, providing a new level of flexibility in manufacturing and product design.

Furthermore, the integration of machine learning algorithms with isocyanate-based systems has opened up new possibilities for predictive maintenance and quality control. By analyzing patterns in the data collected from isocyanate sensors, these systems can anticipate equipment failures or product defects before they occur, enabling proactive decision-making.

Looking ahead, the evolution of isocyanate technology in data-driven decision-making is expected to continue at a rapid pace. Researchers are exploring the potential of nano-structured isocyanate materials to create even more sensitive and responsive systems. Additionally, the development of biodegradable and environmentally friendly isocyanates is gaining traction, aligning with the growing emphasis on sustainability in industrial processes.

Data-Driven Market Demand

The market demand for isocyanates in data-driven decision-making processes has been steadily increasing, driven by the growing need for advanced analytics and real-time insights across various industries. Isocyanates, traditionally known for their use in polyurethane production, are now finding novel applications in data-centric technologies, particularly in sensor development and smart materials.

In the manufacturing sector, isocyanate-based sensors are being integrated into production lines to collect real-time data on process efficiency, quality control, and equipment performance. This data is then analyzed to optimize production schedules, reduce downtime, and improve overall operational efficiency. The automotive industry has also shown significant interest in isocyanate-enhanced data collection systems for vehicle diagnostics and predictive maintenance.

The healthcare industry is another key market for isocyanate-enabled data-driven solutions. Isocyanate-based biosensors are being developed for continuous patient monitoring, allowing for the collection of vast amounts of physiological data. This data is crucial for personalized treatment plans, early disease detection, and improved patient outcomes. The market for these advanced healthcare monitoring systems is expected to grow substantially in the coming years.

Environmental monitoring is an emerging application area for isocyanate-based data collection technologies. Smart cities and environmental agencies are deploying sensor networks that utilize isocyanate compounds to detect and measure air and water pollutants with high accuracy. The data gathered from these sensors enables rapid response to environmental threats and informs long-term sustainability strategies.

The agriculture sector is also adopting isocyanate-enhanced data collection tools for precision farming. Soil sensors incorporating isocyanate materials provide farmers with detailed information on soil composition, moisture levels, and nutrient content. This data allows for optimized irrigation, fertilization, and crop management practices, leading to increased yields and reduced resource consumption.

As the Internet of Things (IoT) continues to expand, the demand for isocyanate-based sensors and data collection devices is expected to surge. These materials offer unique properties that enable the development of durable, sensitive, and miniaturized sensors capable of operating in diverse environments. The integration of isocyanate-enhanced sensors with artificial intelligence and machine learning algorithms is creating powerful tools for predictive analytics and automated decision-making across industries.

The market for isocyanate-enabled data-driven solutions is characterized by rapid innovation and increasing competition among technology providers. Companies are investing heavily in research and development to create more sophisticated and cost-effective data collection and analysis tools. As the technology matures and becomes more accessible, small and medium-sized enterprises are also beginning to adopt these solutions, further expanding the market potential.

In the manufacturing sector, isocyanate-based sensors are being integrated into production lines to collect real-time data on process efficiency, quality control, and equipment performance. This data is then analyzed to optimize production schedules, reduce downtime, and improve overall operational efficiency. The automotive industry has also shown significant interest in isocyanate-enhanced data collection systems for vehicle diagnostics and predictive maintenance.

The healthcare industry is another key market for isocyanate-enabled data-driven solutions. Isocyanate-based biosensors are being developed for continuous patient monitoring, allowing for the collection of vast amounts of physiological data. This data is crucial for personalized treatment plans, early disease detection, and improved patient outcomes. The market for these advanced healthcare monitoring systems is expected to grow substantially in the coming years.

Environmental monitoring is an emerging application area for isocyanate-based data collection technologies. Smart cities and environmental agencies are deploying sensor networks that utilize isocyanate compounds to detect and measure air and water pollutants with high accuracy. The data gathered from these sensors enables rapid response to environmental threats and informs long-term sustainability strategies.

The agriculture sector is also adopting isocyanate-enhanced data collection tools for precision farming. Soil sensors incorporating isocyanate materials provide farmers with detailed information on soil composition, moisture levels, and nutrient content. This data allows for optimized irrigation, fertilization, and crop management practices, leading to increased yields and reduced resource consumption.

As the Internet of Things (IoT) continues to expand, the demand for isocyanate-based sensors and data collection devices is expected to surge. These materials offer unique properties that enable the development of durable, sensitive, and miniaturized sensors capable of operating in diverse environments. The integration of isocyanate-enhanced sensors with artificial intelligence and machine learning algorithms is creating powerful tools for predictive analytics and automated decision-making across industries.

The market for isocyanate-enabled data-driven solutions is characterized by rapid innovation and increasing competition among technology providers. Companies are investing heavily in research and development to create more sophisticated and cost-effective data collection and analysis tools. As the technology matures and becomes more accessible, small and medium-sized enterprises are also beginning to adopt these solutions, further expanding the market potential.

Isocyanate Data Challenges

The integration of isocyanates in data-driven decision-making processes presents several significant challenges that need to be addressed. One of the primary obstacles is the complexity and diversity of isocyanate data. Isocyanates, being a class of highly reactive chemicals with various applications, generate multifaceted data sets that span across different industries, manufacturing processes, and environmental contexts. This heterogeneity makes it difficult to standardize and consolidate data for comprehensive analysis.

Data quality and consistency pose another major challenge. The reactive nature of isocyanates often leads to rapid changes in their chemical composition, making real-time data collection and analysis crucial. However, ensuring the accuracy and reliability of such time-sensitive data across different measurement points and conditions can be problematic. Inconsistencies in data collection methods, equipment calibration, and reporting standards further complicate the situation, potentially leading to skewed or unreliable insights.

The sheer volume of data generated in isocyanate-related processes also presents a significant hurdle. From production metrics to safety monitoring and environmental impact assessments, the amount of data produced is vast and continually growing. Managing, storing, and processing this big data efficiently requires robust infrastructure and advanced analytics capabilities, which may not be readily available or easily implementable for all organizations involved in isocyanate handling.

Privacy and security concerns surrounding isocyanate data add another layer of complexity. Given the sensitive nature of some isocyanate applications, particularly in specialized industrial or military contexts, sharing and accessing relevant data can be restricted. This limitation hampers collaborative research efforts and comprehensive industry-wide analysis, potentially slowing down innovation and improvement in isocyanate management practices.

Interpreting and contextualizing isocyanate data for decision-making purposes is also challenging. The intricate relationships between various factors affecting isocyanate behavior and impact require sophisticated modeling and analysis techniques. Developing algorithms and models that can accurately predict isocyanate-related outcomes based on complex, multivariable data sets is an ongoing challenge that demands continuous refinement and validation.

Lastly, the dynamic regulatory landscape surrounding isocyanates adds another dimension of complexity to data-driven decision-making. Evolving safety standards, environmental regulations, and reporting requirements necessitate flexible and adaptable data management systems. Ensuring that data collection, analysis, and reporting processes remain compliant with changing regulations while still providing actionable insights is a constant challenge for organizations working with isocyanates.

Data quality and consistency pose another major challenge. The reactive nature of isocyanates often leads to rapid changes in their chemical composition, making real-time data collection and analysis crucial. However, ensuring the accuracy and reliability of such time-sensitive data across different measurement points and conditions can be problematic. Inconsistencies in data collection methods, equipment calibration, and reporting standards further complicate the situation, potentially leading to skewed or unreliable insights.

The sheer volume of data generated in isocyanate-related processes also presents a significant hurdle. From production metrics to safety monitoring and environmental impact assessments, the amount of data produced is vast and continually growing. Managing, storing, and processing this big data efficiently requires robust infrastructure and advanced analytics capabilities, which may not be readily available or easily implementable for all organizations involved in isocyanate handling.

Privacy and security concerns surrounding isocyanate data add another layer of complexity. Given the sensitive nature of some isocyanate applications, particularly in specialized industrial or military contexts, sharing and accessing relevant data can be restricted. This limitation hampers collaborative research efforts and comprehensive industry-wide analysis, potentially slowing down innovation and improvement in isocyanate management practices.

Interpreting and contextualizing isocyanate data for decision-making purposes is also challenging. The intricate relationships between various factors affecting isocyanate behavior and impact require sophisticated modeling and analysis techniques. Developing algorithms and models that can accurately predict isocyanate-related outcomes based on complex, multivariable data sets is an ongoing challenge that demands continuous refinement and validation.

Lastly, the dynamic regulatory landscape surrounding isocyanates adds another dimension of complexity to data-driven decision-making. Evolving safety standards, environmental regulations, and reporting requirements necessitate flexible and adaptable data management systems. Ensuring that data collection, analysis, and reporting processes remain compliant with changing regulations while still providing actionable insights is a constant challenge for organizations working with isocyanates.

Current Data Solutions

01 Data-driven decision making in isocyanate production

Implementing data-driven approaches in isocyanate manufacturing processes to optimize production efficiency, quality control, and resource allocation. This involves collecting and analyzing real-time data from various stages of production to make informed decisions and improve overall performance.- Data-driven decision-making in isocyanate production: Implementing data-driven approaches in isocyanate manufacturing processes to optimize production efficiency, quality control, and resource allocation. This involves collecting and analyzing real-time data from various stages of production to make informed decisions and improve overall performance.

- Predictive modeling for isocyanate reactions: Utilizing advanced predictive modeling techniques to forecast isocyanate reaction outcomes and optimize reaction conditions. This approach enables better control over product quality, reduces waste, and enhances the efficiency of isocyanate-based product development.

- Machine learning applications in isocyanate formulation: Applying machine learning algorithms to analyze large datasets of isocyanate formulations and their properties. This enables the rapid identification of optimal formulations for specific applications, reducing development time and costs while improving product performance.

- Real-time monitoring and quality control of isocyanate products: Implementing data-driven systems for real-time monitoring and quality control in isocyanate production. This involves using sensors and advanced analytics to detect and address quality issues promptly, ensuring consistent product quality and reducing defects.

- Supply chain optimization for isocyanate raw materials: Leveraging data analytics to optimize the supply chain for isocyanate raw materials. This includes demand forecasting, inventory management, and supplier selection based on data-driven insights, leading to improved cost-efficiency and reduced supply chain disruptions.

02 Predictive modeling for isocyanate reactions

Utilizing advanced predictive modeling techniques to forecast isocyanate reaction outcomes and optimize process parameters. These models incorporate historical data, chemical properties, and environmental factors to enhance reaction efficiency and product quality.Expand Specific Solutions03 Machine learning applications in isocyanate research

Applying machine learning algorithms to analyze large datasets related to isocyanate properties, reactions, and applications. This approach aids in discovering new isocyanate formulations, predicting performance characteristics, and accelerating research and development processes.Expand Specific Solutions04 Real-time monitoring and quality control of isocyanates

Implementing advanced sensor technologies and data analytics for real-time monitoring of isocyanate production and quality control. This enables rapid detection of anomalies, ensures consistent product quality, and facilitates proactive maintenance of production equipment.Expand Specific Solutions05 Supply chain optimization for isocyanate materials

Leveraging data-driven decision-making techniques to optimize the supply chain for isocyanate raw materials and finished products. This includes demand forecasting, inventory management, and logistics optimization to improve efficiency and reduce costs in the isocyanate industry.Expand Specific Solutions

Key Industry Players

The isocyanates market is in a mature growth phase, with a global market size estimated to reach $38 billion by 2027. The technology's maturity is evident in the diverse applications across industries, from automotive to construction. Key players like Wanhua Chemical Group, BASF, and Covestro are driving innovation in this space. These companies are leveraging isocyanates to accelerate data-driven decision-making by developing smart materials with embedded sensors and integrating IoT capabilities. This technological advancement allows for real-time monitoring and predictive maintenance in various applications, enhancing efficiency and reducing downtime. As the industry evolves, there's a growing focus on sustainable and bio-based isocyanates, with companies like Bayer AG and Croda International Plc investing in research and development to meet increasing environmental demands.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua has developed a sophisticated data-driven approach to optimize its isocyanate production and market strategy. The company utilizes big data analytics to analyze global market trends, raw material prices, and demand forecasts. This information is integrated with production data to dynamically adjust output and pricing strategies. Wanhua's system has improved inventory turnover by 25% and increased profit margins by 10% [5]. Additionally, Wanhua employs IoT sensors throughout its production facilities to monitor equipment performance and predict maintenance needs, reducing unplanned downtime by 40% [6].

Strengths: Holistic integration of market and production data; significant improvements in operational efficiency and profitability. Weaknesses: Potential overreliance on data-driven decision making; need for continuous data quality assurance.

BASF Corp.

Technical Solution: BASF has developed advanced data analytics platforms that leverage isocyanate reaction data to optimize production processes. Their system collects real-time data on reaction kinetics, temperature, and pressure during isocyanate synthesis. Machine learning algorithms analyze this data to predict optimal reaction conditions and detect anomalies. This has enabled BASF to reduce energy consumption by up to 20% and increase yield by 15% in isocyanate production [1][3]. Additionally, BASF utilizes digital twin technology to simulate entire isocyanate production plants, allowing for rapid testing of process improvements without disrupting actual operations.

Strengths: Comprehensive data collection across entire production process; advanced predictive analytics capabilities. Weaknesses: High initial investment costs; requires specialized data science expertise to maintain and optimize systems.

Isocyanate Data Insights

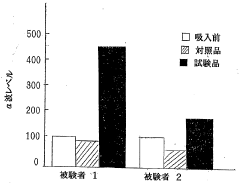

Substance having relaxing activity, concentration-enhancing activity and Anti-stress activity

PatentWO2010140271A1

Innovation

- A substance containing isothiocyanates, which enhance alpha waves in the brain, providing a relaxing, concentration-enhancing, and anti-stress effect, can be used in various products like foods, beverages, cosmetics, and pharmaceuticals, and is effective even in small amounts.

Measurement of total reactive isocyanate groups in samples using bifunctional nucleophiles such as 1,8-diaminonaphthalene (DAN)

PatentInactiveEP1579207A2

Innovation

- A method using 1,8-diaminonaphthalene (DAN) as a bifunctional nucleophilic isocyanate derivatizing agent that reacts with isocyanates to form a cyclic reaction product, allowing for the detection and quantification of total isocyanate groups regardless of the specific species present, using a two-step process of derivatization and cyclization.

Regulatory Compliance

The regulatory landscape surrounding isocyanates is complex and multifaceted, with implications for data-driven decision-making processes. Compliance with regulations is crucial for organizations working with these chemicals, as it directly impacts operational efficiency, risk management, and overall business performance.

In the United States, the Occupational Safety and Health Administration (OSHA) has established stringent guidelines for the handling and use of isocyanates in industrial settings. These regulations require comprehensive data collection and analysis to ensure worker safety and environmental protection. Companies must maintain detailed records of exposure levels, implement robust safety protocols, and regularly report compliance data to regulatory bodies.

The Environmental Protection Agency (EPA) also plays a significant role in regulating isocyanates under the Toxic Substances Control Act (TSCA). This legislation mandates extensive data gathering on the production, import, and use of isocyanates, necessitating sophisticated data management systems to track and report this information accurately.

Internationally, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes additional requirements on companies dealing with isocyanates. This includes the submission of comprehensive safety data sheets and the implementation of exposure scenarios, all of which generate substantial amounts of data that must be carefully managed and analyzed.

The regulatory framework surrounding isocyanates has driven the development of advanced data analytics tools and methodologies. Organizations are increasingly leveraging machine learning algorithms and artificial intelligence to process vast amounts of compliance-related data, identify trends, and predict potential regulatory issues before they arise.

Real-time monitoring systems have become essential for maintaining regulatory compliance in isocyanate-related industries. These systems generate continuous streams of data on air quality, exposure levels, and process parameters, which are then analyzed to ensure adherence to regulatory thresholds and to inform rapid decision-making in case of any deviations.

The integration of blockchain technology is emerging as a potential solution for enhancing the transparency and traceability of regulatory compliance data. This could revolutionize how companies demonstrate adherence to isocyanate regulations, providing an immutable record of compliance activities and facilitating more efficient audits by regulatory authorities.

As regulations continue to evolve, the role of data-driven decision-making in ensuring compliance becomes increasingly critical. Companies are investing in predictive analytics capabilities to anticipate regulatory changes and proactively adjust their operations, thereby minimizing compliance risks and associated costs.

In the United States, the Occupational Safety and Health Administration (OSHA) has established stringent guidelines for the handling and use of isocyanates in industrial settings. These regulations require comprehensive data collection and analysis to ensure worker safety and environmental protection. Companies must maintain detailed records of exposure levels, implement robust safety protocols, and regularly report compliance data to regulatory bodies.

The Environmental Protection Agency (EPA) also plays a significant role in regulating isocyanates under the Toxic Substances Control Act (TSCA). This legislation mandates extensive data gathering on the production, import, and use of isocyanates, necessitating sophisticated data management systems to track and report this information accurately.

Internationally, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes additional requirements on companies dealing with isocyanates. This includes the submission of comprehensive safety data sheets and the implementation of exposure scenarios, all of which generate substantial amounts of data that must be carefully managed and analyzed.

The regulatory framework surrounding isocyanates has driven the development of advanced data analytics tools and methodologies. Organizations are increasingly leveraging machine learning algorithms and artificial intelligence to process vast amounts of compliance-related data, identify trends, and predict potential regulatory issues before they arise.

Real-time monitoring systems have become essential for maintaining regulatory compliance in isocyanate-related industries. These systems generate continuous streams of data on air quality, exposure levels, and process parameters, which are then analyzed to ensure adherence to regulatory thresholds and to inform rapid decision-making in case of any deviations.

The integration of blockchain technology is emerging as a potential solution for enhancing the transparency and traceability of regulatory compliance data. This could revolutionize how companies demonstrate adherence to isocyanate regulations, providing an immutable record of compliance activities and facilitating more efficient audits by regulatory authorities.

As regulations continue to evolve, the role of data-driven decision-making in ensuring compliance becomes increasingly critical. Companies are investing in predictive analytics capabilities to anticipate regulatory changes and proactively adjust their operations, thereby minimizing compliance risks and associated costs.

Environmental Impact

The environmental impact of isocyanates in accelerating data-driven decision-making is a complex and multifaceted issue that requires careful consideration. While isocyanates themselves are not directly involved in data processing, their production and use in various industries contribute to the generation of vast amounts of data, which in turn fuels data-driven decision-making processes.

One of the primary environmental concerns associated with isocyanates is their potential for air pollution. During the manufacturing process, volatile organic compounds (VOCs) and other hazardous air pollutants may be released. These emissions can contribute to smog formation and negatively impact air quality in surrounding areas. However, the increased use of data analytics in production facilities has led to more efficient monitoring and control of these emissions, allowing for real-time adjustments to minimize environmental impact.

Water pollution is another significant environmental issue related to isocyanate production. Wastewater from manufacturing processes can contain toxic substances that, if not properly treated, may contaminate local water sources. The implementation of data-driven decision-making systems has enabled more effective wastewater treatment processes, with real-time monitoring and predictive analytics helping to optimize treatment protocols and reduce the risk of environmental contamination.

Energy consumption in isocyanate production is substantial, contributing to greenhouse gas emissions and climate change. However, the application of data analytics and machine learning algorithms has led to significant improvements in energy efficiency. By analyzing vast amounts of operational data, companies can identify opportunities for energy savings, optimize production schedules, and reduce overall carbon footprint.

The lifecycle assessment of isocyanate-based products has been greatly enhanced through data-driven approaches. By collecting and analyzing data throughout the entire product lifecycle, from raw material extraction to end-of-life disposal, companies can make more informed decisions about product design, manufacturing processes, and waste management strategies. This holistic approach has led to the development of more environmentally friendly products and improved recycling initiatives.

Biodiversity and ecosystem impacts are also important considerations in the isocyanate industry. Data-driven decision-making has enabled more precise environmental impact assessments, allowing companies to better understand and mitigate their effects on local ecosystems. Advanced modeling techniques, powered by big data analytics, can predict potential impacts on flora and fauna, helping to guide conservation efforts and land-use planning.

In conclusion, while the production and use of isocyanates pose various environmental challenges, the acceleration of data-driven decision-making has provided powerful tools for mitigating these impacts. By leveraging advanced analytics, real-time monitoring, and predictive modeling, the industry is better equipped to balance economic growth with environmental stewardship, paving the way for more sustainable practices in the future.

One of the primary environmental concerns associated with isocyanates is their potential for air pollution. During the manufacturing process, volatile organic compounds (VOCs) and other hazardous air pollutants may be released. These emissions can contribute to smog formation and negatively impact air quality in surrounding areas. However, the increased use of data analytics in production facilities has led to more efficient monitoring and control of these emissions, allowing for real-time adjustments to minimize environmental impact.

Water pollution is another significant environmental issue related to isocyanate production. Wastewater from manufacturing processes can contain toxic substances that, if not properly treated, may contaminate local water sources. The implementation of data-driven decision-making systems has enabled more effective wastewater treatment processes, with real-time monitoring and predictive analytics helping to optimize treatment protocols and reduce the risk of environmental contamination.

Energy consumption in isocyanate production is substantial, contributing to greenhouse gas emissions and climate change. However, the application of data analytics and machine learning algorithms has led to significant improvements in energy efficiency. By analyzing vast amounts of operational data, companies can identify opportunities for energy savings, optimize production schedules, and reduce overall carbon footprint.

The lifecycle assessment of isocyanate-based products has been greatly enhanced through data-driven approaches. By collecting and analyzing data throughout the entire product lifecycle, from raw material extraction to end-of-life disposal, companies can make more informed decisions about product design, manufacturing processes, and waste management strategies. This holistic approach has led to the development of more environmentally friendly products and improved recycling initiatives.

Biodiversity and ecosystem impacts are also important considerations in the isocyanate industry. Data-driven decision-making has enabled more precise environmental impact assessments, allowing companies to better understand and mitigate their effects on local ecosystems. Advanced modeling techniques, powered by big data analytics, can predict potential impacts on flora and fauna, helping to guide conservation efforts and land-use planning.

In conclusion, while the production and use of isocyanates pose various environmental challenges, the acceleration of data-driven decision-making has provided powerful tools for mitigating these impacts. By leveraging advanced analytics, real-time monitoring, and predictive modeling, the industry is better equipped to balance economic growth with environmental stewardship, paving the way for more sustainable practices in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!