How Isocyanates Bridge Expertise and Application Fields?

JUL 10, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Technology Evolution and Objectives

Isocyanates have played a pivotal role in the evolution of polymer chemistry and materials science since their discovery in the late 19th century. The journey of isocyanate technology began with the synthesis of the first isocyanate compound by Wurtz in 1848, but it wasn't until the 1930s that their potential in polymer production was fully realized. This realization marked the beginning of a technological revolution that would span decades and transform multiple industries.

The primary objective of isocyanate technology has been to harness the unique reactivity of the -NCO functional group to create versatile materials with tailored properties. Over the years, this objective has expanded to include the development of more efficient and environmentally friendly production processes, as well as the exploration of novel applications across diverse fields.

One of the most significant milestones in isocyanate technology was the invention of polyurethanes by Otto Bayer in 1937. This breakthrough opened up a vast array of possibilities in materials science, leading to the development of flexible and rigid foams, elastomers, coatings, adhesives, and sealants. The versatility of isocyanates in forming these materials has driven continuous innovation in their synthesis, modification, and application.

As environmental concerns gained prominence, the isocyanate industry faced new challenges and opportunities. The focus shifted towards developing isocyanate-based systems with reduced volatile organic compound (VOC) emissions, improved energy efficiency, and enhanced recyclability. This led to the emergence of water-based polyurethane dispersions, low-VOC coatings, and bio-based isocyanates derived from renewable resources.

In recent years, the objectives of isocyanate technology have expanded to address global challenges such as sustainability, energy conservation, and advanced manufacturing. Researchers are now exploring the potential of isocyanates in cutting-edge applications like 3D printing, self-healing materials, and smart coatings. The integration of nanotechnology with isocyanate chemistry has opened up new frontiers in material design, enabling the creation of nanocomposites with enhanced mechanical, thermal, and barrier properties.

The evolution of isocyanate technology continues to bridge various fields of expertise, from organic chemistry and polymer science to materials engineering and industrial design. This interdisciplinary nature has fostered collaborations between academic institutions and industry, driving innovation and pushing the boundaries of what is possible with isocyanate-based materials.

The primary objective of isocyanate technology has been to harness the unique reactivity of the -NCO functional group to create versatile materials with tailored properties. Over the years, this objective has expanded to include the development of more efficient and environmentally friendly production processes, as well as the exploration of novel applications across diverse fields.

One of the most significant milestones in isocyanate technology was the invention of polyurethanes by Otto Bayer in 1937. This breakthrough opened up a vast array of possibilities in materials science, leading to the development of flexible and rigid foams, elastomers, coatings, adhesives, and sealants. The versatility of isocyanates in forming these materials has driven continuous innovation in their synthesis, modification, and application.

As environmental concerns gained prominence, the isocyanate industry faced new challenges and opportunities. The focus shifted towards developing isocyanate-based systems with reduced volatile organic compound (VOC) emissions, improved energy efficiency, and enhanced recyclability. This led to the emergence of water-based polyurethane dispersions, low-VOC coatings, and bio-based isocyanates derived from renewable resources.

In recent years, the objectives of isocyanate technology have expanded to address global challenges such as sustainability, energy conservation, and advanced manufacturing. Researchers are now exploring the potential of isocyanates in cutting-edge applications like 3D printing, self-healing materials, and smart coatings. The integration of nanotechnology with isocyanate chemistry has opened up new frontiers in material design, enabling the creation of nanocomposites with enhanced mechanical, thermal, and barrier properties.

The evolution of isocyanate technology continues to bridge various fields of expertise, from organic chemistry and polymer science to materials engineering and industrial design. This interdisciplinary nature has fostered collaborations between academic institutions and industry, driving innovation and pushing the boundaries of what is possible with isocyanate-based materials.

Market Demand Analysis for Isocyanate Applications

The global market for isocyanates has been experiencing steady growth, driven by increasing demand across various industries. The versatility of isocyanates in forming polyurethane products has led to their widespread adoption in construction, automotive, furniture, and electronics sectors. In the construction industry, isocyanates are crucial for producing insulation materials, sealants, and adhesives, contributing to energy-efficient building solutions. The automotive sector utilizes isocyanates in manufacturing lightweight components, enhancing fuel efficiency and reducing emissions.

The furniture industry relies on isocyanates for producing flexible and rigid foams used in upholstery and mattresses, catering to the growing demand for comfortable and durable furnishings. In the electronics sector, isocyanates play a vital role in the production of protective coatings and encapsulants for electronic components, meeting the increasing need for miniaturization and durability in consumer electronics.

Market analysis indicates a rising demand for eco-friendly and sustainable isocyanate-based products, driven by stringent environmental regulations and consumer preferences. This trend has led to the development of bio-based isocyanates and low-VOC formulations, opening new opportunities for market growth and innovation.

The Asia-Pacific region has emerged as the largest and fastest-growing market for isocyanates, fueled by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance and specialty applications.

The COVID-19 pandemic initially disrupted the isocyanate market due to supply chain interruptions and reduced demand in certain sectors. However, the market has shown resilience, with increased demand for isocyanates in medical applications, such as the production of personal protective equipment and medical devices.

Looking ahead, the isocyanate market is expected to continue its growth trajectory, driven by technological advancements, expanding applications, and the ongoing shift towards sustainable solutions. The development of novel isocyanate formulations with enhanced properties and reduced environmental impact is likely to create new market opportunities and bridge expertise across various application fields.

The furniture industry relies on isocyanates for producing flexible and rigid foams used in upholstery and mattresses, catering to the growing demand for comfortable and durable furnishings. In the electronics sector, isocyanates play a vital role in the production of protective coatings and encapsulants for electronic components, meeting the increasing need for miniaturization and durability in consumer electronics.

Market analysis indicates a rising demand for eco-friendly and sustainable isocyanate-based products, driven by stringent environmental regulations and consumer preferences. This trend has led to the development of bio-based isocyanates and low-VOC formulations, opening new opportunities for market growth and innovation.

The Asia-Pacific region has emerged as the largest and fastest-growing market for isocyanates, fueled by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance and specialty applications.

The COVID-19 pandemic initially disrupted the isocyanate market due to supply chain interruptions and reduced demand in certain sectors. However, the market has shown resilience, with increased demand for isocyanates in medical applications, such as the production of personal protective equipment and medical devices.

Looking ahead, the isocyanate market is expected to continue its growth trajectory, driven by technological advancements, expanding applications, and the ongoing shift towards sustainable solutions. The development of novel isocyanate formulations with enhanced properties and reduced environmental impact is likely to create new market opportunities and bridge expertise across various application fields.

Current Challenges in Isocyanate Chemistry

Isocyanate chemistry, while well-established, continues to face significant challenges that hinder its full potential in various applications. One of the primary concerns is the toxicity of isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This safety issue necessitates stringent handling protocols and protective measures, which can increase production costs and complexity.

Another challenge lies in the moisture sensitivity of isocyanates. Their high reactivity with water can lead to undesired side reactions, affecting product quality and shelf life. This sensitivity complicates storage, transportation, and application processes, requiring careful control of environmental conditions throughout the supply chain.

The environmental impact of isocyanates also presents ongoing challenges. Many traditional isocyanates are derived from fossil fuels, raising sustainability concerns. The industry is under pressure to develop more eco-friendly alternatives and production methods to align with global sustainability goals.

Regulatory compliance poses another significant hurdle. Stringent regulations surrounding the use and handling of isocyanates, particularly in consumer products, can limit their application in certain markets. Adapting to evolving regulatory landscapes while maintaining product performance is a constant challenge for manufacturers.

In terms of performance, achieving the perfect balance between reactivity and stability remains an ongoing issue. While high reactivity is desirable for fast curing and processing, it can also lead to premature reactions and reduced pot life. Conversely, efforts to improve stability can sometimes compromise the desired reactivity and cure speed.

The development of isocyanate-free alternatives is also putting pressure on traditional isocyanate chemistry. As the market demands safer and more sustainable options, researchers are exploring novel chemistries that could potentially replace isocyanates in certain applications. This competition drives the need for continuous innovation in isocyanate technology.

Lastly, the complexity of formulating with isocyanates presents challenges in product development. Achieving the right balance of properties such as flexibility, hardness, and chemical resistance often requires extensive experimentation and expertise. This complexity can lead to longer development cycles and increased costs for new product introductions.

Another challenge lies in the moisture sensitivity of isocyanates. Their high reactivity with water can lead to undesired side reactions, affecting product quality and shelf life. This sensitivity complicates storage, transportation, and application processes, requiring careful control of environmental conditions throughout the supply chain.

The environmental impact of isocyanates also presents ongoing challenges. Many traditional isocyanates are derived from fossil fuels, raising sustainability concerns. The industry is under pressure to develop more eco-friendly alternatives and production methods to align with global sustainability goals.

Regulatory compliance poses another significant hurdle. Stringent regulations surrounding the use and handling of isocyanates, particularly in consumer products, can limit their application in certain markets. Adapting to evolving regulatory landscapes while maintaining product performance is a constant challenge for manufacturers.

In terms of performance, achieving the perfect balance between reactivity and stability remains an ongoing issue. While high reactivity is desirable for fast curing and processing, it can also lead to premature reactions and reduced pot life. Conversely, efforts to improve stability can sometimes compromise the desired reactivity and cure speed.

The development of isocyanate-free alternatives is also putting pressure on traditional isocyanate chemistry. As the market demands safer and more sustainable options, researchers are exploring novel chemistries that could potentially replace isocyanates in certain applications. This competition drives the need for continuous innovation in isocyanate technology.

Lastly, the complexity of formulating with isocyanates presents challenges in product development. Achieving the right balance of properties such as flexibility, hardness, and chemical resistance often requires extensive experimentation and expertise. This complexity can lead to longer development cycles and increased costs for new product introductions.

Current Isocyanate Synthesis Methods

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.

- Isocyanate-based catalysts and additives: Several patents focus on the development of isocyanate-based catalysts and additives for various chemical processes. These include novel compounds and formulations that enhance reaction rates, selectivity, or product properties in different industrial applications.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, patents in this category address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer alternatives or modified isocyanates with reduced health risks.

- Isocyanate-free alternatives and substitutes: Some patents focus on developing alternatives or substitutes for isocyanates in various applications. These include novel chemistries, formulations, and processes that aim to achieve similar properties and performance without the use of traditional isocyanates.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in coatings, adhesives, and foams.Expand Specific Solutions03 Isocyanate-free alternatives and substitutes

Research into isocyanate-free alternatives and substitutes is presented, addressing environmental and health concerns associated with traditional isocyanates. These alternatives aim to provide similar performance characteristics while reducing potential hazards.Expand Specific Solutions04 Modification and functionalization of isocyanates

Techniques for modifying and functionalizing isocyanates to enhance their properties or create novel compounds are described. These modifications can improve reactivity, stability, or introduce new functional groups for specific applications.Expand Specific Solutions05 Safety and handling of isocyanates

Patents addressing the safe handling, storage, and use of isocyanates are included. These cover methods for reducing exposure risks, improving workplace safety, and developing protective equipment for handling isocyanates.Expand Specific Solutions

Key Players in Isocyanate Industry

The isocyanates market is in a mature growth stage, characterized by steady demand across various application fields. The global market size is estimated to be in the billions of dollars, driven by increasing use in polyurethane production for automotive, construction, and furniture industries. Technologically, isocyanates are well-established, with major players like Wanhua Chemical, BASF, Covestro, and Dow focusing on product innovations and sustainable solutions. These companies are investing in R&D to develop bio-based alternatives and improve production efficiency, aiming to address environmental concerns and maintain competitive edge in this consolidated market landscape.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has emerged as a leading player in the isocyanate market, with a focus on MDI and TDI production. Their approach includes the development of innovative catalysts and process technologies to improve isocyanate yield and purity[17]. Wanhua has introduced novel isocyanate-based systems for rigid foam insulation, contributing to energy efficiency in construction and refrigeration applications[18]. In the field of coatings, Wanhua has developed isocyanate-based solutions with enhanced chemical resistance and durability for industrial applications[19]. The company has also focused on developing water-based polyurethane dispersions using isocyanates, addressing environmental concerns and regulatory requirements[20].

Strengths: Large-scale production capabilities, competitive pricing, growing global presence. Weaknesses: Relatively newer entrant in some specialty isocyanate markets, potential geopolitical challenges affecting global expansion.

BASF Corp.

Technical Solution: BASF has developed innovative isocyanate-based solutions for various applications. Their approach includes the use of aliphatic isocyanates for high-performance coatings with excellent weathering resistance and color stability[1]. BASF has also pioneered the development of water-based polyurethane dispersions using isocyanates, which offer improved environmental compatibility and reduced VOC emissions[2]. In the field of automotive applications, BASF has introduced isocyanate-based solutions for lightweight materials, contributing to fuel efficiency and reduced emissions[3]. The company has also focused on developing bio-based isocyanates, addressing sustainability concerns in the industry[4].

Strengths: Wide range of applications, focus on sustainability, strong R&D capabilities. Weaknesses: Potential regulatory challenges due to isocyanate toxicity, dependency on petrochemical feedstocks for some products.

Innovative Isocyanate Research Breakthroughs

Use of beta-hydroxyalkylamide in ambient and low bake liquid coatings

PatentInactiveEP1401906A1

Innovation

- The use of beta-hydroxyalkylamide (HAA) in conjunction with isocyanate in waterborne coating compositions allows for curing at ambient or low-bake temperatures (60°C or less), enhancing hardness, chemical resistance, and viscosity without compromising humidity or salt spray resistance, and reducing hardening time.

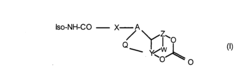

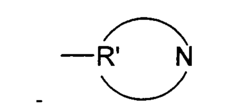

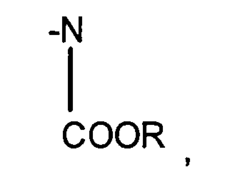

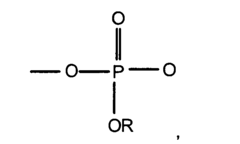

Modified isocyanates

PatentInactiveEP1382626A1

Innovation

- Development of modified isocyanate derivatives with a crosslinking functional group that remains stable at low temperatures and only reacts at high temperatures, allowing for controlled crosslinking reactions without the need for masking agents, using cyclic carbonates to form stable polyisocyanates that can react with nucleophilic compounds to form coatings and polymers.

Environmental Impact of Isocyanates

Isocyanates, widely used in various industries, have significant environmental implications that require careful consideration. These compounds, essential in the production of polyurethanes, can have both direct and indirect impacts on ecosystems and human health.

The production and use of isocyanates contribute to air pollution through the release of volatile organic compounds (VOCs). These emissions can lead to the formation of ground-level ozone, a key component of smog, which negatively affects air quality and can harm plant life. Additionally, some isocyanates are known to have high global warming potential, contributing to climate change when released into the atmosphere.

Water contamination is another environmental concern associated with isocyanates. Improper disposal or accidental spills can lead to these chemicals entering water systems. In aquatic environments, isocyanates can react with water to form potentially harmful byproducts, affecting marine life and water quality. The persistence of these compounds in water bodies can lead to long-term ecological impacts.

Soil contamination is also a potential risk, particularly in areas near production facilities or where isocyanate-containing products are improperly disposed of. This can affect soil microorganisms and potentially enter the food chain through plant uptake.

The environmental impact of isocyanates extends to waste management challenges. Products containing polyurethanes, such as foam insulation or automotive parts, can be difficult to recycle or dispose of safely. This contributes to the growing problem of non-biodegradable waste in landfills.

However, the industry has been making strides in developing more environmentally friendly alternatives and improving production processes. Water-based polyurethanes and bio-based isocyanates are emerging as potential solutions to reduce environmental impact. Additionally, advancements in recycling technologies for polyurethane products are helping to mitigate end-of-life environmental issues.

Regulatory bodies worldwide have implemented strict guidelines for the handling, use, and disposal of isocyanates to minimize their environmental impact. These regulations often require companies to implement emission control technologies and proper waste management practices.

The environmental impact of isocyanates underscores the importance of continued research and development in this field. Balancing the undeniable utility of these compounds with environmental sustainability remains a key challenge for the industry. As expertise in isocyanate chemistry continues to evolve, it is likely that more sustainable practices and alternatives will emerge, bridging the gap between industrial needs and environmental protection.

The production and use of isocyanates contribute to air pollution through the release of volatile organic compounds (VOCs). These emissions can lead to the formation of ground-level ozone, a key component of smog, which negatively affects air quality and can harm plant life. Additionally, some isocyanates are known to have high global warming potential, contributing to climate change when released into the atmosphere.

Water contamination is another environmental concern associated with isocyanates. Improper disposal or accidental spills can lead to these chemicals entering water systems. In aquatic environments, isocyanates can react with water to form potentially harmful byproducts, affecting marine life and water quality. The persistence of these compounds in water bodies can lead to long-term ecological impacts.

Soil contamination is also a potential risk, particularly in areas near production facilities or where isocyanate-containing products are improperly disposed of. This can affect soil microorganisms and potentially enter the food chain through plant uptake.

The environmental impact of isocyanates extends to waste management challenges. Products containing polyurethanes, such as foam insulation or automotive parts, can be difficult to recycle or dispose of safely. This contributes to the growing problem of non-biodegradable waste in landfills.

However, the industry has been making strides in developing more environmentally friendly alternatives and improving production processes. Water-based polyurethanes and bio-based isocyanates are emerging as potential solutions to reduce environmental impact. Additionally, advancements in recycling technologies for polyurethane products are helping to mitigate end-of-life environmental issues.

Regulatory bodies worldwide have implemented strict guidelines for the handling, use, and disposal of isocyanates to minimize their environmental impact. These regulations often require companies to implement emission control technologies and proper waste management practices.

The environmental impact of isocyanates underscores the importance of continued research and development in this field. Balancing the undeniable utility of these compounds with environmental sustainability remains a key challenge for the industry. As expertise in isocyanate chemistry continues to evolve, it is likely that more sustainable practices and alternatives will emerge, bridging the gap between industrial needs and environmental protection.

Safety Regulations for Isocyanate Handling

The handling of isocyanates requires strict adherence to safety regulations due to their potential health hazards and reactive nature. Regulatory bodies worldwide have established comprehensive guidelines to ensure the safe use, storage, and disposal of these chemicals. In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for various isocyanates, typically ranging from 0.005 to 0.02 parts per million (ppm) for an 8-hour time-weighted average.

Personal protective equipment (PPE) is mandatory when working with isocyanates. This includes chemical-resistant gloves, protective clothing, and respiratory protection. The type of respiratory protection required depends on the concentration of isocyanates in the air and the specific task being performed. For low-level exposures, air-purifying respirators with organic vapor cartridges may be sufficient, while higher concentrations or spray applications may necessitate supplied-air respirators.

Proper ventilation is crucial in areas where isocyanates are used or stored. Local exhaust ventilation systems should be installed to capture and remove isocyanate vapors at their source. Regular air monitoring is essential to ensure that exposure levels remain below the established limits. In addition, emergency eyewash stations and safety showers must be readily accessible in case of accidental exposure.

Storage regulations for isocyanates are equally stringent. These chemicals must be kept in tightly sealed containers in cool, dry, well-ventilated areas away from direct sunlight and sources of heat or ignition. Incompatible materials, such as water, acids, and oxidizing agents, should be stored separately to prevent potentially dangerous reactions.

Training is a critical component of isocyanate safety regulations. Employees who work with or may be exposed to isocyanates must receive comprehensive training on the hazards, proper handling procedures, and emergency response protocols. This training should be documented and refreshed periodically to ensure ongoing compliance and safety awareness.

Spill response procedures are another vital aspect of isocyanate safety regulations. Facilities must have clearly defined protocols for containing and cleaning up isocyanate spills, including the use of appropriate absorbents and decontamination methods. Proper disposal of isocyanate-containing waste is regulated to prevent environmental contamination and ensure worker safety throughout the disposal process.

Regular medical surveillance is often required for workers routinely exposed to isocyanates. This may include baseline and periodic pulmonary function tests, as well as skin and respiratory health assessments. Early detection of sensitization or adverse health effects is crucial for preventing long-term health consequences and ensuring the ongoing safety of the workforce.

Personal protective equipment (PPE) is mandatory when working with isocyanates. This includes chemical-resistant gloves, protective clothing, and respiratory protection. The type of respiratory protection required depends on the concentration of isocyanates in the air and the specific task being performed. For low-level exposures, air-purifying respirators with organic vapor cartridges may be sufficient, while higher concentrations or spray applications may necessitate supplied-air respirators.

Proper ventilation is crucial in areas where isocyanates are used or stored. Local exhaust ventilation systems should be installed to capture and remove isocyanate vapors at their source. Regular air monitoring is essential to ensure that exposure levels remain below the established limits. In addition, emergency eyewash stations and safety showers must be readily accessible in case of accidental exposure.

Storage regulations for isocyanates are equally stringent. These chemicals must be kept in tightly sealed containers in cool, dry, well-ventilated areas away from direct sunlight and sources of heat or ignition. Incompatible materials, such as water, acids, and oxidizing agents, should be stored separately to prevent potentially dangerous reactions.

Training is a critical component of isocyanate safety regulations. Employees who work with or may be exposed to isocyanates must receive comprehensive training on the hazards, proper handling procedures, and emergency response protocols. This training should be documented and refreshed periodically to ensure ongoing compliance and safety awareness.

Spill response procedures are another vital aspect of isocyanate safety regulations. Facilities must have clearly defined protocols for containing and cleaning up isocyanate spills, including the use of appropriate absorbents and decontamination methods. Proper disposal of isocyanate-containing waste is regulated to prevent environmental contamination and ensure worker safety throughout the disposal process.

Regular medical surveillance is often required for workers routinely exposed to isocyanates. This may include baseline and periodic pulmonary function tests, as well as skin and respiratory health assessments. Early detection of sensitization or adverse health effects is crucial for preventing long-term health consequences and ensuring the ongoing safety of the workforce.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!