How Isocyanates Enable Superior Structural Integrity?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Technology Evolution and Objectives

Isocyanates have played a pivotal role in the evolution of structural materials, particularly in the realm of polyurethanes. The journey of isocyanate technology began in the 1930s with Otto Bayer's groundbreaking discovery of polyurethane polymers. This innovation laid the foundation for a new era in material science, where the unique properties of isocyanates could be harnessed to create superior structural integrity in various applications.

Over the decades, the development of isocyanate technology has been driven by the increasing demand for materials with enhanced mechanical properties, durability, and versatility. The primary objective has been to create structures that can withstand greater stresses, resist environmental degradation, and maintain their integrity over extended periods. This pursuit has led to significant advancements in the chemistry and processing of isocyanates, resulting in a wide array of formulations tailored to specific industrial needs.

One of the key milestones in isocyanate technology was the introduction of methylene diphenyl diisocyanate (MDI) in the 1960s. MDI offered improved reactivity and structural properties compared to its predecessors, opening up new possibilities in construction, automotive, and aerospace industries. The subsequent development of polymeric MDI further expanded the application scope, allowing for the creation of rigid foams with exceptional insulation properties and structural strength.

The evolution of isocyanate technology has also been marked by a continuous effort to address environmental and health concerns. This has led to the development of low-emission formulations, water-based systems, and bio-based alternatives. These advancements align with the broader objective of creating sustainable materials that maintain superior structural integrity while minimizing environmental impact.

In recent years, the focus has shifted towards smart and responsive isocyanate-based materials. Research is underway to develop self-healing polyurethanes that can repair structural damage autonomously, thereby extending the lifespan of materials and reducing maintenance costs. Additionally, the integration of nanotechnology with isocyanate chemistry is paving the way for ultra-high-performance composites with unprecedented strength-to-weight ratios.

The current objectives in isocyanate technology are multifaceted, aiming to push the boundaries of material performance while addressing global challenges. These include developing isocyanate-based materials with enhanced fire resistance, improved thermal stability, and greater resistance to chemical and biological degradation. There is also a growing emphasis on creating isocyanate formulations that enable easier recycling and end-of-life management of polyurethane products.

As we look to the future, the evolution of isocyanate technology continues to be driven by the quest for materials that can provide superior structural integrity in increasingly demanding applications. From next-generation aerospace composites to advanced construction materials, isocyanates remain at the forefront of innovation in structural materials science.

Over the decades, the development of isocyanate technology has been driven by the increasing demand for materials with enhanced mechanical properties, durability, and versatility. The primary objective has been to create structures that can withstand greater stresses, resist environmental degradation, and maintain their integrity over extended periods. This pursuit has led to significant advancements in the chemistry and processing of isocyanates, resulting in a wide array of formulations tailored to specific industrial needs.

One of the key milestones in isocyanate technology was the introduction of methylene diphenyl diisocyanate (MDI) in the 1960s. MDI offered improved reactivity and structural properties compared to its predecessors, opening up new possibilities in construction, automotive, and aerospace industries. The subsequent development of polymeric MDI further expanded the application scope, allowing for the creation of rigid foams with exceptional insulation properties and structural strength.

The evolution of isocyanate technology has also been marked by a continuous effort to address environmental and health concerns. This has led to the development of low-emission formulations, water-based systems, and bio-based alternatives. These advancements align with the broader objective of creating sustainable materials that maintain superior structural integrity while minimizing environmental impact.

In recent years, the focus has shifted towards smart and responsive isocyanate-based materials. Research is underway to develop self-healing polyurethanes that can repair structural damage autonomously, thereby extending the lifespan of materials and reducing maintenance costs. Additionally, the integration of nanotechnology with isocyanate chemistry is paving the way for ultra-high-performance composites with unprecedented strength-to-weight ratios.

The current objectives in isocyanate technology are multifaceted, aiming to push the boundaries of material performance while addressing global challenges. These include developing isocyanate-based materials with enhanced fire resistance, improved thermal stability, and greater resistance to chemical and biological degradation. There is also a growing emphasis on creating isocyanate formulations that enable easier recycling and end-of-life management of polyurethane products.

As we look to the future, the evolution of isocyanate technology continues to be driven by the quest for materials that can provide superior structural integrity in increasingly demanding applications. From next-generation aerospace composites to advanced construction materials, isocyanates remain at the forefront of innovation in structural materials science.

Market Demand for High-Performance Structural Materials

The market demand for high-performance structural materials has been steadily increasing across various industries, driven by the need for stronger, lighter, and more durable components. Isocyanates, as key ingredients in polyurethane production, play a crucial role in meeting these demands by enabling superior structural integrity in a wide range of applications.

In the automotive sector, there is a growing emphasis on lightweight materials to improve fuel efficiency and reduce emissions. Isocyanate-based composites offer an excellent strength-to-weight ratio, making them ideal for vehicle body parts, interior components, and structural elements. The global automotive lightweight materials market is projected to expand significantly in the coming years, with polyurethanes being a major contributor to this growth.

The construction industry is another major consumer of high-performance structural materials. Isocyanate-based foams and coatings are widely used for insulation, roofing, and structural reinforcement. The increasing focus on energy-efficient buildings and sustainable construction practices has led to a surge in demand for these materials. The global construction chemicals market, which includes polyurethane-based products, is expected to show substantial growth over the next decade.

In the aerospace industry, where structural integrity is paramount, isocyanate-based composites are gaining traction due to their exceptional strength, durability, and resistance to extreme conditions. These materials are used in aircraft interiors, structural components, and even in space applications. The aerospace composites market is forecasted to experience robust growth, driven by the increasing production of commercial and military aircraft.

The marine industry is another sector where the demand for high-performance structural materials is rising. Isocyanate-based coatings and composites offer excellent corrosion resistance and durability in harsh marine environments. These materials are used in boat hulls, decks, and other structural components, contributing to the growth of the marine composites market.

The wind energy sector is also driving the demand for high-performance structural materials. Isocyanate-based composites are used in the production of wind turbine blades, offering a combination of strength, flexibility, and lightweight properties. As the renewable energy market expands, the demand for these materials is expected to grow significantly.

Overall, the market for high-performance structural materials enabled by isocyanates is poised for substantial growth across multiple industries. The unique properties offered by isocyanate-based products, including superior strength, durability, and versatility, position them as key materials in meeting the evolving demands of various sectors for advanced structural solutions.

In the automotive sector, there is a growing emphasis on lightweight materials to improve fuel efficiency and reduce emissions. Isocyanate-based composites offer an excellent strength-to-weight ratio, making them ideal for vehicle body parts, interior components, and structural elements. The global automotive lightweight materials market is projected to expand significantly in the coming years, with polyurethanes being a major contributor to this growth.

The construction industry is another major consumer of high-performance structural materials. Isocyanate-based foams and coatings are widely used for insulation, roofing, and structural reinforcement. The increasing focus on energy-efficient buildings and sustainable construction practices has led to a surge in demand for these materials. The global construction chemicals market, which includes polyurethane-based products, is expected to show substantial growth over the next decade.

In the aerospace industry, where structural integrity is paramount, isocyanate-based composites are gaining traction due to their exceptional strength, durability, and resistance to extreme conditions. These materials are used in aircraft interiors, structural components, and even in space applications. The aerospace composites market is forecasted to experience robust growth, driven by the increasing production of commercial and military aircraft.

The marine industry is another sector where the demand for high-performance structural materials is rising. Isocyanate-based coatings and composites offer excellent corrosion resistance and durability in harsh marine environments. These materials are used in boat hulls, decks, and other structural components, contributing to the growth of the marine composites market.

The wind energy sector is also driving the demand for high-performance structural materials. Isocyanate-based composites are used in the production of wind turbine blades, offering a combination of strength, flexibility, and lightweight properties. As the renewable energy market expands, the demand for these materials is expected to grow significantly.

Overall, the market for high-performance structural materials enabled by isocyanates is poised for substantial growth across multiple industries. The unique properties offered by isocyanate-based products, including superior strength, durability, and versatility, position them as key materials in meeting the evolving demands of various sectors for advanced structural solutions.

Current Isocyanate Applications and Challenges

Isocyanates have become integral components in various industries due to their unique chemical properties and versatility. Currently, these compounds find extensive applications in the production of polyurethanes, which are widely used in construction, automotive, and furniture industries. The superior bonding capabilities of isocyanates enable the creation of high-performance adhesives, sealants, and coatings that significantly enhance structural integrity in diverse applications.

In the construction sector, isocyanate-based products are employed for insulation, roofing, and flooring systems. These materials provide excellent thermal insulation, moisture resistance, and durability, contributing to energy-efficient and long-lasting structures. The automotive industry utilizes isocyanates in the manufacture of lightweight yet strong components, improving fuel efficiency without compromising safety.

Despite their widespread use, isocyanates face several challenges. One of the primary concerns is their potential health hazards. Exposure to isocyanates can cause respiratory irritation, skin sensitization, and in some cases, occupational asthma. This necessitates stringent safety measures and personal protective equipment during handling and application processes.

Environmental concerns also pose challenges to isocyanate usage. The production and disposal of isocyanate-containing products can have negative environmental impacts, prompting the need for more sustainable alternatives and improved recycling methods. Additionally, regulatory pressures are increasing, with some regions implementing stricter controls on isocyanate use and exposure limits.

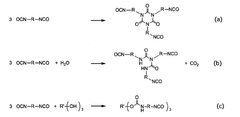

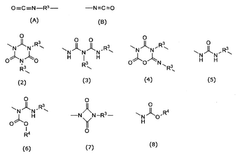

Technical challenges in isocyanate applications include moisture sensitivity and the need for precise mixing ratios. Isocyanates readily react with water, which can lead to undesired foaming or compromised product performance if not properly controlled. Achieving consistent quality in isocyanate-based products requires sophisticated manufacturing processes and quality control measures.

The development of low-VOC (volatile organic compound) and water-based alternatives to traditional solvent-based isocyanate systems is an ongoing challenge. While progress has been made, these alternatives often struggle to match the performance characteristics of conventional isocyanate formulations, particularly in demanding applications requiring high strength and durability.

As the industry evolves, there is a growing focus on developing safer, more environmentally friendly isocyanate technologies. This includes research into bio-based isocyanates, encapsulation technologies to reduce exposure risks, and novel curing mechanisms that enhance performance while minimizing health and environmental concerns. Addressing these challenges is crucial for the continued use and expansion of isocyanate applications in achieving superior structural integrity across various industries.

In the construction sector, isocyanate-based products are employed for insulation, roofing, and flooring systems. These materials provide excellent thermal insulation, moisture resistance, and durability, contributing to energy-efficient and long-lasting structures. The automotive industry utilizes isocyanates in the manufacture of lightweight yet strong components, improving fuel efficiency without compromising safety.

Despite their widespread use, isocyanates face several challenges. One of the primary concerns is their potential health hazards. Exposure to isocyanates can cause respiratory irritation, skin sensitization, and in some cases, occupational asthma. This necessitates stringent safety measures and personal protective equipment during handling and application processes.

Environmental concerns also pose challenges to isocyanate usage. The production and disposal of isocyanate-containing products can have negative environmental impacts, prompting the need for more sustainable alternatives and improved recycling methods. Additionally, regulatory pressures are increasing, with some regions implementing stricter controls on isocyanate use and exposure limits.

Technical challenges in isocyanate applications include moisture sensitivity and the need for precise mixing ratios. Isocyanates readily react with water, which can lead to undesired foaming or compromised product performance if not properly controlled. Achieving consistent quality in isocyanate-based products requires sophisticated manufacturing processes and quality control measures.

The development of low-VOC (volatile organic compound) and water-based alternatives to traditional solvent-based isocyanate systems is an ongoing challenge. While progress has been made, these alternatives often struggle to match the performance characteristics of conventional isocyanate formulations, particularly in demanding applications requiring high strength and durability.

As the industry evolves, there is a growing focus on developing safer, more environmentally friendly isocyanate technologies. This includes research into bio-based isocyanates, encapsulation technologies to reduce exposure risks, and novel curing mechanisms that enhance performance while minimizing health and environmental concerns. Addressing these challenges is crucial for the continued use and expansion of isocyanate applications in achieving superior structural integrity across various industries.

Existing Isocyanate-Based Structural Solutions

01 Structural integrity assessment of isocyanate-based materials

Methods and systems for evaluating the structural integrity of materials containing isocyanates, such as polyurethane foams or coatings. This includes non-destructive testing techniques, monitoring of physical properties, and analysis of chemical composition to ensure the material maintains its intended structural characteristics over time.- Structural integrity assessment of isocyanate-based materials: Methods and systems for evaluating the structural integrity of materials containing isocyanates, such as polyurethane foams or coatings. This includes non-destructive testing techniques, monitoring of physical properties, and analysis of chemical composition to ensure the material maintains its intended structural characteristics over time.

- Isocyanate monitoring in industrial processes: Techniques for monitoring isocyanate levels and reactions during manufacturing processes to maintain product quality and structural integrity. This involves real-time sensors, analytical methods, and process control systems to ensure proper curing and prevent defects in isocyanate-based products.

- Environmental impact on isocyanate structural integrity: Studies and methods to assess how environmental factors such as temperature, humidity, and UV exposure affect the structural integrity of isocyanate-containing materials. This includes accelerated aging tests, weathering simulations, and long-term performance evaluations to predict and improve material durability.

- Isocyanate-based composite materials for enhanced structural properties: Development of composite materials incorporating isocyanates to achieve improved structural integrity. This includes the formulation of novel blends, reinforcement techniques, and optimization of curing processes to enhance mechanical properties, durability, and overall performance of the resulting materials.

- Quality control and testing of isocyanate-based products: Methodologies and equipment for quality control and testing of products containing isocyanates to ensure structural integrity. This encompasses destructive and non-destructive testing protocols, standardized procedures for evaluating mechanical properties, and advanced imaging techniques for defect detection and analysis.

02 Isocyanate monitoring in industrial processes

Techniques for real-time monitoring of isocyanate levels and reactions in industrial settings. This involves the use of sensors, spectroscopic methods, and data analysis to ensure proper curing, detect potential issues, and maintain product quality in manufacturing processes involving isocyanates.Expand Specific Solutions03 Environmental impact and safety of isocyanates

Methods for assessing and mitigating the environmental and safety risks associated with isocyanates. This includes techniques for detecting isocyanate emissions, evaluating exposure levels, and developing protective measures to ensure worker safety and environmental compliance in industries using isocyanate-based products.Expand Specific Solutions04 Isocyanate-based composite materials

Development and characterization of composite materials incorporating isocyanates for enhanced structural properties. This involves the design of novel formulations, optimization of curing processes, and evaluation of mechanical properties to create high-performance materials for various applications.Expand Specific Solutions05 Durability testing of isocyanate-containing structures

Methods for assessing the long-term durability and performance of structures and components containing isocyanate-based materials. This includes accelerated aging tests, weathering simulations, and stress analysis to predict and improve the lifespan of products exposed to various environmental conditions.Expand Specific Solutions

Key Players in Isocyanate Production and Application

The isocyanates market is in a mature growth phase, characterized by steady demand and established applications across various industries. The global market size for isocyanates is substantial, driven by their widespread use in polyurethane production. Technologically, isocyanates are well-developed, with ongoing research focusing on improving performance and sustainability. Key players like Wanhua Chemical, BASF, Covestro, and Bayer are at the forefront of innovation, investing in R&D to enhance product properties and explore new applications. These companies are also addressing environmental concerns by developing eco-friendly alternatives and improving production processes to reduce environmental impact.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has made significant advancements in isocyanate technology for structural integrity applications. Their approach focuses on developing high-purity MDI (Methylene diphenyl diisocyanate) and TDI (Toluene diisocyanate) products that offer superior reactivity and consistency[9]. Wanhua's WANNATE® series of isocyanates provides excellent mechanical properties and thermal stability for polyurethane systems used in construction, automotive, and appliance industries[10]. The company has also developed specialized isocyanate prepolymers that offer improved processing and final product performance. Wanhua's research emphasizes the optimization of isocyanate molecular structure to enhance compatibility with various polyol systems and improve overall system performance.

Strengths: High-purity products, wide range of specialized formulations, strong presence in Asian markets. Weaknesses: Potential environmental concerns related to production processes, regulatory challenges in some regions.

BASF Corp.

Technical Solution: BASF has developed advanced isocyanate-based solutions for superior structural integrity. Their approach involves using aliphatic isocyanates, which offer excellent UV stability and color retention[1]. BASF's Elastocoat® C technology, based on polyurethane chemistry, provides high mechanical strength and durability for various applications[2]. The company has also introduced innovative cross-linking agents that enhance the performance of isocyanate-based coatings, resulting in improved scratch resistance and chemical resistance[3]. BASF's research focuses on optimizing the reaction between isocyanates and polyols to create high-performance materials with tailored properties for specific industrial needs.

Strengths: Wide range of applications, excellent UV stability, high mechanical strength. Weaknesses: Potential health hazards during processing, sensitivity to moisture during application.

Core Innovations in Isocyanate Polymer Science

Isocyanate composition and production method for isocyanate polymer

PatentWO2018070539A1

Innovation

- An isocyanate composition containing a bifunctional diisocyanate and/or a trifunctional or higher functional isocyanate, along with specific compounds such as those with unsaturated bonds and inert compounds, to enhance storage stability and prevent viscosity increase and gel formation.

Isocyanate-based compositions, use method thereof, use of same in the production of direct-adhesion coatings, and coatings thus obtained

PatentInactiveEP1627004A2

Innovation

- Development of isocyanate compositions with anionic functional groups and polyoxygenated chains that self-emulsify in water, allowing for direct adhesion to mineral substrates without the need for primers or conversion layers, while maintaining high isocyanate content and minimizing solvent use.

Environmental Impact of Isocyanate Usage

The use of isocyanates in various industrial applications has raised significant environmental concerns due to their potential impact on ecosystems and human health. While isocyanates enable superior structural integrity in many products, their production, application, and disposal processes can lead to environmental contamination if not properly managed.

One of the primary environmental risks associated with isocyanates is their potential to release toxic substances into the air, water, and soil. During manufacturing and application processes, volatile organic compounds (VOCs) containing isocyanates can be emitted, contributing to air pollution and potentially harming both workers and nearby communities. These emissions can also contribute to the formation of ground-level ozone, a key component of smog.

Water pollution is another critical concern. Improper disposal of isocyanate-containing materials or accidental spills can lead to contamination of water bodies. Once in aquatic environments, isocyanates can react with water to form potentially harmful byproducts, affecting aquatic life and potentially entering the food chain.

Soil contamination is also a risk, particularly in areas where isocyanate-based products are manufactured or heavily used. Contaminated soil can impact local ecosystems and potentially leach into groundwater, further extending the environmental impact.

The persistence of isocyanates in the environment is a subject of ongoing research. While some isocyanates degrade relatively quickly under certain conditions, others may persist longer, potentially accumulating in ecosystems over time. This persistence can lead to long-term environmental effects that are not immediately apparent.

To mitigate these environmental impacts, industries using isocyanates have implemented various control measures. These include improved production processes to reduce emissions, enhanced waste management protocols, and the development of more environmentally friendly alternatives. Regulatory bodies worldwide have also established guidelines and restrictions on isocyanate use and disposal to protect environmental and public health.

Research into bio-based and less toxic alternatives to traditional isocyanates is ongoing, aiming to maintain the superior structural integrity provided by these compounds while reducing their environmental footprint. However, the challenge lies in developing alternatives that can match the performance and cost-effectiveness of conventional isocyanates across various applications.

As awareness of environmental issues grows, there is increasing pressure on industries to adopt more sustainable practices in the use of isocyanates. This includes exploring closed-loop systems for isocyanate production and use, improving recycling technologies for isocyanate-containing products, and investing in the development of greener chemistries that can provide similar structural benefits with reduced environmental impact.

One of the primary environmental risks associated with isocyanates is their potential to release toxic substances into the air, water, and soil. During manufacturing and application processes, volatile organic compounds (VOCs) containing isocyanates can be emitted, contributing to air pollution and potentially harming both workers and nearby communities. These emissions can also contribute to the formation of ground-level ozone, a key component of smog.

Water pollution is another critical concern. Improper disposal of isocyanate-containing materials or accidental spills can lead to contamination of water bodies. Once in aquatic environments, isocyanates can react with water to form potentially harmful byproducts, affecting aquatic life and potentially entering the food chain.

Soil contamination is also a risk, particularly in areas where isocyanate-based products are manufactured or heavily used. Contaminated soil can impact local ecosystems and potentially leach into groundwater, further extending the environmental impact.

The persistence of isocyanates in the environment is a subject of ongoing research. While some isocyanates degrade relatively quickly under certain conditions, others may persist longer, potentially accumulating in ecosystems over time. This persistence can lead to long-term environmental effects that are not immediately apparent.

To mitigate these environmental impacts, industries using isocyanates have implemented various control measures. These include improved production processes to reduce emissions, enhanced waste management protocols, and the development of more environmentally friendly alternatives. Regulatory bodies worldwide have also established guidelines and restrictions on isocyanate use and disposal to protect environmental and public health.

Research into bio-based and less toxic alternatives to traditional isocyanates is ongoing, aiming to maintain the superior structural integrity provided by these compounds while reducing their environmental footprint. However, the challenge lies in developing alternatives that can match the performance and cost-effectiveness of conventional isocyanates across various applications.

As awareness of environmental issues grows, there is increasing pressure on industries to adopt more sustainable practices in the use of isocyanates. This includes exploring closed-loop systems for isocyanate production and use, improving recycling technologies for isocyanate-containing products, and investing in the development of greener chemistries that can provide similar structural benefits with reduced environmental impact.

Safety Regulations for Isocyanate Handling

The handling of isocyanates in industrial settings is subject to stringent safety regulations due to their potential health hazards and reactive nature. Regulatory bodies worldwide have established comprehensive guidelines to ensure the safe use, storage, and disposal of isocyanates. These regulations typically cover aspects such as exposure limits, personal protective equipment (PPE), engineering controls, and emergency response procedures.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for various isocyanates. For instance, the PEL for methylene bisphenyl isocyanate (MDI) is 0.02 parts per million (ppm) as a ceiling limit. OSHA also mandates the use of appropriate PPE, including respirators, gloves, and protective clothing when working with isocyanates.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require manufacturers and importers to register isocyanates and provide safety information. Additionally, the EU has specific directives on the protection of workers from risks related to chemical agents at work, including isocyanates.

Engineering controls play a crucial role in isocyanate safety. Regulations often require the use of closed systems, local exhaust ventilation, and containment measures to minimize worker exposure. Regular air monitoring and medical surveillance programs are also typically mandated to ensure early detection of potential health effects.

Storage and transportation of isocyanates are subject to strict guidelines. Regulations often specify requirements for storage facilities, including temperature control, ventilation, and spill containment measures. Transportation of isocyanates is governed by hazardous materials regulations, which dictate proper packaging, labeling, and documentation.

Emergency response planning is another critical aspect of isocyanate safety regulations. Facilities handling isocyanates are required to have detailed emergency procedures in place, including spill response protocols and evacuation plans. Training programs for workers handling isocyanates are mandatory, covering topics such as hazard recognition, proper handling techniques, and emergency response.

Disposal of isocyanate-containing waste is regulated to prevent environmental contamination. Many jurisdictions classify isocyanate waste as hazardous, requiring specialized disposal methods and documentation. Regulations often mandate the use of licensed waste disposal facilities and proper neutralization techniques before disposal.

As research continues to reveal more about the long-term effects of isocyanate exposure, regulations are evolving. There is a growing trend towards more stringent exposure limits and increased emphasis on substitution with less hazardous alternatives where possible. Regulatory bodies are also focusing on improving risk communication and enhancing worker education programs to further mitigate the risks associated with isocyanate handling.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for various isocyanates. For instance, the PEL for methylene bisphenyl isocyanate (MDI) is 0.02 parts per million (ppm) as a ceiling limit. OSHA also mandates the use of appropriate PPE, including respirators, gloves, and protective clothing when working with isocyanates.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require manufacturers and importers to register isocyanates and provide safety information. Additionally, the EU has specific directives on the protection of workers from risks related to chemical agents at work, including isocyanates.

Engineering controls play a crucial role in isocyanate safety. Regulations often require the use of closed systems, local exhaust ventilation, and containment measures to minimize worker exposure. Regular air monitoring and medical surveillance programs are also typically mandated to ensure early detection of potential health effects.

Storage and transportation of isocyanates are subject to strict guidelines. Regulations often specify requirements for storage facilities, including temperature control, ventilation, and spill containment measures. Transportation of isocyanates is governed by hazardous materials regulations, which dictate proper packaging, labeling, and documentation.

Emergency response planning is another critical aspect of isocyanate safety regulations. Facilities handling isocyanates are required to have detailed emergency procedures in place, including spill response protocols and evacuation plans. Training programs for workers handling isocyanates are mandatory, covering topics such as hazard recognition, proper handling techniques, and emergency response.

Disposal of isocyanate-containing waste is regulated to prevent environmental contamination. Many jurisdictions classify isocyanate waste as hazardous, requiring specialized disposal methods and documentation. Regulations often mandate the use of licensed waste disposal facilities and proper neutralization techniques before disposal.

As research continues to reveal more about the long-term effects of isocyanate exposure, regulations are evolving. There is a growing trend towards more stringent exposure limits and increased emphasis on substitution with less hazardous alternatives where possible. Regulatory bodies are also focusing on improving risk communication and enhancing worker education programs to further mitigate the risks associated with isocyanate handling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!