How Isocyanates Influence Material Durability and Longevity?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Technology Evolution and Objectives

Isocyanates have played a pivotal role in material science since their discovery in the 1930s. The evolution of isocyanate technology has been driven by the continuous pursuit of enhanced material durability and longevity. Initially, the focus was on developing basic polyurethane formulations for coatings and adhesives. As research progressed, scientists began to explore the unique properties of isocyanates that contribute to material resilience.

The 1950s and 1960s saw significant advancements in isocyanate chemistry, leading to the development of more sophisticated polyurethane systems. These innovations expanded the application of isocyanates into various industries, including automotive, construction, and furniture manufacturing. The ability of isocyanates to form strong chemical bonds with a wide range of substrates became a key factor in improving material durability.

By the 1970s and 1980s, researchers had begun to understand the molecular mechanisms by which isocyanates enhance material properties. This knowledge led to the development of specialized isocyanate formulations designed to address specific durability challenges, such as resistance to UV radiation, moisture, and chemical exposure. The introduction of aliphatic isocyanates, for instance, significantly improved the weathering resistance of polyurethane coatings.

The late 20th century witnessed a shift towards environmentally friendly isocyanate technologies. This trend was driven by increasing awareness of the potential health and environmental impacts of certain isocyanate compounds. As a result, research objectives expanded to include the development of low-VOC (volatile organic compound) and water-based isocyanate systems, without compromising on durability and longevity.

In recent years, the focus has shifted towards smart and responsive isocyanate-based materials. These advanced systems can adapt to environmental changes, self-heal, or even enhance their properties over time. Such innovations aim to push the boundaries of material longevity, potentially creating products with significantly extended lifespans.

The current objectives in isocyanate technology research are multifaceted. They include developing bio-based isocyanates to reduce reliance on petrochemicals, improving the recyclability of isocyanate-based materials, and enhancing the overall sustainability of production processes. Additionally, there is a growing interest in nanotechnology applications, where isocyanates are being explored for their potential in creating ultra-durable nanocomposites.

Looking ahead, the evolution of isocyanate technology is expected to continue its trajectory towards more sustainable, durable, and versatile materials. The ultimate goal remains to create materials that can withstand increasingly demanding environmental conditions while meeting stringent performance and longevity requirements across various industries.

The 1950s and 1960s saw significant advancements in isocyanate chemistry, leading to the development of more sophisticated polyurethane systems. These innovations expanded the application of isocyanates into various industries, including automotive, construction, and furniture manufacturing. The ability of isocyanates to form strong chemical bonds with a wide range of substrates became a key factor in improving material durability.

By the 1970s and 1980s, researchers had begun to understand the molecular mechanisms by which isocyanates enhance material properties. This knowledge led to the development of specialized isocyanate formulations designed to address specific durability challenges, such as resistance to UV radiation, moisture, and chemical exposure. The introduction of aliphatic isocyanates, for instance, significantly improved the weathering resistance of polyurethane coatings.

The late 20th century witnessed a shift towards environmentally friendly isocyanate technologies. This trend was driven by increasing awareness of the potential health and environmental impacts of certain isocyanate compounds. As a result, research objectives expanded to include the development of low-VOC (volatile organic compound) and water-based isocyanate systems, without compromising on durability and longevity.

In recent years, the focus has shifted towards smart and responsive isocyanate-based materials. These advanced systems can adapt to environmental changes, self-heal, or even enhance their properties over time. Such innovations aim to push the boundaries of material longevity, potentially creating products with significantly extended lifespans.

The current objectives in isocyanate technology research are multifaceted. They include developing bio-based isocyanates to reduce reliance on petrochemicals, improving the recyclability of isocyanate-based materials, and enhancing the overall sustainability of production processes. Additionally, there is a growing interest in nanotechnology applications, where isocyanates are being explored for their potential in creating ultra-durable nanocomposites.

Looking ahead, the evolution of isocyanate technology is expected to continue its trajectory towards more sustainable, durable, and versatile materials. The ultimate goal remains to create materials that can withstand increasingly demanding environmental conditions while meeting stringent performance and longevity requirements across various industries.

Market Demand for Durable Materials

The market demand for durable materials has been steadily increasing across various industries, driven by the need for long-lasting, high-performance products that can withstand harsh environments and extended use. Isocyanates, as key components in polyurethane chemistry, play a crucial role in enhancing material durability and longevity, making them highly sought after in sectors such as construction, automotive, and consumer goods.

In the construction industry, there is a growing demand for materials that can resist weathering, UV radiation, and chemical exposure. Isocyanate-based coatings and sealants offer superior protection for buildings, bridges, and other infrastructure, extending their lifespan and reducing maintenance costs. This has led to increased adoption of polyurethane-based products in both residential and commercial construction projects.

The automotive sector has also seen a surge in demand for durable materials, particularly in the production of lightweight yet strong components. Isocyanate-based polyurethanes are extensively used in car interiors, exterior body parts, and insulation, contributing to improved fuel efficiency without compromising on durability. As the automotive industry shifts towards electric vehicles, the need for lightweight, durable materials is expected to grow further.

Consumer goods manufacturers are increasingly focusing on product longevity as a key selling point. Isocyanate-based materials are used in a wide range of products, from furniture and appliances to footwear and sports equipment. The ability of these materials to maintain their properties over time, resist wear and tear, and withstand repeated use has made them popular among consumers seeking value for money and environmentally conscious choices.

The marine industry has also recognized the benefits of isocyanate-enhanced materials. Boats and offshore structures face constant exposure to saltwater, UV radiation, and extreme weather conditions. Polyurethane coatings and composites derived from isocyanates offer excellent protection against corrosion and degradation, extending the lifespan of marine vessels and equipment.

In the aerospace sector, where material performance is critical, isocyanate-based composites are in high demand. These materials offer a combination of strength, lightweight properties, and resistance to extreme temperatures, making them ideal for aircraft components and space applications.

The growing emphasis on sustainability and circular economy principles has further boosted the demand for durable materials. Products with longer lifespans reduce waste and resource consumption, aligning with global efforts to minimize environmental impact. This trend has led to increased research and development in isocyanate chemistry to create even more durable and recyclable materials.

In the construction industry, there is a growing demand for materials that can resist weathering, UV radiation, and chemical exposure. Isocyanate-based coatings and sealants offer superior protection for buildings, bridges, and other infrastructure, extending their lifespan and reducing maintenance costs. This has led to increased adoption of polyurethane-based products in both residential and commercial construction projects.

The automotive sector has also seen a surge in demand for durable materials, particularly in the production of lightweight yet strong components. Isocyanate-based polyurethanes are extensively used in car interiors, exterior body parts, and insulation, contributing to improved fuel efficiency without compromising on durability. As the automotive industry shifts towards electric vehicles, the need for lightweight, durable materials is expected to grow further.

Consumer goods manufacturers are increasingly focusing on product longevity as a key selling point. Isocyanate-based materials are used in a wide range of products, from furniture and appliances to footwear and sports equipment. The ability of these materials to maintain their properties over time, resist wear and tear, and withstand repeated use has made them popular among consumers seeking value for money and environmentally conscious choices.

The marine industry has also recognized the benefits of isocyanate-enhanced materials. Boats and offshore structures face constant exposure to saltwater, UV radiation, and extreme weather conditions. Polyurethane coatings and composites derived from isocyanates offer excellent protection against corrosion and degradation, extending the lifespan of marine vessels and equipment.

In the aerospace sector, where material performance is critical, isocyanate-based composites are in high demand. These materials offer a combination of strength, lightweight properties, and resistance to extreme temperatures, making them ideal for aircraft components and space applications.

The growing emphasis on sustainability and circular economy principles has further boosted the demand for durable materials. Products with longer lifespans reduce waste and resource consumption, aligning with global efforts to minimize environmental impact. This trend has led to increased research and development in isocyanate chemistry to create even more durable and recyclable materials.

Current Challenges in Isocyanate Application

Despite the widespread use of isocyanates in various industries, their application still faces several significant challenges. One of the primary concerns is the high reactivity of isocyanates, which can lead to uncontrolled reactions and compromised product quality. This reactivity makes it difficult to achieve consistent results in manufacturing processes, especially when dealing with moisture-sensitive applications.

Another major challenge is the potential health hazards associated with isocyanate exposure. Inhalation of isocyanate vapors or contact with the skin can cause severe respiratory issues and allergic reactions. This necessitates stringent safety measures and personal protective equipment, which can increase production costs and complexity.

The environmental impact of isocyanates is also a growing concern. Many traditional isocyanates are derived from petroleum-based sources, raising questions about sustainability and carbon footprint. Additionally, the disposal of isocyanate-containing products at the end of their lifecycle poses environmental risks, as improper handling can lead to the release of harmful substances.

Formulation challenges persist in balancing the desired properties of the final product with the reactivity of isocyanates. Achieving the right mix of flexibility, durability, and chemical resistance often requires extensive experimentation and fine-tuning of formulations. This process can be time-consuming and resource-intensive, particularly when developing new applications or improving existing ones.

The shelf life and storage of isocyanate-based products and raw materials present another set of challenges. Isocyanates are susceptible to degradation when exposed to heat, light, or moisture, which can affect their performance and reduce the longevity of the final product. Proper storage and handling procedures are crucial but can be difficult to maintain consistently, especially in diverse manufacturing environments.

Regulatory compliance is an ongoing challenge in isocyanate application. As health and environmental concerns grow, regulations governing the use, transport, and disposal of isocyanates are becoming increasingly stringent. Manufacturers must navigate a complex landscape of local, national, and international regulations, which can vary significantly across different regions and applications.

Lastly, the development of alternatives to traditional isocyanates, such as non-isocyanate polyurethanes (NIPUs), presents both a challenge and an opportunity. While these alternatives address some of the health and environmental concerns associated with isocyanates, they often fall short in performance or cost-effectiveness. Bridging this gap requires continued research and development efforts to create viable substitutes that can match or exceed the properties of isocyanate-based materials.

Another major challenge is the potential health hazards associated with isocyanate exposure. Inhalation of isocyanate vapors or contact with the skin can cause severe respiratory issues and allergic reactions. This necessitates stringent safety measures and personal protective equipment, which can increase production costs and complexity.

The environmental impact of isocyanates is also a growing concern. Many traditional isocyanates are derived from petroleum-based sources, raising questions about sustainability and carbon footprint. Additionally, the disposal of isocyanate-containing products at the end of their lifecycle poses environmental risks, as improper handling can lead to the release of harmful substances.

Formulation challenges persist in balancing the desired properties of the final product with the reactivity of isocyanates. Achieving the right mix of flexibility, durability, and chemical resistance often requires extensive experimentation and fine-tuning of formulations. This process can be time-consuming and resource-intensive, particularly when developing new applications or improving existing ones.

The shelf life and storage of isocyanate-based products and raw materials present another set of challenges. Isocyanates are susceptible to degradation when exposed to heat, light, or moisture, which can affect their performance and reduce the longevity of the final product. Proper storage and handling procedures are crucial but can be difficult to maintain consistently, especially in diverse manufacturing environments.

Regulatory compliance is an ongoing challenge in isocyanate application. As health and environmental concerns grow, regulations governing the use, transport, and disposal of isocyanates are becoming increasingly stringent. Manufacturers must navigate a complex landscape of local, national, and international regulations, which can vary significantly across different regions and applications.

Lastly, the development of alternatives to traditional isocyanates, such as non-isocyanate polyurethanes (NIPUs), presents both a challenge and an opportunity. While these alternatives address some of the health and environmental concerns associated with isocyanates, they often fall short in performance or cost-effectiveness. Bridging this gap requires continued research and development efforts to create viable substitutes that can match or exceed the properties of isocyanate-based materials.

Existing Isocyanate-based Solutions

01 Chemical stability and resistance

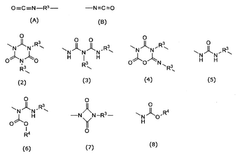

Isocyanates exhibit excellent durability and longevity due to their chemical stability and resistance to various environmental factors. Their unique molecular structure allows them to form strong bonds, resulting in products with enhanced resistance to degradation from heat, moisture, and chemicals. This property contributes to the long-lasting performance of isocyanate-based materials in various applications.- Chemical stability and resistance: Isocyanates exhibit excellent durability and longevity due to their chemical stability and resistance to various environmental factors. Their unique molecular structure allows them to form strong bonds, resulting in products with enhanced resistance to degradation, weathering, and chemical attacks. This property contributes to the long-lasting performance of isocyanate-based materials in various applications.

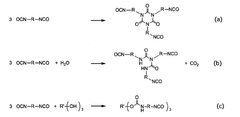

- Cross-linking and polymer formation: The durability of isocyanates is significantly improved through cross-linking reactions and polymer formation. When isocyanates react with other compounds, they create a network of interconnected molecules, resulting in materials with superior mechanical properties, thermal stability, and resistance to wear and tear. This cross-linked structure contributes to the extended lifespan of isocyanate-based products.

- Moisture and heat resistance: Isocyanates demonstrate excellent resistance to moisture and heat, which contributes to their durability and longevity. The hydrophobic nature of isocyanate-based materials helps prevent water absorption and subsequent degradation. Additionally, their thermal stability allows them to maintain their properties and performance even under elevated temperature conditions, extending their useful life in various applications.

- Surface protection and coating applications: Isocyanates are widely used in surface protection and coating applications due to their durability and longevity. When applied as coatings or sealants, they form a protective barrier that resists abrasion, chemicals, and environmental factors. This protective layer significantly extends the lifespan of the underlying substrate, making isocyanate-based coatings ideal for various industries, including automotive, construction, and marine.

- Aging and weathering resistance: Isocyanates exhibit excellent resistance to aging and weathering, contributing to their long-term durability. When exposed to UV radiation, oxygen, and other environmental factors, isocyanate-based materials maintain their physical and chemical properties for extended periods. This resistance to degradation ensures that products made with isocyanates retain their performance characteristics and appearance over time, reducing the need for frequent replacements or maintenance.

02 Cross-linking and polymer formation

The durability of isocyanates is largely attributed to their ability to form cross-linked polymers. When isocyanates react with polyols or other compounds containing active hydrogen groups, they create a network of interconnected molecules. This cross-linking process results in materials with improved mechanical strength, thermal stability, and resistance to wear and tear, contributing to their long-term performance.Expand Specific Solutions03 Moisture-curing mechanisms

Some isocyanate-based systems utilize moisture-curing mechanisms, which contribute to their durability and longevity. These systems react with atmospheric moisture to form strong, durable bonds. This property allows for continuous curing and strengthening of the material over time, even after initial application, leading to improved long-term performance and resistance to environmental factors.Expand Specific Solutions04 Thermal and UV stability

Isocyanates demonstrate excellent thermal and UV stability, which contributes to their durability and longevity. When properly formulated and cured, isocyanate-based materials can withstand high temperatures and prolonged exposure to ultraviolet radiation without significant degradation. This stability makes them suitable for outdoor applications and environments with extreme temperature variations.Expand Specific Solutions05 Adhesion and bonding properties

The strong adhesion and bonding properties of isocyanates contribute to their durability and longevity in various applications. Isocyanates can form robust chemical bonds with a wide range of substrates, including metals, plastics, and composites. This excellent adhesion helps prevent delamination and improves the overall durability of coatings, adhesives, and sealants made with isocyanate-based formulations.Expand Specific Solutions

Key Players in Isocyanate Industry

The isocyanate industry is in a mature growth phase, with a global market size expected to reach $38 billion by 2027. The technology for isocyanate production and application in material durability is well-established, with ongoing innovations focused on improving performance and sustainability. Key players like Wanhua Chemical, Covestro, and Bayer AG dominate the market with advanced R&D capabilities. These companies are investing in eco-friendly alternatives and enhanced formulations to address environmental concerns while maintaining material longevity. The competitive landscape is characterized by strategic partnerships, product diversification, and a focus on high-performance, specialty isocyanates for niche applications in automotive, construction, and electronics industries.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed advanced isocyanate-based technologies to enhance material durability and longevity. Their innovative approach involves the synthesis of high-performance polyurethane systems using specialized isocyanates. These systems exhibit improved resistance to hydrolysis, oxidation, and UV degradation, significantly extending the lifespan of materials in various applications[1]. Wanhua's proprietary crosslinking technology enables the formation of stronger chemical bonds within the polymer matrix, resulting in enhanced mechanical properties and increased durability[2]. The company has also focused on developing bio-based isocyanates, which offer improved environmental sustainability without compromising on performance[3].

Strengths: Cutting-edge isocyanate technology, wide range of applications, strong R&D capabilities. Weaknesses: Potential environmental concerns associated with isocyanate production, regulatory challenges in some markets.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed innovative isocyanate technologies aimed at enhancing material durability and longevity, particularly in the field of high-performance plastics and synthetic fibers. Their approach involves the synthesis of specialized aromatic and aliphatic isocyanates tailored for specific applications. Asahi Kasei's technology includes the development of isocyanate-based thermoplastic polyurethanes (TPUs) with exceptional wear resistance and flexibility, suitable for demanding applications in automotive and industrial sectors[12]. They have also focused on creating isocyanate-modified polyamides that exhibit improved heat resistance and dimensional stability. Asahi Kasei's research extends to the use of isocyanates in the production of durable, high-performance fibers for technical textiles and protective clothing[13].

Strengths: Strong presence in Asian markets, diverse product portfolio, expertise in specialty chemicals and materials. Weaknesses: Potential challenges in global market expansion, competition from established Western companies in some sectors.

Core Innovations in Isocyanate Chemistry

Isocyanate composition and production method for isocyanate polymer

PatentWO2018070539A1

Innovation

- An isocyanate composition containing a bifunctional diisocyanate and/or a trifunctional or higher functional isocyanate, along with specific compounds such as those with unsaturated bonds and inert compounds, to enhance storage stability and prevent viscosity increase and gel formation.

Isocyanate composition, production method for isocyanate composition, and production method for isocyanate polymer

PatentWO2018070540A1

Innovation

- An isocyanate composition containing specific components such as UV-absorbing compounds, isocyanurate or biuret groups, ether or thioether bonds, carbamate groups, and stabilizers like phosphoric acid or sulfuric acid esters, which suppress discoloration and maintain stability during storage.

Environmental Impact of Isocyanates

Isocyanates, widely used in the production of polyurethanes, have significant environmental implications that extend beyond their immediate application. The environmental impact of isocyanates is multifaceted, affecting air, water, and soil quality, as well as posing potential risks to ecosystems and human health.

In terms of air pollution, the volatile nature of many isocyanates contributes to the formation of ground-level ozone and smog when released into the atmosphere. This can lead to respiratory issues in both humans and animals, particularly in urban areas with high industrial activity. Additionally, some isocyanates are known to be potent greenhouse gases, contributing to global warming and climate change when emitted in large quantities.

Water contamination is another critical concern associated with isocyanates. When these compounds enter aquatic environments through industrial runoff or improper disposal, they can react with water to form toxic byproducts. These byproducts may persist in the environment, potentially bioaccumulating in aquatic organisms and disrupting ecosystems. The long-term effects on marine life and water quality can be severe, impacting biodiversity and the overall health of aquatic habitats.

Soil contamination by isocyanates presents challenges for terrestrial ecosystems. When isocyanates leach into the soil, they can alter soil chemistry and affect microbial communities essential for nutrient cycling and plant growth. This can lead to reduced soil fertility and potentially impact agricultural productivity in affected areas. Furthermore, the persistence of isocyanates in soil may result in long-term environmental degradation and pose risks to soil-dwelling organisms.

The production and disposal of isocyanate-containing materials also raise environmental concerns. The manufacturing process often involves energy-intensive procedures and the use of petrochemical feedstocks, contributing to resource depletion and carbon emissions. End-of-life management of products containing isocyanates, such as polyurethane foams and coatings, presents challenges in terms of recycling and waste disposal, potentially leading to increased landfill usage or incineration, both of which have their own environmental consequences.

Efforts to mitigate the environmental impact of isocyanates include the development of alternative, more environmentally friendly compounds, improved manufacturing processes to reduce emissions, and enhanced waste management strategies. Regulatory frameworks in many countries now impose strict controls on the use and disposal of isocyanates, reflecting growing awareness of their potential environmental hazards. As research continues, a better understanding of the long-term ecological effects of isocyanates is emerging, informing more sustainable practices in their production and application.

In terms of air pollution, the volatile nature of many isocyanates contributes to the formation of ground-level ozone and smog when released into the atmosphere. This can lead to respiratory issues in both humans and animals, particularly in urban areas with high industrial activity. Additionally, some isocyanates are known to be potent greenhouse gases, contributing to global warming and climate change when emitted in large quantities.

Water contamination is another critical concern associated with isocyanates. When these compounds enter aquatic environments through industrial runoff or improper disposal, they can react with water to form toxic byproducts. These byproducts may persist in the environment, potentially bioaccumulating in aquatic organisms and disrupting ecosystems. The long-term effects on marine life and water quality can be severe, impacting biodiversity and the overall health of aquatic habitats.

Soil contamination by isocyanates presents challenges for terrestrial ecosystems. When isocyanates leach into the soil, they can alter soil chemistry and affect microbial communities essential for nutrient cycling and plant growth. This can lead to reduced soil fertility and potentially impact agricultural productivity in affected areas. Furthermore, the persistence of isocyanates in soil may result in long-term environmental degradation and pose risks to soil-dwelling organisms.

The production and disposal of isocyanate-containing materials also raise environmental concerns. The manufacturing process often involves energy-intensive procedures and the use of petrochemical feedstocks, contributing to resource depletion and carbon emissions. End-of-life management of products containing isocyanates, such as polyurethane foams and coatings, presents challenges in terms of recycling and waste disposal, potentially leading to increased landfill usage or incineration, both of which have their own environmental consequences.

Efforts to mitigate the environmental impact of isocyanates include the development of alternative, more environmentally friendly compounds, improved manufacturing processes to reduce emissions, and enhanced waste management strategies. Regulatory frameworks in many countries now impose strict controls on the use and disposal of isocyanates, reflecting growing awareness of their potential environmental hazards. As research continues, a better understanding of the long-term ecological effects of isocyanates is emerging, informing more sustainable practices in their production and application.

Safety Regulations for Isocyanate Usage

The use of isocyanates in various industries has led to the implementation of stringent safety regulations due to their potential health hazards. Regulatory bodies worldwide have established comprehensive guidelines to protect workers and the environment from exposure to these chemicals.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for different types of isocyanates. For instance, the PEL for methylene bisphenyl isocyanate (MDI) is 0.02 parts per million (ppm) as a ceiling limit. OSHA also mandates the use of personal protective equipment (PPE) and engineering controls to minimize worker exposure.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which includes specific provisions for isocyanates. Under REACH, manufacturers and importers must register isocyanates and provide safety data sheets detailing proper handling procedures and exposure controls.

Many countries have adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), which standardizes hazard communication for isocyanates. This system requires clear labeling of isocyanate-containing products with hazard pictograms, signal words, and safety precautions.

Specific industry standards have also been developed to address isocyanate safety. For example, the spray polyurethane foam (SPF) industry has established guidelines for proper application techniques, ventilation requirements, and post-application re-occupancy times to ensure safe use of isocyanate-based products in construction.

Environmental regulations play a crucial role in managing isocyanate usage. Many jurisdictions require proper disposal methods for isocyanate waste and mandate the use of emission control technologies in manufacturing facilities to prevent air and water pollution.

Training and education are key components of isocyanate safety regulations. Workers handling these chemicals must receive comprehensive training on proper use, storage, and emergency procedures. Regular health monitoring programs are often required to detect early signs of isocyanate-related health effects.

As research continues to reveal more about the long-term effects of isocyanate exposure, regulations are evolving. Some countries are considering stricter limits on isocyanate concentrations in consumer products and exploring alternatives in certain applications.

Compliance with these regulations is essential for companies using isocyanates, not only to ensure worker safety but also to avoid legal and financial consequences. Regular audits and inspections are conducted by regulatory agencies to enforce these safety standards and promote a culture of responsible isocyanate usage across industries.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for different types of isocyanates. For instance, the PEL for methylene bisphenyl isocyanate (MDI) is 0.02 parts per million (ppm) as a ceiling limit. OSHA also mandates the use of personal protective equipment (PPE) and engineering controls to minimize worker exposure.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which includes specific provisions for isocyanates. Under REACH, manufacturers and importers must register isocyanates and provide safety data sheets detailing proper handling procedures and exposure controls.

Many countries have adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), which standardizes hazard communication for isocyanates. This system requires clear labeling of isocyanate-containing products with hazard pictograms, signal words, and safety precautions.

Specific industry standards have also been developed to address isocyanate safety. For example, the spray polyurethane foam (SPF) industry has established guidelines for proper application techniques, ventilation requirements, and post-application re-occupancy times to ensure safe use of isocyanate-based products in construction.

Environmental regulations play a crucial role in managing isocyanate usage. Many jurisdictions require proper disposal methods for isocyanate waste and mandate the use of emission control technologies in manufacturing facilities to prevent air and water pollution.

Training and education are key components of isocyanate safety regulations. Workers handling these chemicals must receive comprehensive training on proper use, storage, and emergency procedures. Regular health monitoring programs are often required to detect early signs of isocyanate-related health effects.

As research continues to reveal more about the long-term effects of isocyanate exposure, regulations are evolving. Some countries are considering stricter limits on isocyanate concentrations in consumer products and exploring alternatives in certain applications.

Compliance with these regulations is essential for companies using isocyanates, not only to ensure worker safety but also to avoid legal and financial consequences. Regular audits and inspections are conducted by regulatory agencies to enforce these safety standards and promote a culture of responsible isocyanate usage across industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!