How Low-Density Polypropylene Impacts High-Volume Manufacturing

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE in Manufacturing

Low-density polyethylene (LDPE) has become a cornerstone material in high-volume manufacturing, revolutionizing production processes across various industries. Its unique properties, including flexibility, durability, and cost-effectiveness, have made it an indispensable component in modern manufacturing.

LDPE's impact on high-volume manufacturing is most evident in its versatility and adaptability to different production methods. Its low melting point and excellent flow characteristics make it ideal for injection molding, extrusion, and blow molding processes. This versatility allows manufacturers to produce a wide range of products, from packaging materials to consumer goods, with high efficiency and consistency.

One of the key advantages of LDPE in manufacturing is its ability to significantly reduce production costs. The material's low density translates to less raw material usage per unit, leading to substantial savings in large-scale production. Additionally, LDPE's ease of processing reduces energy consumption during manufacturing, further contributing to cost reduction and improved sustainability in industrial operations.

The material's impact on production speed is noteworthy. LDPE's low melting point and quick cooling properties enable faster production cycles, allowing manufacturers to increase their output significantly. This increased speed is particularly crucial in industries where high-volume production is essential, such as packaging and disposable goods manufacturing.

LDPE's flexibility and resistance to cracking under stress have expanded the design possibilities in product development. Manufacturers can now create more complex and innovative designs without compromising on production efficiency or product durability. This has led to the development of new product categories and improvements in existing ones, driving innovation across various sectors.

In the packaging industry, LDPE has been transformative. Its excellent moisture barrier properties and chemical resistance make it ideal for food packaging, pharmaceutical packaging, and industrial packaging solutions. The material's ability to be easily sealed and its clarity in film form have made it a preferred choice for many packaging applications, enhancing product preservation and presentation.

The impact of LDPE on supply chain efficiency is also significant. Its lightweight nature reduces transportation costs and carbon footprint, aligning with the growing emphasis on sustainable manufacturing practices. The material's durability ensures that products remain intact during shipping and handling, reducing waste and improving overall supply chain reliability.

However, the widespread use of LDPE in manufacturing has also raised environmental concerns. While the material is recyclable, its extensive use in single-use products has contributed to plastic pollution. This has spurred research into more sustainable alternatives and improved recycling technologies, driving innovation in the plastics industry and manufacturing sector as a whole.

LDPE's impact on high-volume manufacturing is most evident in its versatility and adaptability to different production methods. Its low melting point and excellent flow characteristics make it ideal for injection molding, extrusion, and blow molding processes. This versatility allows manufacturers to produce a wide range of products, from packaging materials to consumer goods, with high efficiency and consistency.

One of the key advantages of LDPE in manufacturing is its ability to significantly reduce production costs. The material's low density translates to less raw material usage per unit, leading to substantial savings in large-scale production. Additionally, LDPE's ease of processing reduces energy consumption during manufacturing, further contributing to cost reduction and improved sustainability in industrial operations.

The material's impact on production speed is noteworthy. LDPE's low melting point and quick cooling properties enable faster production cycles, allowing manufacturers to increase their output significantly. This increased speed is particularly crucial in industries where high-volume production is essential, such as packaging and disposable goods manufacturing.

LDPE's flexibility and resistance to cracking under stress have expanded the design possibilities in product development. Manufacturers can now create more complex and innovative designs without compromising on production efficiency or product durability. This has led to the development of new product categories and improvements in existing ones, driving innovation across various sectors.

In the packaging industry, LDPE has been transformative. Its excellent moisture barrier properties and chemical resistance make it ideal for food packaging, pharmaceutical packaging, and industrial packaging solutions. The material's ability to be easily sealed and its clarity in film form have made it a preferred choice for many packaging applications, enhancing product preservation and presentation.

The impact of LDPE on supply chain efficiency is also significant. Its lightweight nature reduces transportation costs and carbon footprint, aligning with the growing emphasis on sustainable manufacturing practices. The material's durability ensures that products remain intact during shipping and handling, reducing waste and improving overall supply chain reliability.

However, the widespread use of LDPE in manufacturing has also raised environmental concerns. While the material is recyclable, its extensive use in single-use products has contributed to plastic pollution. This has spurred research into more sustainable alternatives and improved recycling technologies, driving innovation in the plastics industry and manufacturing sector as a whole.

Market Demand Analysis

The market demand for low-density polypropylene (LDPP) in high-volume manufacturing has been steadily increasing due to its unique properties and versatile applications. This lightweight, flexible, and cost-effective material has found widespread use across various industries, driving its market growth.

In the packaging sector, LDPP has become a preferred choice for food containers, flexible packaging, and consumer goods packaging. The material's excellent moisture barrier properties, chemical resistance, and ability to be easily molded into various shapes have contributed to its popularity. As e-commerce continues to expand globally, the demand for LDPP in protective packaging and shipping materials has surged.

The automotive industry has also embraced LDPP for its ability to reduce vehicle weight without compromising safety or performance. With stringent fuel efficiency regulations and the growing trend towards electric vehicles, manufacturers are increasingly turning to LDPP for interior components, bumpers, and other non-structural parts. This shift is expected to drive significant market growth in the coming years.

In the healthcare sector, LDPP's biocompatibility and resistance to sterilization processes have made it a valuable material for medical devices, pharmaceutical packaging, and laboratory equipment. The ongoing global health concerns have further accelerated the demand for LDPP in personal protective equipment (PPE) and medical supplies.

The construction industry has found applications for LDPP in insulation, piping systems, and geomembranes. Its durability, chemical resistance, and ease of installation have made it an attractive option for both residential and commercial construction projects.

Market analysts project a compound annual growth rate (CAGR) of 5-6% for the LDPP market over the next five years. This growth is attributed to the material's expanding applications in emerging economies, technological advancements in production processes, and the increasing focus on sustainable and recyclable materials.

However, the market faces challenges from environmental concerns and regulatory pressures. The push for more sustainable alternatives and the growing awareness of plastic pollution have led to increased scrutiny of LDPP usage. This has prompted manufacturers to invest in recycling technologies and explore bio-based alternatives to maintain market share and meet evolving consumer preferences.

Despite these challenges, the overall market outlook for LDPP in high-volume manufacturing remains positive. The material's cost-effectiveness, versatility, and ongoing innovations in its production and recycling are expected to sustain its demand across multiple industries. As manufacturers continue to seek lightweight, durable, and economical materials, LDPP is poised to play a crucial role in shaping the future of high-volume manufacturing processes.

In the packaging sector, LDPP has become a preferred choice for food containers, flexible packaging, and consumer goods packaging. The material's excellent moisture barrier properties, chemical resistance, and ability to be easily molded into various shapes have contributed to its popularity. As e-commerce continues to expand globally, the demand for LDPP in protective packaging and shipping materials has surged.

The automotive industry has also embraced LDPP for its ability to reduce vehicle weight without compromising safety or performance. With stringent fuel efficiency regulations and the growing trend towards electric vehicles, manufacturers are increasingly turning to LDPP for interior components, bumpers, and other non-structural parts. This shift is expected to drive significant market growth in the coming years.

In the healthcare sector, LDPP's biocompatibility and resistance to sterilization processes have made it a valuable material for medical devices, pharmaceutical packaging, and laboratory equipment. The ongoing global health concerns have further accelerated the demand for LDPP in personal protective equipment (PPE) and medical supplies.

The construction industry has found applications for LDPP in insulation, piping systems, and geomembranes. Its durability, chemical resistance, and ease of installation have made it an attractive option for both residential and commercial construction projects.

Market analysts project a compound annual growth rate (CAGR) of 5-6% for the LDPP market over the next five years. This growth is attributed to the material's expanding applications in emerging economies, technological advancements in production processes, and the increasing focus on sustainable and recyclable materials.

However, the market faces challenges from environmental concerns and regulatory pressures. The push for more sustainable alternatives and the growing awareness of plastic pollution have led to increased scrutiny of LDPP usage. This has prompted manufacturers to invest in recycling technologies and explore bio-based alternatives to maintain market share and meet evolving consumer preferences.

Despite these challenges, the overall market outlook for LDPP in high-volume manufacturing remains positive. The material's cost-effectiveness, versatility, and ongoing innovations in its production and recycling are expected to sustain its demand across multiple industries. As manufacturers continue to seek lightweight, durable, and economical materials, LDPP is poised to play a crucial role in shaping the future of high-volume manufacturing processes.

Technical Challenges

Low-density polypropylene (LDPP) presents several technical challenges in high-volume manufacturing processes. One of the primary issues is its lower melt strength compared to other polyolefins, which can lead to difficulties in maintaining consistent product quality during extrusion and molding operations. This characteristic often results in sagging or deformation of the material during processing, particularly in applications requiring large or complex shapes.

Another significant challenge is the thermal sensitivity of LDPP. The material has a narrow processing window, making it susceptible to degradation if exposed to high temperatures for extended periods. This sensitivity can lead to inconsistencies in product quality and potentially compromise the mechanical properties of the final product. Manufacturers must carefully control temperature profiles throughout the production line to maintain material integrity.

The relatively low stiffness of LDPP compared to high-density polypropylene (HDPP) can also pose challenges in applications where structural rigidity is crucial. This limitation may necessitate the use of thicker walls or additional reinforcement, potentially increasing material costs and product weight. Balancing the trade-off between material properties and product performance becomes a critical consideration in design and manufacturing processes.

LDPP's tendency to exhibit shrinkage and warpage during cooling presents another technical hurdle. These dimensional changes can affect the precision and consistency of manufactured parts, particularly in applications with tight tolerances. Manufacturers must implement sophisticated cooling strategies and mold designs to mitigate these effects and ensure dimensional stability.

The material's lower crystallinity compared to HDPP can impact its barrier properties, potentially limiting its use in packaging applications that require high moisture or gas resistance. This characteristic may necessitate additional processing steps or the incorporation of barrier additives to enhance performance, adding complexity to the manufacturing process.

Achieving consistent dispersion of additives and colorants in LDPP can be challenging due to its lower melt viscosity. This can result in inconsistencies in color, UV resistance, or other enhanced properties across production batches. Advanced mixing technologies and carefully formulated masterbatches are often required to overcome these issues.

Lastly, the recyclability of LDPP in high-volume manufacturing contexts presents both technical and logistical challenges. While the material is recyclable, ensuring proper separation and maintaining material purity during the recycling process can be difficult, especially when LDPP is used in multi-material products or contaminated with other plastics during the recycling stream.

Another significant challenge is the thermal sensitivity of LDPP. The material has a narrow processing window, making it susceptible to degradation if exposed to high temperatures for extended periods. This sensitivity can lead to inconsistencies in product quality and potentially compromise the mechanical properties of the final product. Manufacturers must carefully control temperature profiles throughout the production line to maintain material integrity.

The relatively low stiffness of LDPP compared to high-density polypropylene (HDPP) can also pose challenges in applications where structural rigidity is crucial. This limitation may necessitate the use of thicker walls or additional reinforcement, potentially increasing material costs and product weight. Balancing the trade-off between material properties and product performance becomes a critical consideration in design and manufacturing processes.

LDPP's tendency to exhibit shrinkage and warpage during cooling presents another technical hurdle. These dimensional changes can affect the precision and consistency of manufactured parts, particularly in applications with tight tolerances. Manufacturers must implement sophisticated cooling strategies and mold designs to mitigate these effects and ensure dimensional stability.

The material's lower crystallinity compared to HDPP can impact its barrier properties, potentially limiting its use in packaging applications that require high moisture or gas resistance. This characteristic may necessitate additional processing steps or the incorporation of barrier additives to enhance performance, adding complexity to the manufacturing process.

Achieving consistent dispersion of additives and colorants in LDPP can be challenging due to its lower melt viscosity. This can result in inconsistencies in color, UV resistance, or other enhanced properties across production batches. Advanced mixing technologies and carefully formulated masterbatches are often required to overcome these issues.

Lastly, the recyclability of LDPP in high-volume manufacturing contexts presents both technical and logistical challenges. While the material is recyclable, ensuring proper separation and maintaining material purity during the recycling process can be difficult, especially when LDPP is used in multi-material products or contaminated with other plastics during the recycling stream.

Current LDPE Solutions

01 Composition and properties of low-density polypropylene

Low-density polypropylene is a type of polypropylene with a lower density compared to standard polypropylene. It typically has a density range of 0.85-0.91 g/cm³. This material offers improved flexibility, impact resistance, and lower melting point while maintaining good chemical resistance and processability.- Composition and properties of low-density polypropylene: Low-density polypropylene is a type of polypropylene with a lower density compared to standard polypropylene. It is characterized by its unique molecular structure, which results in improved flexibility, impact resistance, and lower melting point. The composition often includes specific catalysts and additives to achieve the desired properties.

- Manufacturing processes for low-density polypropylene: Various manufacturing processes are employed to produce low-density polypropylene, including specialized polymerization techniques, the use of specific catalysts, and controlled reaction conditions. These processes aim to achieve the desired molecular structure and properties of the final product.

- Applications of low-density polypropylene: Low-density polypropylene finds applications in various industries due to its unique properties. It is commonly used in packaging, automotive parts, consumer goods, and medical devices. The material's flexibility and impact resistance make it suitable for products that require these characteristics.

- Blending and compounding of low-density polypropylene: Low-density polypropylene can be blended or compounded with other materials to enhance its properties or create specialized formulations. This process involves mixing the polymer with additives, fillers, or other polymers to achieve specific performance characteristics or to meet particular application requirements.

- Characterization and testing of low-density polypropylene: Various methods and techniques are used to characterize and test low-density polypropylene. These include analytical techniques to determine molecular weight, density, melt flow rate, and mechanical properties. Advanced testing methods may also be employed to assess the material's performance under specific conditions or applications.

02 Manufacturing methods for low-density polypropylene

Various methods are used to produce low-density polypropylene, including the use of specific catalysts, copolymerization with other olefins, and controlled polymerization conditions. These techniques allow for the creation of a less crystalline structure, resulting in lower density and improved properties.Expand Specific Solutions03 Applications of low-density polypropylene

Low-density polypropylene finds applications in various industries due to its unique properties. It is commonly used in packaging, automotive parts, consumer goods, and medical devices. The material's flexibility and impact resistance make it suitable for products that require durability and lightweight characteristics.Expand Specific Solutions04 Blending and compounding of low-density polypropylene

Low-density polypropylene can be blended with other polymers or compounded with additives to enhance its properties. This process allows for the creation of customized materials with improved performance characteristics, such as increased strength, better thermal stability, or enhanced processability.Expand Specific Solutions05 Characterization and testing of low-density polypropylene

Various analytical techniques and testing methods are employed to characterize low-density polypropylene. These include density measurements, melt flow index determination, mechanical property testing, and thermal analysis. Such characterization is crucial for quality control and ensuring the material meets specific application requirements.Expand Specific Solutions

Key Industry Players

The low-density polypropylene (LDPP) market in high-volume manufacturing is in a mature growth stage, characterized by established players and ongoing innovation. The global market size for LDPP is substantial, driven by its widespread use in packaging, automotive, and consumer goods industries. Technologically, LDPP production is well-developed, with companies like ExxonMobil Chemical, Dow Global Technologies, and SABIC leading in patent filings and product advancements. Chinese firms such as Sinopec and Zhejiang University are also making significant contributions, indicating a competitive and globally diverse landscape. The focus on improving LDPP properties and production efficiency suggests continued technological evolution despite market maturity.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed advanced catalysts and process technologies for producing low-density polypropylene (LDPP) with enhanced properties suitable for high-volume manufacturing. Their VistamaxxTM performance polymers utilize proprietary metallocene catalysis to create LDPP with improved flexibility, impact strength, and processability[1]. This allows for thinner, lighter products and faster production speeds in applications like packaging films and automotive parts. ExxonMobil's gas-phase polymerization process enables precise control of molecular weight distribution and comonomer incorporation, resulting in LDPP tailored for specific end-use requirements[2].

Strengths: Proprietary catalyst technology enables precise polymer design; Extensive R&D capabilities and resources. Weaknesses: Higher production costs compared to conventional PP; Limited production capacity for specialty grades.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered INSITE™ Technology, a revolutionary catalyst and process platform for producing LDPP with enhanced performance attributes. This technology enables the creation of ELITE™ Enhanced Polyethylene resins, which combine the processability of LDPE with the strength and toughness of LLDPE[3]. For high-volume manufacturing, Dow's solution-phase process allows for precise control over polymer architecture, resulting in LDPP with tailored melt strength, elasticity, and optical properties. Their AGILITY™ CE resins offer improved seal strength and hot tack performance for flexible packaging applications, enabling faster filling speeds and reduced material usage[4].

Strengths: Versatile technology platform adaptable to various applications; Strong focus on sustainability and circular economy solutions. Weaknesses: Complex production process may limit scalability; Higher costs associated with specialty grades.

LDPE Innovations

Polypropylene resin composition having high flow and high impact strength and manufacturing method thereof

PatentPendingKR1020240098711A

Innovation

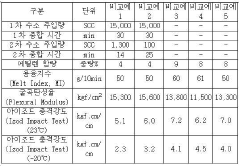

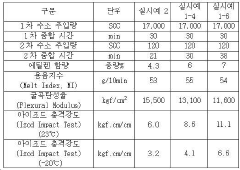

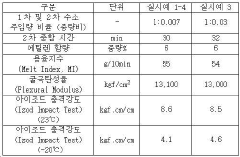

- A method involving controlled hydrogen gas injection during primary and secondary polymerization steps to produce a polypropylene resin composition with a specific ethylene content range (5-7% by weight) and balanced hydrogen gas ratios (1:0.005 to 0.05) to enhance fluidity and impact strength, using a 4th generation Ziegler-Natta catalyst, triethyl aluminum as a cocatalyst, and cyclohexyldimethoxyethylsilane as a donor.

Polypropylene composition with low linear thermal expansion and low density character

PatentInactiveKR1020090086725A

Innovation

- A polypropylene resin composition is developed with a high isotactic fraction of 96% or more, incorporating 1 to 30% rubber component, 1 to 40% nano-polypropylene masterbatch, and optional inorganic fillers like talc, to enhance rigidity, impact properties, and thermal stability.

Supply Chain Analysis

The integration of Low-Density Polypropylene (LDPP) in high-volume manufacturing processes has significantly impacted supply chain dynamics. LDPP's unique properties, including its lightweight nature and cost-effectiveness, have led to a shift in material sourcing strategies across various industries. Manufacturers have increasingly turned to LDPP as a preferred material, particularly in packaging and automotive sectors, due to its ability to reduce transportation costs and improve fuel efficiency.

This shift towards LDPP has created ripple effects throughout the supply chain. Suppliers of raw materials have had to adapt their production capacities to meet the growing demand for LDPP. This has led to increased competition among suppliers, potentially driving down prices but also necessitating investments in new production technologies to maintain quality standards at higher volumes.

The adoption of LDPP has also influenced logistics and transportation within the supply chain. The material's lightweight properties have allowed for more efficient shipping, with the potential to increase load capacities and reduce the number of shipments required. This has not only reduced transportation costs but also contributed to lowering the overall carbon footprint of supply chain operations.

However, the increased use of LDPP has also presented challenges to the supply chain. The material's specific handling and storage requirements have necessitated adjustments in warehousing and distribution practices. Some manufacturers have had to invest in new equipment and training to properly handle and process LDPP, potentially creating short-term disruptions in the supply chain as these changes are implemented.

Furthermore, the recyclability of LDPP has become a critical consideration in supply chain management. As sustainability concerns grow, manufacturers and suppliers are under pressure to establish effective recycling processes for LDPP products. This has led to the development of new reverse logistics systems and partnerships with recycling facilities, adding complexity to the overall supply chain structure.

The impact of LDPP on high-volume manufacturing has also extended to inventory management practices. The material's versatility and longer shelf life compared to some alternatives have allowed for more flexible inventory strategies. Manufacturers can potentially maintain larger stocks of raw LDPP without significant risk of degradation, providing a buffer against supply chain disruptions.

In conclusion, the integration of LDPP in high-volume manufacturing has reshaped supply chain dynamics, offering both opportunities and challenges. While it has enabled cost reductions and efficiency improvements, it has also necessitated adaptations in sourcing, logistics, and sustainability practices. As the use of LDPP continues to grow, further evolution of supply chain strategies is expected to optimize its benefits while addressing associated challenges.

This shift towards LDPP has created ripple effects throughout the supply chain. Suppliers of raw materials have had to adapt their production capacities to meet the growing demand for LDPP. This has led to increased competition among suppliers, potentially driving down prices but also necessitating investments in new production technologies to maintain quality standards at higher volumes.

The adoption of LDPP has also influenced logistics and transportation within the supply chain. The material's lightweight properties have allowed for more efficient shipping, with the potential to increase load capacities and reduce the number of shipments required. This has not only reduced transportation costs but also contributed to lowering the overall carbon footprint of supply chain operations.

However, the increased use of LDPP has also presented challenges to the supply chain. The material's specific handling and storage requirements have necessitated adjustments in warehousing and distribution practices. Some manufacturers have had to invest in new equipment and training to properly handle and process LDPP, potentially creating short-term disruptions in the supply chain as these changes are implemented.

Furthermore, the recyclability of LDPP has become a critical consideration in supply chain management. As sustainability concerns grow, manufacturers and suppliers are under pressure to establish effective recycling processes for LDPP products. This has led to the development of new reverse logistics systems and partnerships with recycling facilities, adding complexity to the overall supply chain structure.

The impact of LDPP on high-volume manufacturing has also extended to inventory management practices. The material's versatility and longer shelf life compared to some alternatives have allowed for more flexible inventory strategies. Manufacturers can potentially maintain larger stocks of raw LDPP without significant risk of degradation, providing a buffer against supply chain disruptions.

In conclusion, the integration of LDPP in high-volume manufacturing has reshaped supply chain dynamics, offering both opportunities and challenges. While it has enabled cost reductions and efficiency improvements, it has also necessitated adaptations in sourcing, logistics, and sustainability practices. As the use of LDPP continues to grow, further evolution of supply chain strategies is expected to optimize its benefits while addressing associated challenges.

Sustainability Aspects

Low-density polypropylene (LDPP) has emerged as a significant material in high-volume manufacturing, offering both advantages and challenges from a sustainability perspective. The production of LDPP requires less energy compared to traditional polypropylene, resulting in a lower carbon footprint during the manufacturing process. This energy efficiency contributes to reduced greenhouse gas emissions and aligns with global efforts to combat climate change.

Furthermore, LDPP's lightweight nature leads to decreased fuel consumption in transportation, both during the distribution of raw materials and finished products. This reduction in transportation-related emissions further enhances the material's overall environmental profile. The durability and resistance to chemicals and moisture of LDPP also contribute to its sustainability by extending product lifespans and reducing the need for frequent replacements.

However, the sustainability of LDPP in high-volume manufacturing is not without its challenges. The material's low density, while beneficial in many aspects, can lead to increased volume of waste if not properly managed. This necessitates the development and implementation of effective recycling systems to ensure that LDPP products can be reprocessed at the end of their life cycle.

The recyclability of LDPP presents both opportunities and obstacles. While the material is technically recyclable, the process can be more complex compared to other plastics due to its specific properties. Investments in advanced recycling technologies and infrastructure are crucial to maximize the circular potential of LDPP and minimize its environmental impact.

Another sustainability consideration is the sourcing of raw materials for LDPP production. As demand for the material grows in high-volume manufacturing, there is an increasing need to ensure sustainable and ethical sourcing practices. This includes exploring bio-based alternatives and developing more efficient catalysts to reduce the reliance on fossil fuel-derived feedstocks.

The use of LDPP in high-volume manufacturing also raises questions about end-of-life management. While the material's durability is an asset during use, it can pose challenges for biodegradation. Research into enhancing the biodegradability of LDPP without compromising its performance characteristics is an important area of focus for improving its overall sustainability profile.

In conclusion, the impact of LDPP on sustainability in high-volume manufacturing is multifaceted. While it offers significant benefits in terms of energy efficiency and reduced emissions, addressing challenges related to recycling, raw material sourcing, and end-of-life management is crucial for maximizing its positive environmental impact and ensuring its long-term viability as a sustainable material choice.

Furthermore, LDPP's lightweight nature leads to decreased fuel consumption in transportation, both during the distribution of raw materials and finished products. This reduction in transportation-related emissions further enhances the material's overall environmental profile. The durability and resistance to chemicals and moisture of LDPP also contribute to its sustainability by extending product lifespans and reducing the need for frequent replacements.

However, the sustainability of LDPP in high-volume manufacturing is not without its challenges. The material's low density, while beneficial in many aspects, can lead to increased volume of waste if not properly managed. This necessitates the development and implementation of effective recycling systems to ensure that LDPP products can be reprocessed at the end of their life cycle.

The recyclability of LDPP presents both opportunities and obstacles. While the material is technically recyclable, the process can be more complex compared to other plastics due to its specific properties. Investments in advanced recycling technologies and infrastructure are crucial to maximize the circular potential of LDPP and minimize its environmental impact.

Another sustainability consideration is the sourcing of raw materials for LDPP production. As demand for the material grows in high-volume manufacturing, there is an increasing need to ensure sustainable and ethical sourcing practices. This includes exploring bio-based alternatives and developing more efficient catalysts to reduce the reliance on fossil fuel-derived feedstocks.

The use of LDPP in high-volume manufacturing also raises questions about end-of-life management. While the material's durability is an asset during use, it can pose challenges for biodegradation. Research into enhancing the biodegradability of LDPP without compromising its performance characteristics is an important area of focus for improving its overall sustainability profile.

In conclusion, the impact of LDPP on sustainability in high-volume manufacturing is multifaceted. While it offers significant benefits in terms of energy efficiency and reduced emissions, addressing challenges related to recycling, raw material sourcing, and end-of-life management is crucial for maximizing its positive environmental impact and ensuring its long-term viability as a sustainable material choice.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!