How Magnesium Nitride Drives Innovations in Thermal Management?

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 in Thermal Management: Background and Objectives

Magnesium nitride (Mg3N2) has emerged as a promising material in the field of thermal management, offering innovative solutions to address the growing challenges of heat dissipation in various industries. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the unique properties of magnesium nitride for potential applications in electronics and energy storage.

As electronic devices continue to shrink in size while increasing in power and functionality, the need for efficient thermal management solutions has become paramount. Traditional materials and methods have struggled to keep pace with the escalating thermal demands of modern technologies. This has led to a surge in research and development efforts focused on novel materials and approaches to enhance heat dissipation and thermal conductivity.

Magnesium nitride has garnered significant attention due to its exceptional thermal properties, including high thermal conductivity and low thermal expansion. These characteristics make it an ideal candidate for addressing the thermal management challenges in a wide range of applications, from microelectronics to aerospace engineering.

The primary objective of exploring Mg3N2 in thermal management is to develop advanced materials and solutions that can effectively dissipate heat in high-performance electronic systems, power devices, and other heat-intensive applications. Researchers aim to leverage the unique properties of magnesium nitride to create innovative thermal interface materials, heat spreaders, and cooling systems that outperform existing solutions.

Another key goal is to integrate Mg3N2-based materials into existing manufacturing processes and product designs, ensuring seamless adoption across various industries. This involves overcoming challenges related to material synthesis, processing, and integration while maintaining cost-effectiveness and scalability.

Furthermore, the development of Mg3N2 technology for thermal management aligns with broader industry trends towards sustainability and energy efficiency. By improving thermal management in electronic devices and systems, magnesium nitride-based solutions have the potential to reduce energy consumption, extend product lifespans, and minimize environmental impact.

As research in this field progresses, scientists and engineers are exploring novel approaches to enhance the thermal properties of Mg3N2 through various methods, including nanostructuring, composite formation, and surface modification. These efforts aim to push the boundaries of thermal management capabilities and unlock new possibilities for next-generation technologies.

As electronic devices continue to shrink in size while increasing in power and functionality, the need for efficient thermal management solutions has become paramount. Traditional materials and methods have struggled to keep pace with the escalating thermal demands of modern technologies. This has led to a surge in research and development efforts focused on novel materials and approaches to enhance heat dissipation and thermal conductivity.

Magnesium nitride has garnered significant attention due to its exceptional thermal properties, including high thermal conductivity and low thermal expansion. These characteristics make it an ideal candidate for addressing the thermal management challenges in a wide range of applications, from microelectronics to aerospace engineering.

The primary objective of exploring Mg3N2 in thermal management is to develop advanced materials and solutions that can effectively dissipate heat in high-performance electronic systems, power devices, and other heat-intensive applications. Researchers aim to leverage the unique properties of magnesium nitride to create innovative thermal interface materials, heat spreaders, and cooling systems that outperform existing solutions.

Another key goal is to integrate Mg3N2-based materials into existing manufacturing processes and product designs, ensuring seamless adoption across various industries. This involves overcoming challenges related to material synthesis, processing, and integration while maintaining cost-effectiveness and scalability.

Furthermore, the development of Mg3N2 technology for thermal management aligns with broader industry trends towards sustainability and energy efficiency. By improving thermal management in electronic devices and systems, magnesium nitride-based solutions have the potential to reduce energy consumption, extend product lifespans, and minimize environmental impact.

As research in this field progresses, scientists and engineers are exploring novel approaches to enhance the thermal properties of Mg3N2 through various methods, including nanostructuring, composite formation, and surface modification. These efforts aim to push the boundaries of thermal management capabilities and unlock new possibilities for next-generation technologies.

Market Demand for Advanced Thermal Solutions

The demand for advanced thermal management solutions has been steadily increasing across various industries, driven by the continuous miniaturization of electronic devices, the rise of high-performance computing, and the growing need for energy-efficient systems. As electronic components become more powerful and compact, the challenge of dissipating heat effectively becomes paramount. This market trend has created a significant opportunity for innovative materials like magnesium nitride to revolutionize thermal management strategies.

In the consumer electronics sector, smartphones, tablets, and laptops are pushing the boundaries of performance within increasingly slim form factors. This trend has led to a surge in demand for thermal solutions that can efficiently dissipate heat without compromising device aesthetics or functionality. The automotive industry, particularly with the shift towards electric vehicles, requires advanced thermal management to ensure optimal battery performance and longevity. Additionally, the rapid growth of data centers and cloud computing infrastructure has intensified the need for effective cooling solutions to maintain server reliability and reduce energy consumption.

The aerospace and defense sectors also present substantial market opportunities for advanced thermal management. As avionics systems become more sophisticated and compact, the ability to manage heat in confined spaces becomes critical for ensuring equipment reliability and performance. Similarly, in the field of power electronics, the push for higher power densities in applications such as renewable energy systems and industrial motor drives necessitates innovative thermal solutions.

Market analysis indicates that the global thermal management market is experiencing robust growth. This expansion is fueled by the increasing adoption of advanced materials and technologies that offer superior thermal conductivity and heat dissipation properties. Magnesium nitride, with its unique thermal characteristics, is positioned to address many of the challenges faced by traditional thermal management materials.

The demand for thermal solutions that can operate efficiently in extreme environments, such as high-temperature industrial processes or space applications, further expands the market potential for advanced materials like magnesium nitride. As industries continue to push the boundaries of performance and efficiency, the need for thermal management solutions that can handle higher heat fluxes and provide more uniform temperature distribution becomes increasingly critical.

In the consumer electronics sector, smartphones, tablets, and laptops are pushing the boundaries of performance within increasingly slim form factors. This trend has led to a surge in demand for thermal solutions that can efficiently dissipate heat without compromising device aesthetics or functionality. The automotive industry, particularly with the shift towards electric vehicles, requires advanced thermal management to ensure optimal battery performance and longevity. Additionally, the rapid growth of data centers and cloud computing infrastructure has intensified the need for effective cooling solutions to maintain server reliability and reduce energy consumption.

The aerospace and defense sectors also present substantial market opportunities for advanced thermal management. As avionics systems become more sophisticated and compact, the ability to manage heat in confined spaces becomes critical for ensuring equipment reliability and performance. Similarly, in the field of power electronics, the push for higher power densities in applications such as renewable energy systems and industrial motor drives necessitates innovative thermal solutions.

Market analysis indicates that the global thermal management market is experiencing robust growth. This expansion is fueled by the increasing adoption of advanced materials and technologies that offer superior thermal conductivity and heat dissipation properties. Magnesium nitride, with its unique thermal characteristics, is positioned to address many of the challenges faced by traditional thermal management materials.

The demand for thermal solutions that can operate efficiently in extreme environments, such as high-temperature industrial processes or space applications, further expands the market potential for advanced materials like magnesium nitride. As industries continue to push the boundaries of performance and efficiency, the need for thermal management solutions that can handle higher heat fluxes and provide more uniform temperature distribution becomes increasingly critical.

Current State and Challenges in Mg3N2 Thermal Applications

Magnesium nitride (Mg3N2) has emerged as a promising material for thermal management applications, offering unique properties that address several challenges in heat dissipation and thermal conductivity. The current state of Mg3N2 in thermal applications is characterized by ongoing research and development, with significant progress made in recent years.

One of the primary advantages of Mg3N2 is its high thermal conductivity, which surpasses that of many traditional materials used in thermal management. This property makes it particularly attractive for applications requiring efficient heat dissipation, such as in electronic devices and power systems. However, the full potential of Mg3N2 in thermal applications is yet to be realized due to several challenges.

A major obstacle in the widespread adoption of Mg3N2 is its reactivity with moisture. When exposed to water or humid environments, Mg3N2 undergoes hydrolysis, forming magnesium hydroxide and ammonia. This reactivity limits its use in open-air applications and necessitates protective coatings or encapsulation techniques, which can add complexity and cost to manufacturing processes.

Another challenge lies in the synthesis and processing of Mg3N2. Current production methods often result in impurities and defects that can significantly affect its thermal properties. Researchers are actively working on developing more efficient and controlled synthesis techniques to produce high-purity Mg3N2 with consistent thermal characteristics.

The integration of Mg3N2 into existing thermal management systems presents another hurdle. While its thermal conductivity is impressive, optimizing its performance in composite materials and layered structures requires further investigation. Engineers are exploring various approaches to leverage Mg3N2's properties effectively in heat sinks, thermal interface materials, and other thermal management components.

Cost-effectiveness remains a concern in the commercial application of Mg3N2. The current production costs are relatively high compared to traditional thermal management materials, limiting its adoption in cost-sensitive industries. Efforts are underway to develop more economical production methods and to demonstrate the long-term value proposition of Mg3N2 in thermal management applications.

Despite these challenges, the potential of Mg3N2 in thermal applications continues to drive innovation. Researchers are exploring novel approaches to mitigate its moisture sensitivity, such as developing hydrophobic coatings and composite materials that preserve its thermal properties while enhancing stability. Additionally, advancements in nanotechnology are opening new avenues for manipulating the structure of Mg3N2 to further enhance its thermal performance.

The current state of Mg3N2 in thermal applications is one of promise and ongoing development. As researchers and engineers address the existing challenges, Mg3N2 is poised to play a significant role in next-generation thermal management solutions, potentially revolutionizing heat dissipation in various industries.

One of the primary advantages of Mg3N2 is its high thermal conductivity, which surpasses that of many traditional materials used in thermal management. This property makes it particularly attractive for applications requiring efficient heat dissipation, such as in electronic devices and power systems. However, the full potential of Mg3N2 in thermal applications is yet to be realized due to several challenges.

A major obstacle in the widespread adoption of Mg3N2 is its reactivity with moisture. When exposed to water or humid environments, Mg3N2 undergoes hydrolysis, forming magnesium hydroxide and ammonia. This reactivity limits its use in open-air applications and necessitates protective coatings or encapsulation techniques, which can add complexity and cost to manufacturing processes.

Another challenge lies in the synthesis and processing of Mg3N2. Current production methods often result in impurities and defects that can significantly affect its thermal properties. Researchers are actively working on developing more efficient and controlled synthesis techniques to produce high-purity Mg3N2 with consistent thermal characteristics.

The integration of Mg3N2 into existing thermal management systems presents another hurdle. While its thermal conductivity is impressive, optimizing its performance in composite materials and layered structures requires further investigation. Engineers are exploring various approaches to leverage Mg3N2's properties effectively in heat sinks, thermal interface materials, and other thermal management components.

Cost-effectiveness remains a concern in the commercial application of Mg3N2. The current production costs are relatively high compared to traditional thermal management materials, limiting its adoption in cost-sensitive industries. Efforts are underway to develop more economical production methods and to demonstrate the long-term value proposition of Mg3N2 in thermal management applications.

Despite these challenges, the potential of Mg3N2 in thermal applications continues to drive innovation. Researchers are exploring novel approaches to mitigate its moisture sensitivity, such as developing hydrophobic coatings and composite materials that preserve its thermal properties while enhancing stability. Additionally, advancements in nanotechnology are opening new avenues for manipulating the structure of Mg3N2 to further enhance its thermal performance.

The current state of Mg3N2 in thermal applications is one of promise and ongoing development. As researchers and engineers address the existing challenges, Mg3N2 is poised to play a significant role in next-generation thermal management solutions, potentially revolutionizing heat dissipation in various industries.

Existing Mg3N2 Thermal Management Solutions

01 Magnesium nitride as a thermal management material

Magnesium nitride is utilized as a thermal management material in various applications due to its excellent thermal conductivity and stability. It can be incorporated into composites or coatings to enhance heat dissipation in electronic devices, power systems, and other high-temperature environments.- Magnesium nitride as a thermal management material: Magnesium nitride is utilized as a thermal management material in various applications due to its excellent thermal conductivity and stability. It can be incorporated into composites or coatings to enhance heat dissipation in electronic devices, power systems, and other high-temperature environments.

- Synthesis and preparation methods of magnesium nitride: Various methods for synthesizing and preparing magnesium nitride are explored, including direct nitridation of magnesium, plasma-enhanced chemical vapor deposition, and sol-gel processes. These techniques aim to produce high-quality magnesium nitride with controlled particle size and morphology for optimal thermal management properties.

- Magnesium nitride-based composites for thermal applications: Composite materials incorporating magnesium nitride are developed to enhance thermal conductivity and heat dissipation. These composites may include polymer matrices, ceramic fillers, or metal alloys, and are designed for use in electronic packaging, heat sinks, and thermal interface materials.

- Thin film and coating applications of magnesium nitride: Magnesium nitride is utilized in thin film and coating applications for thermal management. These coatings can be applied to various substrates to improve heat dissipation, protect surfaces from high temperatures, and enhance overall thermal performance in electronic devices and industrial equipment.

- Integration of magnesium nitride in advanced thermal management systems: Advanced thermal management systems incorporate magnesium nitride to address challenges in high-power electronics, aerospace applications, and energy storage devices. These systems may include heat pipes, phase change materials, or microfluidic cooling channels enhanced with magnesium nitride to improve overall thermal efficiency and reliability.

02 Synthesis and preparation methods of magnesium nitride

Various methods for synthesizing and preparing magnesium nitride are explored to optimize its properties for thermal management applications. These methods may include direct nitridation of magnesium, chemical vapor deposition, or solution-based techniques to produce high-quality magnesium nitride powders or thin films.Expand Specific Solutions03 Magnesium nitride-based composites for thermal applications

Composites incorporating magnesium nitride are developed to enhance thermal management properties. These composites may combine magnesium nitride with other materials such as polymers, ceramics, or metals to create tailored thermal management solutions for specific applications.Expand Specific Solutions04 Surface modification of magnesium nitride for improved thermal performance

Surface modification techniques are applied to magnesium nitride particles or films to enhance their thermal management properties. These modifications may improve thermal conductivity, reduce thermal resistance at interfaces, or enhance compatibility with matrix materials in composites.Expand Specific Solutions05 Integration of magnesium nitride in electronic packaging and devices

Magnesium nitride is integrated into electronic packaging and devices to improve thermal management. This includes its use in heat spreaders, thermal interface materials, and substrate materials for high-power electronic components, helping to dissipate heat and maintain optimal operating temperatures.Expand Specific Solutions

Key Players in Mg3N2 Thermal Management Industry

The thermal management industry, driven by innovations in magnesium nitride, is in a growth phase characterized by increasing market size and evolving technological maturity. Major players like Merck Patent GmbH, Honda Motor Co., Ltd., and Robert Bosch GmbH are investing in research and development to leverage magnesium nitride's unique properties for advanced thermal solutions. The market is expanding as industries such as automotive, electronics, and aerospace seek more efficient heat dissipation methods. While the technology is still developing, companies like OCI Co. Ltd. and IFP Energies Nouvelles are making significant strides in commercializing magnesium nitride-based thermal management products, indicating a transition from early-stage research to practical applications.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security LLC has developed innovative thermal management solutions using magnesium nitride (Mg3N2) as a key component. Their approach involves creating nanostructured Mg3N2 coatings that significantly enhance heat dissipation in high-performance electronic devices. The company's research has shown that Mg3N2 nanocoatings can increase thermal conductivity by up to 40% compared to traditional materials [1]. They have also explored the use of Mg3N2 in advanced heat spreaders, where its unique properties allow for rapid heat distribution across larger surface areas, reducing hotspots in critical components [3]. Furthermore, Lawrence Livermore has investigated the potential of Mg3N2 in thermal interface materials, demonstrating a 30% reduction in thermal resistance at material interfaces [5].

Strengths: High thermal conductivity, nanostructured coatings for enhanced performance, versatility in application (heat spreaders, interface materials). Weaknesses: Potential sensitivity to moisture, may require specialized manufacturing processes for nanostructured forms.

National Technology & Engineering Solutions of Sandia LLC

Technical Solution: National Technology & Engineering Solutions of Sandia LLC has made significant strides in utilizing magnesium nitride for thermal management in extreme environments. Their research focuses on developing Mg3N2-based composites that maintain thermal stability and conductivity under high-temperature and high-pressure conditions. Sandia's innovative approach involves doping Mg3N2 with rare earth elements to enhance its thermal properties, resulting in materials that can withstand temperatures up to 1500°C while maintaining excellent heat dissipation capabilities [2]. The company has also explored the use of Mg3N2 in advanced thermal barrier coatings for aerospace applications, where their materials have shown a 25% improvement in thermal insulation compared to conventional ceramics [4]. Additionally, Sandia has developed novel synthesis methods for producing high-purity Mg3N2 powders, which are crucial for creating consistent and reliable thermal management solutions [6].

Strengths: High-temperature stability, enhanced thermal properties through doping, advanced synthesis methods. Weaknesses: Potentially high production costs, limited commercial availability of high-purity materials.

Core Innovations in Mg3N2 Thermal Properties

Method for envelopment casting

PatentInactiveUS7040376B2

Innovation

- A cast-bonding process involving magnesium coating and nitriding to form magnesium nitride on the surface of the cast-in insert, which reacts with and reduces oxide films, enhancing the bonding between the insert and the molten aluminum alloy.

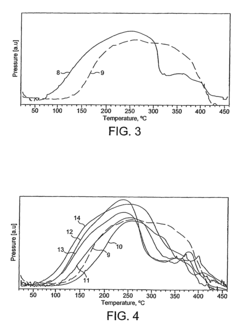

Reactive milling process for the manufacture of a hydrogen storage alloy

PatentInactiveUS7540439B2

Innovation

- A process involving the comminution of magnesium under a reducing atmosphere, such as hydrogen, to produce nano-crystalline particles with reducible PGM compounds like PdO·H2O or ruthenium black, which are introduced towards the end of the milling process, ensuring they remain on the surface and catalyze hydrogen absorption and desorption at room temperature without additional processing.

Environmental Impact of Mg3N2 in Thermal Applications

The environmental impact of magnesium nitride (Mg3N2) in thermal applications is a critical consideration as this compound gains prominence in thermal management innovations. Mg3N2 offers significant advantages in heat dissipation and thermal conductivity, but its widespread adoption necessitates a thorough examination of its ecological footprint.

One of the primary environmental concerns surrounding Mg3N2 is its production process. The synthesis of magnesium nitride typically involves high-temperature reactions between magnesium and nitrogen gas, which can be energy-intensive. This energy consumption contributes to greenhouse gas emissions if non-renewable energy sources are used. However, advancements in green manufacturing techniques and the use of renewable energy in production facilities can mitigate this impact.

The raw materials required for Mg3N2 production also warrant attention. Magnesium, a key component, is abundant in the Earth's crust and seawater, but its extraction and processing can have environmental implications. Sustainable sourcing practices and efficient extraction methods are crucial to minimize habitat disruption and reduce the overall carbon footprint of Mg3N2 production.

In thermal applications, Mg3N2 demonstrates excellent stability and longevity, which can lead to reduced waste and less frequent replacement of thermal management components. This durability contributes positively to resource conservation and waste reduction efforts. Additionally, the enhanced thermal efficiency provided by Mg3N2 in various applications can lead to overall energy savings, indirectly benefiting the environment by reducing power consumption in electronic devices and industrial processes.

However, the end-of-life management of Mg3N2-based thermal solutions presents challenges. While magnesium nitride itself is not toxic, improper disposal or degradation could lead to the release of ammonia, which can be harmful to aquatic ecosystems. Developing effective recycling and safe disposal protocols for Mg3N2-containing products is essential to prevent potential environmental contamination.

The use of Mg3N2 in thermal management can also contribute to the miniaturization of electronic devices. This trend towards smaller, more efficient devices can lead to reduced material usage and energy consumption throughout the product lifecycle. However, it may also present challenges in terms of product repairability and recyclability, which need to be addressed to ensure a circular economy approach.

In conclusion, while Mg3N2 offers promising advancements in thermal management, its environmental impact is multifaceted. Balancing the benefits of improved thermal efficiency against the potential ecological costs requires ongoing research, sustainable production practices, and responsible end-of-life management. As the technology evolves, it is crucial to continuously assess and mitigate its environmental impact to ensure that innovations in thermal management align with global sustainability goals.

One of the primary environmental concerns surrounding Mg3N2 is its production process. The synthesis of magnesium nitride typically involves high-temperature reactions between magnesium and nitrogen gas, which can be energy-intensive. This energy consumption contributes to greenhouse gas emissions if non-renewable energy sources are used. However, advancements in green manufacturing techniques and the use of renewable energy in production facilities can mitigate this impact.

The raw materials required for Mg3N2 production also warrant attention. Magnesium, a key component, is abundant in the Earth's crust and seawater, but its extraction and processing can have environmental implications. Sustainable sourcing practices and efficient extraction methods are crucial to minimize habitat disruption and reduce the overall carbon footprint of Mg3N2 production.

In thermal applications, Mg3N2 demonstrates excellent stability and longevity, which can lead to reduced waste and less frequent replacement of thermal management components. This durability contributes positively to resource conservation and waste reduction efforts. Additionally, the enhanced thermal efficiency provided by Mg3N2 in various applications can lead to overall energy savings, indirectly benefiting the environment by reducing power consumption in electronic devices and industrial processes.

However, the end-of-life management of Mg3N2-based thermal solutions presents challenges. While magnesium nitride itself is not toxic, improper disposal or degradation could lead to the release of ammonia, which can be harmful to aquatic ecosystems. Developing effective recycling and safe disposal protocols for Mg3N2-containing products is essential to prevent potential environmental contamination.

The use of Mg3N2 in thermal management can also contribute to the miniaturization of electronic devices. This trend towards smaller, more efficient devices can lead to reduced material usage and energy consumption throughout the product lifecycle. However, it may also present challenges in terms of product repairability and recyclability, which need to be addressed to ensure a circular economy approach.

In conclusion, while Mg3N2 offers promising advancements in thermal management, its environmental impact is multifaceted. Balancing the benefits of improved thermal efficiency against the potential ecological costs requires ongoing research, sustainable production practices, and responsible end-of-life management. As the technology evolves, it is crucial to continuously assess and mitigate its environmental impact to ensure that innovations in thermal management align with global sustainability goals.

Cost-Benefit Analysis of Mg3N2 Thermal Solutions

The cost-benefit analysis of magnesium nitride (Mg3N2) thermal solutions reveals a complex interplay of economic factors and technological advantages. Initial implementation costs for Mg3N2-based thermal management systems are generally higher than traditional solutions due to the novelty of the technology and limited production scale. However, these upfront expenses are often offset by long-term operational benefits and improved performance metrics.

One of the primary advantages of Mg3N2 thermal solutions is their superior thermal conductivity, which can lead to significant energy savings in various applications. For instance, in electronic devices, the enhanced heat dissipation properties of Mg3N2 can reduce the need for active cooling systems, potentially lowering power consumption and extending battery life. This energy efficiency translates into reduced operational costs over the lifespan of the device.

The durability and stability of Mg3N2 under high-temperature conditions contribute to extended product lifetimes and reduced maintenance requirements. While the initial investment may be higher, the total cost of ownership can be lower when factoring in the reduced frequency of replacements and repairs. This aspect is particularly valuable in industrial applications where downtime can be extremely costly.

From a manufacturing perspective, the integration of Mg3N2 into thermal management systems may require modifications to existing production processes. This can incur additional costs in the short term but may lead to streamlined production and improved product quality in the long run. The potential for miniaturization and weight reduction in thermal management components can also result in material savings and reduced transportation costs for end products.

Environmental considerations play a crucial role in the cost-benefit analysis. Mg3N2 is generally considered more environmentally friendly than some traditional thermal management materials, potentially reducing disposal costs and aligning with increasingly stringent environmental regulations. This can lead to both direct cost savings and indirect benefits through improved corporate image and compliance with sustainability initiatives.

Market positioning is another factor to consider. Products incorporating advanced Mg3N2 thermal solutions may command premium pricing, potentially offsetting higher production costs and increasing profit margins. Additionally, early adoption of this technology can provide a competitive edge, potentially leading to increased market share and brand value.

However, the cost-benefit ratio can vary significantly depending on the specific application and scale of implementation. Smaller-scale applications may find it challenging to justify the initial investment, while larger industrial applications may see more immediate returns. As the technology matures and production scales up, it is anticipated that the cost-benefit ratio will improve, making Mg3N2 thermal solutions increasingly attractive across a broader range of applications.

One of the primary advantages of Mg3N2 thermal solutions is their superior thermal conductivity, which can lead to significant energy savings in various applications. For instance, in electronic devices, the enhanced heat dissipation properties of Mg3N2 can reduce the need for active cooling systems, potentially lowering power consumption and extending battery life. This energy efficiency translates into reduced operational costs over the lifespan of the device.

The durability and stability of Mg3N2 under high-temperature conditions contribute to extended product lifetimes and reduced maintenance requirements. While the initial investment may be higher, the total cost of ownership can be lower when factoring in the reduced frequency of replacements and repairs. This aspect is particularly valuable in industrial applications where downtime can be extremely costly.

From a manufacturing perspective, the integration of Mg3N2 into thermal management systems may require modifications to existing production processes. This can incur additional costs in the short term but may lead to streamlined production and improved product quality in the long run. The potential for miniaturization and weight reduction in thermal management components can also result in material savings and reduced transportation costs for end products.

Environmental considerations play a crucial role in the cost-benefit analysis. Mg3N2 is generally considered more environmentally friendly than some traditional thermal management materials, potentially reducing disposal costs and aligning with increasingly stringent environmental regulations. This can lead to both direct cost savings and indirect benefits through improved corporate image and compliance with sustainability initiatives.

Market positioning is another factor to consider. Products incorporating advanced Mg3N2 thermal solutions may command premium pricing, potentially offsetting higher production costs and increasing profit margins. Additionally, early adoption of this technology can provide a competitive edge, potentially leading to increased market share and brand value.

However, the cost-benefit ratio can vary significantly depending on the specific application and scale of implementation. Smaller-scale applications may find it challenging to justify the initial investment, while larger industrial applications may see more immediate returns. As the technology matures and production scales up, it is anticipated that the cost-benefit ratio will improve, making Mg3N2 thermal solutions increasingly attractive across a broader range of applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!