How Magnesium Nitride is Innovating High-Temperatures Materials?

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 Background & Objectives

Magnesium nitride (Mg3N2) has emerged as a promising material in the field of high-temperature applications, marking a significant advancement in materials science. The evolution of this compound can be traced back to the early 20th century when it was first synthesized, but its potential remained largely unexplored for decades. Recent technological advancements and the growing demand for materials capable of withstanding extreme conditions have reignited interest in Mg3N2, propelling it to the forefront of high-temperature materials research.

The primary objective in exploring Mg3N2 for high-temperature applications is to overcome the limitations of current materials used in extreme environments. Traditional high-temperature materials, such as certain ceramics and superalloys, often struggle with issues like thermal expansion, oxidation resistance, and mechanical stability at elevated temperatures. Mg3N2 offers a unique combination of properties that address these challenges, including high melting point, low density, and excellent thermal stability.

One of the key drivers behind the renewed focus on Mg3N2 is the increasing demand for materials that can perform under extreme conditions in various industries. Aerospace, energy production, and advanced manufacturing sectors are constantly pushing the boundaries of material capabilities, seeking compounds that can maintain structural integrity and functionality at ever-higher temperatures. Mg3N2 has shown promise in meeting these demanding requirements, potentially revolutionizing the design of components for jet engines, gas turbines, and high-temperature reactors.

The technological trajectory of Mg3N2 research is aimed at fully understanding and optimizing its properties for practical applications. This includes investigating its behavior under different temperature ranges, exploring various synthesis methods to enhance its purity and performance, and developing composite materials that leverage Mg3N2's unique characteristics. Researchers are also focusing on improving its resistance to oxidation and hydrolysis, which are critical factors for its long-term stability in high-temperature environments.

As the field progresses, the objectives extend beyond mere material development to encompass the integration of Mg3N2 into existing manufacturing processes and the creation of new fabrication techniques. This holistic approach aims to bridge the gap between laboratory discoveries and industrial applications, ensuring that the innovative potential of Mg3N2 can be fully realized in real-world scenarios. The ultimate goal is to establish Mg3N2 as a versatile and reliable material for a wide range of high-temperature applications, potentially transforming multiple industries and enabling new technological advancements.

The primary objective in exploring Mg3N2 for high-temperature applications is to overcome the limitations of current materials used in extreme environments. Traditional high-temperature materials, such as certain ceramics and superalloys, often struggle with issues like thermal expansion, oxidation resistance, and mechanical stability at elevated temperatures. Mg3N2 offers a unique combination of properties that address these challenges, including high melting point, low density, and excellent thermal stability.

One of the key drivers behind the renewed focus on Mg3N2 is the increasing demand for materials that can perform under extreme conditions in various industries. Aerospace, energy production, and advanced manufacturing sectors are constantly pushing the boundaries of material capabilities, seeking compounds that can maintain structural integrity and functionality at ever-higher temperatures. Mg3N2 has shown promise in meeting these demanding requirements, potentially revolutionizing the design of components for jet engines, gas turbines, and high-temperature reactors.

The technological trajectory of Mg3N2 research is aimed at fully understanding and optimizing its properties for practical applications. This includes investigating its behavior under different temperature ranges, exploring various synthesis methods to enhance its purity and performance, and developing composite materials that leverage Mg3N2's unique characteristics. Researchers are also focusing on improving its resistance to oxidation and hydrolysis, which are critical factors for its long-term stability in high-temperature environments.

As the field progresses, the objectives extend beyond mere material development to encompass the integration of Mg3N2 into existing manufacturing processes and the creation of new fabrication techniques. This holistic approach aims to bridge the gap between laboratory discoveries and industrial applications, ensuring that the innovative potential of Mg3N2 can be fully realized in real-world scenarios. The ultimate goal is to establish Mg3N2 as a versatile and reliable material for a wide range of high-temperature applications, potentially transforming multiple industries and enabling new technological advancements.

Market Demand Analysis

The market demand for high-temperature materials has been steadily increasing across various industries, driven by the need for more efficient and durable components in extreme environments. Magnesium nitride, as an innovative material in this sector, is poised to address several key market needs and potentially disrupt existing solutions.

In the aerospace industry, there is a growing demand for lightweight materials that can withstand high temperatures in jet engines and rocket propulsion systems. Magnesium nitride's unique combination of low density and high-temperature resistance makes it an attractive option for manufacturers looking to improve fuel efficiency and performance in aircraft and spacecraft.

The energy sector, particularly in power generation and oil and gas industries, requires materials that can maintain structural integrity under extreme heat and corrosive conditions. Magnesium nitride's potential applications in turbine components, heat exchangers, and protective coatings could significantly extend the lifespan of critical equipment and reduce maintenance costs.

In the automotive industry, the shift towards electric vehicles and more efficient internal combustion engines has created a need for materials that can handle higher operating temperatures. Magnesium nitride could find applications in brake systems, exhaust components, and engine parts, contributing to improved vehicle performance and durability.

The electronics industry is constantly pushing the boundaries of miniaturization and performance, leading to increased heat generation in devices. Magnesium nitride's thermal management properties could address the growing demand for more effective heat dissipation solutions in high-power electronics and semiconductor manufacturing.

Market analysts project that the global high-temperature materials market will continue to expand at a compound annual growth rate of over 6% in the coming years. This growth is largely attributed to the increasing industrialization in developing economies and the ongoing technological advancements in developed countries.

The potential market size for magnesium nitride-based products is substantial, considering its possible applications across multiple industries. However, the actual market penetration will depend on factors such as production scalability, cost-effectiveness, and the material's performance in real-world applications compared to existing solutions.

As environmental regulations become more stringent, there is also a growing demand for materials that can contribute to reduced emissions and improved energy efficiency. Magnesium nitride's potential to enhance the performance of catalytic converters and enable more efficient combustion processes aligns well with this market trend.

In the aerospace industry, there is a growing demand for lightweight materials that can withstand high temperatures in jet engines and rocket propulsion systems. Magnesium nitride's unique combination of low density and high-temperature resistance makes it an attractive option for manufacturers looking to improve fuel efficiency and performance in aircraft and spacecraft.

The energy sector, particularly in power generation and oil and gas industries, requires materials that can maintain structural integrity under extreme heat and corrosive conditions. Magnesium nitride's potential applications in turbine components, heat exchangers, and protective coatings could significantly extend the lifespan of critical equipment and reduce maintenance costs.

In the automotive industry, the shift towards electric vehicles and more efficient internal combustion engines has created a need for materials that can handle higher operating temperatures. Magnesium nitride could find applications in brake systems, exhaust components, and engine parts, contributing to improved vehicle performance and durability.

The electronics industry is constantly pushing the boundaries of miniaturization and performance, leading to increased heat generation in devices. Magnesium nitride's thermal management properties could address the growing demand for more effective heat dissipation solutions in high-power electronics and semiconductor manufacturing.

Market analysts project that the global high-temperature materials market will continue to expand at a compound annual growth rate of over 6% in the coming years. This growth is largely attributed to the increasing industrialization in developing economies and the ongoing technological advancements in developed countries.

The potential market size for magnesium nitride-based products is substantial, considering its possible applications across multiple industries. However, the actual market penetration will depend on factors such as production scalability, cost-effectiveness, and the material's performance in real-world applications compared to existing solutions.

As environmental regulations become more stringent, there is also a growing demand for materials that can contribute to reduced emissions and improved energy efficiency. Magnesium nitride's potential to enhance the performance of catalytic converters and enable more efficient combustion processes aligns well with this market trend.

Mg3N2 Tech Status & Challenges

Magnesium nitride (Mg3N2) has emerged as a promising material for high-temperature applications, yet its current technological status and challenges present a complex landscape. The development of Mg3N2 as a high-temperature material is still in its early stages, with significant research efforts focused on understanding its properties and potential applications.

One of the primary challenges in working with Mg3N2 is its high reactivity with moisture and air, which can lead to rapid degradation of the material. This reactivity necessitates careful handling and processing techniques, often requiring inert atmospheres or protective coatings. Researchers are actively exploring methods to enhance the stability of Mg3N2 in ambient conditions, which is crucial for its practical implementation in high-temperature applications.

The synthesis of high-quality Mg3N2 presents another significant challenge. Current production methods often result in materials with varying purity levels and inconsistent properties. Developing reliable and scalable synthesis techniques that can produce Mg3N2 with consistent quality and desired microstructures remains an active area of research. This is particularly important for ensuring the material's performance in demanding high-temperature environments.

Thermal stability is a critical factor in high-temperature materials, and Mg3N2 shows promise in this regard. However, further investigation is needed to fully understand its behavior at extreme temperatures, including its phase transitions, thermal expansion characteristics, and potential for sublimation or decomposition. Researchers are working to establish the upper temperature limits for Mg3N2 and to develop strategies for extending its thermal stability range.

The mechanical properties of Mg3N2 at elevated temperatures are another area of focus. While initial studies have shown promising strength and creep resistance, more comprehensive data is needed across a wide range of temperatures and stress conditions. Understanding and improving the material's ductility and fracture toughness at high temperatures are crucial for its application in structural components.

Integration of Mg3N2 into composite systems or as coatings presents both opportunities and challenges. Researchers are exploring ways to combine Mg3N2 with other materials to create composites with enhanced properties. However, issues such as thermal expansion mismatch and interfacial reactions need to be addressed to ensure the long-term stability and performance of these composite systems.

The development of processing techniques for Mg3N2-based materials is an ongoing challenge. Traditional ceramic processing methods may not be directly applicable due to the material's reactivity. Innovative approaches, such as spark plasma sintering or additive manufacturing techniques, are being investigated to fabricate complex shapes and structures while maintaining the material's desirable properties.

One of the primary challenges in working with Mg3N2 is its high reactivity with moisture and air, which can lead to rapid degradation of the material. This reactivity necessitates careful handling and processing techniques, often requiring inert atmospheres or protective coatings. Researchers are actively exploring methods to enhance the stability of Mg3N2 in ambient conditions, which is crucial for its practical implementation in high-temperature applications.

The synthesis of high-quality Mg3N2 presents another significant challenge. Current production methods often result in materials with varying purity levels and inconsistent properties. Developing reliable and scalable synthesis techniques that can produce Mg3N2 with consistent quality and desired microstructures remains an active area of research. This is particularly important for ensuring the material's performance in demanding high-temperature environments.

Thermal stability is a critical factor in high-temperature materials, and Mg3N2 shows promise in this regard. However, further investigation is needed to fully understand its behavior at extreme temperatures, including its phase transitions, thermal expansion characteristics, and potential for sublimation or decomposition. Researchers are working to establish the upper temperature limits for Mg3N2 and to develop strategies for extending its thermal stability range.

The mechanical properties of Mg3N2 at elevated temperatures are another area of focus. While initial studies have shown promising strength and creep resistance, more comprehensive data is needed across a wide range of temperatures and stress conditions. Understanding and improving the material's ductility and fracture toughness at high temperatures are crucial for its application in structural components.

Integration of Mg3N2 into composite systems or as coatings presents both opportunities and challenges. Researchers are exploring ways to combine Mg3N2 with other materials to create composites with enhanced properties. However, issues such as thermal expansion mismatch and interfacial reactions need to be addressed to ensure the long-term stability and performance of these composite systems.

The development of processing techniques for Mg3N2-based materials is an ongoing challenge. Traditional ceramic processing methods may not be directly applicable due to the material's reactivity. Innovative approaches, such as spark plasma sintering or additive manufacturing techniques, are being investigated to fabricate complex shapes and structures while maintaining the material's desirable properties.

Current Mg3N2 Applications

01 High-temperature resistance of magnesium nitride

Magnesium nitride exhibits excellent temperature resistance, making it suitable for applications in high-temperature environments. Its thermal stability allows it to maintain its structural integrity and properties at elevated temperatures, which is crucial for various industrial and technological applications.- High-temperature resistance of magnesium nitride: Magnesium nitride exhibits excellent temperature resistance, making it suitable for applications in high-temperature environments. Its thermal stability allows it to maintain its structural integrity and properties at elevated temperatures, which is crucial for various industrial and technological applications.

- Magnesium nitride in refractory materials: Magnesium nitride is utilized in the production of refractory materials due to its high-temperature resistance. These refractory materials are used in furnaces, kilns, and other high-temperature industrial equipment, where they can withstand extreme heat conditions without degradation.

- Magnesium nitride in semiconductor applications: The temperature resistance of magnesium nitride makes it valuable in semiconductor applications, particularly in the production of high-power and high-frequency electronic devices. Its thermal stability allows for improved device performance and reliability under high-temperature operating conditions.

- Magnesium nitride coatings for thermal protection: Magnesium nitride coatings are applied to various substrates to provide thermal protection. These coatings can withstand high temperatures and protect underlying materials from heat damage, making them useful in aerospace, automotive, and industrial applications.

- Magnesium nitride in energy storage and conversion devices: The temperature resistance of magnesium nitride is exploited in energy storage and conversion devices, such as batteries and fuel cells. Its thermal stability contributes to the safety and efficiency of these devices, particularly in high-temperature operating environments.

02 Magnesium nitride in refractory materials

Magnesium nitride is utilized in the production of refractory materials due to its high-temperature resistance. These refractory materials are used in furnaces, kilns, and other high-temperature industrial equipment, where they can withstand extreme heat without degradation or loss of performance.Expand Specific Solutions03 Magnesium nitride in semiconductor applications

The temperature resistance of magnesium nitride makes it valuable in semiconductor applications, particularly in the fabrication of high-power and high-temperature electronic devices. Its thermal stability allows for improved performance and reliability of semiconductor components operating in harsh environments.Expand Specific Solutions04 Magnesium nitride coatings for thermal protection

Magnesium nitride coatings are applied to various substrates to provide thermal protection. These coatings can withstand high temperatures and protect underlying materials from heat damage, making them useful in aerospace, automotive, and industrial applications where thermal management is critical.Expand Specific Solutions05 Magnesium nitride in energy storage and conversion devices

The temperature resistance of magnesium nitride is exploited in the development of energy storage and conversion devices, such as batteries and fuel cells. Its thermal stability contributes to the safety and efficiency of these devices, particularly in high-temperature operating conditions.Expand Specific Solutions

Key Players in Mg3N2 Research

The innovation of magnesium nitride in high-temperature materials is currently in an early development stage, with a growing market potential driven by increasing demand for advanced materials in various industries. The technology's maturity is still evolving, with key players like NGK Insulators, CeramTec GmbH, and Kyocera Corp. leading research and development efforts. These companies, along with academic institutions such as Wuhan University of Science & Technology and Chongqing University, are focusing on improving the material's properties and exploring new applications. The competitive landscape is characterized by a mix of established ceramic manufacturers and emerging research institutions, indicating a dynamic and collaborative environment for advancing magnesium nitride technology in high-temperature applications.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed innovative magnesium nitride-based materials for high-temperature applications. Their approach involves synthesizing Mg3N2 powders through a proprietary nitridation process, resulting in enhanced thermal stability and mechanical properties. The company has successfully incorporated these materials into their advanced ceramic products, particularly for use in extreme temperature environments. NGK's magnesium nitride composites demonstrate improved resistance to thermal shock and oxidation, making them suitable for applications in aerospace, energy, and industrial sectors [1][3]. The company has also explored doping strategies to further enhance the material's performance, such as adding rare earth elements to improve electrical conductivity at high temperatures [5].

Strengths: Proprietary synthesis process, enhanced thermal stability, and improved mechanical properties. Weaknesses: Potential high production costs and limited scalability for mass production.

CeramTec GmbH

Technical Solution: CeramTec GmbH has made significant strides in the development of magnesium nitride-based high-temperature materials. Their research focuses on creating advanced ceramic composites that incorporate Mg3N2 as a key component. The company has developed a unique sintering process that allows for the production of dense, high-strength magnesium nitride ceramics with improved thermal and chemical stability [2]. CeramTec's materials show exceptional resistance to thermal cycling and maintain their mechanical properties at temperatures exceeding 1000°C. They have successfully applied these materials in the production of high-temperature sensors, thermal insulation components, and specialized refractory products [4]. Additionally, CeramTec has explored the use of magnesium nitride as a precursor for the synthesis of other advanced ceramics, expanding its potential applications in various industries [6].

Strengths: Advanced sintering techniques, high-temperature stability, and diverse application potential. Weaknesses: Possible challenges in large-scale manufacturing and cost-effectiveness for certain applications.

Mg3N2 Core Patents & Literature

Improvements in or relating to processes for the manufacture of magnesium or alloys thereof

PatentInactiveGB464812A

Innovation

- A process involving heating magnesium nitride to 1500°C in the presence of substances like calcium carbide or silicide, which form nitrides with lower melting points, allowing for the separation and distillation of metallic magnesium in an inert atmosphere, preventing recombination with nitrogen.

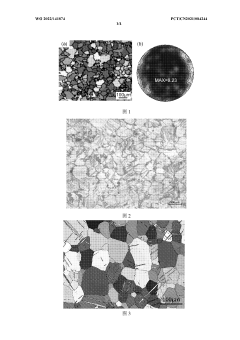

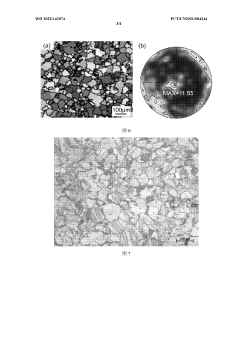

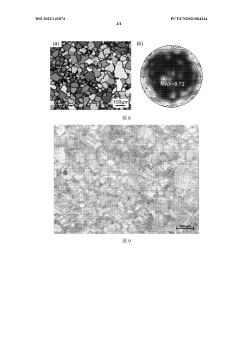

Processing method for improving high-temperature creep properties of magnesium alloy by means of rolling and pre-compression

PatentWO2022141874A1

Innovation

- Through rolling and pre-compression processing methods, the organizational structure of the magnesium alloy is controlled, and solid solution treatment and rolling processes are used to dissolve the Mg17Al12 phase into the matrix to form a preferentially oriented structure, and then pre-compression deformation with a small amount of deformation is performed to obtain a large number of twins , the dynamic precipitated phase is in a dispersed spherical shape, improving high temperature creep resistance.

Environmental Impact of Mg3N2

The environmental impact of magnesium nitride (Mg3N2) in high-temperature materials is a crucial aspect to consider as this compound gains prominence in innovative applications. Mg3N2 offers several environmental advantages compared to traditional high-temperature materials, particularly in terms of energy efficiency and reduced emissions.

One of the primary environmental benefits of Mg3N2 is its potential to improve energy efficiency in various industrial processes. When used in high-temperature applications, Mg3N2-based materials can withstand extreme conditions more effectively than conventional alternatives. This enhanced thermal stability allows for higher operating temperatures in industrial furnaces, engines, and other heat-intensive processes. As a result, these systems can achieve greater energy efficiency, leading to reduced fuel consumption and lower greenhouse gas emissions.

Furthermore, the production of Mg3N2 itself can be more environmentally friendly compared to some other high-temperature materials. The synthesis of Mg3N2 typically involves the direct reaction of magnesium with nitrogen gas, which is abundant in the atmosphere. This process can be less energy-intensive and produce fewer byproducts than the production of some ceramic or metal-based high-temperature materials.

In terms of lifecycle analysis, Mg3N2-based materials may offer advantages in recyclability and end-of-life disposal. Unlike some composite materials or alloys used in high-temperature applications, Mg3N2 can potentially be more easily recycled or repurposed. This characteristic could contribute to a more circular economy approach in industries relying on high-temperature materials.

However, it is essential to consider potential environmental challenges associated with Mg3N2. The compound is highly reactive with water, forming magnesium hydroxide and ammonia. This reactivity necessitates careful handling and storage to prevent unintended release into the environment. Proper safety measures and disposal protocols must be implemented to mitigate any risks of environmental contamination.

Additionally, the long-term environmental effects of Mg3N2 nanoparticles, which may be used in some advanced applications, require further study. As with many nanomaterials, there are concerns about potential impacts on ecosystems and human health if these particles are released into the environment.

In conclusion, while Mg3N2 shows promise in reducing the environmental footprint of high-temperature materials through improved energy efficiency and potentially cleaner production processes, it is crucial to balance these benefits against potential risks. Ongoing research and rigorous environmental assessments will be necessary to fully understand and optimize the environmental impact of Mg3N2 as it continues to innovate in the field of high-temperature materials.

One of the primary environmental benefits of Mg3N2 is its potential to improve energy efficiency in various industrial processes. When used in high-temperature applications, Mg3N2-based materials can withstand extreme conditions more effectively than conventional alternatives. This enhanced thermal stability allows for higher operating temperatures in industrial furnaces, engines, and other heat-intensive processes. As a result, these systems can achieve greater energy efficiency, leading to reduced fuel consumption and lower greenhouse gas emissions.

Furthermore, the production of Mg3N2 itself can be more environmentally friendly compared to some other high-temperature materials. The synthesis of Mg3N2 typically involves the direct reaction of magnesium with nitrogen gas, which is abundant in the atmosphere. This process can be less energy-intensive and produce fewer byproducts than the production of some ceramic or metal-based high-temperature materials.

In terms of lifecycle analysis, Mg3N2-based materials may offer advantages in recyclability and end-of-life disposal. Unlike some composite materials or alloys used in high-temperature applications, Mg3N2 can potentially be more easily recycled or repurposed. This characteristic could contribute to a more circular economy approach in industries relying on high-temperature materials.

However, it is essential to consider potential environmental challenges associated with Mg3N2. The compound is highly reactive with water, forming magnesium hydroxide and ammonia. This reactivity necessitates careful handling and storage to prevent unintended release into the environment. Proper safety measures and disposal protocols must be implemented to mitigate any risks of environmental contamination.

Additionally, the long-term environmental effects of Mg3N2 nanoparticles, which may be used in some advanced applications, require further study. As with many nanomaterials, there are concerns about potential impacts on ecosystems and human health if these particles are released into the environment.

In conclusion, while Mg3N2 shows promise in reducing the environmental footprint of high-temperature materials through improved energy efficiency and potentially cleaner production processes, it is crucial to balance these benefits against potential risks. Ongoing research and rigorous environmental assessments will be necessary to fully understand and optimize the environmental impact of Mg3N2 as it continues to innovate in the field of high-temperature materials.

Mg3N2 Manufacturing Processes

The manufacturing processes for magnesium nitride (Mg3N2) play a crucial role in its application as an innovative high-temperature material. Several methods have been developed to produce Mg3N2, each with its own advantages and challenges.

One of the most common production methods is the direct nitridation of magnesium metal. This process involves heating magnesium powder or ribbons in a nitrogen atmosphere at temperatures ranging from 300°C to 700°C. The reaction is exothermic and self-sustaining once initiated. However, careful control of temperature and nitrogen pressure is essential to prevent the formation of undesired byproducts and ensure complete conversion.

Another approach is the carbothermal reduction-nitridation method. In this process, magnesium oxide (MgO) is mixed with carbon and heated in a nitrogen atmosphere at temperatures above 1200°C. The carbon reduces the MgO to magnesium vapor, which then reacts with nitrogen to form Mg3N2. This method is particularly useful for producing high-purity Mg3N2 but requires precise control of the carbon-to-MgO ratio and reaction conditions.

Plasma-assisted synthesis has emerged as a promising technique for Mg3N2 production. This method utilizes a nitrogen plasma to create highly reactive nitrogen species, which can react with magnesium at lower temperatures compared to conventional thermal processes. Plasma-assisted synthesis offers the advantage of faster reaction rates and potentially higher purity products, but it requires specialized equipment and careful process optimization.

Solution-based methods have also been explored for Mg3N2 synthesis. These include the reaction of magnesium with ammonia in organic solvents or the decomposition of magnesium amides. While these methods can produce nanostructured Mg3N2 with unique properties, they often face challenges in scaling up for industrial production.

Recent advancements in manufacturing processes have focused on improving the quality and consistency of Mg3N2 production. Techniques such as controlled atmosphere ball milling and mechanochemical synthesis have been investigated to produce nanocrystalline Mg3N2 with enhanced reactivity and surface area. These methods offer the potential for more efficient production and tailored material properties.

The choice of manufacturing process significantly influences the properties and performance of the resulting Mg3N2. Factors such as particle size, morphology, and purity can vary depending on the synthesis method, impacting the material's behavior in high-temperature applications. As research in this field progresses, continuous refinement of existing methods and development of novel synthesis techniques are expected to further enhance the potential of Mg3N2 as an innovative high-temperature material.

One of the most common production methods is the direct nitridation of magnesium metal. This process involves heating magnesium powder or ribbons in a nitrogen atmosphere at temperatures ranging from 300°C to 700°C. The reaction is exothermic and self-sustaining once initiated. However, careful control of temperature and nitrogen pressure is essential to prevent the formation of undesired byproducts and ensure complete conversion.

Another approach is the carbothermal reduction-nitridation method. In this process, magnesium oxide (MgO) is mixed with carbon and heated in a nitrogen atmosphere at temperatures above 1200°C. The carbon reduces the MgO to magnesium vapor, which then reacts with nitrogen to form Mg3N2. This method is particularly useful for producing high-purity Mg3N2 but requires precise control of the carbon-to-MgO ratio and reaction conditions.

Plasma-assisted synthesis has emerged as a promising technique for Mg3N2 production. This method utilizes a nitrogen plasma to create highly reactive nitrogen species, which can react with magnesium at lower temperatures compared to conventional thermal processes. Plasma-assisted synthesis offers the advantage of faster reaction rates and potentially higher purity products, but it requires specialized equipment and careful process optimization.

Solution-based methods have also been explored for Mg3N2 synthesis. These include the reaction of magnesium with ammonia in organic solvents or the decomposition of magnesium amides. While these methods can produce nanostructured Mg3N2 with unique properties, they often face challenges in scaling up for industrial production.

Recent advancements in manufacturing processes have focused on improving the quality and consistency of Mg3N2 production. Techniques such as controlled atmosphere ball milling and mechanochemical synthesis have been investigated to produce nanocrystalline Mg3N2 with enhanced reactivity and surface area. These methods offer the potential for more efficient production and tailored material properties.

The choice of manufacturing process significantly influences the properties and performance of the resulting Mg3N2. Factors such as particle size, morphology, and purity can vary depending on the synthesis method, impacting the material's behavior in high-temperature applications. As research in this field progresses, continuous refinement of existing methods and development of novel synthesis techniques are expected to further enhance the potential of Mg3N2 as an innovative high-temperature material.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!