How Neopentane Solutions Address Complex Engineering Problems?

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Tech Overview

Neopentane, a branched alkane with the chemical formula C5H12, has emerged as a versatile solution in addressing complex engineering problems across various industries. This hydrocarbon compound, characterized by its unique molecular structure, offers a range of properties that make it particularly suitable for tackling challenging technical issues.

The molecular structure of neopentane consists of a central carbon atom bonded to four methyl groups, resulting in a highly symmetrical and compact arrangement. This configuration imparts several advantageous properties to neopentane, including low boiling point, high vapor pressure, and excellent thermal stability. These characteristics have led to its widespread adoption in applications ranging from refrigeration systems to chemical synthesis.

One of the key areas where neopentane solutions have proven effective is in thermal management systems. The compound's low boiling point and high vapor pressure make it an ideal working fluid in heat transfer applications, particularly in situations where rapid heat dissipation is crucial. This has led to its use in advanced cooling systems for electronic components, where efficient heat removal is essential for maintaining optimal performance and longevity.

In the field of chemical engineering, neopentane serves as a valuable precursor and intermediate in the synthesis of various organic compounds. Its unique structure allows for selective functionalization, enabling the creation of complex molecules with specific properties. This has found applications in the production of pharmaceuticals, polymers, and specialty chemicals, where precise control over molecular structure is paramount.

The aerospace industry has also benefited from neopentane solutions, particularly in the development of high-performance insulation materials. The compound's low thermal conductivity and stability at extreme temperatures make it an excellent choice for creating lightweight, efficient insulation systems for spacecraft and aircraft. This contributes to improved fuel efficiency and enhanced thermal protection in challenging environments.

Furthermore, neopentane has shown promise in the field of energy storage and conversion. Its properties make it suitable for use in certain types of batteries and fuel cells, where it can serve as an electrolyte or energy carrier. This opens up new possibilities for developing more efficient and environmentally friendly energy storage solutions, addressing the growing demand for sustainable power systems.

As research into neopentane and its applications continues, new and innovative solutions to complex engineering problems are likely to emerge. The compound's unique properties and versatility position it as a valuable tool in the arsenal of engineers and scientists working to overcome technical challenges across a wide range of industries.

The molecular structure of neopentane consists of a central carbon atom bonded to four methyl groups, resulting in a highly symmetrical and compact arrangement. This configuration imparts several advantageous properties to neopentane, including low boiling point, high vapor pressure, and excellent thermal stability. These characteristics have led to its widespread adoption in applications ranging from refrigeration systems to chemical synthesis.

One of the key areas where neopentane solutions have proven effective is in thermal management systems. The compound's low boiling point and high vapor pressure make it an ideal working fluid in heat transfer applications, particularly in situations where rapid heat dissipation is crucial. This has led to its use in advanced cooling systems for electronic components, where efficient heat removal is essential for maintaining optimal performance and longevity.

In the field of chemical engineering, neopentane serves as a valuable precursor and intermediate in the synthesis of various organic compounds. Its unique structure allows for selective functionalization, enabling the creation of complex molecules with specific properties. This has found applications in the production of pharmaceuticals, polymers, and specialty chemicals, where precise control over molecular structure is paramount.

The aerospace industry has also benefited from neopentane solutions, particularly in the development of high-performance insulation materials. The compound's low thermal conductivity and stability at extreme temperatures make it an excellent choice for creating lightweight, efficient insulation systems for spacecraft and aircraft. This contributes to improved fuel efficiency and enhanced thermal protection in challenging environments.

Furthermore, neopentane has shown promise in the field of energy storage and conversion. Its properties make it suitable for use in certain types of batteries and fuel cells, where it can serve as an electrolyte or energy carrier. This opens up new possibilities for developing more efficient and environmentally friendly energy storage solutions, addressing the growing demand for sustainable power systems.

As research into neopentane and its applications continues, new and innovative solutions to complex engineering problems are likely to emerge. The compound's unique properties and versatility position it as a valuable tool in the arsenal of engineers and scientists working to overcome technical challenges across a wide range of industries.

Engineering Challenges

Engineering challenges in the context of neopentane solutions encompass a wide range of complex problems that require innovative approaches and advanced technological solutions. These challenges often arise in various industries, including aerospace, automotive, chemical processing, and energy production, where traditional engineering methods may fall short.

One of the primary engineering challenges addressed by neopentane solutions is thermal management. In high-performance applications, such as rocket engines and advanced electronics, controlling heat dissipation is crucial for optimal performance and system longevity. Neopentane, with its unique thermodynamic properties, offers superior heat transfer capabilities compared to conventional coolants. This allows engineers to design more efficient cooling systems that can handle extreme temperature conditions while maintaining system stability.

Another significant challenge is the need for lightweight yet durable materials in aerospace and automotive industries. Neopentane-based composite materials provide an excellent balance of strength-to-weight ratio, making them ideal for applications where weight reduction is critical. These materials can withstand high stress and extreme environmental conditions, enabling the development of more fuel-efficient vehicles and spacecraft.

In the field of chemical processing, engineers face the challenge of improving reaction efficiency and selectivity. Neopentane solutions offer novel approaches to catalysis and reaction engineering. By utilizing neopentane as a solvent or reactant, engineers can design more efficient chemical processes with higher yields and reduced byproduct formation. This not only enhances productivity but also contributes to more sustainable manufacturing practices.

Energy storage and conversion represent another area where neopentane solutions address complex engineering problems. In the development of advanced batteries and fuel cells, neopentane-based electrolytes and membranes show promise in improving energy density, cycle life, and overall system performance. These advancements are crucial for the widespread adoption of electric vehicles and renewable energy systems.

Furthermore, neopentane solutions play a significant role in addressing environmental challenges. As industries strive to reduce their carbon footprint, engineers are exploring neopentane as a potential replacement for harmful refrigerants and propellants. Its low global warming potential and ozone depletion potential make it an attractive option for environmentally friendly cooling systems and aerosol applications.

In the realm of materials science, neopentane-based polymers and foams present innovative solutions to insulation and structural challenges. These materials offer exceptional thermal insulation properties while maintaining low density, making them ideal for applications in construction, aerospace, and cryogenic systems. The ability to tailor the properties of these materials allows engineers to address specific performance requirements in diverse applications.

One of the primary engineering challenges addressed by neopentane solutions is thermal management. In high-performance applications, such as rocket engines and advanced electronics, controlling heat dissipation is crucial for optimal performance and system longevity. Neopentane, with its unique thermodynamic properties, offers superior heat transfer capabilities compared to conventional coolants. This allows engineers to design more efficient cooling systems that can handle extreme temperature conditions while maintaining system stability.

Another significant challenge is the need for lightweight yet durable materials in aerospace and automotive industries. Neopentane-based composite materials provide an excellent balance of strength-to-weight ratio, making them ideal for applications where weight reduction is critical. These materials can withstand high stress and extreme environmental conditions, enabling the development of more fuel-efficient vehicles and spacecraft.

In the field of chemical processing, engineers face the challenge of improving reaction efficiency and selectivity. Neopentane solutions offer novel approaches to catalysis and reaction engineering. By utilizing neopentane as a solvent or reactant, engineers can design more efficient chemical processes with higher yields and reduced byproduct formation. This not only enhances productivity but also contributes to more sustainable manufacturing practices.

Energy storage and conversion represent another area where neopentane solutions address complex engineering problems. In the development of advanced batteries and fuel cells, neopentane-based electrolytes and membranes show promise in improving energy density, cycle life, and overall system performance. These advancements are crucial for the widespread adoption of electric vehicles and renewable energy systems.

Furthermore, neopentane solutions play a significant role in addressing environmental challenges. As industries strive to reduce their carbon footprint, engineers are exploring neopentane as a potential replacement for harmful refrigerants and propellants. Its low global warming potential and ozone depletion potential make it an attractive option for environmentally friendly cooling systems and aerosol applications.

In the realm of materials science, neopentane-based polymers and foams present innovative solutions to insulation and structural challenges. These materials offer exceptional thermal insulation properties while maintaining low density, making them ideal for applications in construction, aerospace, and cryogenic systems. The ability to tailor the properties of these materials allows engineers to address specific performance requirements in diverse applications.

Neopentane Properties

Neopentane, also known as 2,2-dimethylpropane, is a unique hydrocarbon compound with distinct properties that make it valuable in addressing complex engineering problems. This branched alkane has a molecular formula of C5H12 and a symmetrical tetrahedral structure, which contributes to its exceptional characteristics.

One of the most notable properties of neopentane is its low boiling point of 9.5°C (49.1°F), significantly lower than its straight-chain isomer, n-pentane. This low boiling point is attributed to its compact, spherical shape, which minimizes intermolecular forces. As a result, neopentane readily transitions from liquid to gas at near-ambient temperatures, making it ideal for applications requiring rapid phase changes or low-temperature operations.

Neopentane exhibits excellent thermal stability compared to other hydrocarbons of similar molecular weight. This stability is due to its highly branched structure, which resists thermal decomposition and oxidation. The compound maintains its integrity under high-temperature conditions, making it suitable for use in heat transfer systems and thermal management applications in extreme environments.

The compound's low viscosity and high compressibility are additional properties that contribute to its effectiveness in engineering solutions. These characteristics allow neopentane to flow easily through complex systems and respond quickly to pressure changes, enhancing its performance in hydraulic and pneumatic applications.

Neopentane's low surface tension is another valuable property, enabling it to wet surfaces effectively and penetrate small spaces. This feature is particularly useful in precision cleaning processes and as a propellant in aerosol formulations. The compound's ability to disperse easily also makes it an excellent candidate for use as a blowing agent in foam production and insulation materials.

From an environmental perspective, neopentane has a relatively low global warming potential compared to many other hydrocarbons and fluorinated compounds. This property makes it an attractive alternative in applications where environmental impact is a significant concern, such as in refrigeration systems and heat pumps.

The compound's unique molecular structure also results in interesting solvent properties. Neopentane is non-polar and has limited solubility in water but is miscible with many organic solvents. This selective solubility can be exploited in extraction processes and as a reaction medium for specific chemical syntheses.

In summary, neopentane's combination of low boiling point, high thermal stability, low viscosity, high compressibility, low surface tension, and environmentally friendly characteristics make it a versatile compound for addressing a wide range of complex engineering challenges across various industries.

One of the most notable properties of neopentane is its low boiling point of 9.5°C (49.1°F), significantly lower than its straight-chain isomer, n-pentane. This low boiling point is attributed to its compact, spherical shape, which minimizes intermolecular forces. As a result, neopentane readily transitions from liquid to gas at near-ambient temperatures, making it ideal for applications requiring rapid phase changes or low-temperature operations.

Neopentane exhibits excellent thermal stability compared to other hydrocarbons of similar molecular weight. This stability is due to its highly branched structure, which resists thermal decomposition and oxidation. The compound maintains its integrity under high-temperature conditions, making it suitable for use in heat transfer systems and thermal management applications in extreme environments.

The compound's low viscosity and high compressibility are additional properties that contribute to its effectiveness in engineering solutions. These characteristics allow neopentane to flow easily through complex systems and respond quickly to pressure changes, enhancing its performance in hydraulic and pneumatic applications.

Neopentane's low surface tension is another valuable property, enabling it to wet surfaces effectively and penetrate small spaces. This feature is particularly useful in precision cleaning processes and as a propellant in aerosol formulations. The compound's ability to disperse easily also makes it an excellent candidate for use as a blowing agent in foam production and insulation materials.

From an environmental perspective, neopentane has a relatively low global warming potential compared to many other hydrocarbons and fluorinated compounds. This property makes it an attractive alternative in applications where environmental impact is a significant concern, such as in refrigeration systems and heat pumps.

The compound's unique molecular structure also results in interesting solvent properties. Neopentane is non-polar and has limited solubility in water but is miscible with many organic solvents. This selective solubility can be exploited in extraction processes and as a reaction medium for specific chemical syntheses.

In summary, neopentane's combination of low boiling point, high thermal stability, low viscosity, high compressibility, low surface tension, and environmentally friendly characteristics make it a versatile compound for addressing a wide range of complex engineering challenges across various industries.

Current Applications

01 Neopentane as a solvent in chemical processes

Neopentane is utilized as a solvent in various chemical processes due to its unique properties. It can be used in reactions involving organic compounds, particularly in situations where a non-polar solvent with low boiling point is required. The use of neopentane as a solvent can enhance reaction efficiency and product yield in certain applications.- Neopentane as a solvent in chemical processes: Neopentane is utilized as a solvent in various chemical processes due to its unique properties. It is particularly useful in reactions involving organic compounds and can enhance the efficiency of certain chemical transformations. Its low boiling point and inert nature make it suitable for applications where a volatile, non-reactive solvent is required.

- Neopentane in refrigeration and cooling systems: Neopentane finds applications in refrigeration and cooling systems due to its thermodynamic properties. It can be used as a refrigerant or as part of a refrigerant mixture, offering advantages in terms of energy efficiency and environmental impact. The compound's low global warming potential makes it an attractive alternative to traditional refrigerants.

- Neopentane in foam production and insulation: Neopentane is employed in the production of foam materials, particularly for insulation purposes. Its low thermal conductivity and ability to form stable foam structures make it valuable in the manufacture of insulation products for construction and industrial applications. The compound's properties contribute to improved energy efficiency in buildings and other structures.

- Neopentane in fuel and energy applications: Neopentane has potential uses in fuel and energy-related applications. Its high energy density and clean-burning characteristics make it suitable for specialized fuel formulations. Additionally, it may be used in energy storage systems or as a component in certain types of batteries or fuel cells.

- Purification and separation processes involving neopentane: Neopentane is involved in various purification and separation processes in the chemical industry. Its unique physical properties, such as boiling point and molecular structure, make it useful in distillation, extraction, and other separation techniques. It can be used to isolate specific compounds or to purify mixtures in industrial-scale operations.

02 Neopentane in refrigeration and cooling systems

Neopentane finds applications in refrigeration and cooling systems due to its thermodynamic properties. It can be used as a refrigerant or as part of refrigerant mixtures, offering advantages such as low global warming potential and good energy efficiency. The use of neopentane in these systems can contribute to improved performance and environmental sustainability.Expand Specific Solutions03 Neopentane in foam production

Neopentane is employed as a blowing agent in the production of various types of foams, including insulation materials. Its low boiling point and gaseous nature at room temperature make it suitable for creating cellular structures in polymers. The use of neopentane in foam production can result in improved insulation properties and reduced environmental impact compared to some traditional blowing agents.Expand Specific Solutions04 Neopentane in separation and purification processes

Neopentane is utilized in separation and purification processes, particularly in the petrochemical industry. Its unique physical properties make it suitable for extractive distillation and other separation techniques. The use of neopentane in these processes can enhance the efficiency of separating complex mixtures and purifying specific compounds.Expand Specific Solutions05 Neopentane as a propellant and aerosol component

Neopentane is used as a propellant in aerosol formulations and as a component in pressurized systems. Its low boiling point and vapor pressure characteristics make it suitable for applications requiring controlled release of substances. The use of neopentane in these applications can provide advantages in terms of product performance and environmental considerations.Expand Specific Solutions

Key Industry Players

The neopentane solutions market is in a growth phase, driven by increasing demand for complex engineering problem-solving in industries like oil and gas, petrochemicals, and aerospace. The market size is expanding as more companies recognize the potential of neopentane-based technologies. While the technology is still evolving, major players like ExxonMobil Chemical, China Petroleum & Chemical Corp, and SINOPEC are investing heavily in research and development. These industry leaders, along with innovative companies like Boeing and Schott AG, are pushing the boundaries of neopentane applications, indicating a moderate level of technological maturity with significant room for advancement and market expansion.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil's neopentane solutions address complex engineering problems in the petrochemical industry through innovative process technologies. They have developed advanced catalysts and reactor designs that enable more efficient production of neopentane-based products. Their approach includes optimizing reaction conditions to maximize yield and selectivity, while minimizing energy consumption and waste generation. ExxonMobil has also implemented sophisticated process control systems that utilize real-time data analytics to maintain optimal operating conditions and quickly respond to process disturbances[1][3]. Additionally, they have developed novel separation techniques that improve the purity of neopentane products, enhancing their value for specialized applications in refrigerants, blowing agents, and aerosol propellants[2].

Strengths: Industry-leading expertise in petrochemical processes, extensive R&D capabilities, and global scale. Weaknesses: High capital investment requirements and potential environmental concerns associated with fossil fuel-based products.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) addresses complex engineering problems related to neopentane through integrated refining and petrochemical processes. Their approach focuses on maximizing the utilization of neopentane as a valuable intermediate in the production of high-performance materials. Sinopec has developed proprietary technologies for the efficient extraction and purification of neopentane from natural gas and refinery streams[4]. They have also implemented advanced process integration strategies that optimize energy efficiency and reduce carbon emissions in neopentane production. Sinopec's solutions include the use of membrane separation technologies and advanced distillation techniques to achieve high-purity neopentane products[5]. Furthermore, they have invested in research on neopentane-based polymer applications, exploring its potential in lightweight materials for automotive and aerospace industries.

Strengths: Vertically integrated operations, strong domestic market position, and government support for technological innovation. Weaknesses: Relatively less international presence compared to global majors and potential geopolitical risks.

Innovative Approaches

Processes to Make Neopentane Using Shell and Tube Reactors

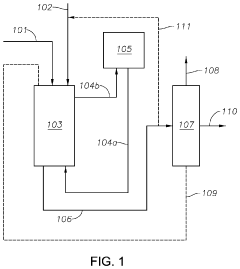

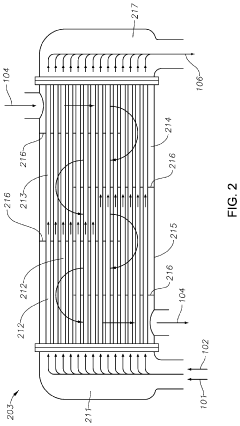

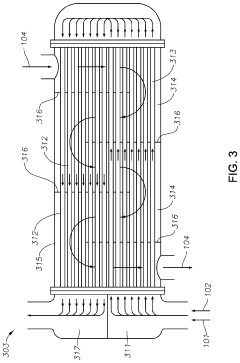

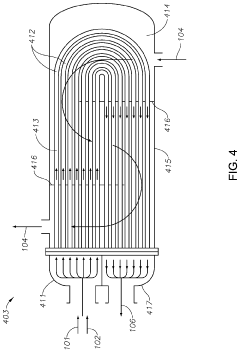

PatentActiveUS20190367429A1

Innovation

- The process involves demethylating C6-C8 alkanes in a shell and tube reactor to produce neopentane, utilizing a catalyst and controlling temperature to achieve high conversion and purity, with a shell and tube reactor design that includes a heat-exchange system to manage the exothermic nature of the reaction.

Environmental Impact

Neopentane solutions have emerged as a promising approach to address complex engineering problems, but their environmental impact requires careful consideration. These solutions, while offering innovative ways to tackle intricate technical challenges, also present potential environmental concerns that must be thoroughly evaluated and mitigated.

One of the primary environmental considerations associated with neopentane solutions is their contribution to greenhouse gas emissions. Neopentane, a hydrocarbon compound, has a global warming potential significantly higher than carbon dioxide. When used in industrial processes or released into the atmosphere, it can contribute to climate change. Therefore, implementing robust containment and recovery systems is crucial to minimize unintended emissions and reduce the overall carbon footprint of neopentane-based engineering solutions.

Water pollution is another environmental aspect that demands attention when utilizing neopentane solutions. The compound's low water solubility can lead to the formation of separate phases in aquatic environments, potentially impacting marine ecosystems. Proper handling, storage, and disposal protocols must be established to prevent accidental spills or leaks that could contaminate water sources.

Air quality is also a concern, as neopentane can contribute to the formation of ground-level ozone and smog when released into the atmosphere. This can have adverse effects on human health and vegetation in affected areas. Implementing advanced air pollution control technologies and monitoring systems is essential to mitigate these risks and ensure compliance with air quality regulations.

The production and use of neopentane solutions may also have implications for biodiversity and ecosystem health. The extraction of raw materials, manufacturing processes, and potential habitat disruption during implementation of engineering solutions must be carefully managed to minimize negative impacts on local flora and fauna.

However, it is important to note that neopentane solutions can also offer environmental benefits in certain applications. For instance, when used as a blowing agent in foam insulation, neopentane can contribute to improved energy efficiency in buildings, potentially reducing overall energy consumption and associated carbon emissions.

To address these environmental concerns, a comprehensive life cycle assessment of neopentane-based engineering solutions is crucial. This assessment should consider the entire process from raw material extraction to end-of-life disposal, identifying opportunities for optimization and environmental impact reduction. Additionally, investing in research and development of more environmentally friendly alternatives or improved containment technologies can help mitigate the potential negative impacts of neopentane solutions.

One of the primary environmental considerations associated with neopentane solutions is their contribution to greenhouse gas emissions. Neopentane, a hydrocarbon compound, has a global warming potential significantly higher than carbon dioxide. When used in industrial processes or released into the atmosphere, it can contribute to climate change. Therefore, implementing robust containment and recovery systems is crucial to minimize unintended emissions and reduce the overall carbon footprint of neopentane-based engineering solutions.

Water pollution is another environmental aspect that demands attention when utilizing neopentane solutions. The compound's low water solubility can lead to the formation of separate phases in aquatic environments, potentially impacting marine ecosystems. Proper handling, storage, and disposal protocols must be established to prevent accidental spills or leaks that could contaminate water sources.

Air quality is also a concern, as neopentane can contribute to the formation of ground-level ozone and smog when released into the atmosphere. This can have adverse effects on human health and vegetation in affected areas. Implementing advanced air pollution control technologies and monitoring systems is essential to mitigate these risks and ensure compliance with air quality regulations.

The production and use of neopentane solutions may also have implications for biodiversity and ecosystem health. The extraction of raw materials, manufacturing processes, and potential habitat disruption during implementation of engineering solutions must be carefully managed to minimize negative impacts on local flora and fauna.

However, it is important to note that neopentane solutions can also offer environmental benefits in certain applications. For instance, when used as a blowing agent in foam insulation, neopentane can contribute to improved energy efficiency in buildings, potentially reducing overall energy consumption and associated carbon emissions.

To address these environmental concerns, a comprehensive life cycle assessment of neopentane-based engineering solutions is crucial. This assessment should consider the entire process from raw material extraction to end-of-life disposal, identifying opportunities for optimization and environmental impact reduction. Additionally, investing in research and development of more environmentally friendly alternatives or improved containment technologies can help mitigate the potential negative impacts of neopentane solutions.

Safety Considerations

Safety considerations are paramount when working with neopentane solutions in complex engineering problems. Due to the volatile nature of neopentane, strict safety protocols must be implemented to mitigate potential risks. Proper handling and storage of neopentane solutions require specialized equipment and facilities designed to prevent leaks, spills, and accidental ignition.

Personal protective equipment (PPE) is essential for workers handling neopentane solutions. This includes chemical-resistant gloves, safety goggles, and flame-resistant clothing. Adequate ventilation systems must be in place to prevent the accumulation of neopentane vapors, which can create explosive atmospheres in confined spaces.

Fire safety is a critical concern when working with neopentane solutions. The use of explosion-proof electrical equipment and grounding systems is necessary to prevent static electricity buildup and potential ignition sources. Fire suppression systems specifically designed for flammable liquids should be installed in areas where neopentane solutions are used or stored.

Environmental considerations are also crucial when dealing with neopentane solutions. Proper disposal methods must be employed to prevent contamination of soil and water sources. Spill containment systems and emergency response plans should be in place to quickly address any accidental releases.

Regular safety training and drills are essential for personnel working with neopentane solutions. This includes education on the properties of neopentane, proper handling techniques, and emergency procedures. Continuous monitoring of work areas for neopentane vapor concentrations is necessary to ensure a safe working environment.

Risk assessments should be conducted regularly to identify potential hazards associated with the use of neopentane solutions in specific engineering applications. This includes evaluating the compatibility of neopentane with other materials and chemicals used in the process, as well as assessing the potential for equipment failure or human error.

Compliance with local, national, and international safety regulations is mandatory when working with neopentane solutions. This includes adherence to guidelines set by organizations such as OSHA, EPA, and NFPA. Regular safety audits and inspections should be conducted to ensure ongoing compliance and identify areas for improvement in safety protocols.

In conclusion, while neopentane solutions offer significant benefits in addressing complex engineering problems, their use requires a comprehensive approach to safety management. By implementing robust safety measures and fostering a culture of safety awareness, organizations can harness the potential of neopentane solutions while minimizing associated risks.

Personal protective equipment (PPE) is essential for workers handling neopentane solutions. This includes chemical-resistant gloves, safety goggles, and flame-resistant clothing. Adequate ventilation systems must be in place to prevent the accumulation of neopentane vapors, which can create explosive atmospheres in confined spaces.

Fire safety is a critical concern when working with neopentane solutions. The use of explosion-proof electrical equipment and grounding systems is necessary to prevent static electricity buildup and potential ignition sources. Fire suppression systems specifically designed for flammable liquids should be installed in areas where neopentane solutions are used or stored.

Environmental considerations are also crucial when dealing with neopentane solutions. Proper disposal methods must be employed to prevent contamination of soil and water sources. Spill containment systems and emergency response plans should be in place to quickly address any accidental releases.

Regular safety training and drills are essential for personnel working with neopentane solutions. This includes education on the properties of neopentane, proper handling techniques, and emergency procedures. Continuous monitoring of work areas for neopentane vapor concentrations is necessary to ensure a safe working environment.

Risk assessments should be conducted regularly to identify potential hazards associated with the use of neopentane solutions in specific engineering applications. This includes evaluating the compatibility of neopentane with other materials and chemicals used in the process, as well as assessing the potential for equipment failure or human error.

Compliance with local, national, and international safety regulations is mandatory when working with neopentane solutions. This includes adherence to guidelines set by organizations such as OSHA, EPA, and NFPA. Regular safety audits and inspections should be conducted to ensure ongoing compliance and identify areas for improvement in safety protocols.

In conclusion, while neopentane solutions offer significant benefits in addressing complex engineering problems, their use requires a comprehensive approach to safety management. By implementing robust safety measures and fostering a culture of safety awareness, organizations can harness the potential of neopentane solutions while minimizing associated risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!