How Polypropylene Optimizes Gas Barrier Coatings

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PP Gas Barrier Evolution

The evolution of polypropylene (PP) as a gas barrier coating has been marked by significant advancements in material science and polymer technology. Initially, PP was primarily used for its mechanical properties and chemical resistance. However, its potential as a gas barrier material was recognized in the late 1970s, leading to extensive research and development efforts.

In the 1980s, the focus shifted towards enhancing PP's inherent barrier properties. Scientists discovered that by manipulating the polymer's crystalline structure, they could significantly improve its resistance to gas permeation. This led to the development of high-crystallinity PP grades, which exhibited improved barrier properties compared to conventional PP.

The 1990s saw the introduction of multilayer PP films, where different types of PP were combined to create synergistic barrier effects. This approach allowed for the optimization of both mechanical and barrier properties, making PP a viable option for packaging applications that required moderate gas barrier performance.

A major breakthrough came in the early 2000s with the development of nanocomposite PP materials. By incorporating nanoscale particles, such as clay or graphene, into the PP matrix, researchers were able to create tortuous paths for gas molecules, significantly enhancing the barrier properties. This technology opened up new possibilities for PP in high-performance barrier applications.

The late 2000s and early 2010s witnessed the emergence of surface modification techniques for PP. Plasma treatment and chemical grafting methods were developed to alter the surface properties of PP films, improving their compatibility with other barrier materials and enhancing overall barrier performance.

In recent years, the focus has shifted towards sustainable and bio-based solutions. Researchers have been exploring the use of bio-derived additives and fillers to enhance PP's barrier properties while reducing its environmental impact. Additionally, advances in polymer blending and compatibilization techniques have allowed for the creation of PP-based barrier materials with improved recyclability.

The latest frontier in PP gas barrier evolution involves the development of active and intelligent barrier systems. These innovative coatings incorporate reactive components or sensors that can actively respond to environmental changes or detect gas permeation, providing enhanced protection and monitoring capabilities.

Throughout its evolution, PP has consistently demonstrated its versatility and adaptability as a gas barrier material. From simple homopolymers to complex nanocomposites and smart coatings, PP continues to play a crucial role in the development of advanced gas barrier solutions across various industries.

In the 1980s, the focus shifted towards enhancing PP's inherent barrier properties. Scientists discovered that by manipulating the polymer's crystalline structure, they could significantly improve its resistance to gas permeation. This led to the development of high-crystallinity PP grades, which exhibited improved barrier properties compared to conventional PP.

The 1990s saw the introduction of multilayer PP films, where different types of PP were combined to create synergistic barrier effects. This approach allowed for the optimization of both mechanical and barrier properties, making PP a viable option for packaging applications that required moderate gas barrier performance.

A major breakthrough came in the early 2000s with the development of nanocomposite PP materials. By incorporating nanoscale particles, such as clay or graphene, into the PP matrix, researchers were able to create tortuous paths for gas molecules, significantly enhancing the barrier properties. This technology opened up new possibilities for PP in high-performance barrier applications.

The late 2000s and early 2010s witnessed the emergence of surface modification techniques for PP. Plasma treatment and chemical grafting methods were developed to alter the surface properties of PP films, improving their compatibility with other barrier materials and enhancing overall barrier performance.

In recent years, the focus has shifted towards sustainable and bio-based solutions. Researchers have been exploring the use of bio-derived additives and fillers to enhance PP's barrier properties while reducing its environmental impact. Additionally, advances in polymer blending and compatibilization techniques have allowed for the creation of PP-based barrier materials with improved recyclability.

The latest frontier in PP gas barrier evolution involves the development of active and intelligent barrier systems. These innovative coatings incorporate reactive components or sensors that can actively respond to environmental changes or detect gas permeation, providing enhanced protection and monitoring capabilities.

Throughout its evolution, PP has consistently demonstrated its versatility and adaptability as a gas barrier material. From simple homopolymers to complex nanocomposites and smart coatings, PP continues to play a crucial role in the development of advanced gas barrier solutions across various industries.

Market Demand Analysis

The market demand for gas barrier coatings optimized with polypropylene has been steadily increasing across various industries. This growth is primarily driven by the packaging sector, where the need for extended shelf life and improved product protection is paramount. The food and beverage industry, in particular, has shown a significant uptake in polypropylene-enhanced gas barrier coatings due to their ability to preserve freshness and prevent contamination.

In the automotive and electronics sectors, there is a growing demand for lightweight, durable materials that can protect sensitive components from moisture and gas penetration. Polypropylene-optimized gas barrier coatings offer an effective solution, contributing to the overall performance and longevity of products in these industries.

The pharmaceutical industry has also recognized the potential of these coatings, particularly in drug packaging and medical device protection. The ability to maintain sterile conditions and prevent gas exchange is crucial in this field, driving the adoption of advanced barrier technologies.

Environmental concerns and sustainability initiatives have further boosted the market for polypropylene-optimized gas barrier coatings. As companies seek to reduce their carbon footprint and improve recyclability, these coatings offer a more eco-friendly alternative to traditional barrier materials.

The Asia-Pacific region has emerged as a key growth market for gas barrier coatings, fueled by rapid industrialization and increasing consumer demand for packaged goods. North America and Europe continue to be significant markets, with a focus on high-performance applications in aerospace and defense industries.

Market analysts project a compound annual growth rate for the gas barrier coatings market, with polypropylene-optimized solutions playing a crucial role in this expansion. The demand is expected to be particularly strong in flexible packaging applications, where the combination of barrier properties and material flexibility is highly valued.

Technological advancements in coating formulations and application methods are anticipated to further drive market growth. Innovations in nanotechnology and polymer science are opening new possibilities for enhancing the performance of polypropylene-based gas barrier coatings, potentially expanding their application into new industries and markets.

As consumer awareness of food safety and product quality increases, manufacturers are likely to invest more in advanced packaging solutions, including those utilizing polypropylene-optimized gas barrier coatings. This trend is expected to contribute significantly to market expansion in the coming years.

In the automotive and electronics sectors, there is a growing demand for lightweight, durable materials that can protect sensitive components from moisture and gas penetration. Polypropylene-optimized gas barrier coatings offer an effective solution, contributing to the overall performance and longevity of products in these industries.

The pharmaceutical industry has also recognized the potential of these coatings, particularly in drug packaging and medical device protection. The ability to maintain sterile conditions and prevent gas exchange is crucial in this field, driving the adoption of advanced barrier technologies.

Environmental concerns and sustainability initiatives have further boosted the market for polypropylene-optimized gas barrier coatings. As companies seek to reduce their carbon footprint and improve recyclability, these coatings offer a more eco-friendly alternative to traditional barrier materials.

The Asia-Pacific region has emerged as a key growth market for gas barrier coatings, fueled by rapid industrialization and increasing consumer demand for packaged goods. North America and Europe continue to be significant markets, with a focus on high-performance applications in aerospace and defense industries.

Market analysts project a compound annual growth rate for the gas barrier coatings market, with polypropylene-optimized solutions playing a crucial role in this expansion. The demand is expected to be particularly strong in flexible packaging applications, where the combination of barrier properties and material flexibility is highly valued.

Technological advancements in coating formulations and application methods are anticipated to further drive market growth. Innovations in nanotechnology and polymer science are opening new possibilities for enhancing the performance of polypropylene-based gas barrier coatings, potentially expanding their application into new industries and markets.

As consumer awareness of food safety and product quality increases, manufacturers are likely to invest more in advanced packaging solutions, including those utilizing polypropylene-optimized gas barrier coatings. This trend is expected to contribute significantly to market expansion in the coming years.

Technical Challenges

The development of polypropylene-based gas barrier coatings faces several technical challenges that researchers and manufacturers must overcome to optimize their performance. One of the primary obstacles is achieving a balance between barrier properties and other essential characteristics such as flexibility, transparency, and cost-effectiveness. Polypropylene, while offering excellent moisture resistance, inherently lacks sufficient gas barrier properties, particularly against oxygen and carbon dioxide.

A significant challenge lies in enhancing the gas barrier properties of polypropylene without compromising its inherent advantages. This often requires the incorporation of additional materials or the modification of the polymer structure, which can lead to complexities in processing and increased production costs. The development of effective dispersion techniques for nanomaterials, such as clay platelets or graphene oxide, within the polypropylene matrix is crucial for improving gas barrier properties but remains technically demanding.

Another technical hurdle is the adhesion of polypropylene-based coatings to various substrates. The low surface energy of polypropylene can result in poor adhesion, necessitating the use of adhesion promoters or surface treatments. However, these additional steps can complicate the manufacturing process and potentially affect the overall barrier performance.

The stability of polypropylene-based gas barrier coatings under various environmental conditions poses another challenge. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can degrade the coating's performance over time. Developing formulations that maintain their barrier properties under diverse and demanding conditions is essential for widespread application but requires extensive research and testing.

Scalability and consistency in production represent additional technical challenges. Translating laboratory-scale successes to industrial-scale manufacturing while maintaining uniform coating thickness and performance across large surface areas is complex. This often necessitates the development of specialized equipment and precise control over processing parameters.

Furthermore, the recyclability and environmental impact of polypropylene-based gas barrier coatings are growing concerns. Creating coatings that are both high-performing and easily recyclable or biodegradable is a significant technical challenge, as these properties are often at odds with each other. Balancing environmental sustainability with functional requirements adds another layer of complexity to the optimization process.

Lastly, the integration of polypropylene-based gas barrier coatings into smart packaging solutions presents new technical challenges. Developing coatings that can incorporate sensors or indicators while maintaining their barrier properties requires innovative approaches and multidisciplinary expertise. This emerging area of research opens up new possibilities but also introduces additional complexities in material design and manufacturing processes.

A significant challenge lies in enhancing the gas barrier properties of polypropylene without compromising its inherent advantages. This often requires the incorporation of additional materials or the modification of the polymer structure, which can lead to complexities in processing and increased production costs. The development of effective dispersion techniques for nanomaterials, such as clay platelets or graphene oxide, within the polypropylene matrix is crucial for improving gas barrier properties but remains technically demanding.

Another technical hurdle is the adhesion of polypropylene-based coatings to various substrates. The low surface energy of polypropylene can result in poor adhesion, necessitating the use of adhesion promoters or surface treatments. However, these additional steps can complicate the manufacturing process and potentially affect the overall barrier performance.

The stability of polypropylene-based gas barrier coatings under various environmental conditions poses another challenge. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can degrade the coating's performance over time. Developing formulations that maintain their barrier properties under diverse and demanding conditions is essential for widespread application but requires extensive research and testing.

Scalability and consistency in production represent additional technical challenges. Translating laboratory-scale successes to industrial-scale manufacturing while maintaining uniform coating thickness and performance across large surface areas is complex. This often necessitates the development of specialized equipment and precise control over processing parameters.

Furthermore, the recyclability and environmental impact of polypropylene-based gas barrier coatings are growing concerns. Creating coatings that are both high-performing and easily recyclable or biodegradable is a significant technical challenge, as these properties are often at odds with each other. Balancing environmental sustainability with functional requirements adds another layer of complexity to the optimization process.

Lastly, the integration of polypropylene-based gas barrier coatings into smart packaging solutions presents new technical challenges. Developing coatings that can incorporate sensors or indicators while maintaining their barrier properties requires innovative approaches and multidisciplinary expertise. This emerging area of research opens up new possibilities but also introduces additional complexities in material design and manufacturing processes.

Current PP Solutions

01 Multilayer polypropylene films with gas barrier properties

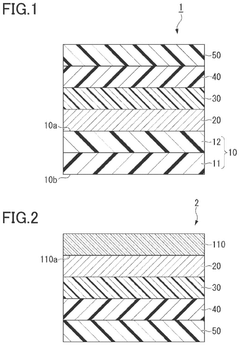

Multilayer films incorporating polypropylene and gas barrier layers are developed to enhance gas barrier properties. These films often include additional layers such as adhesive layers or tie layers to improve bonding between different materials. The combination of polypropylene with barrier materials like EVOH or nylon results in films with improved gas barrier performance for various packaging applications.- Multilayer polypropylene films with gas barrier properties: Multilayer polypropylene films are developed to enhance gas barrier properties. These films typically consist of a polypropylene base layer combined with one or more barrier layers made of materials such as ethylene vinyl alcohol (EVOH) or polyamide. The multilayer structure helps to reduce gas permeation, making the films suitable for packaging applications requiring extended shelf life.

- Incorporation of nanoparticles for improved gas barrier: Nanoparticles, such as clay or graphene, are incorporated into polypropylene matrices to enhance gas barrier properties. These nanoparticles create a tortuous path for gas molecules, effectively reducing permeability. The nanocomposite materials show improved barrier performance while maintaining the desirable properties of polypropylene.

- Surface treatment and coating techniques: Various surface treatment and coating techniques are employed to improve the gas barrier properties of polypropylene. These methods include plasma treatment, chemical modification, and application of barrier coatings such as metal oxides or specialized polymers. These treatments enhance the surface properties of polypropylene, reducing gas permeation.

- Blending with other polymers for enhanced barrier properties: Polypropylene is blended with other polymers to create materials with improved gas barrier characteristics. Common blend partners include polyethylene, polyamides, or barrier resins. These polymer blends combine the desirable properties of polypropylene with the enhanced gas barrier performance of the added polymers.

- Orientation and crystallinity control for gas barrier improvement: The gas barrier properties of polypropylene are enhanced through controlled orientation and crystallinity. Techniques such as biaxial orientation and annealing are used to manipulate the polymer structure, resulting in improved barrier performance. These processes create a more ordered structure that reduces gas permeation through the material.

02 Surface treatment of polypropylene for improved gas barrier

Various surface treatment methods are applied to polypropylene films to enhance their gas barrier properties. These treatments may include plasma treatment, corona discharge, or chemical modifications. Such treatments can improve the adhesion of barrier coatings or modify the surface structure of polypropylene to reduce gas permeability.Expand Specific Solutions03 Nanocomposite polypropylene materials for gas barrier

Nanocomposite materials incorporating polypropylene and nanoparticles are developed to enhance gas barrier properties. These nanocomposites often use clay nanoparticles or other nanomaterials to create tortuous paths for gas molecules, thereby reducing gas permeation through the polymer matrix.Expand Specific Solutions04 Blending polypropylene with other polymers for improved gas barrier

Polymer blends incorporating polypropylene and other polymers with good gas barrier properties are developed. These blends may include materials such as polyamides, ethylene vinyl alcohol copolymers, or other barrier polymers. The resulting materials combine the desirable properties of polypropylene with enhanced gas barrier performance.Expand Specific Solutions05 Coating technologies for polypropylene gas barrier enhancement

Various coating technologies are applied to polypropylene substrates to improve gas barrier properties. These may include vacuum deposition of inorganic materials, application of barrier polymer coatings, or use of hybrid organic-inorganic coatings. Such coatings can significantly reduce gas permeation through polypropylene-based materials.Expand Specific Solutions

Industry Leaders

The market for polypropylene gas barrier coatings is in a growth phase, driven by increasing demand for high-performance packaging solutions across various industries. The global market size is expanding, with projections indicating continued growth due to rising applications in food, pharmaceuticals, and electronics sectors. Technologically, the field is advancing rapidly, with companies like TOPPAN, Inc., Mitsui Chemicals, Inc., and Toyobo Co., Ltd. leading innovation in barrier properties and coating techniques. These firms, along with others like Kureha Corp. and DIC Corp., are investing heavily in R&D to enhance coating performance, sustainability, and cost-effectiveness. The competitive landscape is characterized by a mix of established chemical conglomerates and specialized materials companies, all vying to develop superior gas barrier solutions.

TOPPAN, Inc.

Technical Solution: TOPPAN has developed a proprietary GL BARRIER technology for polypropylene gas barrier coatings. This technology utilizes a transparent vapor-deposited film that combines polymer and inorganic layers to achieve high gas barrier performance. The coating process involves depositing alternating layers of inorganic material (typically silicon oxide) and organic material onto a polypropylene substrate. This multi-layer structure creates a tortuous path for gas molecules, significantly reducing permeability[1]. TOPPAN's GL BARRIER films can achieve oxygen transmission rates as low as 0.1 cc/m²/day and water vapor transmission rates below 0.1 g/m²/day[2], making them suitable for food packaging and other applications requiring high barrier properties.

Strengths: Excellent gas barrier properties, transparency, and flexibility. Suitable for various packaging applications. Weaknesses: May require specialized equipment for coating application, potentially higher cost compared to standard polypropylene films.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced polypropylene resins with enhanced gas barrier properties. Their approach involves the incorporation of nanocomposites into the polypropylene matrix. By dispersing nanoscale clay particles or other nanofillers throughout the polymer, they create a more tortuous path for gas molecules to penetrate[3]. This nanocomposite technology can improve oxygen barrier properties by up to 40% compared to standard polypropylene[4]. Sinopec has also explored the use of metallocene catalysts to produce polypropylene with more controlled molecular weight distribution and improved barrier properties. Their research indicates that these metallocene-catalyzed polypropylenes can achieve up to 25% reduction in oxygen transmission rates when used in packaging applications[5].

Strengths: Improved barrier properties without the need for additional coating layers, potentially more cost-effective for large-scale production. Weaknesses: May affect the transparency of the material, potential challenges in achieving uniform nanofiller dispersion.

Key PP Innovations

Gas barrier film

PatentActiveUS12269240B2

Innovation

- A gas barrier film comprising a substrate with polypropylene as the main component, a gas barrier layer formed on one surface, and a coating layer on top, where the infrared spectroscopy of the first surface indicates specific peak intensities in a ratio satisfying a particular formula, enhancing the film's resistance to hot-water treatment.

Gas barrier coatings

PatentActiveEP2501765A1

Innovation

- A gas barrier coating composition is developed by mixing a solution or dispersion of polyvinyl alcohol (PVOH) and/or ethylene vinyl alcohol (EVOH) copolymer with a polycarboxylic acid polymer and a well-dispersed clay dispersion, which is then applied to a flexible polymer film, eliminating the need for additional primer layers and enhancing both gas barrier performance and laminate bond strength at high humidity.

Environmental Impact

The environmental impact of polypropylene-based gas barrier coatings is a crucial consideration in their development and application. These coatings offer significant advantages in terms of reducing food waste and extending product shelf life, which indirectly contributes to environmental conservation. By effectively preventing gas permeation, these coatings help maintain the quality and freshness of packaged goods, thereby reducing the need for preservatives and minimizing food spoilage.

However, the production and disposal of polypropylene coatings also present environmental challenges. The manufacturing process of polypropylene involves the use of fossil fuels and energy-intensive procedures, contributing to greenhouse gas emissions. Additionally, the non-biodegradable nature of polypropylene raises concerns about its long-term environmental persistence and potential accumulation in ecosystems.

Efforts to mitigate these environmental impacts have led to the development of more sustainable approaches in polypropylene coating technology. One such approach is the incorporation of bio-based additives or fillers into the polypropylene matrix, which can enhance biodegradability without compromising barrier properties. Research has also focused on improving the recyclability of polypropylene coatings, exploring methods to separate and recover the coating material from the substrate for reuse.

The optimization of polypropylene gas barrier coatings has also led to advancements in thin-film technology, allowing for the use of less material while maintaining or even improving barrier performance. This reduction in material usage not only decreases the environmental footprint of production but also facilitates easier recycling and disposal processes.

Furthermore, the development of multi-layer coating systems that combine polypropylene with other materials has shown promise in enhancing overall sustainability. These systems can optimize the use of each material, potentially reducing the total environmental impact while maintaining or improving barrier properties. Research into the use of nanotechnology in polypropylene coatings has also demonstrated potential for improving barrier properties with minimal material use, further contributing to environmental sustainability.

As regulations and consumer awareness regarding environmental issues continue to grow, the industry is increasingly focusing on life cycle assessments of polypropylene gas barrier coatings. These assessments consider the environmental impact from raw material extraction through production, use, and disposal, providing a comprehensive view of the coating's ecological footprint. This holistic approach is driving innovation towards more environmentally friendly solutions in gas barrier coating technology.

However, the production and disposal of polypropylene coatings also present environmental challenges. The manufacturing process of polypropylene involves the use of fossil fuels and energy-intensive procedures, contributing to greenhouse gas emissions. Additionally, the non-biodegradable nature of polypropylene raises concerns about its long-term environmental persistence and potential accumulation in ecosystems.

Efforts to mitigate these environmental impacts have led to the development of more sustainable approaches in polypropylene coating technology. One such approach is the incorporation of bio-based additives or fillers into the polypropylene matrix, which can enhance biodegradability without compromising barrier properties. Research has also focused on improving the recyclability of polypropylene coatings, exploring methods to separate and recover the coating material from the substrate for reuse.

The optimization of polypropylene gas barrier coatings has also led to advancements in thin-film technology, allowing for the use of less material while maintaining or even improving barrier performance. This reduction in material usage not only decreases the environmental footprint of production but also facilitates easier recycling and disposal processes.

Furthermore, the development of multi-layer coating systems that combine polypropylene with other materials has shown promise in enhancing overall sustainability. These systems can optimize the use of each material, potentially reducing the total environmental impact while maintaining or improving barrier properties. Research into the use of nanotechnology in polypropylene coatings has also demonstrated potential for improving barrier properties with minimal material use, further contributing to environmental sustainability.

As regulations and consumer awareness regarding environmental issues continue to grow, the industry is increasingly focusing on life cycle assessments of polypropylene gas barrier coatings. These assessments consider the environmental impact from raw material extraction through production, use, and disposal, providing a comprehensive view of the coating's ecological footprint. This holistic approach is driving innovation towards more environmentally friendly solutions in gas barrier coating technology.

Cost-Benefit Analysis

The cost-benefit analysis of using polypropylene to optimize gas barrier coatings reveals significant advantages that justify its implementation in various industries. The primary benefit lies in the enhanced barrier properties achieved through polypropylene-based coatings, which effectively reduce gas permeation rates. This improvement in barrier performance translates to extended shelf life for packaged products, particularly in the food and beverage industry, leading to reduced waste and increased product value.

From a cost perspective, polypropylene-based gas barrier coatings offer a competitive edge over alternative materials. The raw material cost of polypropylene is relatively low compared to other high-performance barrier polymers, such as ethylene vinyl alcohol (EVOH) or polyvinyl alcohol (PVOH). Additionally, the processing of polypropylene for coating applications is less energy-intensive, contributing to lower production costs.

The durability and chemical resistance of polypropylene coatings further enhance their cost-effectiveness. These coatings exhibit excellent resistance to moisture, oils, and many common solvents, reducing the need for frequent reapplication or maintenance. This longevity translates to lower long-term costs for end-users and improved overall product performance.

In terms of manufacturing efficiency, polypropylene-based coatings can be applied using existing coating equipment with minimal modifications. This compatibility with current production lines minimizes the capital investment required for implementation, making it an attractive option for manufacturers looking to upgrade their barrier coating capabilities.

Environmental considerations also factor into the cost-benefit analysis. Polypropylene is recyclable, and its use in gas barrier coatings can contribute to the development of more sustainable packaging solutions. This aligns with growing consumer demand for environmentally friendly products and can potentially lead to increased market share and brand value.

However, it is important to note that the optimization of gas barrier properties using polypropylene may require additional additives or processing techniques, which can incrementally increase production costs. These additional expenses should be weighed against the improved performance and potential market advantages gained through enhanced barrier properties.

In conclusion, the cost-benefit analysis strongly favors the use of polypropylene in optimizing gas barrier coatings. The combination of improved performance, cost-effective production, and environmental benefits presents a compelling case for its adoption across various industries, particularly in packaging applications where barrier properties are critical.

From a cost perspective, polypropylene-based gas barrier coatings offer a competitive edge over alternative materials. The raw material cost of polypropylene is relatively low compared to other high-performance barrier polymers, such as ethylene vinyl alcohol (EVOH) or polyvinyl alcohol (PVOH). Additionally, the processing of polypropylene for coating applications is less energy-intensive, contributing to lower production costs.

The durability and chemical resistance of polypropylene coatings further enhance their cost-effectiveness. These coatings exhibit excellent resistance to moisture, oils, and many common solvents, reducing the need for frequent reapplication or maintenance. This longevity translates to lower long-term costs for end-users and improved overall product performance.

In terms of manufacturing efficiency, polypropylene-based coatings can be applied using existing coating equipment with minimal modifications. This compatibility with current production lines minimizes the capital investment required for implementation, making it an attractive option for manufacturers looking to upgrade their barrier coating capabilities.

Environmental considerations also factor into the cost-benefit analysis. Polypropylene is recyclable, and its use in gas barrier coatings can contribute to the development of more sustainable packaging solutions. This aligns with growing consumer demand for environmentally friendly products and can potentially lead to increased market share and brand value.

However, it is important to note that the optimization of gas barrier properties using polypropylene may require additional additives or processing techniques, which can incrementally increase production costs. These additional expenses should be weighed against the improved performance and potential market advantages gained through enhanced barrier properties.

In conclusion, the cost-benefit analysis strongly favors the use of polypropylene in optimizing gas barrier coatings. The combination of improved performance, cost-effective production, and environmental benefits presents a compelling case for its adoption across various industries, particularly in packaging applications where barrier properties are critical.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!