How Polypropylene Supports Cold Chain Logistics

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PP in Cold Chain: Background and Objectives

Polypropylene (PP) has emerged as a crucial material in supporting cold chain logistics, revolutionizing the transportation and storage of temperature-sensitive products. The evolution of PP in this field can be traced back to the mid-20th century when its unique properties were first recognized for packaging applications. As global trade expanded and the demand for efficient cold chain solutions grew, PP's role became increasingly significant.

The primary objective of utilizing PP in cold chain logistics is to maintain product integrity throughout the supply chain, ensuring that temperature-sensitive goods remain within specified temperature ranges from production to consumption. This is particularly critical for industries such as pharmaceuticals, food and beverages, and biotechnology, where even slight temperature deviations can compromise product quality and safety.

PP's journey in cold chain logistics has been marked by continuous technological advancements. Initially used for simple packaging, it has evolved to become an integral component of sophisticated insulation systems, thermal packaging solutions, and reusable containers. The material's versatility has allowed for the development of innovative products such as vacuum insulated panels (VIPs) with PP cores, which offer superior thermal performance in a compact form factor.

The trend towards sustainability has also shaped PP's trajectory in cold chain applications. As environmental concerns gain prominence, there is a growing focus on developing recyclable and reusable PP-based solutions. This aligns with the broader industry goal of reducing the carbon footprint of cold chain operations while maintaining operational efficiency.

Looking ahead, the objectives for PP in cold chain logistics are multifaceted. There is a push for enhancing the material's thermal insulation properties to extend temperature control durations and reduce the need for active cooling systems. Additionally, researchers are exploring ways to improve PP's barrier properties against moisture and gases, which could further extend product shelf life and reduce spoilage.

Another key objective is the development of smart PP-based packaging that incorporates sensors and indicators. These advanced solutions aim to provide real-time monitoring of temperature conditions, enabling more precise control and traceability throughout the cold chain. This integration of technology with PP materials represents a significant step towards creating more intelligent and responsive cold chain systems.

As the global cold chain market continues to expand, driven by factors such as the growth of e-commerce and the increasing demand for fresh and frozen products, the role of PP is expected to become even more critical. The material's ability to adapt to diverse requirements while offering cost-effectiveness and sustainability makes it a cornerstone of future cold chain innovations.

The primary objective of utilizing PP in cold chain logistics is to maintain product integrity throughout the supply chain, ensuring that temperature-sensitive goods remain within specified temperature ranges from production to consumption. This is particularly critical for industries such as pharmaceuticals, food and beverages, and biotechnology, where even slight temperature deviations can compromise product quality and safety.

PP's journey in cold chain logistics has been marked by continuous technological advancements. Initially used for simple packaging, it has evolved to become an integral component of sophisticated insulation systems, thermal packaging solutions, and reusable containers. The material's versatility has allowed for the development of innovative products such as vacuum insulated panels (VIPs) with PP cores, which offer superior thermal performance in a compact form factor.

The trend towards sustainability has also shaped PP's trajectory in cold chain applications. As environmental concerns gain prominence, there is a growing focus on developing recyclable and reusable PP-based solutions. This aligns with the broader industry goal of reducing the carbon footprint of cold chain operations while maintaining operational efficiency.

Looking ahead, the objectives for PP in cold chain logistics are multifaceted. There is a push for enhancing the material's thermal insulation properties to extend temperature control durations and reduce the need for active cooling systems. Additionally, researchers are exploring ways to improve PP's barrier properties against moisture and gases, which could further extend product shelf life and reduce spoilage.

Another key objective is the development of smart PP-based packaging that incorporates sensors and indicators. These advanced solutions aim to provide real-time monitoring of temperature conditions, enabling more precise control and traceability throughout the cold chain. This integration of technology with PP materials represents a significant step towards creating more intelligent and responsive cold chain systems.

As the global cold chain market continues to expand, driven by factors such as the growth of e-commerce and the increasing demand for fresh and frozen products, the role of PP is expected to become even more critical. The material's ability to adapt to diverse requirements while offering cost-effectiveness and sustainability makes it a cornerstone of future cold chain innovations.

Market Demand Analysis for Cold Chain Packaging

The global cold chain packaging market has experienced significant growth in recent years, driven by the increasing demand for temperature-sensitive products across various industries. The pharmaceutical and healthcare sectors, in particular, have been major contributors to this growth, with the rising need for safe transportation of vaccines, biologics, and other temperature-sensitive medications. The food and beverage industry has also played a crucial role in expanding the market, as consumers increasingly demand fresh and frozen products.

The COVID-19 pandemic has further accelerated the demand for cold chain packaging solutions, especially in the pharmaceutical sector. The global distribution of vaccines has highlighted the critical importance of maintaining product integrity throughout the supply chain. This has led to increased investments in cold chain infrastructure and packaging technologies.

Market research indicates that the global cold chain packaging market is expected to continue its growth trajectory in the coming years. Factors such as urbanization, changing consumer preferences, and the expansion of e-commerce platforms for perishable goods are driving this trend. Additionally, stringent regulations regarding the transportation and storage of temperature-sensitive products are compelling companies to adopt advanced cold chain packaging solutions.

Polypropylene has emerged as a key material in cold chain packaging due to its excellent properties. Its low thermal conductivity, moisture resistance, and durability make it an ideal choice for insulation in cold chain applications. The market for polypropylene-based cold chain packaging solutions is witnessing steady growth, as manufacturers recognize its benefits in maintaining product quality and reducing spoilage during transportation.

The food and beverage industry represents a significant portion of the cold chain packaging market. With the increasing globalization of food supply chains and growing consumer demand for fresh produce and ready-to-eat meals, the need for effective cold chain packaging solutions has never been greater. Polypropylene-based packaging plays a crucial role in preserving food quality and extending shelf life, thereby reducing food waste and improving overall supply chain efficiency.

In the pharmaceutical sector, the demand for cold chain packaging is driven by the growing biopharmaceutical market and the increasing complexity of drug formulations. Many new drugs and vaccines require strict temperature control during storage and transportation, creating opportunities for innovative polypropylene-based packaging solutions. The market is also seeing a shift towards reusable and sustainable packaging options, aligning with global sustainability goals and regulations.

The COVID-19 pandemic has further accelerated the demand for cold chain packaging solutions, especially in the pharmaceutical sector. The global distribution of vaccines has highlighted the critical importance of maintaining product integrity throughout the supply chain. This has led to increased investments in cold chain infrastructure and packaging technologies.

Market research indicates that the global cold chain packaging market is expected to continue its growth trajectory in the coming years. Factors such as urbanization, changing consumer preferences, and the expansion of e-commerce platforms for perishable goods are driving this trend. Additionally, stringent regulations regarding the transportation and storage of temperature-sensitive products are compelling companies to adopt advanced cold chain packaging solutions.

Polypropylene has emerged as a key material in cold chain packaging due to its excellent properties. Its low thermal conductivity, moisture resistance, and durability make it an ideal choice for insulation in cold chain applications. The market for polypropylene-based cold chain packaging solutions is witnessing steady growth, as manufacturers recognize its benefits in maintaining product quality and reducing spoilage during transportation.

The food and beverage industry represents a significant portion of the cold chain packaging market. With the increasing globalization of food supply chains and growing consumer demand for fresh produce and ready-to-eat meals, the need for effective cold chain packaging solutions has never been greater. Polypropylene-based packaging plays a crucial role in preserving food quality and extending shelf life, thereby reducing food waste and improving overall supply chain efficiency.

In the pharmaceutical sector, the demand for cold chain packaging is driven by the growing biopharmaceutical market and the increasing complexity of drug formulations. Many new drugs and vaccines require strict temperature control during storage and transportation, creating opportunities for innovative polypropylene-based packaging solutions. The market is also seeing a shift towards reusable and sustainable packaging options, aligning with global sustainability goals and regulations.

Current PP Technology in Cold Chain Logistics

Polypropylene (PP) has become a cornerstone material in cold chain logistics, offering a unique combination of properties that make it ideal for temperature-sensitive packaging and transportation. In current cold chain applications, PP is primarily utilized in the form of insulated containers, packaging materials, and protective films.

One of the most significant applications of PP in cold chain logistics is in the production of insulated containers. These containers, often in the form of boxes or crates, are manufactured using expanded polypropylene (EPP) foam. EPP foam provides excellent thermal insulation properties, maintaining the desired temperature range for extended periods. The closed-cell structure of EPP foam creates tiny air pockets that significantly reduce heat transfer, making it an effective barrier against temperature fluctuations.

PP-based packaging materials are also widely used in cold chain logistics. Flexible PP films and rigid PP containers are employed to protect perishable goods from moisture, contamination, and physical damage during transportation. These materials offer a high barrier to water vapor and gases, ensuring that products remain fresh and maintain their quality throughout the supply chain.

In addition to packaging, PP is utilized in the production of thermal blankets and pallet covers. These items provide an additional layer of insulation during transit, helping to maintain consistent temperatures even in challenging environmental conditions. The lightweight nature of PP-based thermal blankets makes them easy to handle and cost-effective to transport.

PP's chemical resistance and durability make it suitable for reusable packaging solutions in cold chain logistics. Many companies are adopting returnable PP containers and crates, which can withstand multiple use cycles and cleaning processes without degradation. This approach not only reduces waste but also provides long-term cost savings for businesses operating in the cold chain sector.

The versatility of PP extends to its use in temperature-controlled pharmaceutical packaging. Specialized PP containers with integrated cooling elements or phase change materials are designed to maintain precise temperature ranges required for sensitive medications and biologics. These advanced packaging solutions often incorporate smart technologies, such as temperature sensors and data loggers, to ensure product integrity throughout the distribution process.

Furthermore, PP's compatibility with various sterilization methods, including gamma irradiation and ethylene oxide treatment, makes it particularly valuable in the medical and food industries where stringent hygiene standards must be met. This characteristic allows PP-based cold chain packaging to be used in sterile environments without compromising product safety.

One of the most significant applications of PP in cold chain logistics is in the production of insulated containers. These containers, often in the form of boxes or crates, are manufactured using expanded polypropylene (EPP) foam. EPP foam provides excellent thermal insulation properties, maintaining the desired temperature range for extended periods. The closed-cell structure of EPP foam creates tiny air pockets that significantly reduce heat transfer, making it an effective barrier against temperature fluctuations.

PP-based packaging materials are also widely used in cold chain logistics. Flexible PP films and rigid PP containers are employed to protect perishable goods from moisture, contamination, and physical damage during transportation. These materials offer a high barrier to water vapor and gases, ensuring that products remain fresh and maintain their quality throughout the supply chain.

In addition to packaging, PP is utilized in the production of thermal blankets and pallet covers. These items provide an additional layer of insulation during transit, helping to maintain consistent temperatures even in challenging environmental conditions. The lightweight nature of PP-based thermal blankets makes them easy to handle and cost-effective to transport.

PP's chemical resistance and durability make it suitable for reusable packaging solutions in cold chain logistics. Many companies are adopting returnable PP containers and crates, which can withstand multiple use cycles and cleaning processes without degradation. This approach not only reduces waste but also provides long-term cost savings for businesses operating in the cold chain sector.

The versatility of PP extends to its use in temperature-controlled pharmaceutical packaging. Specialized PP containers with integrated cooling elements or phase change materials are designed to maintain precise temperature ranges required for sensitive medications and biologics. These advanced packaging solutions often incorporate smart technologies, such as temperature sensors and data loggers, to ensure product integrity throughout the distribution process.

Furthermore, PP's compatibility with various sterilization methods, including gamma irradiation and ethylene oxide treatment, makes it particularly valuable in the medical and food industries where stringent hygiene standards must be met. This characteristic allows PP-based cold chain packaging to be used in sterile environments without compromising product safety.

Existing PP-based Cold Chain Packaging Solutions

01 Polypropylene synthesis and production methods

Various methods for synthesizing and producing polypropylene, including catalytic processes, polymerization techniques, and reactor designs. These methods aim to improve the efficiency and quality of polypropylene production, resulting in materials with enhanced properties for diverse applications.- Polypropylene composition and manufacturing: Various methods and compositions for manufacturing polypropylene with improved properties are described. These include techniques for controlling molecular weight distribution, enhancing crystallinity, and incorporating additives to achieve desired characteristics such as increased strength, flexibility, or thermal stability.

- Polypropylene applications in packaging: Polypropylene is widely used in packaging applications due to its versatility and favorable properties. Innovations in this area include the development of multi-layer films, barrier coatings, and modified polypropylene formulations to enhance packaging performance for food, consumer goods, and industrial products.

- Polypropylene blends and composites: Research focuses on creating polypropylene blends and composites to enhance material properties. This includes combining polypropylene with other polymers, incorporating fillers or reinforcing agents, and developing novel compatibilizers to improve the performance of the resulting materials for various applications.

- Polypropylene modification techniques: Various modification techniques are employed to enhance the properties of polypropylene. These include chemical modification, surface treatments, and the use of specific catalysts or processing conditions to tailor the polymer's characteristics for specific end-use requirements.

- Recycling and sustainability of polypropylene: Efforts are being made to improve the recyclability and sustainability of polypropylene. This includes developing more efficient recycling processes, creating polypropylene grades with enhanced recyclability, and exploring bio-based alternatives to traditional petroleum-derived polypropylene.

02 Polypropylene composites and blends

Development of polypropylene-based composites and blends with other materials to enhance specific properties such as strength, durability, or thermal resistance. These formulations can be tailored for various industrial applications, including automotive parts, packaging, and construction materials.Expand Specific Solutions03 Polypropylene modification techniques

Methods for modifying polypropylene to improve its characteristics, such as impact resistance, weatherability, or compatibility with other materials. These techniques may include chemical treatments, additives, or physical modifications to enhance the polymer's performance in specific applications.Expand Specific Solutions04 Polypropylene film and fiber production

Specialized processes for manufacturing polypropylene films and fibers, focusing on improving properties such as tensile strength, elasticity, and barrier characteristics. These methods are crucial for applications in packaging, textiles, and non-woven materials.Expand Specific Solutions05 Recycling and sustainability of polypropylene

Innovative approaches to recycling polypropylene and improving its environmental sustainability. This includes developing more efficient recycling processes, creating biodegradable polypropylene variants, and exploring ways to reduce the environmental impact of polypropylene production and use.Expand Specific Solutions

Key Players in PP Cold Chain Solutions

The polypropylene market for cold chain logistics is in a growth phase, driven by increasing demand for temperature-sensitive product transportation. The global market size is expanding rapidly, with key players like Borealis AG, ExxonMobil Chemical, and BASF Corp leading innovation. These companies are developing advanced polypropylene solutions with enhanced thermal insulation and durability properties. The technology is maturing, with continuous improvements in material performance and sustainability. Emerging players such as SunAllomer Ltd and Kingfa Sci. & Tech. Co., Ltd are also contributing to market competitiveness, focusing on specialized applications and eco-friendly alternatives. As the cold chain logistics sector evolves, polypropylene technology is expected to play a crucial role in maintaining product integrity and reducing energy consumption.

Borealis AG

Technical Solution: Borealis AG has developed advanced polypropylene (PP) solutions specifically tailored for cold chain logistics. Their Bormed™ BJ868MO grade offers excellent impact strength at low temperatures, crucial for maintaining package integrity during transportation and storage in cold environments [1]. This high-performance PP material exhibits enhanced stiffness and dimensional stability, allowing for the production of thin-walled containers that reduce material usage while maintaining structural integrity. Borealis has also incorporated nucleating and clarifying agents into their PP formulations, resulting in improved transparency and aesthetics of packaging materials used in cold chain applications [2]. Additionally, their proprietary Borstar® technology enables the production of PP with a unique balance of properties, including high melt strength and excellent processability, which are essential for manufacturing efficient insulated containers and packaging solutions for temperature-sensitive products [3].

Strengths: Superior low-temperature impact resistance, excellent dimensional stability, and enhanced clarity. Weaknesses: Potentially higher cost compared to standard PP grades, may require specialized processing equipment.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed innovative polypropylene solutions for cold chain logistics through their Vistamaxx™ performance polymers. These polymers offer a unique combination of flexibility and toughness, making them ideal for cold temperature applications [1]. The company's Achieve™ Advanced PP technology provides enhanced impact resistance and stiffness balance, crucial for maintaining package integrity in cold environments [2]. ExxonMobil's PP grades also feature improved seal integrity and puncture resistance, essential for preserving product quality during transportation and storage at low temperatures. Their proprietary catalyst and process technology allows for the production of PP with controlled crystallinity and molecular weight distribution, resulting in materials with excellent low-temperature performance and processability [3]. Additionally, ExxonMobil has developed PP grades with enhanced barrier properties, reducing moisture transmission and helping to maintain the desired temperature within insulated packaging systems [4].

Strengths: Excellent low-temperature flexibility and impact resistance, improved seal integrity, and enhanced barrier properties. Weaknesses: May have higher production costs, potential limitations in extreme temperature conditions.

Innovations in PP for Temperature Control

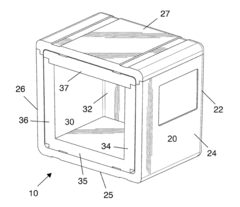

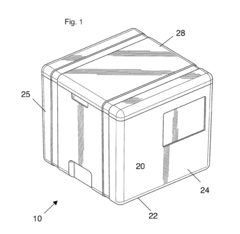

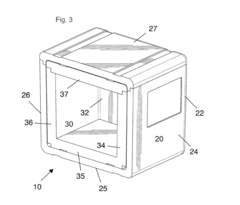

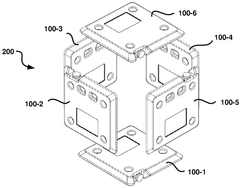

Returnable Cold Chain Packaging Composite

PatentInactiveUS20170158411A1

Innovation

- A composite packaging solution featuring a thermally insulating inner container made of expanded polystyrene surrounded by a durable, thermally insulating outer container composed of materials like expanded polypropylene, which enhances durability and reusability while maintaining temperature control.

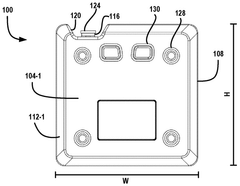

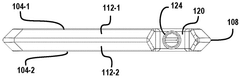

Phase change material panels and container with phase change material panels

PatentWO2025074277A1

Innovation

- A container design incorporating rectangular PCM panels with beveled perimeters, arranged at right angles to form a payload enclosure, combined with an inner tub and vacuum insulated panels (VIPs) for enhanced thermal performance and structural integrity.

Environmental Impact of PP in Cold Chain

The use of polypropylene (PP) in cold chain logistics has significant environmental implications that warrant careful consideration. While PP offers numerous benefits in terms of thermal insulation and durability, its production and disposal processes can contribute to environmental challenges.

PP manufacturing requires substantial energy inputs and relies on fossil fuel-derived raw materials, leading to greenhouse gas emissions and resource depletion. The production process also involves the use of various chemicals and additives, which can result in air and water pollution if not properly managed. However, advancements in manufacturing technologies have led to more efficient production methods, reducing the overall environmental footprint of PP production.

In the context of cold chain logistics, PP's durability and reusability present both advantages and challenges from an environmental perspective. The long lifespan of PP containers and packaging materials reduces the need for frequent replacements, potentially lowering overall resource consumption. Additionally, PP's resistance to moisture and chemicals extends the life of perishable goods, reducing food waste and the associated environmental impacts.

However, the widespread use of PP in cold chain applications has led to concerns about plastic waste accumulation. While PP is recyclable, the recycling rates for PP products used in cold chain logistics remain relatively low due to contamination issues and the lack of widespread recycling infrastructure. This results in a significant portion of PP materials ending up in landfills or, worse, in natural environments.

The environmental impact of PP in cold chain logistics extends beyond its production and disposal. The lightweight nature of PP contributes to fuel efficiency in transportation, potentially reducing carbon emissions associated with cold chain distribution. Moreover, PP's excellent insulation properties help maintain required temperatures with less energy consumption, further reducing the carbon footprint of cold storage and transportation.

To address the environmental challenges associated with PP use in cold chain logistics, various initiatives are being pursued. These include the development of bio-based and biodegradable alternatives to traditional PP, improvements in PP recycling technologies, and the implementation of closed-loop systems for PP packaging materials. Additionally, efforts are being made to optimize the design of PP containers and packaging to minimize material usage while maintaining performance.

In conclusion, while PP plays a crucial role in supporting efficient cold chain logistics, its environmental impact is complex and multifaceted. Balancing the benefits of PP use with its potential environmental drawbacks requires ongoing research, innovation, and the adoption of sustainable practices throughout the cold chain industry.

PP manufacturing requires substantial energy inputs and relies on fossil fuel-derived raw materials, leading to greenhouse gas emissions and resource depletion. The production process also involves the use of various chemicals and additives, which can result in air and water pollution if not properly managed. However, advancements in manufacturing technologies have led to more efficient production methods, reducing the overall environmental footprint of PP production.

In the context of cold chain logistics, PP's durability and reusability present both advantages and challenges from an environmental perspective. The long lifespan of PP containers and packaging materials reduces the need for frequent replacements, potentially lowering overall resource consumption. Additionally, PP's resistance to moisture and chemicals extends the life of perishable goods, reducing food waste and the associated environmental impacts.

However, the widespread use of PP in cold chain applications has led to concerns about plastic waste accumulation. While PP is recyclable, the recycling rates for PP products used in cold chain logistics remain relatively low due to contamination issues and the lack of widespread recycling infrastructure. This results in a significant portion of PP materials ending up in landfills or, worse, in natural environments.

The environmental impact of PP in cold chain logistics extends beyond its production and disposal. The lightweight nature of PP contributes to fuel efficiency in transportation, potentially reducing carbon emissions associated with cold chain distribution. Moreover, PP's excellent insulation properties help maintain required temperatures with less energy consumption, further reducing the carbon footprint of cold storage and transportation.

To address the environmental challenges associated with PP use in cold chain logistics, various initiatives are being pursued. These include the development of bio-based and biodegradable alternatives to traditional PP, improvements in PP recycling technologies, and the implementation of closed-loop systems for PP packaging materials. Additionally, efforts are being made to optimize the design of PP containers and packaging to minimize material usage while maintaining performance.

In conclusion, while PP plays a crucial role in supporting efficient cold chain logistics, its environmental impact is complex and multifaceted. Balancing the benefits of PP use with its potential environmental drawbacks requires ongoing research, innovation, and the adoption of sustainable practices throughout the cold chain industry.

Regulatory Framework for Cold Chain Materials

The regulatory framework for cold chain materials, particularly in relation to polypropylene's use in cold chain logistics, is a complex and evolving landscape. Governments and international organizations have established stringent guidelines to ensure the safety, quality, and efficacy of temperature-sensitive products throughout the supply chain.

At the forefront of these regulations is the Good Distribution Practice (GDP) for pharmaceutical products, which sets standards for the proper distribution of medicinal products for human use. The World Health Organization (WHO) and various national health authorities have adopted GDP guidelines that directly impact the use of materials like polypropylene in cold chain packaging and containers.

In the United States, the Food and Drug Administration (FDA) has implemented regulations under the Food Safety Modernization Act (FSMA) that affect cold chain logistics. These regulations require companies to implement preventive controls and maintain proper temperature conditions during transportation. The FDA's 21 CFR Part 211 also outlines current Good Manufacturing Practices (cGMP) for finished pharmaceuticals, which include requirements for packaging components.

The European Union has established its own set of regulations through the EU GDP Guidelines (2013/C 343/01), which provide specific requirements for temperature-controlled storage and transportation. These guidelines influence the selection and use of materials like polypropylene in cold chain applications within the EU market.

International standards such as ISO 22000 for food safety management systems and ISO 13485 for medical devices also play a crucial role in shaping the regulatory landscape for cold chain materials. These standards often reference the use of appropriate packaging materials and temperature control measures.

Specific to polypropylene, regulations focus on its suitability for food contact and pharmaceutical packaging. In the US, the FDA regulates food contact substances under 21 CFR 177.1520, which includes specifications for polypropylene. In the EU, Regulation (EC) No 1935/2004 governs materials intended to come into contact with food, with specific measures for plastic materials outlined in Regulation (EU) No 10/2011.

Environmental regulations also impact the use of polypropylene in cold chain logistics. Many countries have implemented or are considering regulations to reduce single-use plastics and promote recycling. These initiatives may influence the design and disposal of polypropylene-based cold chain packaging solutions.

As sustainability becomes increasingly important, regulatory bodies are beginning to incorporate lifecycle assessments and circular economy principles into their frameworks. This trend is likely to shape future regulations governing the use of materials like polypropylene in cold chain applications, potentially leading to increased emphasis on reusable or recyclable solutions.

At the forefront of these regulations is the Good Distribution Practice (GDP) for pharmaceutical products, which sets standards for the proper distribution of medicinal products for human use. The World Health Organization (WHO) and various national health authorities have adopted GDP guidelines that directly impact the use of materials like polypropylene in cold chain packaging and containers.

In the United States, the Food and Drug Administration (FDA) has implemented regulations under the Food Safety Modernization Act (FSMA) that affect cold chain logistics. These regulations require companies to implement preventive controls and maintain proper temperature conditions during transportation. The FDA's 21 CFR Part 211 also outlines current Good Manufacturing Practices (cGMP) for finished pharmaceuticals, which include requirements for packaging components.

The European Union has established its own set of regulations through the EU GDP Guidelines (2013/C 343/01), which provide specific requirements for temperature-controlled storage and transportation. These guidelines influence the selection and use of materials like polypropylene in cold chain applications within the EU market.

International standards such as ISO 22000 for food safety management systems and ISO 13485 for medical devices also play a crucial role in shaping the regulatory landscape for cold chain materials. These standards often reference the use of appropriate packaging materials and temperature control measures.

Specific to polypropylene, regulations focus on its suitability for food contact and pharmaceutical packaging. In the US, the FDA regulates food contact substances under 21 CFR 177.1520, which includes specifications for polypropylene. In the EU, Regulation (EC) No 1935/2004 governs materials intended to come into contact with food, with specific measures for plastic materials outlined in Regulation (EU) No 10/2011.

Environmental regulations also impact the use of polypropylene in cold chain logistics. Many countries have implemented or are considering regulations to reduce single-use plastics and promote recycling. These initiatives may influence the design and disposal of polypropylene-based cold chain packaging solutions.

As sustainability becomes increasingly important, regulatory bodies are beginning to incorporate lifecycle assessments and circular economy principles into their frameworks. This trend is likely to shape future regulations governing the use of materials like polypropylene in cold chain applications, potentially leading to increased emphasis on reusable or recyclable solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!