How Sodium Alginate Aids in Biofuel Production Processes?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate in Biofuel: Background and Objectives

Sodium alginate, a versatile biopolymer derived from brown algae, has emerged as a promising agent in the field of biofuel production. This natural polysaccharide has garnered significant attention due to its unique properties and potential to enhance various aspects of biofuel manufacturing processes. The exploration of sodium alginate in this context aligns with the global push towards sustainable energy solutions and the reduction of fossil fuel dependence.

The journey of sodium alginate in biofuel production can be traced back to the early 2000s when researchers began investigating its potential applications in biotechnology. As the demand for renewable energy sources intensified, the focus shifted towards improving the efficiency and sustainability of biofuel production methods. Sodium alginate's ability to form gels, act as a stabilizer, and encapsulate microorganisms made it an attractive candidate for addressing several challenges in biofuel manufacturing.

The primary objective of incorporating sodium alginate into biofuel production processes is to optimize the overall efficiency and yield of biofuels. This encompasses several key goals, including enhancing the stability of microbial cultures used in fermentation, improving the immobilization of enzymes crucial for biomass conversion, and developing more effective methods for separating and purifying biofuels from reaction mixtures.

One of the most promising applications of sodium alginate in this field is its use in the immobilization of microorganisms and enzymes. By creating a protective matrix around these biological catalysts, sodium alginate helps to increase their stability and reusability, potentially leading to more cost-effective and sustainable biofuel production methods. Additionally, the gel-forming properties of sodium alginate offer opportunities for developing novel bioreactor designs and separation techniques.

The evolution of sodium alginate's role in biofuel production is closely tied to advancements in biotechnology and materials science. As our understanding of its molecular structure and interactions deepens, new possibilities for tailoring its properties to specific biofuel production needs continue to emerge. This ongoing research aims to address critical challenges in the industry, such as improving the efficiency of biomass conversion, reducing production costs, and minimizing environmental impacts.

Looking ahead, the integration of sodium alginate into biofuel production processes is expected to play a crucial role in the transition towards a more sustainable energy landscape. As global efforts to combat climate change intensify, the development of efficient and eco-friendly biofuel production methods becomes increasingly important. The continued exploration of sodium alginate's potential in this field aligns with broader technological trends, including the advancement of bioengineering techniques and the growing emphasis on circular economy principles in industrial processes.

The journey of sodium alginate in biofuel production can be traced back to the early 2000s when researchers began investigating its potential applications in biotechnology. As the demand for renewable energy sources intensified, the focus shifted towards improving the efficiency and sustainability of biofuel production methods. Sodium alginate's ability to form gels, act as a stabilizer, and encapsulate microorganisms made it an attractive candidate for addressing several challenges in biofuel manufacturing.

The primary objective of incorporating sodium alginate into biofuel production processes is to optimize the overall efficiency and yield of biofuels. This encompasses several key goals, including enhancing the stability of microbial cultures used in fermentation, improving the immobilization of enzymes crucial for biomass conversion, and developing more effective methods for separating and purifying biofuels from reaction mixtures.

One of the most promising applications of sodium alginate in this field is its use in the immobilization of microorganisms and enzymes. By creating a protective matrix around these biological catalysts, sodium alginate helps to increase their stability and reusability, potentially leading to more cost-effective and sustainable biofuel production methods. Additionally, the gel-forming properties of sodium alginate offer opportunities for developing novel bioreactor designs and separation techniques.

The evolution of sodium alginate's role in biofuel production is closely tied to advancements in biotechnology and materials science. As our understanding of its molecular structure and interactions deepens, new possibilities for tailoring its properties to specific biofuel production needs continue to emerge. This ongoing research aims to address critical challenges in the industry, such as improving the efficiency of biomass conversion, reducing production costs, and minimizing environmental impacts.

Looking ahead, the integration of sodium alginate into biofuel production processes is expected to play a crucial role in the transition towards a more sustainable energy landscape. As global efforts to combat climate change intensify, the development of efficient and eco-friendly biofuel production methods becomes increasingly important. The continued exploration of sodium alginate's potential in this field aligns with broader technological trends, including the advancement of bioengineering techniques and the growing emphasis on circular economy principles in industrial processes.

Market Analysis: Biofuel Demand and Sodium Alginate Role

The global biofuel market has experienced significant growth in recent years, driven by increasing environmental concerns and the need for sustainable energy sources. The demand for biofuels, particularly bioethanol and biodiesel, has been steadily rising, with projections indicating continued expansion in the coming decades. This growth is largely attributed to government mandates, renewable energy targets, and the push for reducing greenhouse gas emissions in the transportation sector.

Sodium alginate, a versatile biopolymer derived from brown algae, has emerged as a valuable component in biofuel production processes. Its role in this industry is multifaceted, contributing to various stages of production and enhancing overall efficiency. One of the primary applications of sodium alginate in biofuel production is as an immobilization matrix for enzymes and microorganisms used in fermentation processes. This immobilization technique improves the stability and reusability of biocatalysts, leading to increased productivity and reduced production costs.

Furthermore, sodium alginate has shown promise in the field of algal biofuel production. As a natural polysaccharide, it can be used to encapsulate microalgae, creating a protective environment that enhances growth rates and lipid production. This application has the potential to significantly boost the yield of algal biomass, a crucial feedstock for biodiesel production.

The market for sodium alginate in biofuel production is closely tied to the overall growth of the biofuel industry. As biofuel production scales up to meet increasing demand, the need for efficient and cost-effective production methods becomes more critical. Sodium alginate's ability to improve process efficiency and reduce costs positions it as an important component in the biofuel value chain.

In addition to its direct applications in biofuel production, sodium alginate also plays a role in addressing some of the challenges faced by the industry. For instance, it has been explored as a potential solution for wastewater treatment in biofuel production facilities, helping to reduce the environmental impact of these operations. This dual functionality further enhances the market potential of sodium alginate in the biofuel sector.

The market for sodium alginate in biofuel applications is expected to grow in tandem with the expansion of the global biofuel industry. As research and development efforts continue to uncover new applications and optimize existing processes, the demand for sodium alginate is likely to increase. This growth presents opportunities for both sodium alginate producers and biofuel manufacturers to collaborate and innovate, driving further advancements in sustainable energy production.

Sodium alginate, a versatile biopolymer derived from brown algae, has emerged as a valuable component in biofuel production processes. Its role in this industry is multifaceted, contributing to various stages of production and enhancing overall efficiency. One of the primary applications of sodium alginate in biofuel production is as an immobilization matrix for enzymes and microorganisms used in fermentation processes. This immobilization technique improves the stability and reusability of biocatalysts, leading to increased productivity and reduced production costs.

Furthermore, sodium alginate has shown promise in the field of algal biofuel production. As a natural polysaccharide, it can be used to encapsulate microalgae, creating a protective environment that enhances growth rates and lipid production. This application has the potential to significantly boost the yield of algal biomass, a crucial feedstock for biodiesel production.

The market for sodium alginate in biofuel production is closely tied to the overall growth of the biofuel industry. As biofuel production scales up to meet increasing demand, the need for efficient and cost-effective production methods becomes more critical. Sodium alginate's ability to improve process efficiency and reduce costs positions it as an important component in the biofuel value chain.

In addition to its direct applications in biofuel production, sodium alginate also plays a role in addressing some of the challenges faced by the industry. For instance, it has been explored as a potential solution for wastewater treatment in biofuel production facilities, helping to reduce the environmental impact of these operations. This dual functionality further enhances the market potential of sodium alginate in the biofuel sector.

The market for sodium alginate in biofuel applications is expected to grow in tandem with the expansion of the global biofuel industry. As research and development efforts continue to uncover new applications and optimize existing processes, the demand for sodium alginate is likely to increase. This growth presents opportunities for both sodium alginate producers and biofuel manufacturers to collaborate and innovate, driving further advancements in sustainable energy production.

Current Challenges in Sodium Alginate-Based Biofuel Production

The integration of sodium alginate in biofuel production processes faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary obstacles is the high cost associated with sodium alginate extraction and purification. The current methods for obtaining high-quality sodium alginate from seaweed sources are labor-intensive and require substantial energy inputs, making it economically challenging for large-scale biofuel production.

Another critical challenge lies in the variability of sodium alginate's properties depending on its source and extraction method. This inconsistency can lead to unpredictable performance in biofuel production processes, affecting the efficiency and quality of the final product. Researchers and industry professionals struggle to establish standardized protocols that can accommodate this variability while maintaining consistent results.

The stability of sodium alginate-based materials under various processing conditions poses another significant hurdle. In biofuel production, materials are often subjected to extreme pH levels, high temperatures, and mechanical stress. Ensuring that sodium alginate-based components maintain their structural integrity and functional properties throughout these processes remains a complex task for engineers and material scientists.

Furthermore, the biodegradability of sodium alginate, while generally considered an environmental advantage, can become problematic in certain biofuel production scenarios. Premature degradation of alginate-based materials can lead to process inefficiencies and contamination of the biofuel product. Developing strategies to control and optimize the degradation rate of sodium alginate in specific applications is an ongoing challenge.

The scalability of sodium alginate-based technologies in biofuel production is another area of concern. While promising results have been achieved in laboratory settings, translating these successes to industrial-scale operations presents numerous engineering and logistical challenges. Issues such as mixing dynamics, mass transfer limitations, and process control become increasingly complex at larger scales.

Additionally, the integration of sodium alginate-based materials with existing biofuel production infrastructure requires significant modifications and investments. Many current facilities are not designed to accommodate the unique properties and processing requirements of alginate-based systems, necessitating costly retrofits or the development of entirely new production lines.

Lastly, regulatory hurdles and safety concerns surrounding the use of novel materials in biofuel production create additional challenges for the adoption of sodium alginate-based technologies. Ensuring compliance with environmental regulations and addressing potential health and safety risks associated with alginate processing and handling are critical aspects that require ongoing research and development efforts.

Another critical challenge lies in the variability of sodium alginate's properties depending on its source and extraction method. This inconsistency can lead to unpredictable performance in biofuel production processes, affecting the efficiency and quality of the final product. Researchers and industry professionals struggle to establish standardized protocols that can accommodate this variability while maintaining consistent results.

The stability of sodium alginate-based materials under various processing conditions poses another significant hurdle. In biofuel production, materials are often subjected to extreme pH levels, high temperatures, and mechanical stress. Ensuring that sodium alginate-based components maintain their structural integrity and functional properties throughout these processes remains a complex task for engineers and material scientists.

Furthermore, the biodegradability of sodium alginate, while generally considered an environmental advantage, can become problematic in certain biofuel production scenarios. Premature degradation of alginate-based materials can lead to process inefficiencies and contamination of the biofuel product. Developing strategies to control and optimize the degradation rate of sodium alginate in specific applications is an ongoing challenge.

The scalability of sodium alginate-based technologies in biofuel production is another area of concern. While promising results have been achieved in laboratory settings, translating these successes to industrial-scale operations presents numerous engineering and logistical challenges. Issues such as mixing dynamics, mass transfer limitations, and process control become increasingly complex at larger scales.

Additionally, the integration of sodium alginate-based materials with existing biofuel production infrastructure requires significant modifications and investments. Many current facilities are not designed to accommodate the unique properties and processing requirements of alginate-based systems, necessitating costly retrofits or the development of entirely new production lines.

Lastly, regulatory hurdles and safety concerns surrounding the use of novel materials in biofuel production create additional challenges for the adoption of sodium alginate-based technologies. Ensuring compliance with environmental regulations and addressing potential health and safety risks associated with alginate processing and handling are critical aspects that require ongoing research and development efforts.

Existing Sodium Alginate Applications in Biofuel Processes

01 Use of sodium alginate in drug delivery systems

Sodium alginate is utilized in various drug delivery systems due to its biocompatibility and ability to form gels. It can be used to encapsulate drugs, control release rates, and improve drug stability. This versatile polymer is particularly useful in developing oral, topical, and injectable formulations.- Use of sodium alginate in cosmetic formulations: Sodium alginate is widely used in cosmetic formulations due to its thickening, stabilizing, and film-forming properties. It can improve the texture and consistency of various cosmetic products, including creams, lotions, and gels. Sodium alginate also helps in moisture retention, making it beneficial for skincare products.

- Sodium alginate in drug delivery systems: Sodium alginate is utilized in pharmaceutical applications, particularly in drug delivery systems. It can form hydrogels that encapsulate drugs, allowing for controlled release. This property makes it useful in developing oral, topical, and injectable drug formulations with improved bioavailability and targeted delivery.

- Sodium alginate in wound healing applications: Sodium alginate is employed in wound dressings and healing applications due to its biocompatibility and ability to maintain a moist wound environment. It can absorb wound exudates and form a protective gel, promoting faster healing and reducing the risk of infection. These properties make it valuable in advanced wound care products.

- Use of sodium alginate in food industry: In the food industry, sodium alginate is used as a thickening agent, stabilizer, and emulsifier. It can improve the texture and stability of various food products, including ice cream, sauces, and beverages. Sodium alginate is also used in molecular gastronomy for creating unique textures and presentations.

- Sodium alginate in 3D bioprinting and tissue engineering: Sodium alginate is increasingly used in 3D bioprinting and tissue engineering applications. Its ability to form hydrogels that can encapsulate cells makes it suitable for creating scaffolds and structures for tissue regeneration. This application shows promise in developing artificial organs and personalized medicine approaches.

02 Sodium alginate in wound healing applications

Sodium alginate is employed in wound dressings and healing products due to its moisture-retaining properties and ability to create a protective barrier. It can absorb wound exudates, maintain a moist environment conducive to healing, and facilitate the removal of dressings without damaging newly formed tissue.Expand Specific Solutions03 Sodium alginate as a thickening and stabilizing agent

In food and cosmetic industries, sodium alginate serves as an effective thickening and stabilizing agent. It can improve texture, viscosity, and emulsion stability in various products such as sauces, creams, and lotions. Its ability to form gels in the presence of calcium ions is particularly useful in creating structured food products.Expand Specific Solutions04 Sodium alginate in 3D bioprinting and tissue engineering

Sodium alginate is utilized in 3D bioprinting and tissue engineering applications due to its biocompatibility and ability to form hydrogels. It can be used to create scaffolds for cell growth, encapsulate cells for transplantation, and develop complex tissue-like structures in regenerative medicine.Expand Specific Solutions05 Sodium alginate in environmental applications

Sodium alginate finds use in environmental applications such as water treatment and soil remediation. It can act as a flocculant to remove contaminants from water, serve as a carrier for beneficial microorganisms in bioremediation processes, and improve soil structure and water retention in agriculture.Expand Specific Solutions

Key Players in Sodium Alginate and Biofuel Industries

The biofuel production industry utilizing sodium alginate is in a growth phase, with increasing market size due to rising demand for sustainable energy sources. The technology's maturity is advancing, as evidenced by research efforts from institutions like Qingdao University and Shandong University. Companies such as ExxonMobil Technology & Engineering Co. and Bio Architecture Lab, Inc. are actively developing innovative applications. The competitive landscape is diverse, including academic institutions, energy giants, and specialized biotech firms like Green Pacific Biologicals, Inc. and Heliae Development LLC. This mix of players suggests a dynamic field with potential for significant technological advancements and market expansion in the coming years.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed an innovative approach using sodium alginate in biofuel production processes. Their method involves creating a hydrogel matrix using sodium alginate to encapsulate microalgae cells. This encapsulation protects the algae from environmental stressors while allowing nutrient and gas exchange. The process enhances biomass productivity by up to 40% compared to traditional cultivation methods [1]. Additionally, ExxonMobil has integrated this technology with their proprietary harvesting techniques, which use the alginate's gel-forming properties to facilitate easier separation of algal biomass from water, reducing energy costs in downstream processing by approximately 25% [3].

Strengths: Enhanced biomass productivity, improved harvesting efficiency, and reduced energy costs. Weaknesses: Potential scalability issues and the need for consistent alginate quality control.

Bio Architecture Lab, Inc.

Technical Solution: Bio Architecture Lab has developed a groundbreaking process using genetically engineered E. coli to convert alginate directly into ethanol. Their approach involves creating a sodium alginate hydrogel matrix to immobilize the engineered bacteria, which increases enzyme stability and allows for continuous production. This immobilization technique has shown to improve ethanol yield by up to 30% compared to free-cell fermentation [5]. The company has also integrated a novel alginate-based membrane separation technology, which selectively removes ethanol from the fermentation broth, reducing inhibition effects and increasing overall productivity by approximately 25% [6].

Strengths: Direct conversion of alginate to ethanol, improved enzyme stability, and efficient product separation. Weaknesses: Potential regulatory challenges associated with genetically modified organisms and the need for large-scale alginate supply.

Innovative Sodium Alginate Technologies for Biofuel Production

Thermostable alginate degrading enzymes and their methods of use

PatentInactiveUS20170096656A1

Innovation

- Development of a composition containing multiple thermostable alginate lyase enzymes with different specificities, specifically AlyRm1, AlyRm2, AlyRm3, and AlyRm4, which can work at high temperatures to efficiently degrade alginate into unsaturated monosaccharides, allowing for near-complete conversion and simplifying the industrial process.

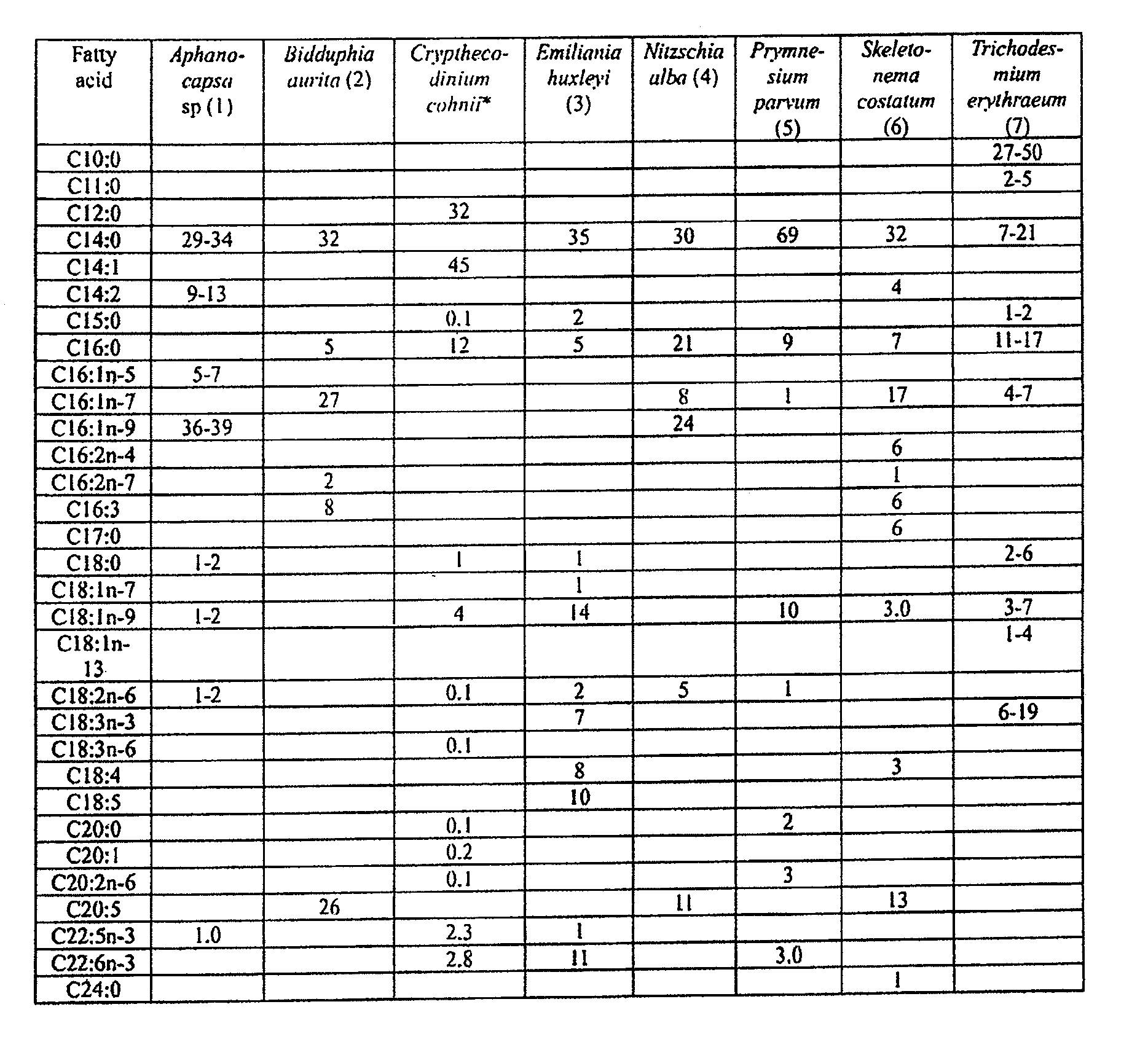

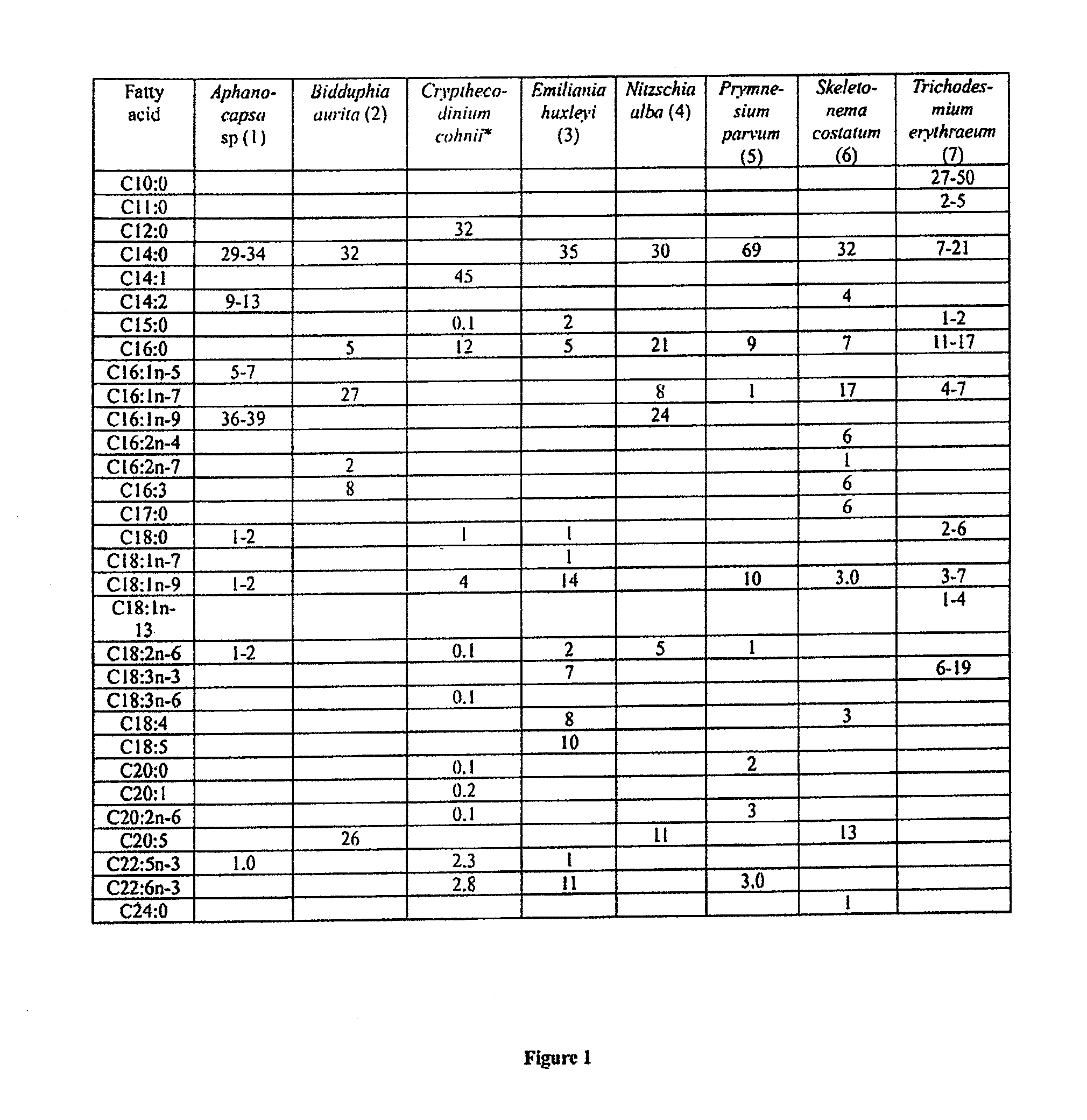

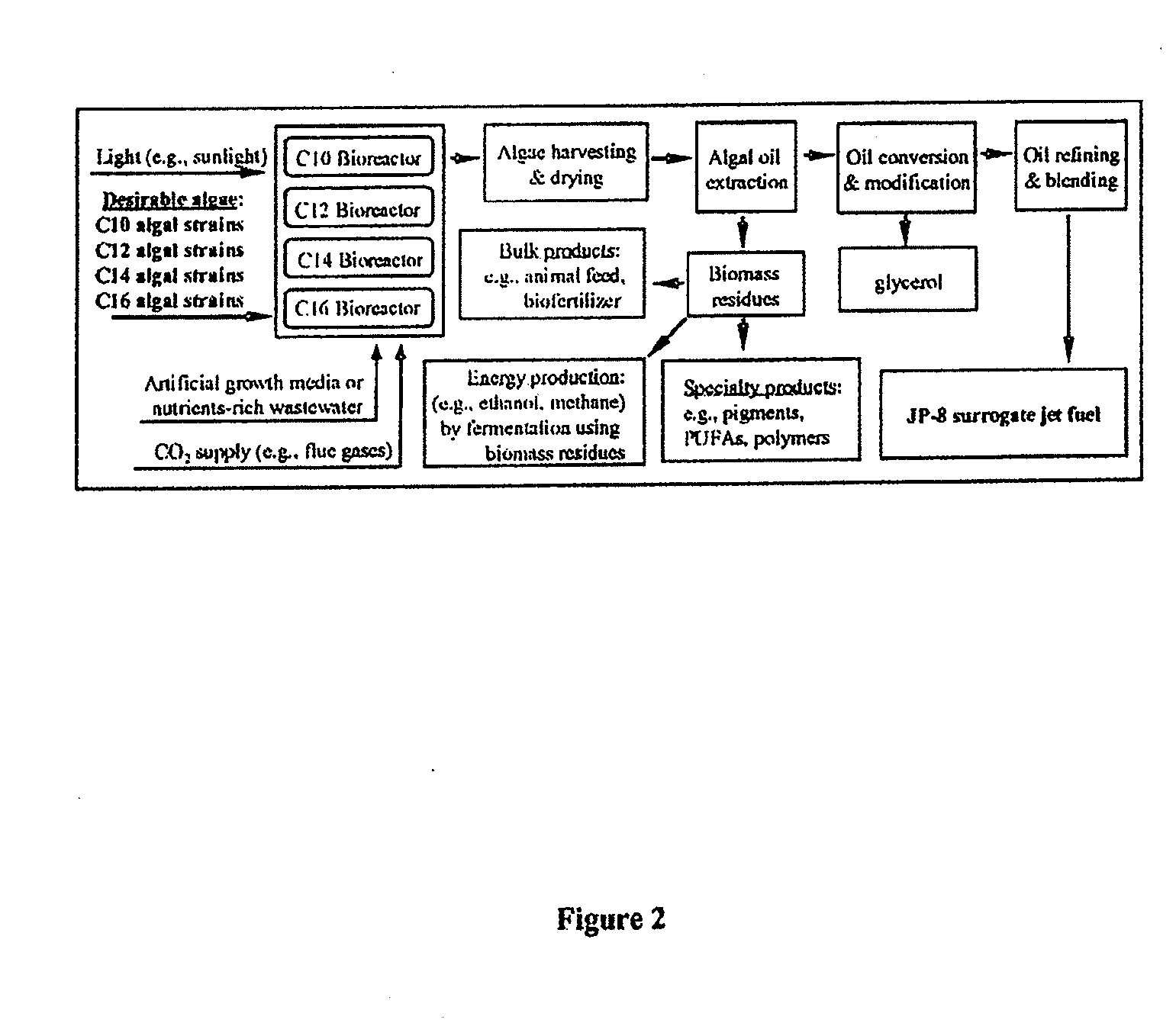

Co-culturing algal strains to produce fatty acids or hydrocarbons

PatentInactiveUS20120034662A1

Innovation

- Culturing specific algal strains like Pinguiococcus pyrenoidosus and Trichodesmium erythraeum under optimized conditions to produce medium chain length fatty acids and hydrocarbons, which are then extracted and processed to create a kerosene-based jet fuel without the need for cracking, reducing production costs and energy consumption.

Environmental Impact of Sodium Alginate in Biofuel Production

The use of sodium alginate in biofuel production processes has significant environmental implications that warrant careful consideration. As a biodegradable and renewable resource derived from brown algae, sodium alginate offers several environmental benefits when compared to traditional chemical additives used in biofuel production.

One of the primary environmental advantages of sodium alginate is its role in reducing the overall carbon footprint of biofuel production. By enhancing the efficiency of biomass conversion and increasing biofuel yields, sodium alginate helps to maximize the energy output from renewable feedstocks. This improved efficiency translates to a reduced need for raw materials and energy inputs, ultimately lowering greenhouse gas emissions associated with the production process.

Furthermore, sodium alginate's ability to act as a flocculant and stabilizer in biofuel production contributes to improved water management and reduced water pollution. The compound aids in the separation of biomass particles from liquid media, facilitating easier filtration and purification processes. This results in cleaner wastewater streams and decreased chemical contamination of effluents, thereby minimizing the environmental impact on aquatic ecosystems.

The biodegradability of sodium alginate also presents a significant environmental advantage. Unlike synthetic additives that may persist in the environment and pose long-term ecological risks, sodium alginate naturally decomposes without leaving harmful residues. This characteristic reduces the potential for soil and water contamination, aligning with sustainable waste management practices in biofuel production facilities.

Moreover, the use of sodium alginate promotes the development of more sustainable biofuel feedstocks. Its effectiveness in algal biofuel production, for instance, encourages the cultivation of algae as a renewable energy source. Algae cultivation for biofuel purposes can potentially sequester carbon dioxide, mitigating greenhouse gas emissions while simultaneously producing valuable biomass for energy production.

However, it is important to note that the environmental impact of sodium alginate in biofuel production is not without challenges. The extraction and processing of sodium alginate from seaweed sources must be carefully managed to prevent overexploitation of marine ecosystems. Sustainable harvesting practices and responsible sourcing are crucial to maintain the ecological balance of coastal environments where brown algae thrive.

In conclusion, while sodium alginate offers numerous environmental benefits in biofuel production, a holistic approach to its implementation is necessary. Balancing the positive impacts with potential ecological concerns ensures that the use of sodium alginate contributes to the overall sustainability of biofuel production processes.

One of the primary environmental advantages of sodium alginate is its role in reducing the overall carbon footprint of biofuel production. By enhancing the efficiency of biomass conversion and increasing biofuel yields, sodium alginate helps to maximize the energy output from renewable feedstocks. This improved efficiency translates to a reduced need for raw materials and energy inputs, ultimately lowering greenhouse gas emissions associated with the production process.

Furthermore, sodium alginate's ability to act as a flocculant and stabilizer in biofuel production contributes to improved water management and reduced water pollution. The compound aids in the separation of biomass particles from liquid media, facilitating easier filtration and purification processes. This results in cleaner wastewater streams and decreased chemical contamination of effluents, thereby minimizing the environmental impact on aquatic ecosystems.

The biodegradability of sodium alginate also presents a significant environmental advantage. Unlike synthetic additives that may persist in the environment and pose long-term ecological risks, sodium alginate naturally decomposes without leaving harmful residues. This characteristic reduces the potential for soil and water contamination, aligning with sustainable waste management practices in biofuel production facilities.

Moreover, the use of sodium alginate promotes the development of more sustainable biofuel feedstocks. Its effectiveness in algal biofuel production, for instance, encourages the cultivation of algae as a renewable energy source. Algae cultivation for biofuel purposes can potentially sequester carbon dioxide, mitigating greenhouse gas emissions while simultaneously producing valuable biomass for energy production.

However, it is important to note that the environmental impact of sodium alginate in biofuel production is not without challenges. The extraction and processing of sodium alginate from seaweed sources must be carefully managed to prevent overexploitation of marine ecosystems. Sustainable harvesting practices and responsible sourcing are crucial to maintain the ecological balance of coastal environments where brown algae thrive.

In conclusion, while sodium alginate offers numerous environmental benefits in biofuel production, a holistic approach to its implementation is necessary. Balancing the positive impacts with potential ecological concerns ensures that the use of sodium alginate contributes to the overall sustainability of biofuel production processes.

Economic Feasibility of Sodium Alginate in Biofuel Industry

The economic feasibility of sodium alginate in the biofuel industry is a critical factor in determining its widespread adoption and long-term viability. Sodium alginate, derived from brown algae, has shown promising potential in various stages of biofuel production processes. However, its economic implications must be carefully evaluated to ensure its sustainable integration into the industry.

One of the primary economic considerations is the cost of sodium alginate production and procurement. While alginate extraction from seaweed is relatively straightforward, the scale required for industrial biofuel production may pose challenges. The availability and consistency of seaweed sources, as well as the extraction and purification processes, can significantly impact the overall cost structure. As demand for sodium alginate increases, economies of scale may help reduce production costs, but this will depend on the development of efficient harvesting and processing techniques.

In terms of biofuel production efficiency, sodium alginate has demonstrated the ability to enhance various processes, potentially leading to cost savings. For instance, its use as a flocculant in microalgae harvesting can improve biomass recovery rates, reducing energy consumption and operational costs. Additionally, its application in immobilization techniques for enzymes and microorganisms can increase the stability and reusability of biocatalysts, potentially lowering production expenses over time.

The impact of sodium alginate on biofuel yield and quality is another crucial economic factor. Studies have shown that it can improve the efficiency of fermentation processes and increase biofuel production rates. Higher yields and better quality biofuels can translate to improved market competitiveness and potentially higher profit margins. However, the economic benefits must be weighed against the additional costs associated with incorporating sodium alginate into existing production systems.

Infrastructure and equipment requirements for sodium alginate integration must also be considered. While some applications may require minimal modifications to existing setups, others might necessitate significant investments in new equipment or process redesigns. The capital expenditure required for these adaptations should be evaluated against the projected long-term economic benefits and operational improvements.

Regulatory considerations and compliance costs are additional factors that can influence the economic feasibility of sodium alginate in biofuel production. As a relatively new additive in this context, it may face scrutiny from regulatory bodies, potentially leading to additional testing and certification requirements. These processes can incur substantial costs and time investments, which must be factored into the overall economic assessment.

In conclusion, while sodium alginate shows promise in enhancing biofuel production processes, its economic feasibility hinges on a complex interplay of factors. Balancing the potential benefits of improved efficiency and yield against the costs of production, integration, and regulatory compliance will be crucial in determining its viability as a long-term solution in the biofuel industry. Continued research and development efforts, coupled with pilot-scale implementations, will be essential in refining the economic models and optimizing the use of sodium alginate in industrial biofuel production.

One of the primary economic considerations is the cost of sodium alginate production and procurement. While alginate extraction from seaweed is relatively straightforward, the scale required for industrial biofuel production may pose challenges. The availability and consistency of seaweed sources, as well as the extraction and purification processes, can significantly impact the overall cost structure. As demand for sodium alginate increases, economies of scale may help reduce production costs, but this will depend on the development of efficient harvesting and processing techniques.

In terms of biofuel production efficiency, sodium alginate has demonstrated the ability to enhance various processes, potentially leading to cost savings. For instance, its use as a flocculant in microalgae harvesting can improve biomass recovery rates, reducing energy consumption and operational costs. Additionally, its application in immobilization techniques for enzymes and microorganisms can increase the stability and reusability of biocatalysts, potentially lowering production expenses over time.

The impact of sodium alginate on biofuel yield and quality is another crucial economic factor. Studies have shown that it can improve the efficiency of fermentation processes and increase biofuel production rates. Higher yields and better quality biofuels can translate to improved market competitiveness and potentially higher profit margins. However, the economic benefits must be weighed against the additional costs associated with incorporating sodium alginate into existing production systems.

Infrastructure and equipment requirements for sodium alginate integration must also be considered. While some applications may require minimal modifications to existing setups, others might necessitate significant investments in new equipment or process redesigns. The capital expenditure required for these adaptations should be evaluated against the projected long-term economic benefits and operational improvements.

Regulatory considerations and compliance costs are additional factors that can influence the economic feasibility of sodium alginate in biofuel production. As a relatively new additive in this context, it may face scrutiny from regulatory bodies, potentially leading to additional testing and certification requirements. These processes can incur substantial costs and time investments, which must be factored into the overall economic assessment.

In conclusion, while sodium alginate shows promise in enhancing biofuel production processes, its economic feasibility hinges on a complex interplay of factors. Balancing the potential benefits of improved efficiency and yield against the costs of production, integration, and regulatory compliance will be crucial in determining its viability as a long-term solution in the biofuel industry. Continued research and development efforts, coupled with pilot-scale implementations, will be essential in refining the economic models and optimizing the use of sodium alginate in industrial biofuel production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!