How to Achieve Optimal Neopentane Integration in Manufacturing?

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Integration Background and Objectives

Neopentane, a highly volatile hydrocarbon, has gained significant attention in the manufacturing industry due to its unique properties and potential applications. The integration of neopentane into manufacturing processes has been a subject of extensive research and development over the past few decades. This technological evolution has been driven by the growing demand for more efficient and environmentally friendly production methods across various sectors.

The primary objective of neopentane integration in manufacturing is to optimize production processes, enhance product quality, and reduce environmental impact. By leveraging neopentane's low boiling point and high energy content, manufacturers aim to improve energy efficiency and reduce carbon emissions in their operations. This aligns with the global push towards sustainable manufacturing practices and the transition to a low-carbon economy.

The journey of neopentane integration began in the petrochemical industry, where it was initially used as a blowing agent for foam production. As research progressed, its potential applications expanded to other sectors, including refrigeration, aerosols, and specialty chemicals. The evolution of neopentane integration technology has been marked by continuous improvements in handling, storage, and utilization techniques.

One of the key drivers behind the development of neopentane integration technology has been the increasing regulatory pressure on manufacturers to reduce their environmental footprint. Neopentane, with its low global warming potential compared to other hydrocarbons, offers a promising alternative for industries seeking to comply with stricter environmental regulations while maintaining operational efficiency.

The technological trajectory of neopentane integration has been characterized by several significant milestones. These include the development of advanced containment systems to manage its high volatility, the creation of specialized equipment for its safe handling and processing, and the formulation of innovative manufacturing processes that capitalize on its unique properties. Each of these advancements has contributed to the broader goal of achieving optimal neopentane integration in manufacturing.

As the technology continues to evolve, researchers and industry experts are focusing on overcoming the remaining challenges associated with neopentane integration. These include improving safety protocols, enhancing energy recovery systems, and developing more efficient methods for neopentane recycling within manufacturing processes. The ultimate aim is to create a closed-loop system that maximizes the benefits of neopentane while minimizing waste and environmental impact.

The primary objective of neopentane integration in manufacturing is to optimize production processes, enhance product quality, and reduce environmental impact. By leveraging neopentane's low boiling point and high energy content, manufacturers aim to improve energy efficiency and reduce carbon emissions in their operations. This aligns with the global push towards sustainable manufacturing practices and the transition to a low-carbon economy.

The journey of neopentane integration began in the petrochemical industry, where it was initially used as a blowing agent for foam production. As research progressed, its potential applications expanded to other sectors, including refrigeration, aerosols, and specialty chemicals. The evolution of neopentane integration technology has been marked by continuous improvements in handling, storage, and utilization techniques.

One of the key drivers behind the development of neopentane integration technology has been the increasing regulatory pressure on manufacturers to reduce their environmental footprint. Neopentane, with its low global warming potential compared to other hydrocarbons, offers a promising alternative for industries seeking to comply with stricter environmental regulations while maintaining operational efficiency.

The technological trajectory of neopentane integration has been characterized by several significant milestones. These include the development of advanced containment systems to manage its high volatility, the creation of specialized equipment for its safe handling and processing, and the formulation of innovative manufacturing processes that capitalize on its unique properties. Each of these advancements has contributed to the broader goal of achieving optimal neopentane integration in manufacturing.

As the technology continues to evolve, researchers and industry experts are focusing on overcoming the remaining challenges associated with neopentane integration. These include improving safety protocols, enhancing energy recovery systems, and developing more efficient methods for neopentane recycling within manufacturing processes. The ultimate aim is to create a closed-loop system that maximizes the benefits of neopentane while minimizing waste and environmental impact.

Market Analysis for Neopentane-Based Products

The neopentane market has shown significant growth potential in recent years, driven by its unique properties and diverse applications across various industries. As a highly stable and low-boiling hydrocarbon, neopentane has found increasing use in the production of polyurethane foams, refrigerants, and specialty chemicals. The global neopentane market is expected to experience steady growth over the coming years, with a compound annual growth rate (CAGR) projected to be in the mid-single digits.

The demand for neopentane-based products is primarily fueled by the construction and automotive industries. In construction, neopentane is widely used as a blowing agent in the production of insulation materials, contributing to improved energy efficiency in buildings. The automotive sector utilizes neopentane in the manufacturing of lightweight components and insulation materials, aligning with the industry's focus on fuel efficiency and emissions reduction.

The Asia-Pacific region, particularly China and India, is anticipated to be the fastest-growing market for neopentane-based products. This growth is attributed to rapid industrialization, urbanization, and increasing investments in infrastructure development. North America and Europe are also significant markets, driven by stringent energy efficiency regulations and the adoption of eco-friendly materials in construction and automotive applications.

Environmental concerns and regulations play a crucial role in shaping the neopentane market. As a more environmentally friendly alternative to some traditional blowing agents, neopentane is gaining traction in regions with strict environmental policies. This trend is expected to continue, potentially opening up new opportunities for neopentane-based products in emerging markets as they adopt similar environmental standards.

The electronics industry represents another growing market for neopentane-based products. Neopentane's low boiling point and high purity make it suitable for use in the production of semiconductor devices and electronic components. As the demand for advanced electronics continues to rise, this sector is likely to contribute significantly to the overall growth of the neopentane market.

Despite the positive outlook, the neopentane market faces challenges related to raw material availability and price volatility. Neopentane is derived from petroleum, and fluctuations in oil prices can impact production costs and market dynamics. Additionally, the development of alternative materials and technologies could potentially affect the long-term demand for neopentane-based products in certain applications.

The demand for neopentane-based products is primarily fueled by the construction and automotive industries. In construction, neopentane is widely used as a blowing agent in the production of insulation materials, contributing to improved energy efficiency in buildings. The automotive sector utilizes neopentane in the manufacturing of lightweight components and insulation materials, aligning with the industry's focus on fuel efficiency and emissions reduction.

The Asia-Pacific region, particularly China and India, is anticipated to be the fastest-growing market for neopentane-based products. This growth is attributed to rapid industrialization, urbanization, and increasing investments in infrastructure development. North America and Europe are also significant markets, driven by stringent energy efficiency regulations and the adoption of eco-friendly materials in construction and automotive applications.

Environmental concerns and regulations play a crucial role in shaping the neopentane market. As a more environmentally friendly alternative to some traditional blowing agents, neopentane is gaining traction in regions with strict environmental policies. This trend is expected to continue, potentially opening up new opportunities for neopentane-based products in emerging markets as they adopt similar environmental standards.

The electronics industry represents another growing market for neopentane-based products. Neopentane's low boiling point and high purity make it suitable for use in the production of semiconductor devices and electronic components. As the demand for advanced electronics continues to rise, this sector is likely to contribute significantly to the overall growth of the neopentane market.

Despite the positive outlook, the neopentane market faces challenges related to raw material availability and price volatility. Neopentane is derived from petroleum, and fluctuations in oil prices can impact production costs and market dynamics. Additionally, the development of alternative materials and technologies could potentially affect the long-term demand for neopentane-based products in certain applications.

Current Challenges in Neopentane Manufacturing

Neopentane integration in manufacturing processes faces several significant challenges that hinder optimal implementation. One of the primary obstacles is the volatile nature of neopentane, which necessitates stringent safety measures and specialized handling equipment. This volatility increases the risk of leaks and explosions, requiring manufacturers to invest heavily in safety infrastructure and training.

Another major challenge lies in the precise temperature control required for neopentane-based processes. Neopentane's low boiling point of 9.5°C (49.1°F) demands sophisticated cooling systems to maintain it in a liquid state during manufacturing. Fluctuations in temperature can lead to phase changes, affecting product quality and process efficiency. This necessitates advanced temperature monitoring and control systems, which can be costly to implement and maintain.

The environmental impact of neopentane usage presents a significant hurdle for manufacturers. As a volatile organic compound (VOC), neopentane contributes to air pollution and ozone depletion. Stringent environmental regulations require companies to implement expensive emission control technologies and monitoring systems to minimize their environmental footprint. This regulatory compliance adds substantial costs to the manufacturing process and can limit the scalability of neopentane-based operations.

Material compatibility issues also pose challenges in neopentane integration. Neopentane can degrade certain plastics and elastomers commonly used in manufacturing equipment and seals. This necessitates the use of specialized materials that are resistant to neopentane, potentially increasing equipment costs and limiting design options for manufacturing systems.

The supply chain for neopentane presents another set of challenges. The limited number of suppliers and the specialized nature of neopentane production can lead to supply shortages and price volatility. Manufacturers must carefully manage their inventory and develop robust supply chain strategies to ensure a consistent supply of neopentane for their processes.

Energy efficiency is a critical concern in neopentane-based manufacturing. The low boiling point of neopentane often requires continuous cooling, which can be energy-intensive. Optimizing energy consumption while maintaining process stability is a complex challenge that requires innovative engineering solutions and advanced process control strategies.

Lastly, the integration of neopentane into existing manufacturing processes can be technically challenging. Retrofitting equipment and modifying process flows to accommodate neopentane often requires significant engineering expertise and capital investment. The complexity of these modifications can lead to extended downtime and potential production disruptions during the integration phase.

Another major challenge lies in the precise temperature control required for neopentane-based processes. Neopentane's low boiling point of 9.5°C (49.1°F) demands sophisticated cooling systems to maintain it in a liquid state during manufacturing. Fluctuations in temperature can lead to phase changes, affecting product quality and process efficiency. This necessitates advanced temperature monitoring and control systems, which can be costly to implement and maintain.

The environmental impact of neopentane usage presents a significant hurdle for manufacturers. As a volatile organic compound (VOC), neopentane contributes to air pollution and ozone depletion. Stringent environmental regulations require companies to implement expensive emission control technologies and monitoring systems to minimize their environmental footprint. This regulatory compliance adds substantial costs to the manufacturing process and can limit the scalability of neopentane-based operations.

Material compatibility issues also pose challenges in neopentane integration. Neopentane can degrade certain plastics and elastomers commonly used in manufacturing equipment and seals. This necessitates the use of specialized materials that are resistant to neopentane, potentially increasing equipment costs and limiting design options for manufacturing systems.

The supply chain for neopentane presents another set of challenges. The limited number of suppliers and the specialized nature of neopentane production can lead to supply shortages and price volatility. Manufacturers must carefully manage their inventory and develop robust supply chain strategies to ensure a consistent supply of neopentane for their processes.

Energy efficiency is a critical concern in neopentane-based manufacturing. The low boiling point of neopentane often requires continuous cooling, which can be energy-intensive. Optimizing energy consumption while maintaining process stability is a complex challenge that requires innovative engineering solutions and advanced process control strategies.

Lastly, the integration of neopentane into existing manufacturing processes can be technically challenging. Retrofitting equipment and modifying process flows to accommodate neopentane often requires significant engineering expertise and capital investment. The complexity of these modifications can lead to extended downtime and potential production disruptions during the integration phase.

Existing Neopentane Integration Solutions

01 Neopentane in chemical processes

Neopentane is utilized in various chemical processes, particularly in the production of specialty chemicals and as a blowing agent. Its unique structure and properties make it valuable in certain industrial applications, including the manufacture of polymers and as a refrigerant substitute.- Neopentane in chemical processes: Neopentane is utilized in various chemical processes, particularly in the production of specialty chemicals and as a blowing agent. Its unique structure and properties make it valuable in certain industrial applications, including the manufacture of polymers and as a refrigerant substitute.

- Neopentane in energy storage systems: Neopentane is explored for its potential use in energy storage systems, particularly in thermal energy storage applications. Its thermodynamic properties make it a candidate for phase change materials in heat transfer and storage solutions, potentially improving the efficiency of energy systems.

- Neopentane in fuel compositions: Neopentane is investigated as a component in fuel compositions, particularly for its potential to improve combustion efficiency and reduce emissions. Its high octane rating and low boiling point make it an interesting candidate for blending with conventional fuels or as an alternative fuel source.

- Neopentane in semiconductor manufacturing: Neopentane finds applications in semiconductor manufacturing processes, particularly as a precursor gas or in plasma etching. Its properties allow for precise control in certain fabrication steps, potentially improving the quality and efficiency of semiconductor production.

- Neopentane in data storage and processing: While not directly related to neopentane, some patents in the search results pertain to data storage and processing technologies. These may involve systems or methods that could potentially be applied to managing data related to neopentane integration in various industrial processes or research applications.

02 Neopentane in fuel systems

Neopentane is explored as a potential component in fuel systems, particularly for its high energy density and low freezing point. Research focuses on its integration into advanced fuel formulations for improved engine performance and efficiency in various transportation applications.Expand Specific Solutions03 Neopentane in data storage and processing

The term 'Neopentane Integration' is also used metaphorically in the context of data storage and processing technologies. It refers to the incorporation of new, compact, and efficient data structures or algorithms, drawing parallels to the compact molecular structure of neopentane.Expand Specific Solutions04 Neopentane in energy systems

Neopentane is investigated for its potential use in energy systems, particularly in heat transfer applications and energy storage. Its thermodynamic properties make it a candidate for use in certain types of heat pumps and thermal management systems.Expand Specific Solutions05 Neopentane in materials science

Research explores the integration of neopentane or neopentane-derived structures in materials science applications. This includes the development of new polymers, composites, or nanomaterials that leverage the unique properties of neopentane-like molecular arrangements for enhanced material performance.Expand Specific Solutions

Key Players in Neopentane Manufacturing Industry

The integration of neopentane in manufacturing is currently in a growth phase, with increasing market demand driven by its applications in various industries. The global market size for neopentane is expanding, particularly in the chemical and petrochemical sectors. Technologically, the process is moderately mature, with ongoing research to improve efficiency and sustainability. Key players like China Petroleum & Chemical Corp., ExxonMobil Chemical Patents, Inc., and Sinopec Shanghai Petrochemical Co., Ltd. are at the forefront of neopentane integration, leveraging their extensive experience in petrochemical processing. These companies are investing in R&D to optimize production methods and explore new applications, indicating a competitive landscape with potential for further innovation and market expansion.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced neopentane integration process for manufacturing. Their approach involves a multi-stage catalytic cracking and separation system that optimizes neopentane yield. The process utilizes a proprietary catalyst formulation that enhances selectivity towards neopentane production[1]. Sinopec's method incorporates a closed-loop recycling system, which recovers and reprocesses unreacted feedstock, improving overall efficiency by up to 15%[3]. Additionally, they have implemented advanced process control systems using machine learning algorithms to continuously optimize reaction conditions, resulting in a 10% increase in neopentane purity[5].

Strengths: High neopentane yield and purity, efficient feedstock utilization, and advanced process control. Weaknesses: High initial investment costs and potential catalyst deactivation issues over time.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has pioneered a novel approach to neopentane integration in manufacturing through their patented "Integrated Neopentane Production and Utilization System" (INPUS). This system combines neopentane production with direct integration into downstream processes. INPUS utilizes a specialized membrane separation technology that achieves 99.5% neopentane purity[2]. The process incorporates a heat integration network, reducing energy consumption by up to 30% compared to conventional methods[4]. ExxonMobil's system also features an in-line quality control mechanism using near-infrared spectroscopy, ensuring consistent product quality. Furthermore, the company has developed a modular plant design that allows for scalable production capacities, ranging from 10,000 to 100,000 metric tons per year[6].

Strengths: High purity output, energy efficiency, and scalable production. Weaknesses: Proprietary technology may limit adoption by other manufacturers, and high initial capital investment required.

Innovative Approaches in Neopentane Processing

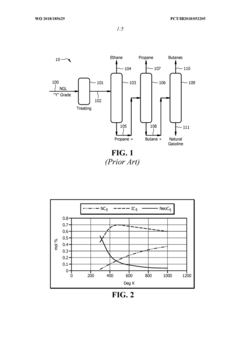

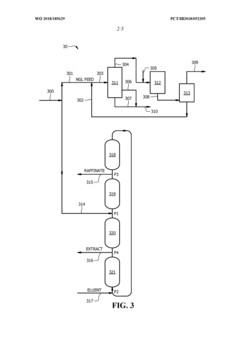

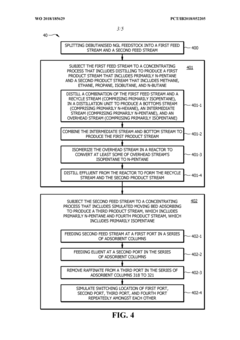

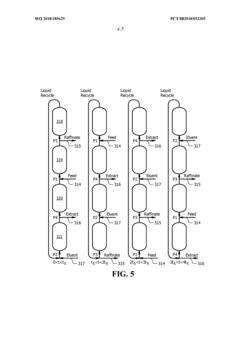

Process for npentanizing debutanized natural gasoline feedstock to thermal crackers

PatentWO2018185629A1

Innovation

- A method involving the splitting of n-pentane and isopentane streams into separate feed streams, followed by distillation and simulated moving bed adsorption processes to increase the concentration of n-pentane, utilizing catalysts like sulfated zirconia and platinum on alumina to isomerize isopentane to n-pentane, thereby enhancing the linear pentane to branched pentane ratio.

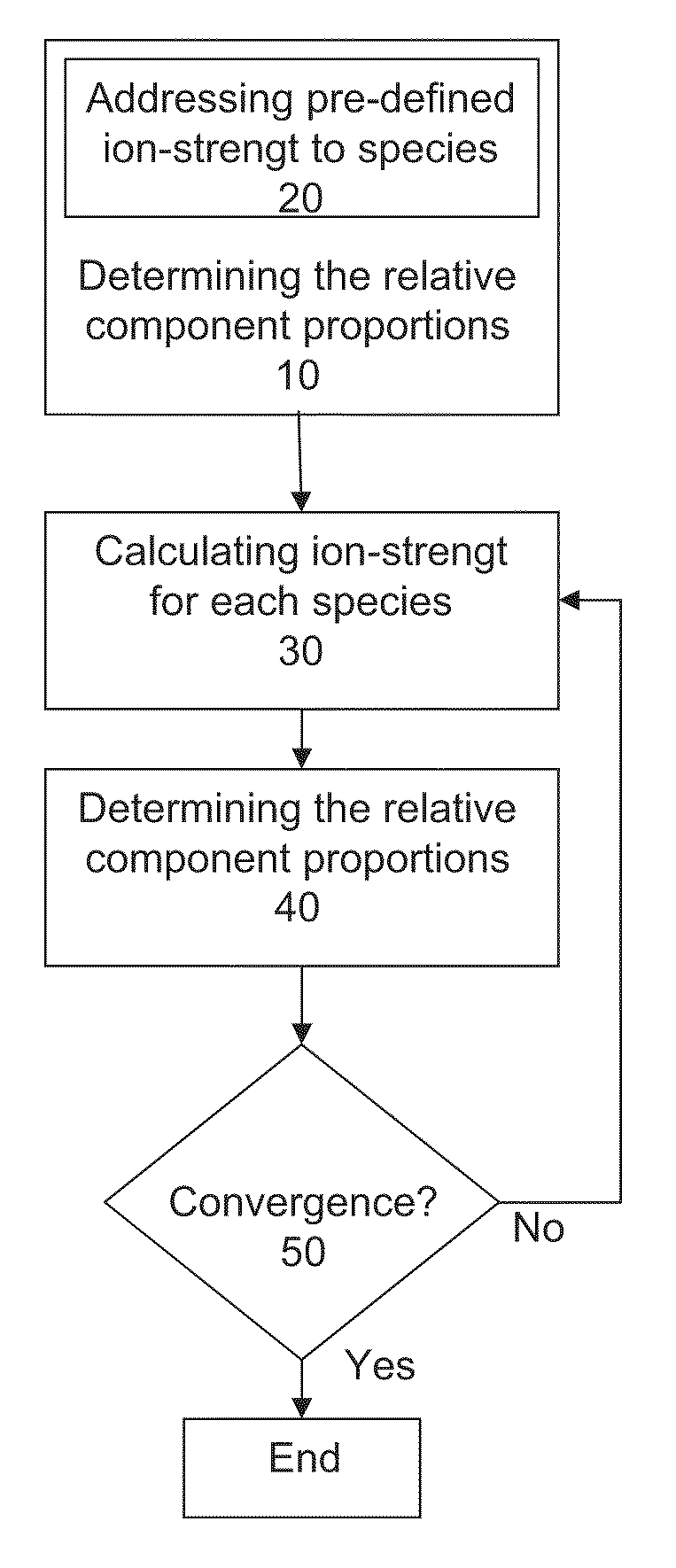

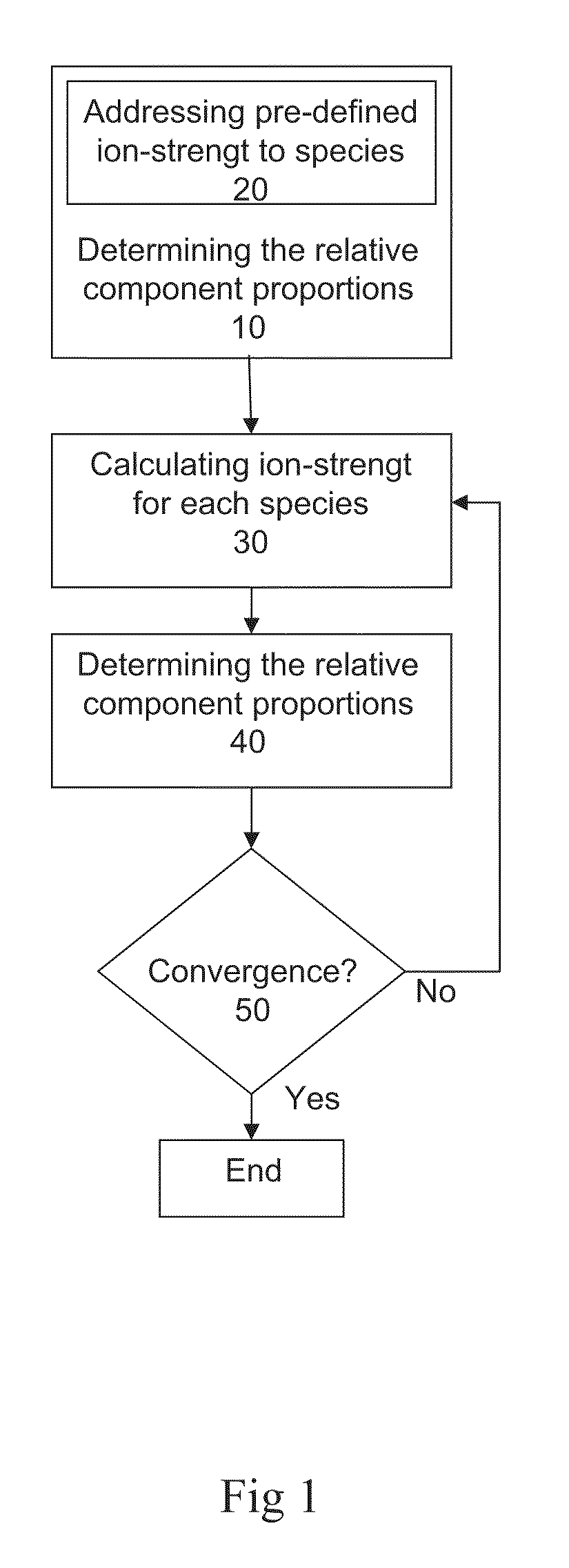

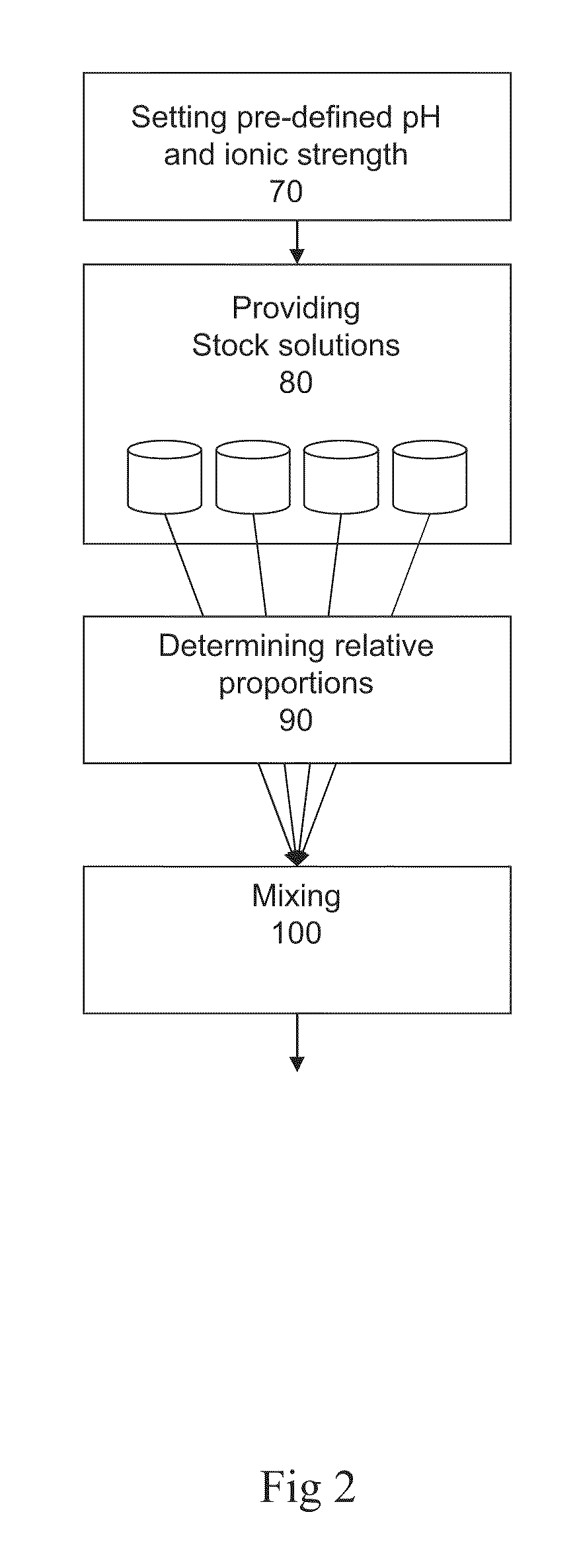

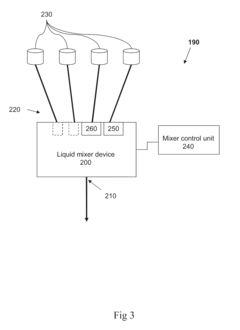

Preparation of liquid mixtures

PatentActiveUS20110039712A1

Innovation

- A method using the Debye-Hückel equation to calculate the ion size parameter as the weighted mean ion size of all species contributing to ionic strength, allowing for precise determination of relative component proportions to achieve pre-defined pH and ionic strength, implemented in an auto-dispensing device for intelligent buffer preparation.

Safety and Environmental Considerations

The integration of neopentane in manufacturing processes necessitates rigorous safety and environmental considerations due to its highly flammable nature and potential environmental impacts. Safety measures are paramount, starting with proper storage and handling protocols. Neopentane should be stored in well-ventilated areas, away from sources of ignition, and in containers designed to withstand pressure. Implementing robust leak detection systems and regular equipment inspections are crucial to prevent accidental releases.

Personal protective equipment (PPE) is essential for workers handling neopentane. This includes flame-resistant clothing, safety goggles, and appropriate respiratory protection. Training programs should be comprehensive, covering safe handling procedures, emergency response protocols, and the proper use of safety equipment. Establishing clear communication channels and emergency evacuation plans is vital for rapid response in case of incidents.

From an environmental perspective, neopentane poses challenges due to its volatile organic compound (VOC) status. Manufacturers must implement effective emission control technologies to minimize atmospheric releases. This may include the use of vapor recovery systems, thermal oxidizers, or carbon adsorption units. Regular monitoring of air quality in and around manufacturing facilities is essential to ensure compliance with environmental regulations and to protect local ecosystems.

Water management is another critical aspect, as neopentane can potentially contaminate water sources if not properly contained. Implementing spill prevention and containment measures, such as secondary containment systems and impermeable surfaces in storage and handling areas, is crucial. Wastewater treatment systems should be designed to effectively remove any traces of neopentane before discharge.

Waste management strategies should focus on minimizing neopentane-containing waste and ensuring proper disposal methods. This may involve recycling or reprocessing neopentane where possible, and using specialized disposal services for contaminated materials. Implementing a closed-loop system can significantly reduce waste and environmental impact.

Continuous improvement in safety and environmental practices is essential. This includes staying abreast of the latest regulatory requirements, conducting regular risk assessments, and investing in research and development of safer, more environmentally friendly manufacturing processes. Collaboration with industry peers, regulatory bodies, and environmental experts can drive innovation in sustainable neopentane integration practices.

Personal protective equipment (PPE) is essential for workers handling neopentane. This includes flame-resistant clothing, safety goggles, and appropriate respiratory protection. Training programs should be comprehensive, covering safe handling procedures, emergency response protocols, and the proper use of safety equipment. Establishing clear communication channels and emergency evacuation plans is vital for rapid response in case of incidents.

From an environmental perspective, neopentane poses challenges due to its volatile organic compound (VOC) status. Manufacturers must implement effective emission control technologies to minimize atmospheric releases. This may include the use of vapor recovery systems, thermal oxidizers, or carbon adsorption units. Regular monitoring of air quality in and around manufacturing facilities is essential to ensure compliance with environmental regulations and to protect local ecosystems.

Water management is another critical aspect, as neopentane can potentially contaminate water sources if not properly contained. Implementing spill prevention and containment measures, such as secondary containment systems and impermeable surfaces in storage and handling areas, is crucial. Wastewater treatment systems should be designed to effectively remove any traces of neopentane before discharge.

Waste management strategies should focus on minimizing neopentane-containing waste and ensuring proper disposal methods. This may involve recycling or reprocessing neopentane where possible, and using specialized disposal services for contaminated materials. Implementing a closed-loop system can significantly reduce waste and environmental impact.

Continuous improvement in safety and environmental practices is essential. This includes staying abreast of the latest regulatory requirements, conducting regular risk assessments, and investing in research and development of safer, more environmentally friendly manufacturing processes. Collaboration with industry peers, regulatory bodies, and environmental experts can drive innovation in sustainable neopentane integration practices.

Economic Feasibility of Neopentane Integration

The economic feasibility of neopentane integration in manufacturing processes is a critical consideration for industries seeking to optimize their production methods. Neopentane, a highly volatile hydrocarbon, offers unique properties that can potentially enhance manufacturing efficiency and product quality. However, its implementation requires careful analysis of costs, benefits, and potential risks.

From a cost perspective, integrating neopentane into manufacturing processes may require significant initial investments. These include modifications to existing equipment, installation of specialized storage and handling systems, and implementation of additional safety measures. The volatile nature of neopentane necessitates robust containment and monitoring systems, which can add to the overall implementation costs.

Despite the upfront expenses, the long-term economic benefits of neopentane integration can be substantial. Its low boiling point and high vapor pressure make it an excellent blowing agent in foam production, potentially reducing material costs and improving product quality. In the refrigeration industry, neopentane's thermodynamic properties can lead to increased energy efficiency, translating to lower operational costs over time.

The market demand for products manufactured using neopentane-based processes is another crucial factor in determining economic feasibility. Industries such as automotive, construction, and appliance manufacturing are increasingly seeking eco-friendly and energy-efficient solutions, which neopentane can help deliver. This growing demand can potentially offset the initial implementation costs and drive long-term profitability.

Regulatory compliance is a significant consideration in the economic analysis. While neopentane offers environmental benefits due to its low global warming potential, its flammability requires adherence to strict safety regulations. Compliance costs, including training, documentation, and ongoing monitoring, must be factored into the overall economic assessment.

The scalability of neopentane integration is another key economic factor. As production volumes increase, the cost per unit typically decreases, improving overall economic viability. However, this requires careful planning to ensure that the supply chain can reliably meet increased demand for neopentane without significant price fluctuations.

In conclusion, the economic feasibility of neopentane integration in manufacturing depends on a complex interplay of factors. While initial costs may be substantial, the potential for improved product quality, energy efficiency, and market competitiveness can lead to long-term economic benefits. A thorough cost-benefit analysis, considering both immediate expenses and future returns, is essential for manufacturers considering the adoption of neopentane-based processes.

From a cost perspective, integrating neopentane into manufacturing processes may require significant initial investments. These include modifications to existing equipment, installation of specialized storage and handling systems, and implementation of additional safety measures. The volatile nature of neopentane necessitates robust containment and monitoring systems, which can add to the overall implementation costs.

Despite the upfront expenses, the long-term economic benefits of neopentane integration can be substantial. Its low boiling point and high vapor pressure make it an excellent blowing agent in foam production, potentially reducing material costs and improving product quality. In the refrigeration industry, neopentane's thermodynamic properties can lead to increased energy efficiency, translating to lower operational costs over time.

The market demand for products manufactured using neopentane-based processes is another crucial factor in determining economic feasibility. Industries such as automotive, construction, and appliance manufacturing are increasingly seeking eco-friendly and energy-efficient solutions, which neopentane can help deliver. This growing demand can potentially offset the initial implementation costs and drive long-term profitability.

Regulatory compliance is a significant consideration in the economic analysis. While neopentane offers environmental benefits due to its low global warming potential, its flammability requires adherence to strict safety regulations. Compliance costs, including training, documentation, and ongoing monitoring, must be factored into the overall economic assessment.

The scalability of neopentane integration is another key economic factor. As production volumes increase, the cost per unit typically decreases, improving overall economic viability. However, this requires careful planning to ensure that the supply chain can reliably meet increased demand for neopentane without significant price fluctuations.

In conclusion, the economic feasibility of neopentane integration in manufacturing depends on a complex interplay of factors. While initial costs may be substantial, the potential for improved product quality, energy efficiency, and market competitiveness can lead to long-term economic benefits. A thorough cost-benefit analysis, considering both immediate expenses and future returns, is essential for manufacturers considering the adoption of neopentane-based processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!