Neopentane: Future Applications in Synthetic Fibers

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Overview and Research Objectives

Neopentane, also known as 2,2-dimethylpropane, is a branched-chain alkane with the molecular formula C5H12. This colorless, flammable gas has gained significant attention in recent years due to its unique properties and potential applications in various industries, particularly in the field of synthetic fibers. The evolution of neopentane as a key component in advanced materials has been driven by the increasing demand for high-performance textiles and the need for more sustainable manufacturing processes.

The development of neopentane-based technologies for synthetic fiber production represents a promising frontier in materials science. This research aims to explore the potential of neopentane as a precursor or additive in the synthesis of novel fibers with enhanced properties. The primary objective is to investigate how neopentane's molecular structure and chemical characteristics can be leveraged to create fibers with improved strength, elasticity, thermal resistance, and environmental sustainability.

Historical trends in synthetic fiber technology have shown a continuous push towards materials that offer superior performance while minimizing environmental impact. Neopentane's unique branched structure and relatively low boiling point present intriguing possibilities for fiber engineering. By incorporating neopentane into the fiber production process, researchers anticipate the development of materials with exceptional insulation properties, lightweight characteristics, and potentially self-healing capabilities.

The current technological landscape surrounding neopentane in synthetic fibers is characterized by a blend of theoretical research and early-stage experimental applications. Scientists are exploring various approaches, including the use of neopentane as a blowing agent in foam-based fibers, as a reactive intermediate in polymer synthesis, and as a modifier in existing fiber production methods. These diverse avenues of investigation reflect the multifaceted potential of neopentane in revolutionizing the synthetic fiber industry.

As we delve deeper into the research objectives, it is crucial to consider the broader implications of neopentane-based fiber technologies. This includes assessing the scalability of production processes, evaluating the economic viability of neopentane integration, and addressing potential environmental concerns associated with its use. The ultimate goal is to establish a comprehensive understanding of neopentane's role in next-generation synthetic fibers, paving the way for innovative textile solutions that meet the evolving needs of various sectors, from fashion and sports to aerospace and medical applications.

The development of neopentane-based technologies for synthetic fiber production represents a promising frontier in materials science. This research aims to explore the potential of neopentane as a precursor or additive in the synthesis of novel fibers with enhanced properties. The primary objective is to investigate how neopentane's molecular structure and chemical characteristics can be leveraged to create fibers with improved strength, elasticity, thermal resistance, and environmental sustainability.

Historical trends in synthetic fiber technology have shown a continuous push towards materials that offer superior performance while minimizing environmental impact. Neopentane's unique branched structure and relatively low boiling point present intriguing possibilities for fiber engineering. By incorporating neopentane into the fiber production process, researchers anticipate the development of materials with exceptional insulation properties, lightweight characteristics, and potentially self-healing capabilities.

The current technological landscape surrounding neopentane in synthetic fibers is characterized by a blend of theoretical research and early-stage experimental applications. Scientists are exploring various approaches, including the use of neopentane as a blowing agent in foam-based fibers, as a reactive intermediate in polymer synthesis, and as a modifier in existing fiber production methods. These diverse avenues of investigation reflect the multifaceted potential of neopentane in revolutionizing the synthetic fiber industry.

As we delve deeper into the research objectives, it is crucial to consider the broader implications of neopentane-based fiber technologies. This includes assessing the scalability of production processes, evaluating the economic viability of neopentane integration, and addressing potential environmental concerns associated with its use. The ultimate goal is to establish a comprehensive understanding of neopentane's role in next-generation synthetic fibers, paving the way for innovative textile solutions that meet the evolving needs of various sectors, from fashion and sports to aerospace and medical applications.

Synthetic Fiber Market Analysis

The synthetic fiber market has experienced significant growth over the past decade, driven by increasing demand from various end-use industries such as textiles, automotive, and construction. This market is characterized by its versatility, cost-effectiveness, and superior performance characteristics compared to natural fibers. The global synthetic fiber market size was valued at approximately $59 billion in 2020 and is projected to reach $88 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.8% during the forecast period.

Polyester remains the dominant synthetic fiber, accounting for over 50% of the market share due to its widespread use in clothing and home textiles. Nylon and acrylic fibers follow, with growing applications in industrial and technical textiles. The Asia-Pacific region leads the market, with China being the largest producer and consumer of synthetic fibers, followed by India and Southeast Asian countries.

The market is witnessing several key trends that are shaping its future trajectory. Sustainability has become a critical focus, with manufacturers investing in recycled and bio-based synthetic fibers to address environmental concerns. This shift is driven by increasing consumer awareness and stringent regulations on plastic waste and carbon emissions. Additionally, there is a growing demand for high-performance fibers in technical textiles, particularly in sectors such as aerospace, defense, and healthcare.

Innovation in fiber technology is another significant driver of market growth. Advanced fibers with properties such as enhanced durability, moisture-wicking, and temperature regulation are gaining traction in sportswear and athleisure markets. The integration of smart textiles, incorporating conductive fibers and sensors, is opening new avenues in wearable technology and medical textiles.

The potential application of neopentane in synthetic fiber production presents an intriguing opportunity for market expansion. Neopentane, with its unique chemical properties, could potentially enhance the performance characteristics of synthetic fibers, particularly in terms of thermal insulation and lightweight properties. This innovation could find applications in outdoor apparel, aerospace materials, and high-performance sportswear, potentially creating a new segment within the synthetic fiber market.

However, the market faces challenges such as volatile raw material prices, particularly petroleum-based feedstocks, which impact production costs and profit margins. Environmental concerns and the push towards circular economy models also pose challenges, necessitating significant investments in research and development for sustainable alternatives.

Polyester remains the dominant synthetic fiber, accounting for over 50% of the market share due to its widespread use in clothing and home textiles. Nylon and acrylic fibers follow, with growing applications in industrial and technical textiles. The Asia-Pacific region leads the market, with China being the largest producer and consumer of synthetic fibers, followed by India and Southeast Asian countries.

The market is witnessing several key trends that are shaping its future trajectory. Sustainability has become a critical focus, with manufacturers investing in recycled and bio-based synthetic fibers to address environmental concerns. This shift is driven by increasing consumer awareness and stringent regulations on plastic waste and carbon emissions. Additionally, there is a growing demand for high-performance fibers in technical textiles, particularly in sectors such as aerospace, defense, and healthcare.

Innovation in fiber technology is another significant driver of market growth. Advanced fibers with properties such as enhanced durability, moisture-wicking, and temperature regulation are gaining traction in sportswear and athleisure markets. The integration of smart textiles, incorporating conductive fibers and sensors, is opening new avenues in wearable technology and medical textiles.

The potential application of neopentane in synthetic fiber production presents an intriguing opportunity for market expansion. Neopentane, with its unique chemical properties, could potentially enhance the performance characteristics of synthetic fibers, particularly in terms of thermal insulation and lightweight properties. This innovation could find applications in outdoor apparel, aerospace materials, and high-performance sportswear, potentially creating a new segment within the synthetic fiber market.

However, the market faces challenges such as volatile raw material prices, particularly petroleum-based feedstocks, which impact production costs and profit margins. Environmental concerns and the push towards circular economy models also pose challenges, necessitating significant investments in research and development for sustainable alternatives.

Neopentane Properties and Technical Challenges

Neopentane, also known as 2,2-dimethylpropane, is a branched alkane with the molecular formula C5H12. Its unique structure, consisting of a central carbon atom bonded to four methyl groups, imparts distinctive properties that make it an intriguing candidate for various applications, including synthetic fiber production. However, these same characteristics also present significant technical challenges that must be addressed for its effective utilization.

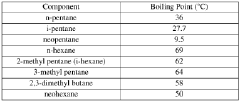

One of the key properties of neopentane is its low boiling point of 9.5°C (49.1°F), which is considerably lower than its straight-chain isomer, n-pentane. This low boiling point is attributed to its compact, spherical shape, which minimizes intermolecular forces. While this property can be advantageous in certain applications, it poses challenges in handling and storage, particularly in warmer environments where the compound may readily vaporize.

Neopentane's high volatility is accompanied by a relatively high vapor pressure, which can lead to increased evaporation rates and potential safety concerns in industrial settings. This characteristic necessitates specialized containment and handling procedures to prevent unintended release and ensure worker safety.

The compound's branched structure contributes to its high octane rating and resistance to autoignition, properties that have made it valuable in the fuel industry. However, these same attributes can present challenges in chemical reactions and processing for synthetic fiber applications, as the molecule's stability may hinder desired transformations or incorporations into polymer structures.

Another significant property of neopentane is its low reactivity compared to linear alkanes. The absence of secondary or tertiary carbon atoms makes it less susceptible to certain types of chemical reactions, such as substitution or elimination. This chemical inertness can be both an advantage and a challenge, depending on the desired application in synthetic fiber production.

From a technical perspective, integrating neopentane into synthetic fiber manufacturing processes presents several challenges. The compound's low boiling point and high vapor pressure require specialized equipment and process controls to maintain it in a liquid state during fiber formation. Additionally, its limited solubility in many common solvents used in fiber production may necessitate the development of new solvent systems or processing techniques.

The incorporation of neopentane into polymer structures for fiber production also faces hurdles related to its molecular geometry. The bulky, spherical shape of neopentane molecules can disrupt the typical linear or semi-crystalline arrangements found in many synthetic fibers, potentially affecting properties such as strength, elasticity, and thermal stability.

One of the key properties of neopentane is its low boiling point of 9.5°C (49.1°F), which is considerably lower than its straight-chain isomer, n-pentane. This low boiling point is attributed to its compact, spherical shape, which minimizes intermolecular forces. While this property can be advantageous in certain applications, it poses challenges in handling and storage, particularly in warmer environments where the compound may readily vaporize.

Neopentane's high volatility is accompanied by a relatively high vapor pressure, which can lead to increased evaporation rates and potential safety concerns in industrial settings. This characteristic necessitates specialized containment and handling procedures to prevent unintended release and ensure worker safety.

The compound's branched structure contributes to its high octane rating and resistance to autoignition, properties that have made it valuable in the fuel industry. However, these same attributes can present challenges in chemical reactions and processing for synthetic fiber applications, as the molecule's stability may hinder desired transformations or incorporations into polymer structures.

Another significant property of neopentane is its low reactivity compared to linear alkanes. The absence of secondary or tertiary carbon atoms makes it less susceptible to certain types of chemical reactions, such as substitution or elimination. This chemical inertness can be both an advantage and a challenge, depending on the desired application in synthetic fiber production.

From a technical perspective, integrating neopentane into synthetic fiber manufacturing processes presents several challenges. The compound's low boiling point and high vapor pressure require specialized equipment and process controls to maintain it in a liquid state during fiber formation. Additionally, its limited solubility in many common solvents used in fiber production may necessitate the development of new solvent systems or processing techniques.

The incorporation of neopentane into polymer structures for fiber production also faces hurdles related to its molecular geometry. The bulky, spherical shape of neopentane molecules can disrupt the typical linear or semi-crystalline arrangements found in many synthetic fibers, potentially affecting properties such as strength, elasticity, and thermal stability.

Current Neopentane-based Fiber Production Methods

01 Production and purification of neopentane

Methods for producing and purifying neopentane, including separation techniques from hydrocarbon mixtures and catalytic processes for its synthesis. These processes aim to obtain high-purity neopentane for various industrial applications.- Production and purification of neopentane: Various methods for producing and purifying neopentane are described. These include processes for separating neopentane from other hydrocarbons, such as using distillation or membrane separation techniques. The purification methods aim to obtain high-purity neopentane for industrial applications.

- Neopentane as a blowing agent: Neopentane is utilized as a blowing agent in the production of foams and other expanded materials. Its low boiling point and non-flammability make it suitable for use in various polymer foaming processes, particularly in the production of insulation materials and packaging.

- Neopentane in refrigeration systems: The use of neopentane in refrigeration systems is explored due to its thermodynamic properties. It is considered as a potential alternative refrigerant in certain applications, offering environmental benefits compared to some traditional refrigerants.

- Neopentane as a chemical intermediate: Neopentane serves as a valuable chemical intermediate in various synthetic processes. It is used in the production of specialty chemicals, pharmaceuticals, and other organic compounds. The unique structure of neopentane makes it useful for creating branched hydrocarbons and other derivatives.

- Safety and handling of neopentane: Due to its flammability and volatility, special considerations are required for the safe handling and storage of neopentane. This includes proper containment methods, safety measures during transportation, and guidelines for its use in industrial processes to minimize risks associated with its physical properties.

02 Use of neopentane in refrigeration systems

Neopentane is utilized as a refrigerant in various cooling systems due to its thermodynamic properties. It serves as an environmentally friendly alternative to traditional refrigerants, offering improved energy efficiency and reduced environmental impact.Expand Specific Solutions03 Neopentane as a blowing agent

Applications of neopentane as a blowing agent in the production of foams and insulation materials. Its low boiling point and non-flammability make it suitable for creating lightweight, thermally efficient products in construction and packaging industries.Expand Specific Solutions04 Neopentane in chemical synthesis

Use of neopentane as a starting material or intermediate in various chemical synthesis processes. Its unique structure and reactivity make it valuable in the production of specialty chemicals, pharmaceuticals, and advanced materials.Expand Specific Solutions05 Safety and handling of neopentane

Guidelines and technologies for the safe storage, transportation, and handling of neopentane. This includes methods for preventing leaks, managing vapor pressure, and ensuring proper containment to minimize environmental and safety risks associated with its use.Expand Specific Solutions

Key Players in Neopentane and Synthetic Fiber Industries

The development of neopentane applications in synthetic fibers is in its early stages, with a growing market potential due to increasing demand for advanced materials. The technology's maturity varies among key players, with research institutions like North Carolina State University and the University of Akron leading academic efforts. Industry giants such as DuPont de Nemours, Shin-Etsu Chemical, and Kuraray are leveraging their expertise in chemical engineering to explore commercial applications. Emerging companies like OneD Material and Cathay Biotech are focusing on innovative approaches to synthetic biology and nanomaterials, potentially disrupting traditional manufacturing processes. The competitive landscape is diverse, with collaborations between academia and industry driving progress in this niche but promising field.

DuPont de Nemours, Inc.

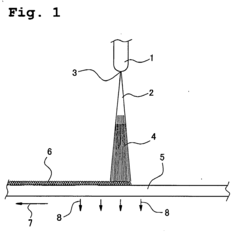

Technical Solution: DuPont has been exploring the use of neopentane in synthetic fiber production, particularly for high-performance polymers. Their approach involves incorporating neopentane as a blowing agent in the fiber extrusion process, resulting in fibers with enhanced thermal insulation properties[1]. The company has developed a proprietary method to control the neopentane dispersion within the fiber structure, creating micro-voids that significantly improve the fiber's insulation capacity without compromising its strength[2]. This technology has shown promise in producing lightweight, thermally efficient fabrics for outdoor and protective wear applications[3].

Strengths: Improved thermal insulation, lightweight fibers, and potential for high-performance fabrics. Weaknesses: Potential volatility of neopentane during processing and long-term stability concerns.

Dow Global Technologies LLC

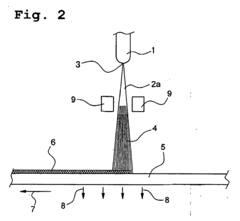

Technical Solution: Dow has been investigating the use of neopentane as a key component in developing advanced synthetic fibers with unique properties. Their research focuses on utilizing neopentane's low boiling point and high vapor pressure to create fibers with controlled porosity[4]. By incorporating neopentane into the polymer matrix during fiber formation, Dow has achieved a novel method of producing fibers with adjustable density and thermal conductivity[5]. This technology has potential applications in creating adaptive clothing materials that can respond to environmental changes, offering improved comfort and performance in various conditions[6].

Strengths: Adaptable fiber properties, potential for smart textiles, and versatile applications. Weaknesses: Complexity in manufacturing process and potential cost implications.

Innovative Neopentane Applications in Fiber Technology

Production of neopentane

PatentWO2018044592A1

Innovation

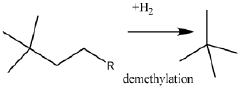

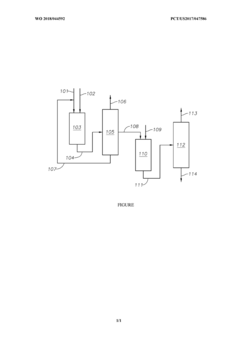

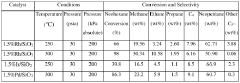

- A process involving the isomerization of C6-C7 paraffins to produce neohexane or neoheptane, followed by demethylation using a catalyst in the presence of hydrogen, which allows for the production of neopentane with yields greater than 40 wt% from readily available C4-C7 paraffinic feed streams, such as light virgin naphtha.

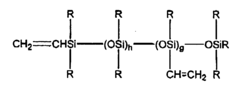

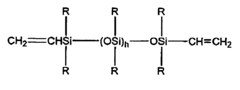

Silicone-based fiber, nonwoven fabric formed therefrom, and methods of producing same

PatentInactiveEP1895032A2

Innovation

- Development of a non-melting silicone-based fiber with a specific elemental composition (SiC a H b O c) that is produced through melt spinning and non-melting treatment, and a method for forming a silicone nonwoven fabric using curable silicone compositions, which provides superior heat resistance, wettability, and mechanical strength.

Environmental Impact of Neopentane in Fiber Production

The environmental impact of neopentane in fiber production is a critical consideration as the synthetic fiber industry explores new applications for this compound. Neopentane, a branched alkane isomer of pentane, has shown promise in various industrial processes due to its unique chemical properties. However, its potential use in synthetic fiber production raises important questions about its ecological footprint.

One of the primary environmental concerns associated with neopentane in fiber production is its volatile organic compound (VOC) emissions. As a highly volatile substance, neopentane can easily evaporate during manufacturing processes, contributing to air pollution and potentially affecting local air quality. This issue necessitates the implementation of advanced emission control technologies and strict handling protocols to minimize atmospheric release.

Water pollution is another significant environmental factor to consider. Although neopentane is not highly soluble in water, accidental spills or improper disposal of neopentane-containing waste could lead to contamination of water bodies. This risk underscores the importance of developing robust waste management systems and spill prevention measures in facilities utilizing neopentane for fiber production.

The production of neopentane itself also carries environmental implications. As a petroleum-derived compound, its manufacture contributes to the carbon footprint of the fiber production process. The energy-intensive nature of neopentane synthesis, coupled with the environmental impacts of oil extraction and refining, adds to the overall ecological burden of synthetic fibers incorporating this compound.

However, it is essential to consider the potential environmental benefits that neopentane might bring to synthetic fiber production. If its use leads to more efficient manufacturing processes or results in fibers with enhanced durability and longevity, it could potentially reduce overall resource consumption and waste generation in the long term. This balance between immediate environmental impacts and long-term sustainability benefits requires careful analysis and consideration.

Biodegradability and end-of-life disposal of neopentane-infused fibers present another environmental challenge. The persistence of synthetic materials in the environment is a well-documented issue, and the addition of neopentane to fiber compositions may further complicate recycling and decomposition processes. Research into the long-term environmental fate of these materials is crucial to understanding their full ecological impact.

As the synthetic fiber industry explores the integration of neopentane, it must also consider the regulatory landscape surrounding its use. Environmental regulations regarding VOC emissions, waste disposal, and chemical safety are likely to influence the adoption and implementation of neopentane in fiber production processes. Compliance with these regulations will be essential for ensuring environmentally responsible manufacturing practices.

One of the primary environmental concerns associated with neopentane in fiber production is its volatile organic compound (VOC) emissions. As a highly volatile substance, neopentane can easily evaporate during manufacturing processes, contributing to air pollution and potentially affecting local air quality. This issue necessitates the implementation of advanced emission control technologies and strict handling protocols to minimize atmospheric release.

Water pollution is another significant environmental factor to consider. Although neopentane is not highly soluble in water, accidental spills or improper disposal of neopentane-containing waste could lead to contamination of water bodies. This risk underscores the importance of developing robust waste management systems and spill prevention measures in facilities utilizing neopentane for fiber production.

The production of neopentane itself also carries environmental implications. As a petroleum-derived compound, its manufacture contributes to the carbon footprint of the fiber production process. The energy-intensive nature of neopentane synthesis, coupled with the environmental impacts of oil extraction and refining, adds to the overall ecological burden of synthetic fibers incorporating this compound.

However, it is essential to consider the potential environmental benefits that neopentane might bring to synthetic fiber production. If its use leads to more efficient manufacturing processes or results in fibers with enhanced durability and longevity, it could potentially reduce overall resource consumption and waste generation in the long term. This balance between immediate environmental impacts and long-term sustainability benefits requires careful analysis and consideration.

Biodegradability and end-of-life disposal of neopentane-infused fibers present another environmental challenge. The persistence of synthetic materials in the environment is a well-documented issue, and the addition of neopentane to fiber compositions may further complicate recycling and decomposition processes. Research into the long-term environmental fate of these materials is crucial to understanding their full ecological impact.

As the synthetic fiber industry explores the integration of neopentane, it must also consider the regulatory landscape surrounding its use. Environmental regulations regarding VOC emissions, waste disposal, and chemical safety are likely to influence the adoption and implementation of neopentane in fiber production processes. Compliance with these regulations will be essential for ensuring environmentally responsible manufacturing practices.

Regulatory Framework for Neopentane Use in Textiles

The regulatory framework for neopentane use in textiles is a complex and evolving landscape that requires careful consideration by manufacturers, retailers, and policymakers. As neopentane gains traction as a potential component in synthetic fiber production, it is crucial to understand the current regulatory environment and anticipate future developments.

At present, the use of neopentane in textiles is not specifically regulated in most jurisdictions. However, its application falls under broader chemical and textile regulations. In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is the primary framework governing chemical use. Manufacturers intending to use neopentane in synthetic fibers would need to register the substance and provide safety data to the European Chemicals Agency (ECHA).

In the United States, the Toxic Substances Control Act (TSCA) oversees chemical regulations. The Environmental Protection Agency (EPA) maintains an inventory of existing chemicals and requires notification for new chemical substances. Neopentane, being an existing chemical, is listed in the TSCA inventory. However, its novel use in textiles may require additional reporting and risk assessment.

Safety considerations are paramount in the regulatory framework. Neopentane is highly flammable, which raises concerns about fire safety in textile applications. Regulatory bodies such as the Consumer Product Safety Commission (CPSC) in the US and the European Committee for Standardization (CEN) may need to develop specific standards for neopentane-containing textiles to ensure consumer safety.

Environmental regulations also play a significant role. Neopentane is a volatile organic compound (VOC) and may be subject to emissions controls. The Clean Air Act in the US and similar legislation in other countries may impose limits on neopentane emissions during the manufacturing process. Additionally, the potential for neopentane to contribute to greenhouse gas emissions may lead to scrutiny under climate change regulations.

Looking ahead, the regulatory landscape for neopentane in textiles is likely to evolve. As research progresses and potential applications become more defined, regulators may develop more specific guidelines. This could include requirements for labeling, disposal, and recycling of neopentane-containing textiles. The textile industry may also see the emergence of voluntary standards and certifications related to the use of neopentane, similar to existing eco-labels for other synthetic materials.

International harmonization of regulations will be crucial as the global textile industry adopts new technologies. Organizations such as the International Organization for Standardization (ISO) may play a role in developing uniform standards for neopentane use in textiles, facilitating international trade and ensuring consistent safety measures across borders.

At present, the use of neopentane in textiles is not specifically regulated in most jurisdictions. However, its application falls under broader chemical and textile regulations. In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is the primary framework governing chemical use. Manufacturers intending to use neopentane in synthetic fibers would need to register the substance and provide safety data to the European Chemicals Agency (ECHA).

In the United States, the Toxic Substances Control Act (TSCA) oversees chemical regulations. The Environmental Protection Agency (EPA) maintains an inventory of existing chemicals and requires notification for new chemical substances. Neopentane, being an existing chemical, is listed in the TSCA inventory. However, its novel use in textiles may require additional reporting and risk assessment.

Safety considerations are paramount in the regulatory framework. Neopentane is highly flammable, which raises concerns about fire safety in textile applications. Regulatory bodies such as the Consumer Product Safety Commission (CPSC) in the US and the European Committee for Standardization (CEN) may need to develop specific standards for neopentane-containing textiles to ensure consumer safety.

Environmental regulations also play a significant role. Neopentane is a volatile organic compound (VOC) and may be subject to emissions controls. The Clean Air Act in the US and similar legislation in other countries may impose limits on neopentane emissions during the manufacturing process. Additionally, the potential for neopentane to contribute to greenhouse gas emissions may lead to scrutiny under climate change regulations.

Looking ahead, the regulatory landscape for neopentane in textiles is likely to evolve. As research progresses and potential applications become more defined, regulators may develop more specific guidelines. This could include requirements for labeling, disposal, and recycling of neopentane-containing textiles. The textile industry may also see the emergence of voluntary standards and certifications related to the use of neopentane, similar to existing eco-labels for other synthetic materials.

International harmonization of regulations will be crucial as the global textile industry adopts new technologies. Organizations such as the International Organization for Standardization (ISO) may play a role in developing uniform standards for neopentane use in textiles, facilitating international trade and ensuring consistent safety measures across borders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!