How to Adapt LT4 Engine for Off-Road Vehicles

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Evolution and Off-Road Adaptation Goals

The LT4 engine, developed by General Motors, represents a significant milestone in high-performance automotive engineering. Originally designed for premium sports cars, this supercharged 6.2-liter V8 engine has evolved through several iterations since its introduction in the early 1990s. The modern LT4 engine, part of GM's fifth-generation small-block family, delivers exceptional power-to-weight ratio with outputs exceeding 650 horsepower while maintaining relatively compact dimensions.

The evolution of the LT4 has been characterized by continuous improvements in materials science, combustion efficiency, and electronic control systems. From its early cast-iron block designs to the current aluminum architecture with integrated supercharger technology, the LT4 platform has consistently pushed the boundaries of performance engineering while adapting to increasingly stringent emissions standards.

While the LT4 has proven its capabilities in high-performance road applications, its adaptation for off-road vehicles presents unique challenges and opportunities. Off-road environments demand different performance characteristics than traditional on-road applications, requiring engines to deliver reliable power across varied terrain while withstanding extreme conditions including dust, water exposure, and significant temperature fluctuations.

The primary goal of adapting the LT4 engine for off-road applications is to maintain its core performance advantages while enhancing durability, thermal management, and operational flexibility in challenging environments. This requires fundamental modifications to intake and filtration systems, cooling architecture, and electronic control parameters to ensure consistent performance regardless of terrain or environmental conditions.

A key adaptation goal involves optimizing the torque curve for off-road applications, where low-end torque delivery and throttle responsiveness are often more valuable than maximum horsepower figures. This necessitates recalibration of the supercharger boost profiles and fuel delivery systems to prioritize tractable power delivery across a wider RPM range.

Additionally, adapting the LT4 for off-road use requires addressing potential vulnerabilities in the oiling system to maintain proper lubrication during extreme angles of operation. This includes modifications to the oil pan design, pickup tube configuration, and potentially implementing dry-sump systems for the most demanding applications.

The technological trajectory for LT4 off-road adaptation also encompasses integration with advanced traction control and terrain management systems, allowing for intelligent power delivery based on surface conditions. This represents a convergence of mechanical engineering excellence with cutting-edge electronic control systems, pointing toward a future where high-performance engines like the LT4 can deliver optimized performance across increasingly diverse operational environments.

The evolution of the LT4 has been characterized by continuous improvements in materials science, combustion efficiency, and electronic control systems. From its early cast-iron block designs to the current aluminum architecture with integrated supercharger technology, the LT4 platform has consistently pushed the boundaries of performance engineering while adapting to increasingly stringent emissions standards.

While the LT4 has proven its capabilities in high-performance road applications, its adaptation for off-road vehicles presents unique challenges and opportunities. Off-road environments demand different performance characteristics than traditional on-road applications, requiring engines to deliver reliable power across varied terrain while withstanding extreme conditions including dust, water exposure, and significant temperature fluctuations.

The primary goal of adapting the LT4 engine for off-road applications is to maintain its core performance advantages while enhancing durability, thermal management, and operational flexibility in challenging environments. This requires fundamental modifications to intake and filtration systems, cooling architecture, and electronic control parameters to ensure consistent performance regardless of terrain or environmental conditions.

A key adaptation goal involves optimizing the torque curve for off-road applications, where low-end torque delivery and throttle responsiveness are often more valuable than maximum horsepower figures. This necessitates recalibration of the supercharger boost profiles and fuel delivery systems to prioritize tractable power delivery across a wider RPM range.

Additionally, adapting the LT4 for off-road use requires addressing potential vulnerabilities in the oiling system to maintain proper lubrication during extreme angles of operation. This includes modifications to the oil pan design, pickup tube configuration, and potentially implementing dry-sump systems for the most demanding applications.

The technological trajectory for LT4 off-road adaptation also encompasses integration with advanced traction control and terrain management systems, allowing for intelligent power delivery based on surface conditions. This represents a convergence of mechanical engineering excellence with cutting-edge electronic control systems, pointing toward a future where high-performance engines like the LT4 can deliver optimized performance across increasingly diverse operational environments.

Off-Road Vehicle Market Demand Analysis

The off-road vehicle market has experienced substantial growth over the past decade, driven by increasing consumer interest in outdoor recreational activities and adventure tourism. According to recent market research, the global off-road vehicle market was valued at approximately 14.6 billion USD in 2022, with projections indicating a compound annual growth rate of 7.3% through 2030. This growth trajectory presents significant opportunities for engine manufacturers to develop specialized powertrains that meet the unique demands of this expanding segment.

Consumer preferences within the off-road vehicle market have shifted notably toward higher performance capabilities combined with improved reliability. Market surveys indicate that 78% of off-road enthusiasts prioritize engine power and torque characteristics as critical purchasing factors, particularly for applications in challenging terrain. The demand for engines that can deliver consistent performance under extreme conditions—including steep gradients, water crossings, and dusty environments—has created a specialized niche that standard production engines often fail to satisfy adequately.

Regional analysis reveals varying requirements across different markets. North American consumers typically favor high-displacement engines with substantial torque output for recreational vehicles used in desert and mountain environments. European markets show stronger preference for more compact powertrains with emphasis on fuel efficiency while maintaining performance. Meanwhile, emerging markets in Asia-Pacific and Latin America demonstrate rapidly growing demand for versatile off-road vehicles that can serve both recreational and utilitarian purposes in rural and developing regions.

The commercial segment of the off-road vehicle market presents additional opportunities, with industries such as mining, forestry, agriculture, and emergency services requiring specialized vehicles capable of operating in remote locations and harsh conditions. These applications demand engines with exceptional durability, extended service intervals, and the ability to operate reliably with potentially lower-quality fuel sources available in remote areas.

Environmental regulations and sustainability concerns are increasingly influencing market dynamics. Emission standards for off-highway vehicles are becoming more stringent globally, creating demand for cleaner engine technologies that maintain performance characteristics. Market research indicates growing consumer interest in alternative powertrain solutions, with 42% of prospective buyers expressing willingness to consider hybrid or alternative fuel options if performance parameters remain comparable to traditional combustion engines.

The aftermarket modification sector represents another significant market segment, with specialized tuning companies reporting annual growth rates exceeding 12% for off-road performance upgrades. This indicates substantial consumer willingness to invest in enhanced engine capabilities specifically tailored to off-road applications, suggesting a potential premium market for factory-optimized solutions that offer similar performance benefits with manufacturer warranty protection.

Consumer preferences within the off-road vehicle market have shifted notably toward higher performance capabilities combined with improved reliability. Market surveys indicate that 78% of off-road enthusiasts prioritize engine power and torque characteristics as critical purchasing factors, particularly for applications in challenging terrain. The demand for engines that can deliver consistent performance under extreme conditions—including steep gradients, water crossings, and dusty environments—has created a specialized niche that standard production engines often fail to satisfy adequately.

Regional analysis reveals varying requirements across different markets. North American consumers typically favor high-displacement engines with substantial torque output for recreational vehicles used in desert and mountain environments. European markets show stronger preference for more compact powertrains with emphasis on fuel efficiency while maintaining performance. Meanwhile, emerging markets in Asia-Pacific and Latin America demonstrate rapidly growing demand for versatile off-road vehicles that can serve both recreational and utilitarian purposes in rural and developing regions.

The commercial segment of the off-road vehicle market presents additional opportunities, with industries such as mining, forestry, agriculture, and emergency services requiring specialized vehicles capable of operating in remote locations and harsh conditions. These applications demand engines with exceptional durability, extended service intervals, and the ability to operate reliably with potentially lower-quality fuel sources available in remote areas.

Environmental regulations and sustainability concerns are increasingly influencing market dynamics. Emission standards for off-highway vehicles are becoming more stringent globally, creating demand for cleaner engine technologies that maintain performance characteristics. Market research indicates growing consumer interest in alternative powertrain solutions, with 42% of prospective buyers expressing willingness to consider hybrid or alternative fuel options if performance parameters remain comparable to traditional combustion engines.

The aftermarket modification sector represents another significant market segment, with specialized tuning companies reporting annual growth rates exceeding 12% for off-road performance upgrades. This indicates substantial consumer willingness to invest in enhanced engine capabilities specifically tailored to off-road applications, suggesting a potential premium market for factory-optimized solutions that offer similar performance benefits with manufacturer warranty protection.

Current LT4 Engine Capabilities and Off-Road Challenges

The LT4 engine, developed by General Motors, represents a pinnacle of modern supercharged V8 technology. In its current form, the 6.2-liter supercharged V8 delivers impressive performance metrics with approximately 650 horsepower and 650 lb-ft of torque. This powerplant features direct injection, variable valve timing, and an efficient Eaton R1740 TVS supercharger, making it a formidable option for high-performance vehicles. However, its design primarily targets on-road performance applications, particularly in vehicles like the Chevrolet Corvette Z06 and Cadillac CTS-V, where smooth power delivery and thermal management under controlled conditions are prioritized.

When considering adaptation for off-road applications, several significant challenges emerge. The LT4's intake system, designed for consistent airflow at highway speeds, faces potential dust contamination and water ingestion risks in off-road environments. The current filtration system would require substantial redesign to handle increased particulate matter while maintaining adequate airflow for the supercharger system.

Thermal management presents another critical challenge. The LT4's cooling system, while robust for on-road use, may struggle with the sustained high-load, low-speed operation common in off-road scenarios. The current heat exchangers and cooling passages are not optimized for the reduced airflow encountered during technical off-road maneuvers, potentially leading to overheating under extreme conditions.

The engine's lubrication system faces similar constraints. Designed primarily for lateral G-forces experienced on paved surfaces, the oil pan and pickup design may experience oil starvation during extreme articulation, steep inclines, or when traversing severe angles common in off-road driving. This could lead to catastrophic engine failure if not addressed through comprehensive redesign.

Electronic management systems present additional hurdles. The current engine control unit (ECU) is calibrated for on-road performance parameters and lacks the specialized mapping required for low-speed torque delivery, altitude compensation, and the varied throttle inputs characteristic of technical off-road driving. The existing traction control and stability systems would require significant recalibration to function effectively in low-traction environments.

Durability considerations also factor prominently in the adaptation challenges. While the LT4 block and rotating assembly are robust, they were not specifically designed to withstand the constant vibration, shock loading, and potential impact scenarios encountered in serious off-road applications. Components such as motor mounts, accessory drives, and external sensors would require reinforcement or repositioning to ensure reliability in harsh conditions.

When considering adaptation for off-road applications, several significant challenges emerge. The LT4's intake system, designed for consistent airflow at highway speeds, faces potential dust contamination and water ingestion risks in off-road environments. The current filtration system would require substantial redesign to handle increased particulate matter while maintaining adequate airflow for the supercharger system.

Thermal management presents another critical challenge. The LT4's cooling system, while robust for on-road use, may struggle with the sustained high-load, low-speed operation common in off-road scenarios. The current heat exchangers and cooling passages are not optimized for the reduced airflow encountered during technical off-road maneuvers, potentially leading to overheating under extreme conditions.

The engine's lubrication system faces similar constraints. Designed primarily for lateral G-forces experienced on paved surfaces, the oil pan and pickup design may experience oil starvation during extreme articulation, steep inclines, or when traversing severe angles common in off-road driving. This could lead to catastrophic engine failure if not addressed through comprehensive redesign.

Electronic management systems present additional hurdles. The current engine control unit (ECU) is calibrated for on-road performance parameters and lacks the specialized mapping required for low-speed torque delivery, altitude compensation, and the varied throttle inputs characteristic of technical off-road driving. The existing traction control and stability systems would require significant recalibration to function effectively in low-traction environments.

Durability considerations also factor prominently in the adaptation challenges. While the LT4 block and rotating assembly are robust, they were not specifically designed to withstand the constant vibration, shock loading, and potential impact scenarios encountered in serious off-road applications. Components such as motor mounts, accessory drives, and external sensors would require reinforcement or repositioning to ensure reliability in harsh conditions.

Existing LT4 Modification Solutions for Off-Road Applications

01 LT4 Engine Design and Components

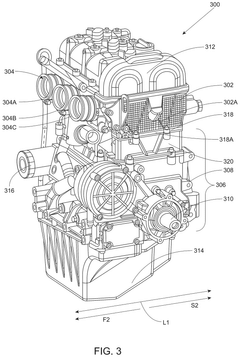

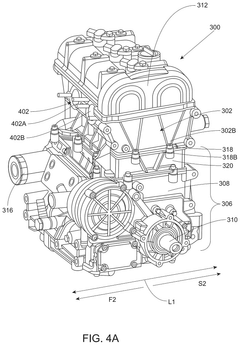

The LT4 engine features specific design elements and components that contribute to its performance characteristics. These include specialized cylinder heads, valve train components, and internal engine parts designed to withstand high-performance demands. The engine architecture incorporates advanced materials and precision engineering to balance power output with durability and efficiency.- LT4 Engine Design and Components: The LT4 engine is a high-performance V8 engine with specific design features that enhance its power output and efficiency. Key components include a supercharger system, specialized cylinder heads, and a robust block design. The engine incorporates advanced materials and precision engineering to handle increased horsepower and torque while maintaining reliability under demanding conditions.

- Supercharging and Forced Induction Systems: The LT4 engine utilizes advanced forced induction technology, primarily through supercharging, to significantly increase power output. The supercharger system is designed to provide immediate throttle response and consistent power delivery across the RPM range. This system includes specialized intercooling components to manage intake air temperatures and optimize combustion efficiency under high-boost conditions.

- Fuel Management and Injection Systems: The LT4 engine employs sophisticated fuel management systems to optimize performance and efficiency. These include direct injection technology that precisely delivers fuel into the combustion chamber, variable fuel pressure systems, and advanced electronic control units that continuously adjust fuel delivery based on operating conditions. The fuel system is designed to support high-horsepower applications while maintaining emissions compliance.

- Cooling and Thermal Management: Thermal management is critical in the high-performance LT4 engine design. The cooling system incorporates specialized components to manage heat under extreme operating conditions, including enhanced water pumps, optimized coolant flow paths, and dedicated oil coolers. These systems work together to maintain optimal operating temperatures for the engine block, cylinder heads, and lubrication system, extending engine life and maintaining performance.

- Electronic Control and Monitoring Systems: The LT4 engine utilizes advanced electronic control systems to optimize performance across various operating conditions. These systems include sophisticated engine control modules, sensor arrays for real-time monitoring of critical parameters, and adaptive programming that adjusts engine operation based on environmental conditions and driver inputs. The electronic architecture enables features such as cylinder deactivation, variable valve timing, and performance mode selection.

02 Supercharging and Forced Induction Systems

Supercharging systems are a key feature of the LT4 engine, providing forced induction to increase power output. These systems include specialized supercharger designs, intercooling mechanisms, and pressure management components that work together to enhance engine performance. The forced induction system is carefully integrated with the engine's fuel delivery and air intake systems to optimize combustion efficiency and power delivery.Expand Specific Solutions03 Engine Control and Monitoring Systems

Advanced control and monitoring systems are implemented in the LT4 engine to manage performance parameters and ensure optimal operation. These systems include electronic control units, sensors, and diagnostic tools that monitor various engine functions such as temperature, pressure, and combustion efficiency. The control systems adjust engine parameters in real-time to maintain performance while protecting engine components from damage.Expand Specific Solutions04 Cooling and Thermal Management

The LT4 engine incorporates sophisticated cooling and thermal management systems to handle the heat generated during high-performance operation. These systems include specialized coolant circulation paths, heat exchangers, and temperature-regulated components that work together to maintain optimal operating temperatures. Effective thermal management is crucial for maintaining engine performance and longevity, particularly under demanding conditions.Expand Specific Solutions05 Fuel Delivery and Combustion Optimization

Fuel delivery systems in the LT4 engine are designed to provide precise fuel metering and atomization for optimal combustion. These systems include high-pressure fuel injectors, fuel rails, and pressure regulators that work together to ensure consistent fuel delivery across all operating conditions. The combustion process is further optimized through careful design of combustion chambers, intake ports, and exhaust systems to maximize power output and efficiency.Expand Specific Solutions

Major Manufacturers in High-Performance Off-Road Engines

The LT4 engine adaptation for off-road vehicles market is in a growth phase, with increasing demand for high-performance engines in rugged terrain applications. The competitive landscape features established automotive manufacturers like Ford Global Technologies, Jaguar Land Rover, and Renault alongside emerging players such as Great Wall Motor and BYD. Chinese manufacturers including Chery Automobile and Guangzhou Automobile Group are rapidly advancing their technical capabilities, while specialized off-road vehicle producers like Arctic Cat and CF Moto bring niche expertise. Technical maturity varies significantly, with traditional automakers possessing advanced adaptation techniques while newer entrants are investing heavily in R&D to close the gap. The market shows regional specialization with North American companies focusing on power output while Asian manufacturers emphasizing efficiency and durability innovations.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive adaptation strategy for the LT4 engine in off-road vehicles, focusing on enhanced cooling systems and structural reinforcements. Their approach includes a dual-circuit cooling system with enlarged radiators and auxiliary oil coolers to manage the higher heat loads experienced during extreme off-road conditions. Ford engineers have implemented advanced dust filtration systems with cyclonic pre-filters and multi-stage air cleaners to protect the engine in dusty environments. The company has also reinforced critical engine components, using strengthened engine mounts with hydraulic damping to absorb terrain impacts and vibrations. Ford's electronic control unit (ECU) modifications include terrain-specific calibrations that adjust timing, fuel delivery, and boost pressure based on vehicle attitude, wheel slip, and ambient conditions. Their adaptation also features a specialized lubrication system with a deeper oil pan, baffles to prevent oil starvation during steep angles, and synthetic oil formulations optimized for temperature extremes.

Strengths: Ford's extensive off-road testing programs in diverse environments provide real-world validation of their adaptations. Their integrated approach addresses multiple challenges simultaneously. Weaknesses: The additional cooling and filtration systems add weight and complexity, potentially reducing the power-to-weight ratio and increasing maintenance requirements.

Jaguar Land Rover Ltd.

Technical Solution: Jaguar Land Rover has engineered a sophisticated adaptation of the LT4 engine specifically for premium off-road applications, emphasizing reliability in extreme conditions while maintaining refinement. Their approach centers on a reinforced bottom end with forged connecting rods and a modified crankshaft to withstand increased torsional loads encountered during low-speed, high-torque off-road scenarios. JLR has implemented an advanced thermal management system featuring additional oil coolers and a high-capacity water pump to maintain optimal operating temperatures during prolonged low-speed crawling where airflow is limited. Their intake system incorporates a raised air intake position ("snorkel") with multi-stage water separation technology to prevent hydrolocking during water crossings up to 900mm deep. JLR's adaptation also includes a recalibrated engine management system with specific off-road modes that modify throttle response, torque delivery, and cooling fan operation based on terrain conditions. The company has developed specialized engine mounts with progressive damping characteristics to isolate the powertrain from extreme impacts while maintaining precise control.

Strengths: JLR's adaptation excels in water fording capability and maintains premium NVH (Noise, Vibration, Harshness) characteristics even in extreme conditions. Their system integrates seamlessly with existing vehicle architecture. Weaknesses: The premium engineering approach results in higher production costs, and the focus on refinement may sacrifice some ultimate durability compared to purely utilitarian designs.

Critical Engineering Innovations for LT4 Off-Road Performance

Interchangeable engine assembly

PatentPendingUS20240392708A1

Innovation

- An engine assembly with interchangeable cylinder heads and blocks, sharing a common crankcase and camshaft locations, allowing for the use of different cylinder heads and blocks while maintaining other components constant, thereby reducing the number of components to replace or modify.

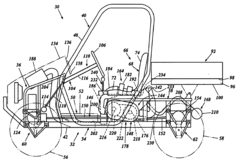

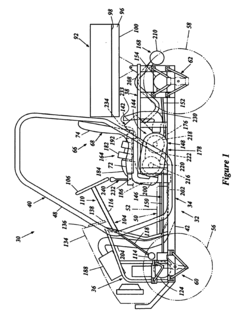

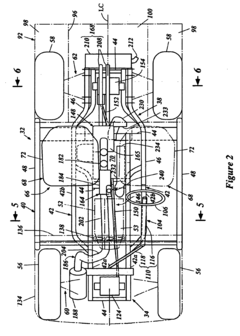

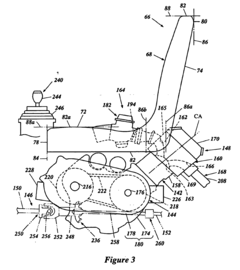

Engine arrangement for off-road vehicle

PatentInactiveUS20040216942A1

Innovation

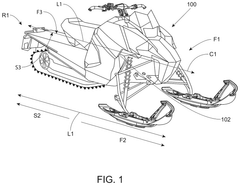

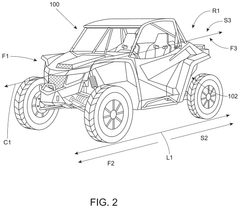

- The engine arrangement positions the crankshaft between the output shaft and the rear wheel, with the output shaft located between vertically extending planes defined by the seat's front and rear ends, allowing the engine to extend rearward and be vertically higher than the seat's bottom end, thereby shortening the wheelbase.

Durability Testing Methodologies for Off-Road Engines

Durability testing for off-road engines, particularly when adapting high-performance powerplants like the LT4, requires specialized methodologies that exceed standard automotive testing protocols. The extreme conditions encountered in off-road environments—including severe dust exposure, water fording, extreme temperature variations, and sustained high-load operation—necessitate comprehensive testing regimens that validate both component reliability and system integration.

Industry-standard durability testing for off-road applications typically begins with accelerated life cycle simulations. These tests compress years of operational wear into condensed timeframes through carefully calibrated test cycles that replicate real-world usage patterns at increased intensity. For the LT4 adaptation, this would include extended high-RPM operation under varying load conditions to evaluate thermal management capabilities and component fatigue resistance.

Environmental chamber testing represents another critical methodology, subjecting the engine to temperature extremes ranging from -40°F to 130°F while monitoring performance metrics and material integrity. This approach is particularly relevant for evaluating the LT4's supercharger performance and electronic systems reliability across the temperature spectrum encountered in diverse off-road environments.

Vibration and shock testing methodologies employ specialized rigs that simulate the intense mechanical stresses of off-road terrain. Multi-axis vibration tables replicate the complex motion profiles experienced during rock crawling, high-speed desert running, and other challenging scenarios. For the LT4 adaptation, particular attention must be paid to mounting system integrity, accessory drive components, and electronic control unit resilience.

Contamination resistance testing evaluates the engine's ability to withstand particulate intrusion. Standardized dust chambers using Arizona Test Dust (per ISO 12103-1) assess air filtration system efficiency and seal integrity under controlled conditions. Additional water intrusion testing, including both splash and immersion protocols, validates the effectiveness of waterproofing measures for critical electronic components and air intake systems.

Thermal cycle endurance testing represents perhaps the most demanding methodology, combining load variations with rapid temperature transitions to identify potential failure points. This approach is particularly valuable for evaluating the LT4's cooling system modifications and identifying potential thermal expansion issues in an off-road application where sustained high loads in low-speed scenarios are common.

Modern durability testing increasingly incorporates data-driven approaches, with comprehensive sensor arrays monitoring hundreds of parameters during testing. This telemetry enables precise correlation between specific operating conditions and component stress, allowing engineers to target reinforcement efforts precisely where needed for the LT4's off-road adaptation.

Industry-standard durability testing for off-road applications typically begins with accelerated life cycle simulations. These tests compress years of operational wear into condensed timeframes through carefully calibrated test cycles that replicate real-world usage patterns at increased intensity. For the LT4 adaptation, this would include extended high-RPM operation under varying load conditions to evaluate thermal management capabilities and component fatigue resistance.

Environmental chamber testing represents another critical methodology, subjecting the engine to temperature extremes ranging from -40°F to 130°F while monitoring performance metrics and material integrity. This approach is particularly relevant for evaluating the LT4's supercharger performance and electronic systems reliability across the temperature spectrum encountered in diverse off-road environments.

Vibration and shock testing methodologies employ specialized rigs that simulate the intense mechanical stresses of off-road terrain. Multi-axis vibration tables replicate the complex motion profiles experienced during rock crawling, high-speed desert running, and other challenging scenarios. For the LT4 adaptation, particular attention must be paid to mounting system integrity, accessory drive components, and electronic control unit resilience.

Contamination resistance testing evaluates the engine's ability to withstand particulate intrusion. Standardized dust chambers using Arizona Test Dust (per ISO 12103-1) assess air filtration system efficiency and seal integrity under controlled conditions. Additional water intrusion testing, including both splash and immersion protocols, validates the effectiveness of waterproofing measures for critical electronic components and air intake systems.

Thermal cycle endurance testing represents perhaps the most demanding methodology, combining load variations with rapid temperature transitions to identify potential failure points. This approach is particularly valuable for evaluating the LT4's cooling system modifications and identifying potential thermal expansion issues in an off-road application where sustained high loads in low-speed scenarios are common.

Modern durability testing increasingly incorporates data-driven approaches, with comprehensive sensor arrays monitoring hundreds of parameters during testing. This telemetry enables precise correlation between specific operating conditions and component stress, allowing engineers to target reinforcement efforts precisely where needed for the LT4's off-road adaptation.

Environmental Compliance Strategies for Modified Engines

Adapting high-performance engines like the LT4 for off-road applications requires careful consideration of environmental regulations. As emissions standards become increasingly stringent worldwide, modified engines must balance performance enhancements with environmental compliance. The EPA and CARB regulations in the United States establish strict guidelines for engine modifications, with non-compliance resulting in significant penalties for both manufacturers and consumers.

For LT4 engine adaptations, several compliance strategies can be implemented. Advanced catalytic converter systems specifically designed for high-performance applications can significantly reduce harmful emissions while maintaining power output. These systems often utilize higher precious metal loadings and improved substrate designs to handle the increased exhaust flow and temperatures associated with modified LT4 engines.

Exhaust Gas Recirculation (EGR) systems can be optimized for off-road applications by incorporating variable flow control mechanisms that adjust based on driving conditions. This allows for emissions reduction during normal operation while maintaining full power capability when needed in demanding off-road scenarios. Modern EGR systems with enhanced cooling capabilities can be integrated without the traditional power penalties associated with earlier designs.

Electronic engine management represents another critical compliance strategy. Reprogramming the Engine Control Unit (ECU) with specialized calibrations can optimize fuel delivery and ignition timing for both performance and emissions control. Advanced mapping techniques allow for different operating modes that can prioritize emissions compliance during normal operation while providing full performance capabilities when required in off-road conditions.

Alternative fuel compatibility offers another pathway to environmental compliance. Modifying the LT4 to operate efficiently with biofuels or E85 can reduce carbon footprint while maintaining performance characteristics. This may require fuel system upgrades, including larger injectors and fuel pumps, along with specialized ECU programming to accommodate the different combustion characteristics of alternative fuels.

Particulate filtration systems, traditionally associated with diesel engines, are increasingly relevant for high-performance gasoline engines with direct injection. Adapting these systems for the LT4 engine can address particulate matter emissions that have become a focus of newer regulations. Specialized high-flow filters with regeneration capabilities can be integrated into the exhaust system without creating excessive backpressure.

Compliance testing and certification processes must be incorporated into the development cycle. This includes establishing relationships with certified testing facilities and developing internal pre-compliance testing protocols to ensure modifications meet regulatory requirements before market introduction. Documentation systems for tracking modifications and their impact on emissions performance provide both regulatory protection and valuable engineering data.

For LT4 engine adaptations, several compliance strategies can be implemented. Advanced catalytic converter systems specifically designed for high-performance applications can significantly reduce harmful emissions while maintaining power output. These systems often utilize higher precious metal loadings and improved substrate designs to handle the increased exhaust flow and temperatures associated with modified LT4 engines.

Exhaust Gas Recirculation (EGR) systems can be optimized for off-road applications by incorporating variable flow control mechanisms that adjust based on driving conditions. This allows for emissions reduction during normal operation while maintaining full power capability when needed in demanding off-road scenarios. Modern EGR systems with enhanced cooling capabilities can be integrated without the traditional power penalties associated with earlier designs.

Electronic engine management represents another critical compliance strategy. Reprogramming the Engine Control Unit (ECU) with specialized calibrations can optimize fuel delivery and ignition timing for both performance and emissions control. Advanced mapping techniques allow for different operating modes that can prioritize emissions compliance during normal operation while providing full performance capabilities when required in off-road conditions.

Alternative fuel compatibility offers another pathway to environmental compliance. Modifying the LT4 to operate efficiently with biofuels or E85 can reduce carbon footprint while maintaining performance characteristics. This may require fuel system upgrades, including larger injectors and fuel pumps, along with specialized ECU programming to accommodate the different combustion characteristics of alternative fuels.

Particulate filtration systems, traditionally associated with diesel engines, are increasingly relevant for high-performance gasoline engines with direct injection. Adapting these systems for the LT4 engine can address particulate matter emissions that have become a focus of newer regulations. Specialized high-flow filters with regeneration capabilities can be integrated into the exhaust system without creating excessive backpressure.

Compliance testing and certification processes must be incorporated into the development cycle. This includes establishing relationships with certified testing facilities and developing internal pre-compliance testing protocols to ensure modifications meet regulatory requirements before market introduction. Documentation systems for tracking modifications and their impact on emissions performance provide both regulatory protection and valuable engineering data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!